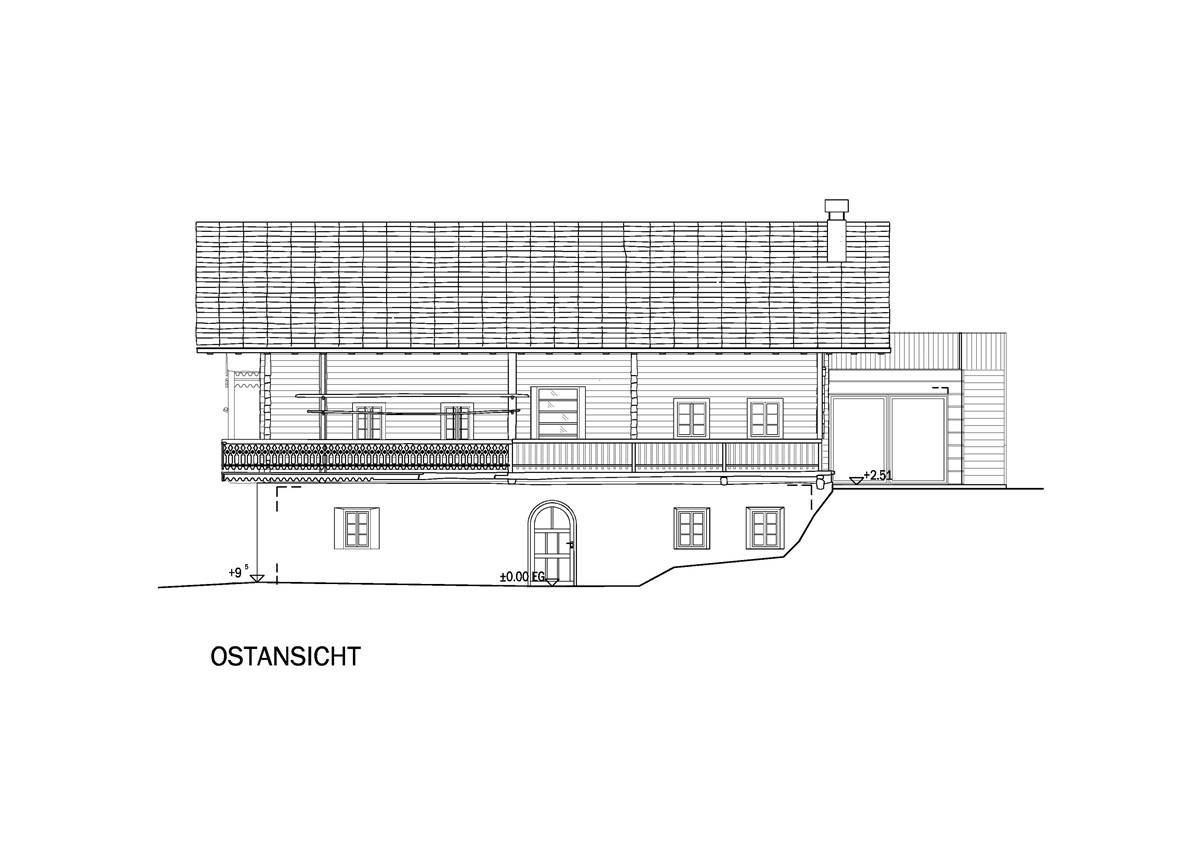

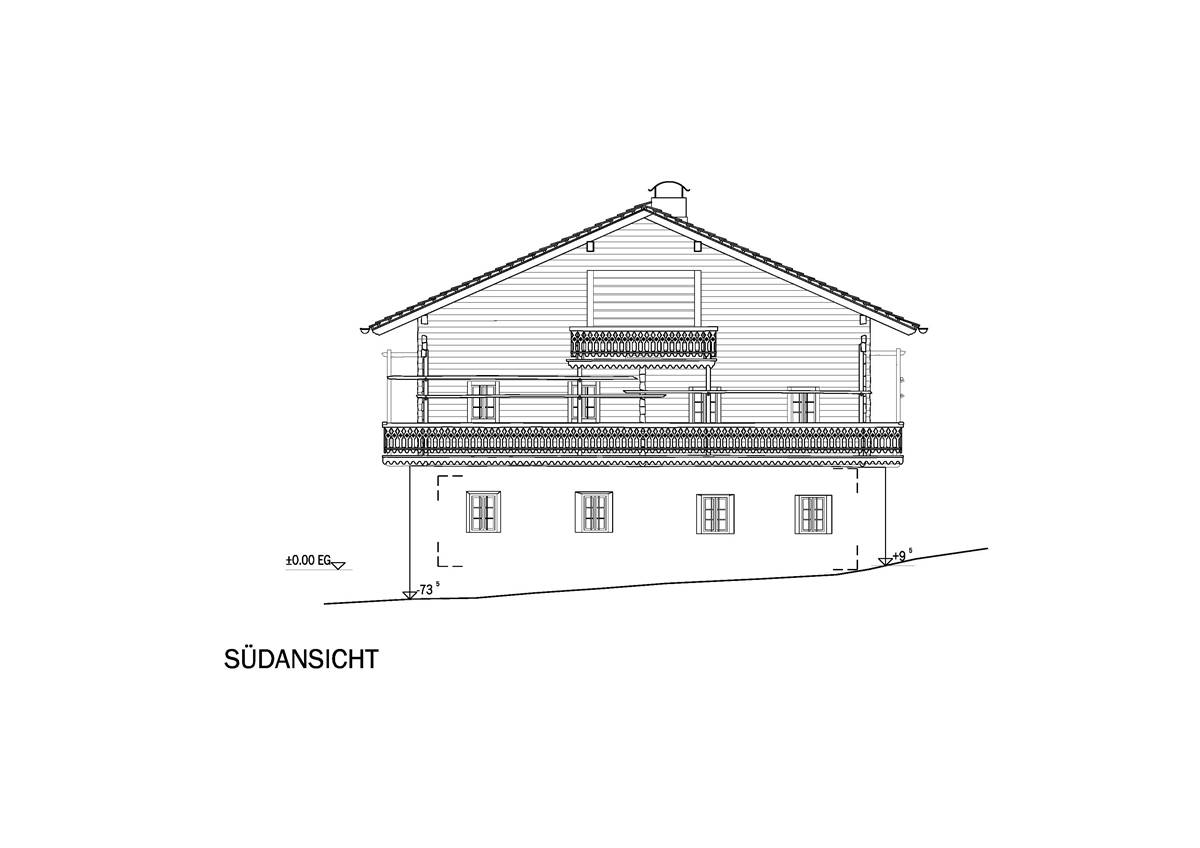

Rainhof

Magdalenastraße 29

39100

Gsies, Italy

Architect

Owner

User

Contact Details

Other Information

Please contact either the builiding owner or the architect

