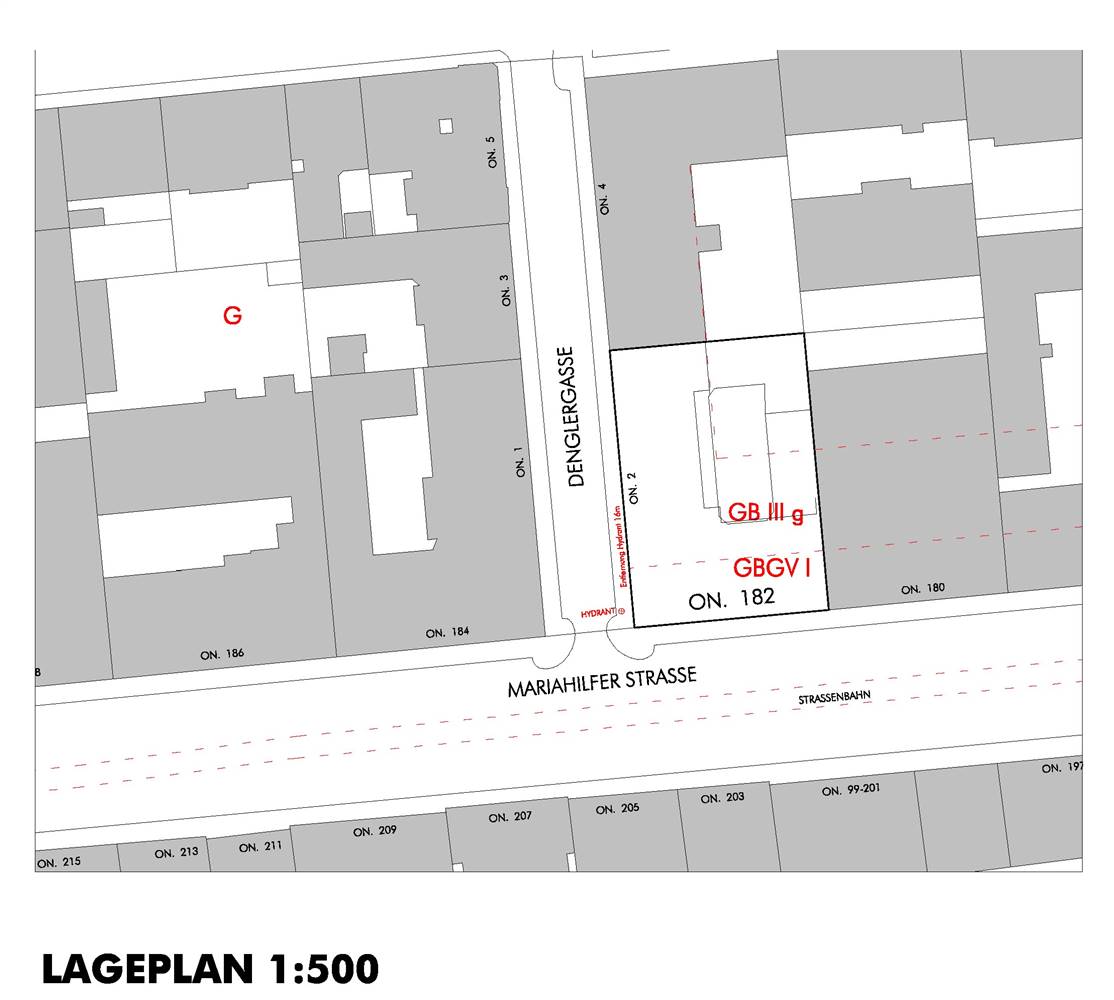

Mariahilferstrasse

Mariahilferstrasse 182

1150

Vienna, Austria

Architect

Owner

Contact Details

Other Information

Climate Zone Cfb

Altitude 199 m a.s.l.

HDD 3490

CDD 0

Conservation Area:

No

Level of Protection:

---

Year of last renovation:

2018

Secondary use:

Industrial

Building occupancy:

Permanently occupied

Number of occupants/users:

0

Building typology:

Semidetached house

Number of floors:

