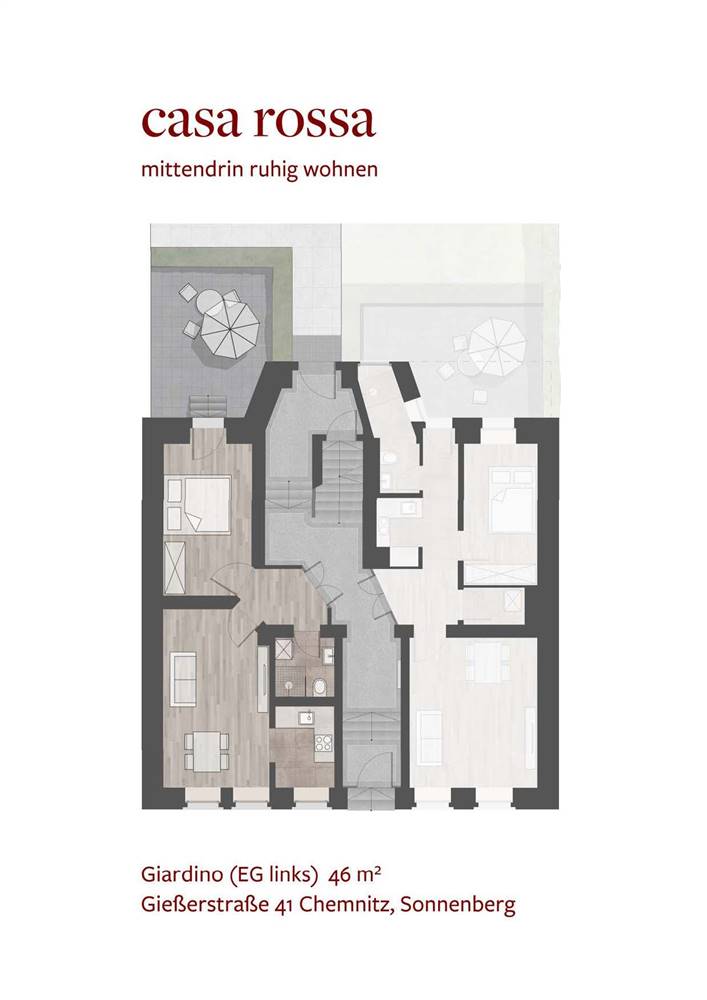

Casa Rossa Chemnitz

Gießerstraße 41

09130

Chemnitz, Germany

Architect

Contact Details

Other Information

upon request

https://www.bodensteiner-fest.de/projekte/2019/GIE-casa-rossa-chemnitz.php

Climate Zone Cfb

Altitude 298 m a.s.l.

HDD 3486

CDD 150

Conservation Area:

Yes

Level of Protection:

Building is not protected

Year of last renovation:

2018

Building occupancy:

Permanently occupied

Building typology:

Tenement (apartments)

Number of floors:

5

Basement yes/no:

Yes

Number of heated floors:

5

NFA calculation method:

NGF (de)

External finish:

Exposed brickwork

Internal finish:

Exposed brickwork

Roof type:

Pitched roof

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

bodensteiner fest Architekten BDA, Stadtplaner PartGmbB

Ickstattstraße 9 Rgb, D 80469 München

mail@bodensteiner-fest.de

Tel. 49 (0)89 89223388

Hygrothermal assessment Thermal bridge calculations for individual components

Life Cycle Analysis (LCA) No LCA tool applied

Other Die ursprünglich verputzte Fassade wurde als sichtbare Ziegelfassade ertüchtigt und prägt das Erscheinungsbild

RETROFIT SOLUTIONS

External Walls

Street facade unplastered

Backyard facade with cladding

The tectonics of the facade were further worked out: concrete lintels, cornices and steel girders were restored, reveals were insulated, the brickwork with cassettes and pilaster strips was re-grouted and coated with a light mineral glaze and made hydrophobic. The joints of the facades have been refurbished and the facade has been hydrophobized with a 20-year warranty and is maintained like a facade painting.

Window formats have been kept, the outside trims have been articulated. The view of the street side was not changed. On the garden side, balconies were added

2 mm

300 mm

30 mm

2mm

300 mm

30 mm

The rear courtyard facade was made with 12cm mineral WD as ETICS with 15mm thick plaster

The rear courtyard facade was largely retained in terms of design, door openings for balconies were necessary to increase living quality, the balconies were placed in front of them as a light steel construction

30 mm

300 mm

30 mm

15mm

120 mm

300 mm

30 mm

Windows

Wooden window with insulated window frame, visible from the inside

Accurate bezels hide the window frames and hold the narrow window sashes. They stand in contrast to the rough brick facade with all its irregularities and the visible wounds of the last century. The tectonics of the facade was further worked out: concrete falls, Cornices and steel girders were restored, the brickwork with cofferings and pilaster strips was re-grouted and coated with a light mineral glaze and made hydrophobic.