Turris Babel no. 106 - 07/2017, page 108: "Rainhof, Gsies"; http://atlas.arch.bz.it/de/rainhofbz/ The retrofitted building was eventually designated “heritage building of the month” by the heritage office: http://www.provinz.bz.it/kunst-kultur/denkmalpfle

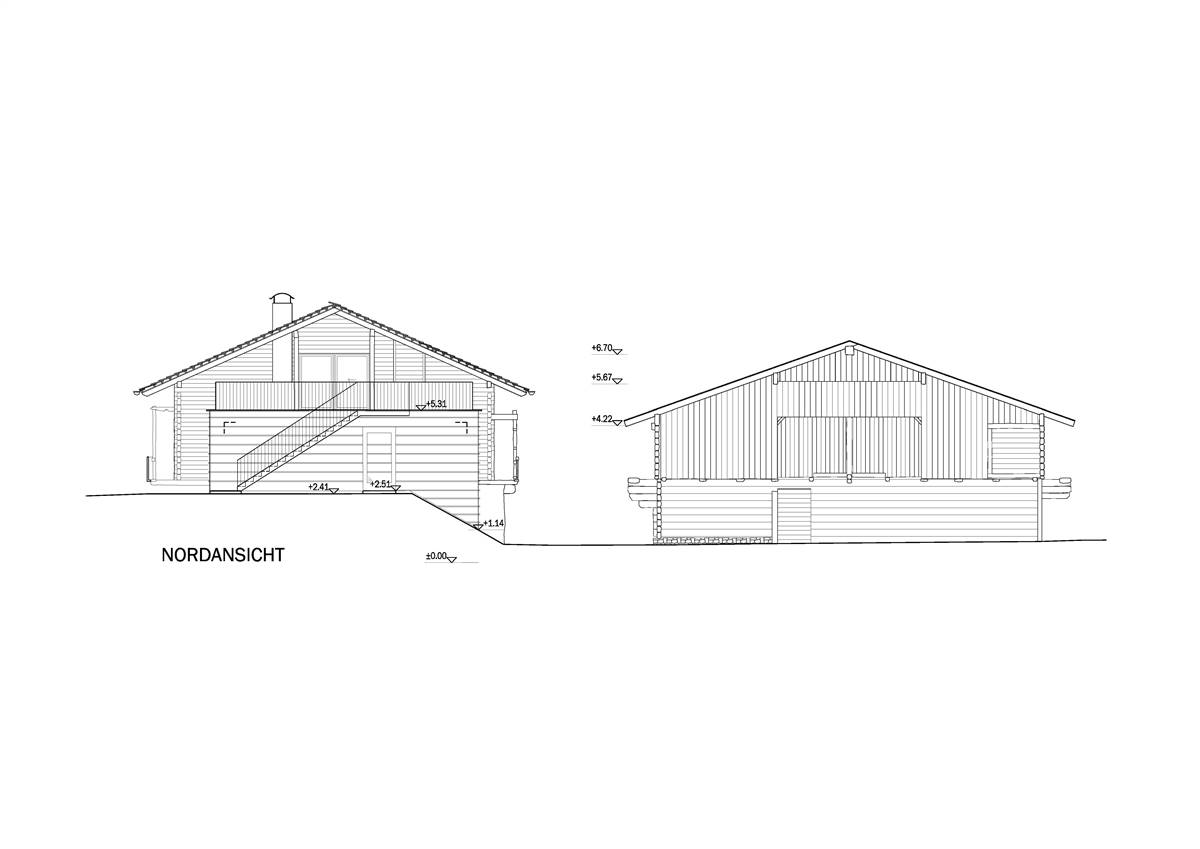

Altitude 1500 m a.s.l.