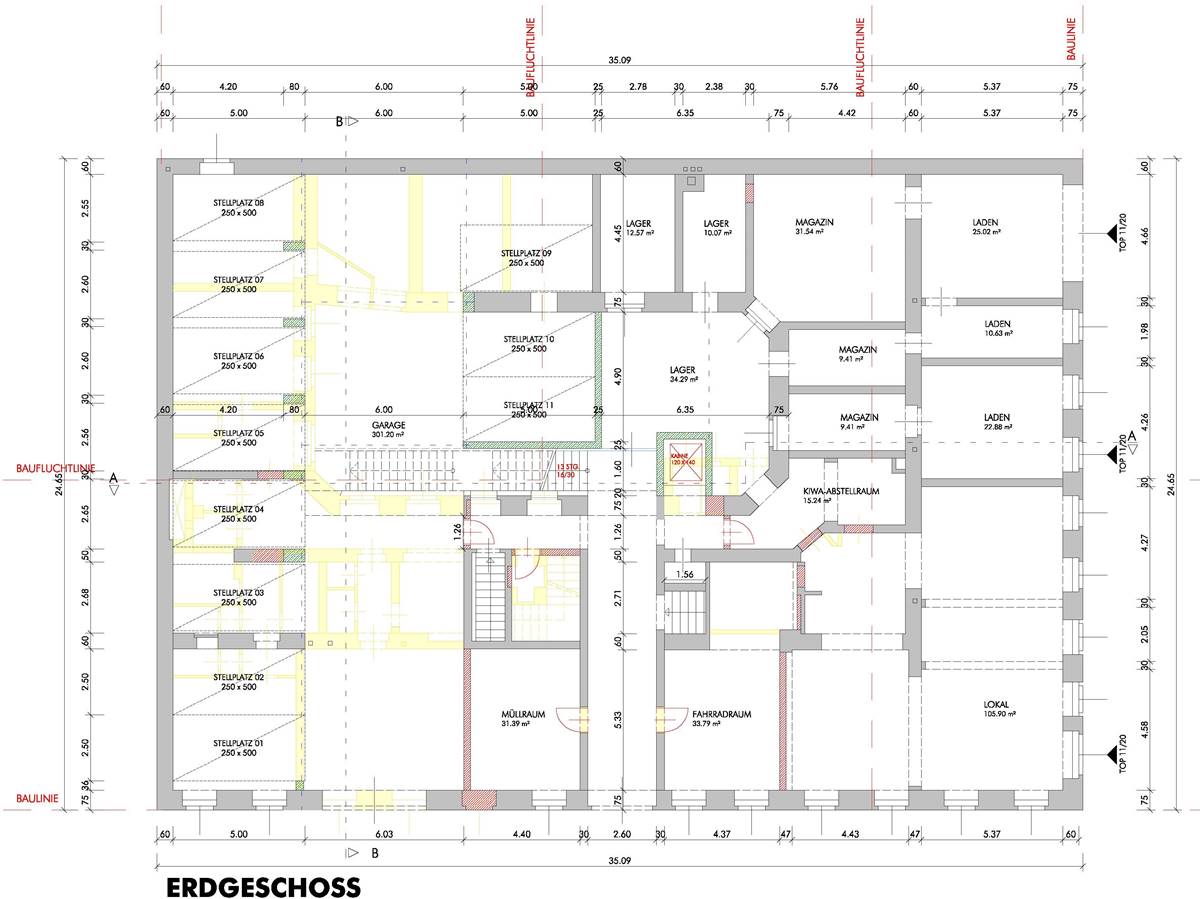

6

Basement yes/no:

Yes

Number of heated floors:

6

Gross floor area [m²]:

3328,0

Thermal envelope area [m²]:

0,0

Volume [m³]:

11555,63

NFA calculation method:

NGF (de)

External finish:

Rendered

Internal finish:

Plastered (on hard)

Roof type:

Pitched roof

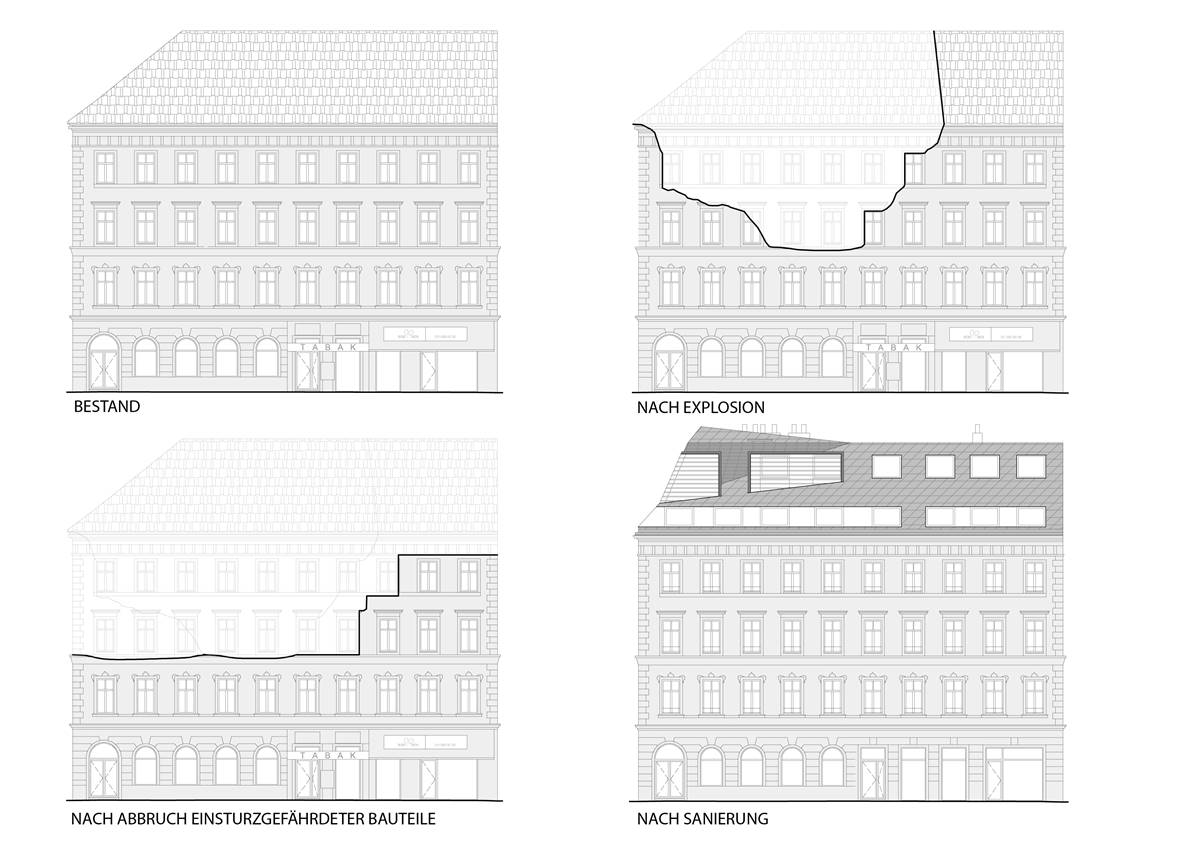

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Federal Ministry for Transport, Innovation and Technolog (BMVIT)

Radetzkystraße 2, 1030 Vienna

Brun Immobilienverwaltung und – Vermittlung

Grimmgasse 31, 1150 Vienna

Technical University Vienna, Institute of Construction, Structural Dynamics and Building Technology

Karlsplatz 13/208, 1040 Vienna

Trimmel Wall Architekten ZT GmbH

Johann-Hörbiger-Gasse 30, 1230 Vienna - Mauer

e7 energy innovation & engineering

Walcherstraße 11/43, 1020 Vienna

Dr. Karlheinz Hollinsky & Partner ZT Ges.m.b.H

Münichreiterstraße 25, 1130 Vienna

Schöberl & Pöll GmbH Bauphysik und Forschung

Lassallestraße 2, 1020 Vienna

Hygrothermal assessment Comfort monitoring with heat meters and sub-flow meters to show the energy flows in the building. Temperature and humidity sensors in the ventilation system and for detecting the outside climate.