The windows were exchanged and replaced with new windows. The wall connection was made with adapted insulation frames

| Existing window type | Casement window |

| Existing glazing type | Single |

| Existing shading type | NA |

| Approximate installation year | 1910 |

| New window type | Casement window |

| New glazing type | Triple |

| New shading type | NA |

| New window solar factor g [-] | 0,55 |

Other interventions

ROOF

OTHER

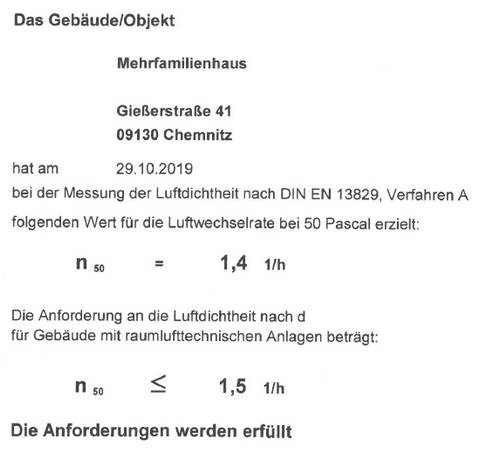

MEASURES TO INCREASE AIRTIGHTNESS

The roof was completely demolished and rebuilt using demolition bricks. By opening the roof side on the courtyard side, additional living space is created, which is oriented towards a spacious roof terrace with sliding doors.

The roof view of the street side was changed minimally, the flat built-in parts in the roof were adapted in color to the roof covering. Roof terraces were integrated on the garden side, these are not visible from the garden.

20 mm

24 mm

140 mm

5 mm

20 mm

24 mm

280 mm

24 mm

The floor to the cellar, a cap ceiling, was insulated with perlite fill (on average approx 8cm, on top of it insulation of the underfloor heating 4cm)

The insulation was invisibly applied to the existing cap ceiling and does not impair the visual appearance

HVAC

HEATING

VENTILATION

DOMESTIC HOT WATER

A completely new heating system was installed. A solar system supplies floor heating and domestic hot water. Many close-meshed heating circuits have been laid to optimize solar use for low-temperature heating.

The existing shafts were largely used. The heating was designed as underfloor heating because the floors had to be completely renewed. Cables were partially laid on the plaster.

| New primary heating system | New secondary heating system | |

|---|---|---|

| New system type | Condensing | |

| Fuel | Gas | Solar |

| Distribuition system | Radiating floor | Radiating floor |

| Nominal power | 18 kW | kW |

Exhaust system for internal bathrooms with overflow opening, fresh air supply via window rebate ventilation

Exhaust air is moved into shafts

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Decentralized |

| Type flow regime | Overflow |

| Heat recovery | No |

| Humitidy recovery | No |

| Nominal power | 0.015 kW |

| Electric power | 0,015 kW |

| Control system | light and CO2 sensor |

Solar thermal system for domestic hot water and heating support. Heating system with gas boiler

Thermal solar collectors match the color of the roof

| New DHW system | |

|---|---|

| Type | with heating system |

| Hot_water_tank | Yes |

| With heat recovery | No |

RENEWABLE ENERGY SYSTEMS

SolarThermal

Solar thermal collectors

The color was adapted to the roof skin. A roof-top system was chosen to enable simple reversibility of the technical component as soon as there are fully compatible components in terms of design, which is often a requirement for monument protection. Together with the roof windows, they represent a neglibible disturbance of the roof landscape. The installation of components for the generation of renewable energies are often privileged compared to the preservation of monuments. So far there are no adequate components in terms of color and haptics.

| SolarThermal System | |

|---|---|

| Type | Flat collector |

| Collector area | 20,0 m² |

| Elevation angle | 30,0 |

| Overall yearly production | 12000,0 kWh |

| Heating_contribuition | 2000,0 kWh |

| DHW contribuition | 10000,0 kWh |

| Cooling contribuition | 0,0 kWh |

Energy Efficiency

Voluntary certificates: No

Primary Energy 62,8 kWh/m2.y

Consumption_estimation_After: 55,3 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: NA

Consumption_estimation_Including_DHW: Yes

Consumption_estimation_After: 62,8 kWh/m2.y

Type_of_monitoring: Punctual

Description: Annual billing of energy consumption

Internal Climate

The building envelope was made airtight with new, highly efficient windows. The roof was provided with maximum insulation thickness. There was positive feedback on comfort from users

In summer, the building mass and the cellulose roof insulation ensures an appropriate temperature level. In winter, the underfloor heating offers radiant heat at the highest level of comfort

The existing window sizes have not been changed, they offer adequate lighting comfort. The attic apartment was provided with roof windows and large terrace windows for the best lighting conditions.

The floors have been upgraded according to the acoustic standards. All HVAC istallations comply with acoustic norms

Costs

The renovation standard was adapted to the state of the art and comfort. A market analysis showed an economic viability for the chosen renovation strategy

No