HDD 2905

CDD 16

Conservation Area:

No

Level of Protection:

Protection status: Unterschutzstellung/Provvedimento di vincolo: BLR-LAB 607 from 16/02/1987

Year of last renovation:

2016

Year of previous renovation:

0

Secondary use:

Holiday apartments

Building occupancy:

Discontinuous occupancy (i.e. holiday home)

Number of occupants/users:

10

Building typology:

Detached house

Number of floors:

3

Basement yes/no:

No

Number of heated floors:

3

Gross floor area [m²]:

454,0

Thermal envelope area [m²]:

667,32

Volume [m³]:

1350,0

NFA calculation method:

Useful area (it)

External finish:

Rendered

Internal finish:

Plastered (on hard)

Roof type:

Pitched roof

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Dr. Arch. Stefan Taschler - archilab

Paul von Sternbach Straße 9; 39031 Bruneck

taschler@archilab.com

Tel.0039 0474 530672

Dr. Arch. Bonaventura, Dr. Kofler Engl (Amt für Bau- und Kunstdenkmäler)

Armando-Diaz-Strasse 8; I-39100 Bozen

kunstdenkmaeler@provinz.bz.it

Tel.0039 0471 41 19 10

Arch. Silvia Bruni

Heilig Kreuz Str. 23 C; St. Lorenzen

arch.silviabruni@gmail.com

Tel.0039 349 5361160

Südtiroler Bauernbund

K.-M. Gamper Str. 5

info@sbb.it

ITAS Versicherungsverein

http://itaspreis.gruppoitas.it/

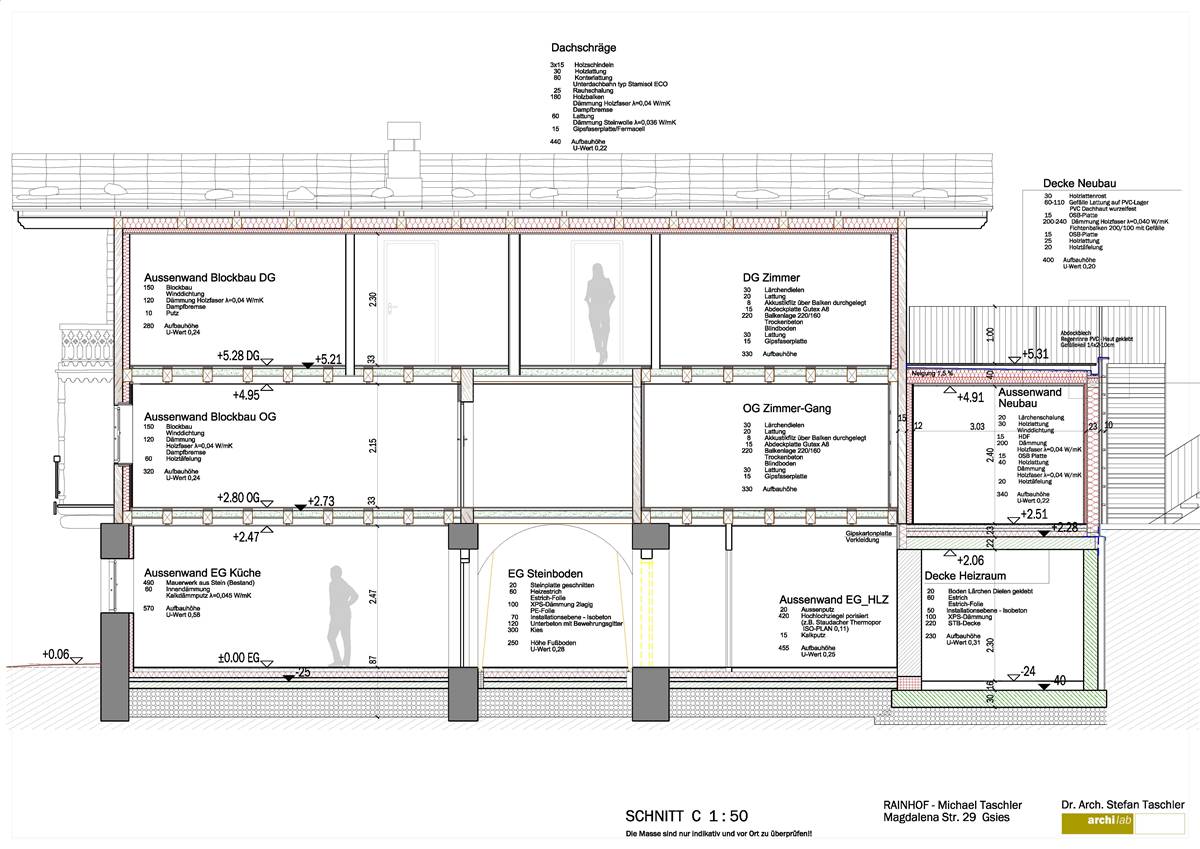

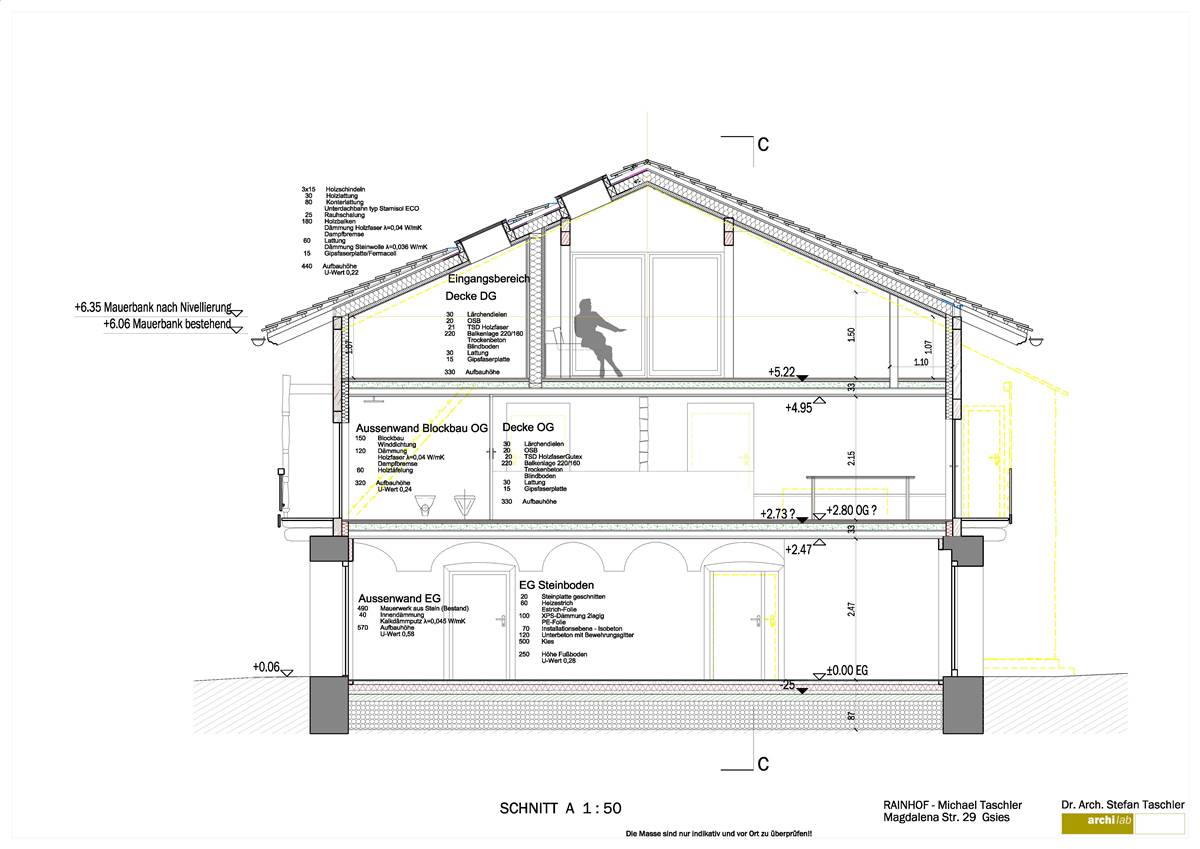

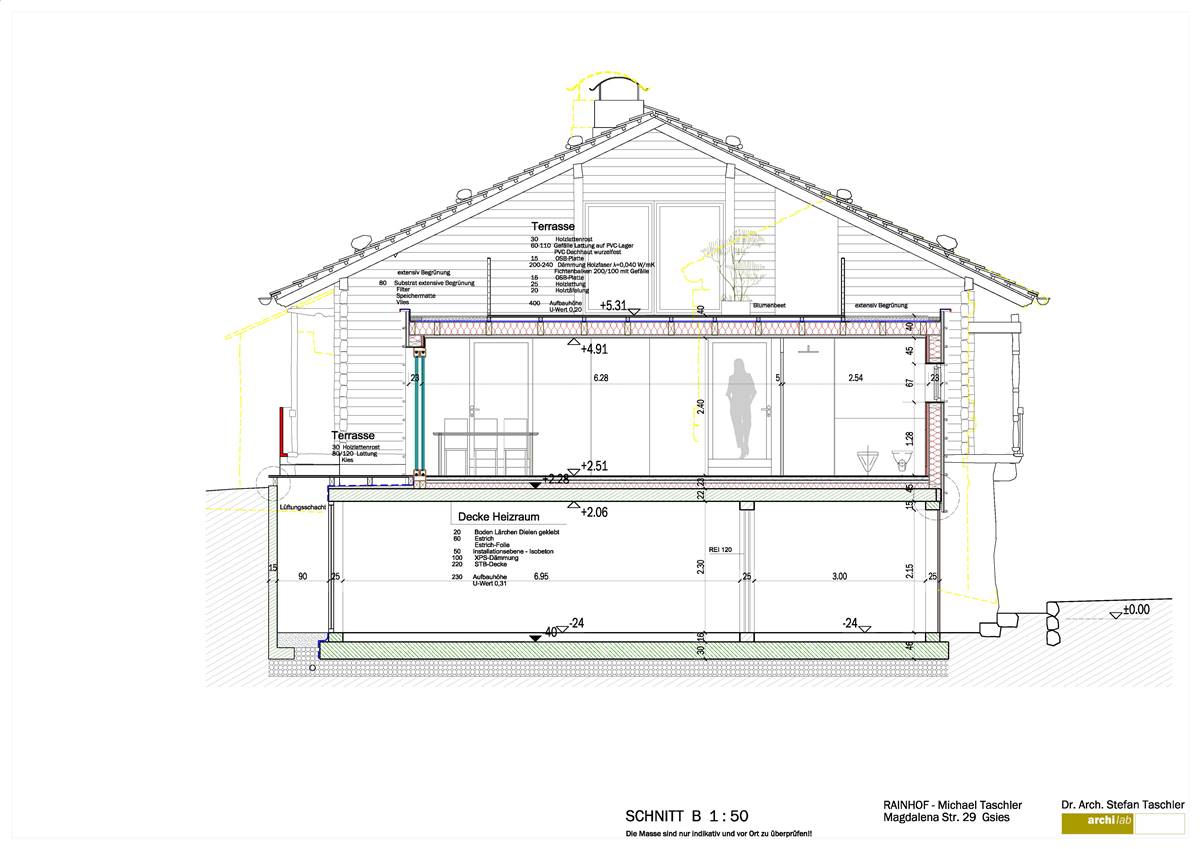

RETROFIT SOLUTIONS

External Walls

Ground floor - Existing stone wall

Ground floor - existing stone wall "Stube"

Ground floor - Substitution of existing wall

First floor - existing "Blockbau" construction (with wooden cladding)