RETROFIT SOLUTIONS

External Walls

Exterior wall

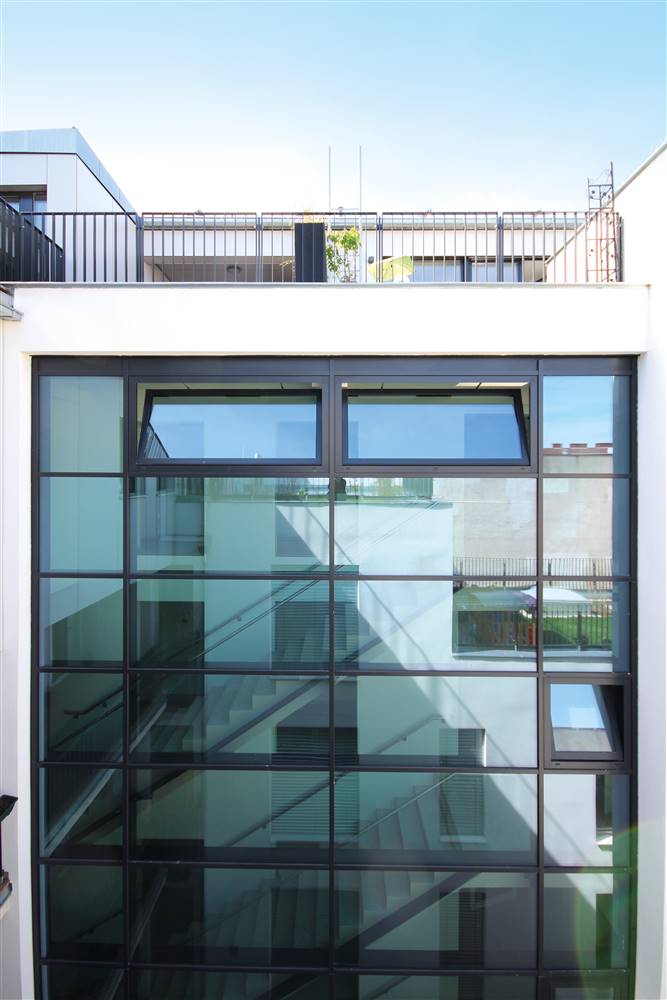

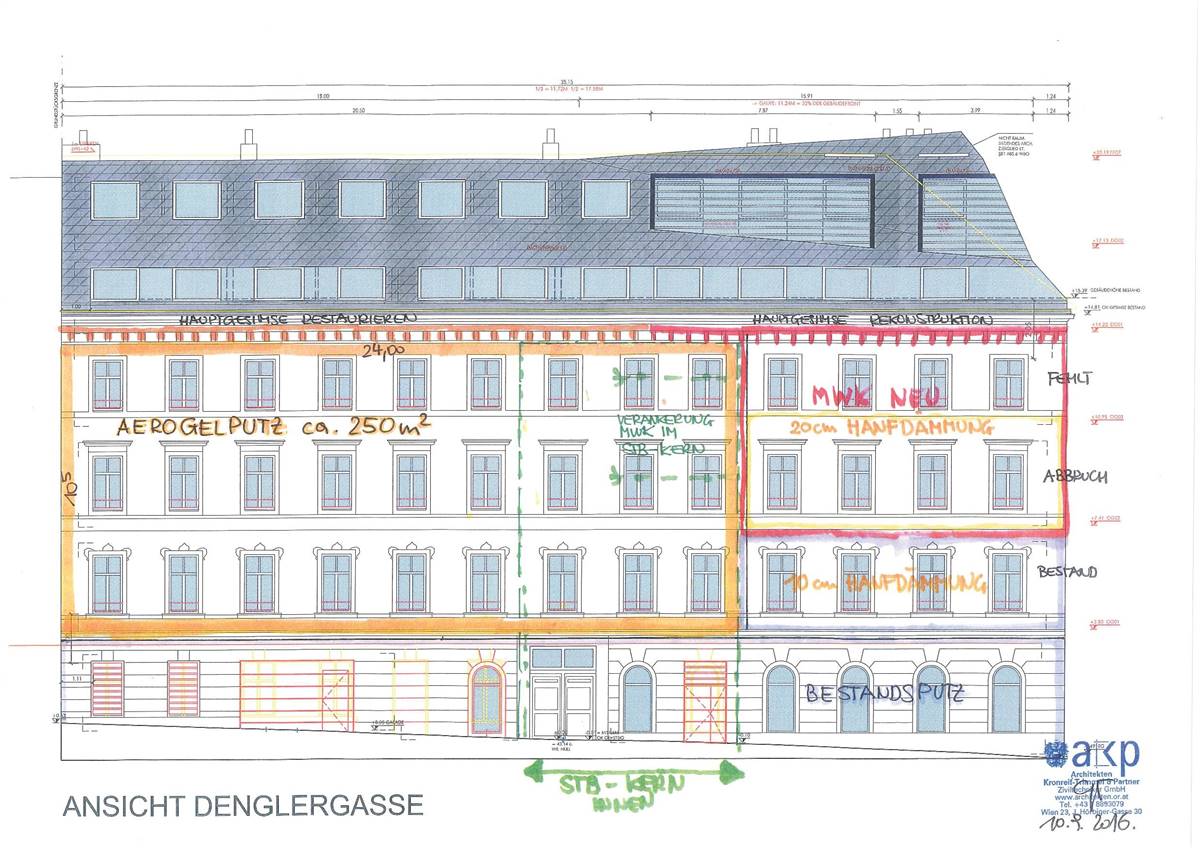

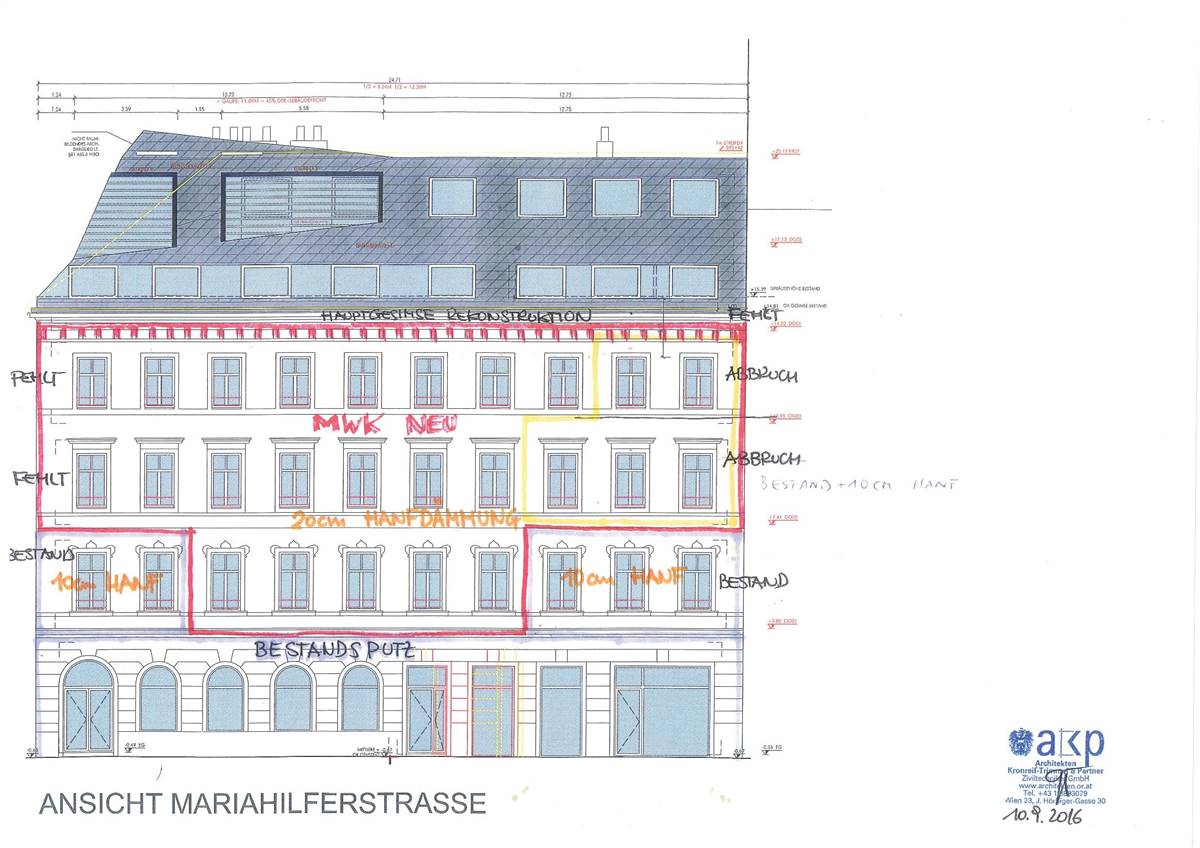

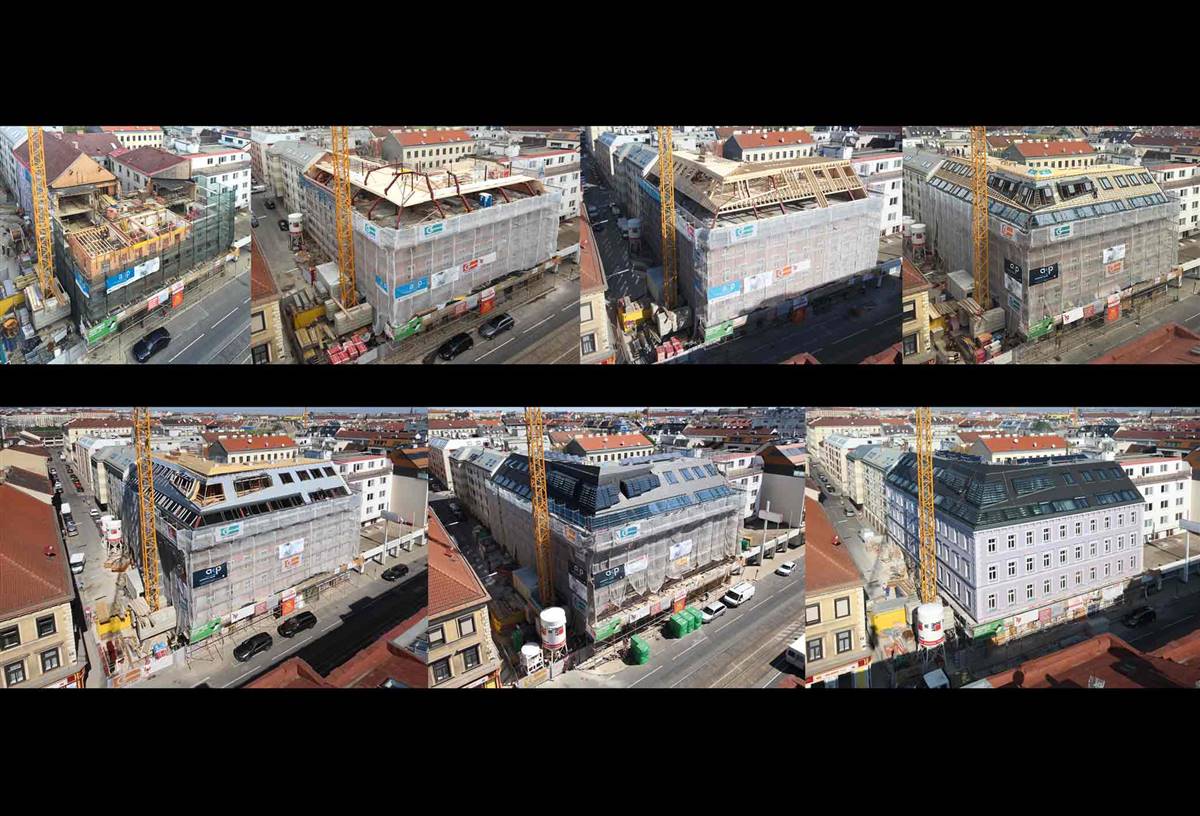

Along Denglergasse, on an area of around 205 m², Austria's largest airgel façade was built. Until now only tested on inner walls and smooth walls, this offered the chance to use the aggregate, which has extraordinarily good thermal insulation properties, on an articulated façade. With only five centimeters of the machine applied airgel plaster, the effect of a 15 centimeter thick, conventional insulation board can be achieved - an excellent environmental and aesthetic option. On the Mariahilfer Straße, the façade was much more damaged. Therefore, the newly constructed outer wall was moved a bit to the inside of the building to be able to attach 20 cm of hemp insulation. The decorative parts of the façade were made of prefabricated foam glass parts. Generally, PVC-free building materials were used.

Destroyed facade decoration elements were refilled in cooperation with a restorer made of foam glass, because a restoration from the original material would not have been economically justifiable.