First floor - existing "Blockbau" construction

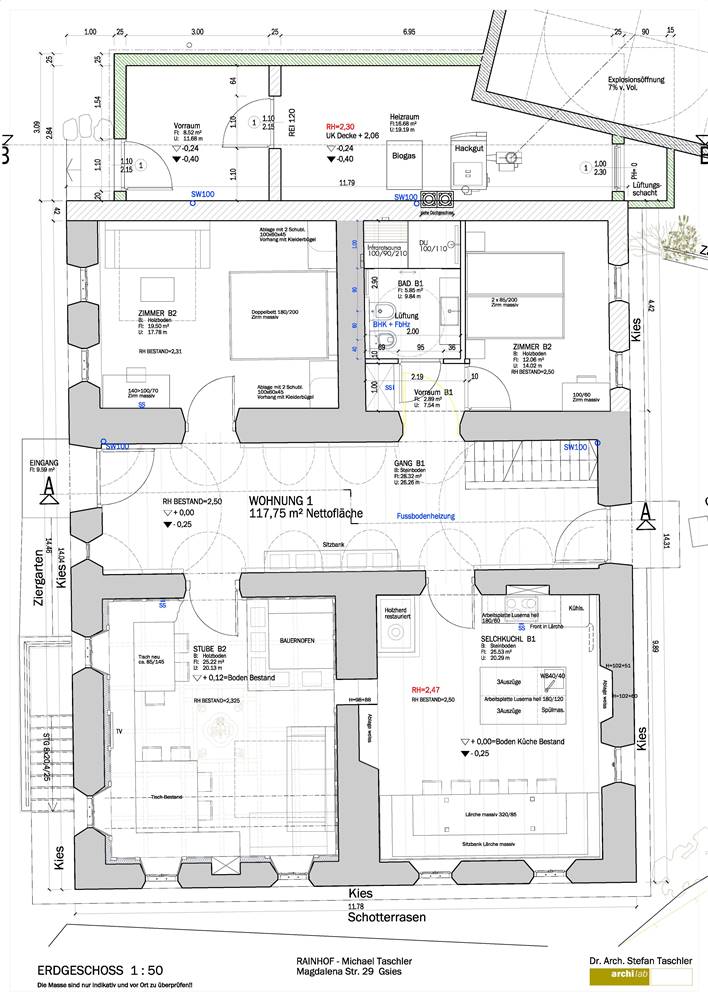

A large part of the stone masonry wall in the ground floor (except in the "Stube" and "Labe") was insulated internally with a thin layer (4-6 cm) of insulating plaster (Calcetherm λ=0,068W/mK). The U-value was improved from 2,39 W/m2K to 0,87 W/m2K (based on standard values of the energy calculation tool).

This insulating plaster is lime-based and, unlike an insulating panel, it is applied in a thin layer that can follow the uneven surface of the original wall surface ensuring a similar appearance to the original plaster.

30 mm

400 mm

30 mm

30mm

400 mm

30 mm

50 mm

The external wall around the “Stube” was insulated with 8 cm of wood fibreboard placed in the space between the masonry and the wooden cladding.