20 mm

620 mm

10 mm

55mm

620 mm

10 mm

Other interventions

ROOF

OTHER

MEASURES TO INCREASE AIRTIGHTNESS

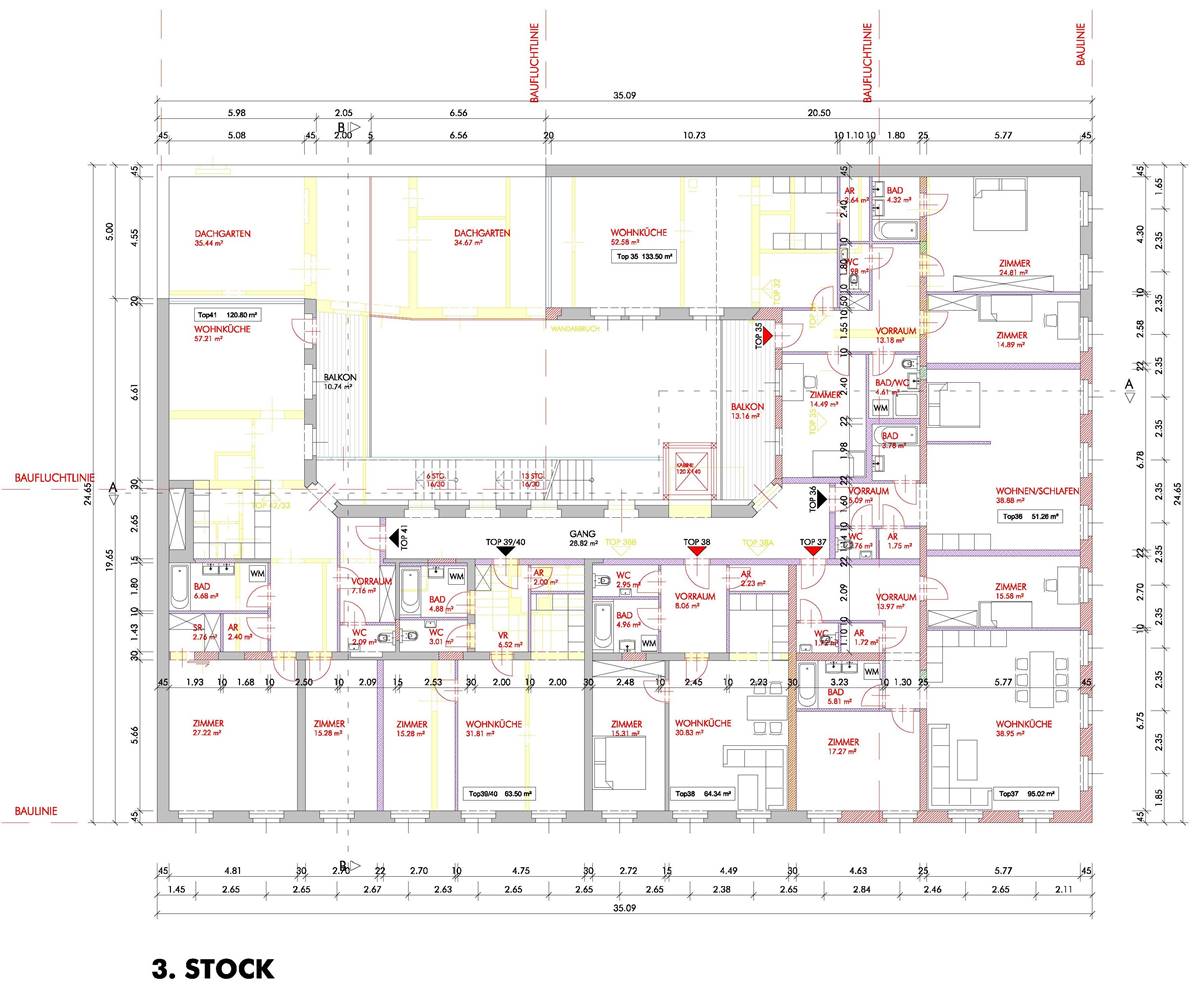

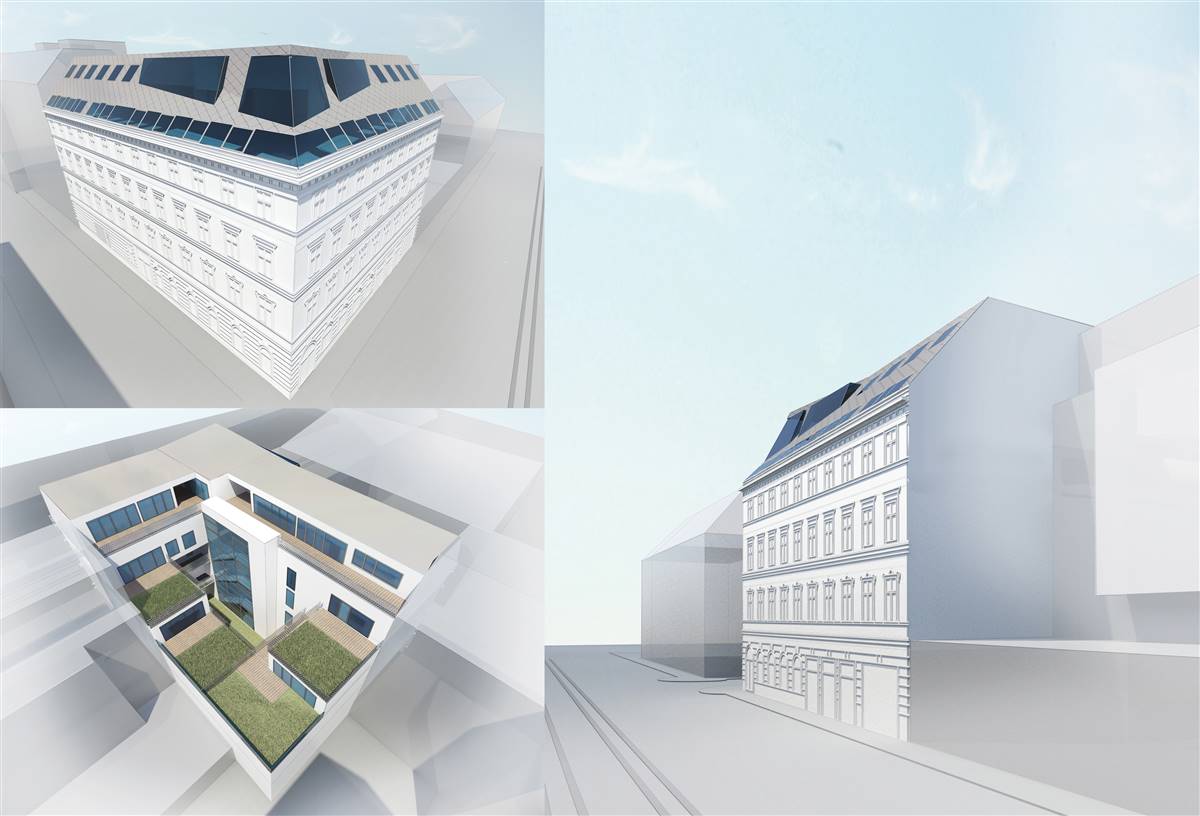

A two-storey loft conversion with seven additional maisonettes and around 760 m² of living space was realized.

Special importance was attached to a high energy-technical standard, the loft conversion meets the passive house standard.

Textile Window awnings: Aubergine-colored textile webs of roll-out sunscreen were attached to the windows. They bring accents to the cityscape and increase living comfort on hot days clearly.