Using the space behind the wooden cladding, the original wooden panelling and of the proportions of the room were not altered.

30 mm

400 mm

30 mm

80 mm

30 mm

30mm

400 mm

30 mm

80 mm

30 mm

Due to the salt contamination of the northeast corner of the building, it was necessary the demolition of part of the existing wall. A new wall was built with perforated thermal bricks (lambda 0,11 W/(mK)).

Here the appearance from outside is similar to the original wall. Most parts of this wall are also below ground and thus not visible from outside.

30 mm

400 mm

30 mm

20mm

420 mm

15 mm

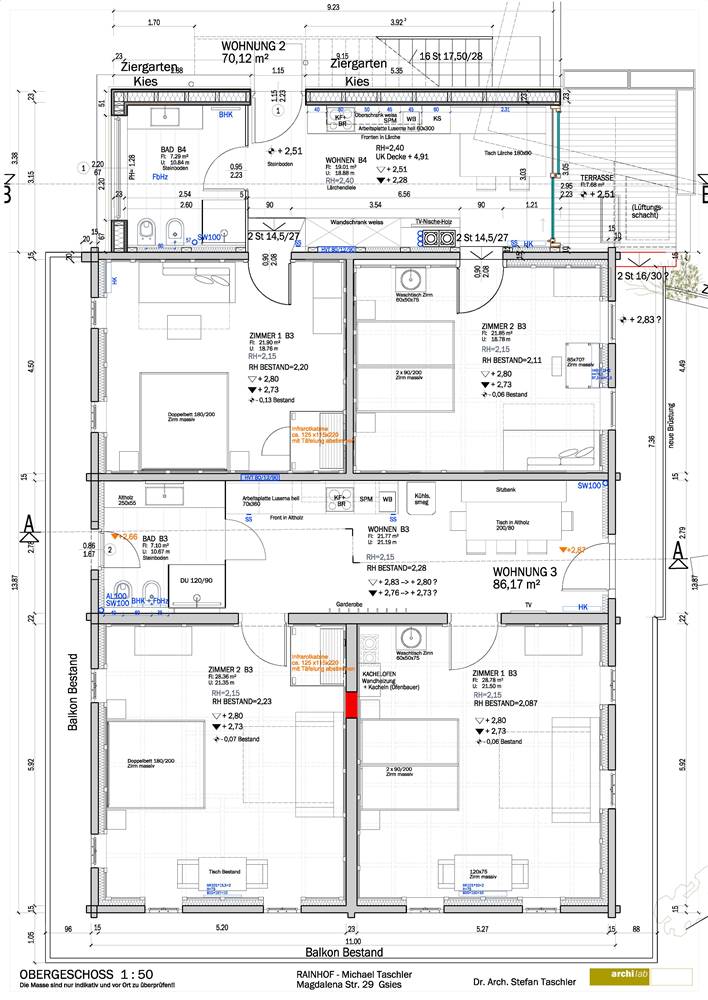

The existing “Blockbau” (solid wood) construction, consisting of horizontal rectangular hewn beams and wooden paneling was insulated from the inside with 12 cm of wood fiber board. In addition to the thermal resistance improvement (from 0,64 W/m2K to 0,24 W/m2K) the addition of a windproof layer between the old structure and insulation panel improved significantly the air tightness of the whole construction. The insulation layer is covered from the inside with a vapor barrier and a service gap that allows the installation of ducting and wires while protecting the integrity of the construction.

Through the intervention from inside the original wooden construction, the outside appearance does not change. The existing wooden cladding similar was reinstalled as internal finish of the wall. Thus, the original wooden construction was kept with minor modifications to the internal appearance of the rooms.

150 mm

150mm

0 mm

120 mm

15 mm

29 mm

25 mm

In those parts of the existing “Blockbau” (solid wood) construction, where there was no internal wooden paneling the wood construction was as well insulated from the inside with 12 cm of wood fiber board (cf. Wall "First floor - existing "Blockbau" construction (with wooden cladding)") . Also here, in addition to the thermal resistance improvement (from 0,76 W/m2K to 0,24 W/m2K) the addition of a windproof layer between the old structure and insulation panel improved significantly the air tightness of the whole construction. The insulation layer is covered from the inside with a vapor barrier and a service gap that allows the installation of ducting and wires while protecting the integrity of the construction.

A new wooden cladding similar to the original surface was installed as internal finish of the wall. Thus, the original wooden construction was kept with minor modifications to the internal appearance of the rooms.

Windows

All windows

All existing windows were exchanged with new units made ad-hoc by a local furniture maker. The aim was building a two-sash window with two glazing bars each that on the one hand achieved high levels energy performance and on the other hand were of high aesthetic quality.

In order to preserve the original appearance of the windows in the façade, one of the original windows was used as a model for the new windows in terms of proportions and profile widths. To improve the thermal performance of the window, an insulating glass unit was installed.

| Existing window type | Box-type window |

| Existing glazing type | Single |

| Existing shading type | Outer shutter |

| New window type | Casement window |

| New glazing type | Double |

| New shading type | NA |

| New window solar factor g [-] | 0,0 |

Other interventions

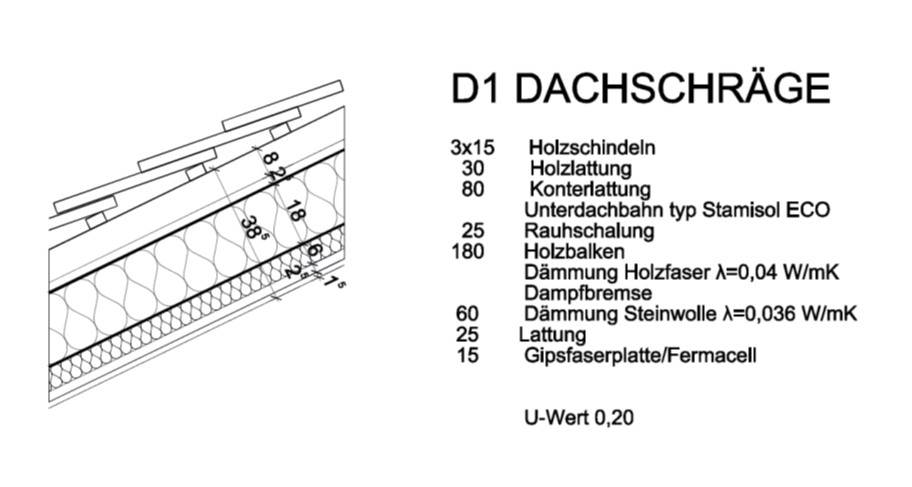

ROOF

GROUND FLOOR

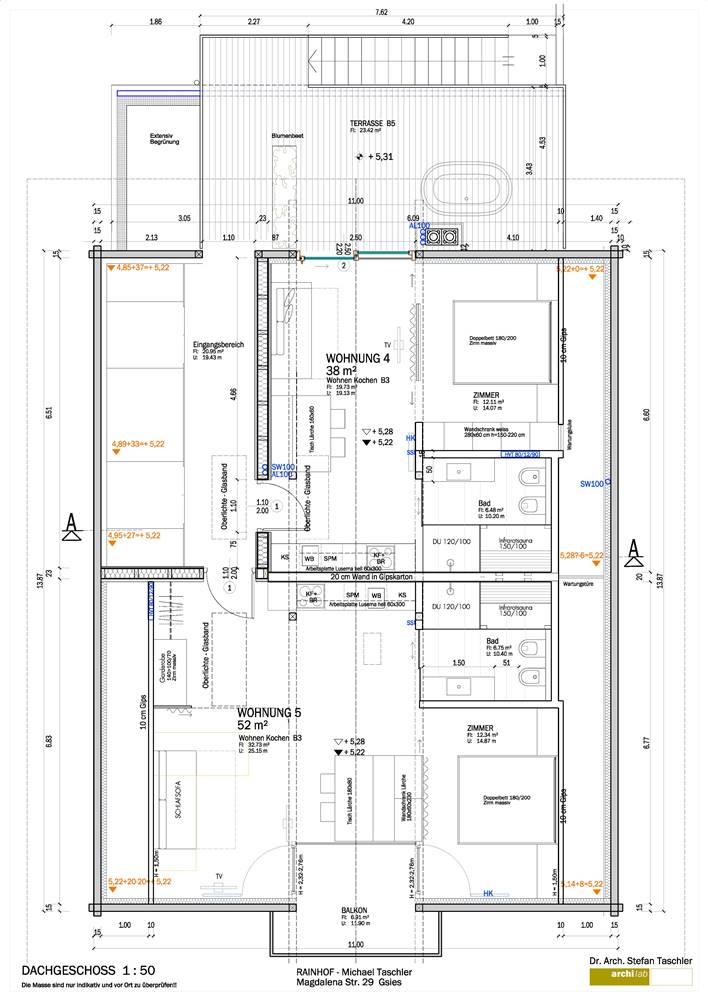

Insulation of the former "cold" pitched roof. The insulation was applied internally to maintain the existing wood shingle roof.