Old cityscapes, prove that window-awnings, which are more familiar from southern cities, used to be common in Vienna. This encouraged the implementation of the new textile sunscreens.

Air exchange rate: n50 = 1,0 1/h

HVAC

HEATING

VENTILATION

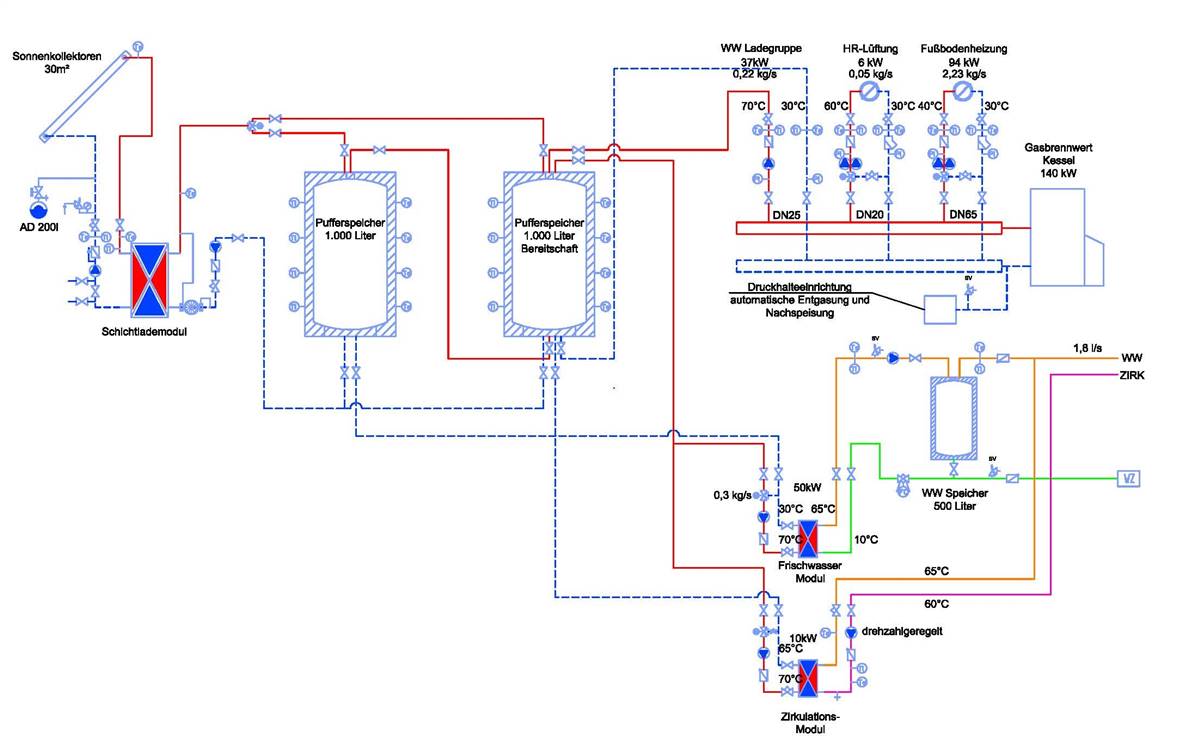

There was a changeover from a decentralised gas heating system with thermae to a centralised system in which a solar thermal system is integrated. Unfortunately, it was not possible to connect to the district heating network, but everything is prepared to change the energy source as soon as the district heating pipeline passes by the house in the foreseeable future.