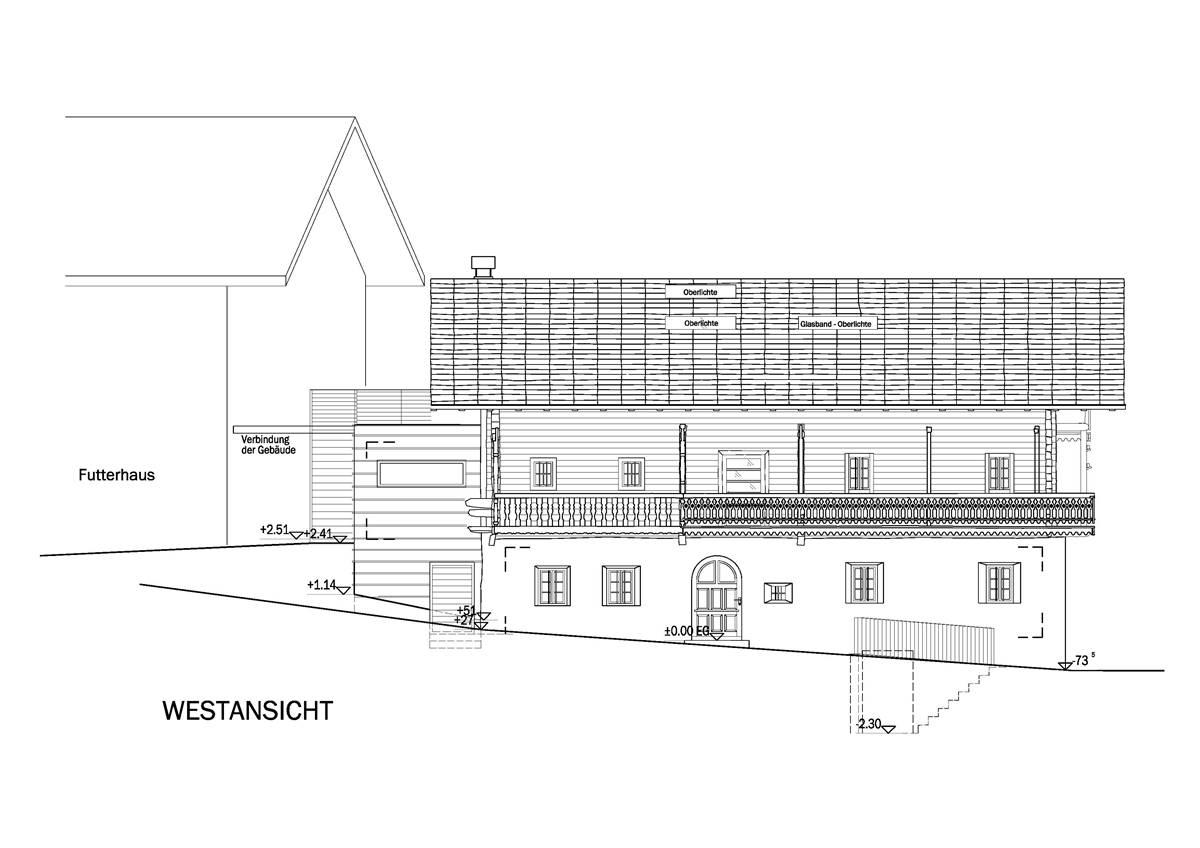

To improve the supply of daylight in the two holiday apartments in the attic, two glass bands were installed in consultation with the heritage office.

15 mm

110 mm

30 mm

180 mm

15 mm

110 mm

30 mm

180 mm

40 mm

Usually the ground floor was built directly on the soil. The retrofit included 50 cm of gravel, subconcrete (12 cm), installation layer/insulating concrete (7 cm), insulation (7 + 2 cm ), floating floor with radiation system, stone slabs (2,5)

30 mm

120 mm

500 mm

30 mm

65 mm

75 mm

120 mm

500 mm

HVAC

HEATING

DOMESTIC HOT WATER

A new heating system works as a combination of a biogas boiler and wood-chip boiler (2). Almost all rooms are heated through a floor heating system.

The traditional stove is kept in the “Stube” although it is not heated with firewood anymore, instead it is connected to the central boiler. In the rooms where the old wood floorboards were restored, no floor heating was used, but single radiators.

| New primary heating system | New secondary heating system | |

|---|---|---|

| New system type | Boiler | Stove |

| Fuel | Gas | Biomass |

| Distribuition system | Radiating floor | Stove |

| Nominal power | test kW | NA kW |

RENEWABLE ENERGY SYSTEMS

Biomass

As described above, space heating and domestic hot water is provided by two different boilers, both running with renewable energy. The biomass boiler uses wood chip produced directly from the farm woodland and stored in the silo next to the building. The gas boiler runs with the biogas produced from the manure of the cattle reared in the farm in a biogas plant built between the stable and residential building. The energy produced from biogas and wood chips cover the energy need of the Rainhof, a nearby house (included holiday apartments) and the stable.

| Biomass System | |

|---|---|

| Type | |

| Storage size | |

| Origin of biomass | |

| Overall yearly production | 50,0 kWh |

Energy Efficiency

Voluntary certificates: No

Consumption_estimation_After: 60 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: The energy produced from biogas and wood chips cover the energy need of the Rainhof, a nearby house (included holiday apartments) and the stable.

Internal Climate

The impact of the intervention on the indoor climate was evaluated by means of a post-occupancy evaluation, including the opinions of the building owner (and occupier of the main dwelling unit) and a number of guests. The overall impression on the comfort was positive. Guests opinions on the thermal comfort was very positive. They appreciated the control of two independent circuits of the heating system in the apartment (kitchen, living room, and bedroom and separately the bathroom).

Building owner and guests evaluate the indoor air quality as positive.

Building owner and guests evaluate the daylight supply as sufficient, despite the reduced dimensions of traditional window openings, even in winter.

Building owner and guests evaluate the overall living comfort as positive. The appartments towarts the courtyard have better conditions, as they are turned away from the street