The new heating system did not interfere with the conservation compatibility.

| New primary heating system | |

|---|---|

| New system type | Boiler |

| Fuel | Gas |

| Distribuition system | Radiating floor, ventilation system and buffer tank for water heating |

| Nominal power | 150 kW kW |

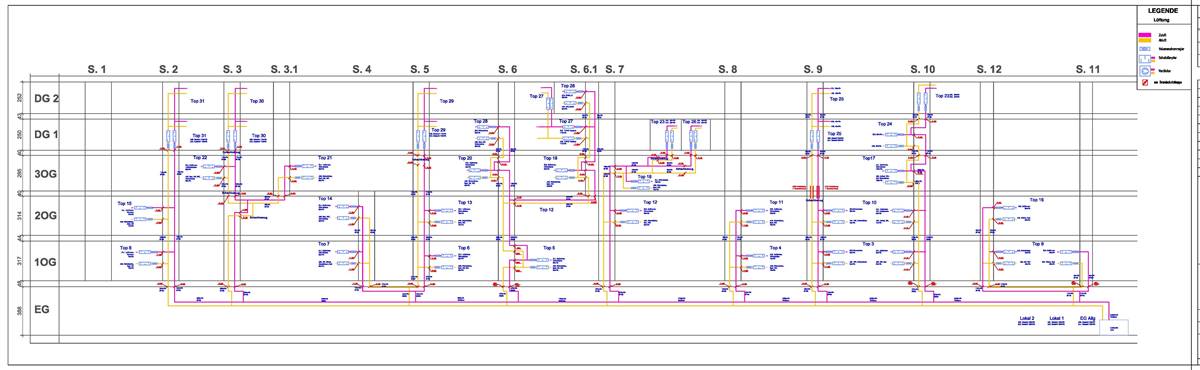

Controlled ventilation of the residential units is provided by a central compact ventilation unit from the Systemair TOPVEX SC08 HW series. The air volume in the residential units is controlled by means of volume flow controllers. The unit is equipped with a recuperative heat recovery unit with bypass. The design volume flow rate is around 3,000 m³/h, the specific fan output is specified according to the data sheet as 0.456 Wh/m³ at nominal volume flow.

The new ventilation system did not interfere with the conservation compatibility.

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Centralized controlled aeration and ventilation |

| Type flow regime | Overflow |

| Heat recovery | Yes |

| Humitidy recovery | No |

| Nominal power | 10 kW kW |

| Electric power | kW |

| Control system | Air volume control in the residential units by means of volume flow controllers |

RENEWABLE ENERGY SYSTEMS

SolarThermal

A solar thermal system, which is located on the roof of the building, supports the hot water supply.

The new solar thermal system did not interfere with the conservation compatibility.

| SolarThermal System | |

|---|---|

| Type | Flat collector |

| Collector area | 30,0 m² |

| Elevation angle | 45,0 |

| Azimuth | -5,0 |

| Heating_contribuition | 0,0 kWh |

| Cooling contribuition | 0,0 kWh |

Energy Efficiency

Primary Energy 92,3 kWh/m2.y

Consumption_estimation_After: 27,7 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: OIB 2015

Consumption_estimation_After: 92,3 kWh/m2.y

Type_of_monitoring: Continuous

Description: The three parameters room temperature and humidity, summer overheating, and CO2 concentration were continuoulsy measured for two years.

External Climate

Type_of_monitoring: Continuous

Description: The average daily outside temperature at the site and the resulting heating degree days 20/12 were measured continuously over a period of two years (2018, 2019). The site-specific heating degree days (20/12) add up to 2,229 HGT in the second year of measurement. In the first year of measurement 2,471 HGT were determined. In the energy performance certificate, these are set at 3,490 HGT. This results in a difference of 242 heating degree days compared to the first year of measurement (-10 %), or 1,171 heating degree days to the calculation basis of the energy certificate. In the second year of measurement, the outdoor temperature records only show isolated daily mean temperatures below freezing point. A cold period as in the first measurement year before was not recorded. In the second measurement year, a long period with very high outside temperatures and peaks above 30°C is recorded, but below the level of the first measurement year.

Internal Climate

The room air temperature during the heating period is above 20 °C in all residential units, in two residential units mostly above 22 °C. There is a strong correlation between outside and inside temperature. Especially the one-room apartment shows strong overheating tendencies. The lowest indoor temperatures in summer are recorded in the apartment, which has, among other things, higher external shading from other buildings.

Humidity: With regard to the room air humidity, it can be seen that in two reference apartments the winter room air humidity decreases to about 20 % and can therefore already be classified as dry. The maximum room air humidity, on the other hand, is almost below 60 %, so there is no risk of condensation damage. CO2 concentration: The CO2 concentration was measured in three reference apartments in the bedroom and in one apartment in the kitchen. All residential units in the building are connected to the central comfort ventilation system. The level of CO2 concentration is at a very low level and does not exceed a limit value of 1,000 ppm. It can be concluded that the air volumes for these residential units are sufficient or slightly oversized.

Costs

7,000,000 € (total)

Amount includes: The total costs for the production of the finished facade surface were calculated with 200.000 Euro settled. The costs include all necessary activities from preparation of the existing facade (knocking off old plaster, pre-spray work, etc.), the application of the aerogel plaster incl. substrate preparation and finishing plaster as well as the formation the traction and decorative elements and the cornices. This results in specific costs of around 800 euros per m² of facade surface. The aerogel insulation plaster is just over 400 Euro per m² with an executed layer thickness of 5.5 - 6 cm and thus makes 50 % of the total production costs of the façade. The costs are thus around one third above that of a standard thermal insulation plaster.

No

Environment

emissions_at_use_stage_after_intervention: 14,32 per m2

7 car parking spaces with e-charging station with separate billing were established.

silbersalz.jpg)

CarolineBegle - 1.jpg)