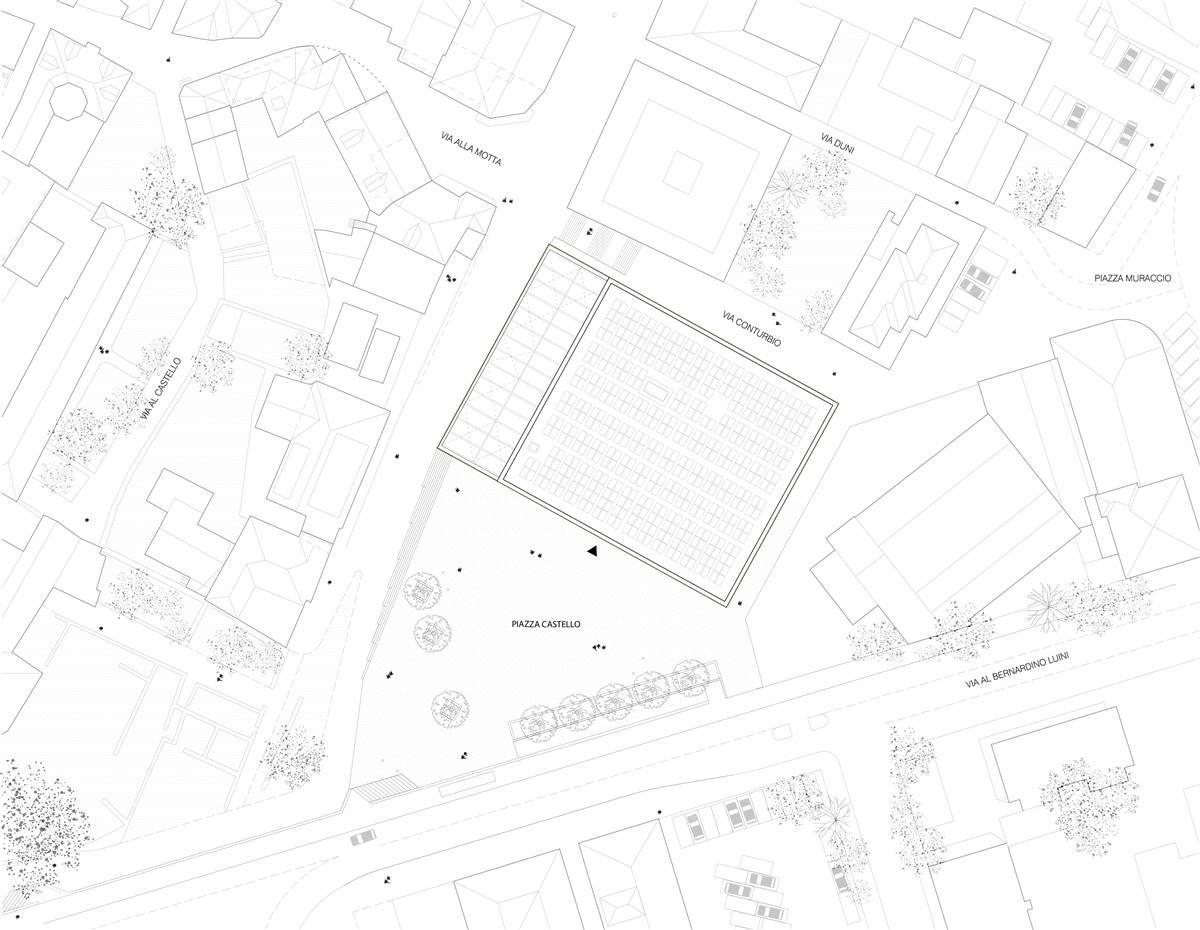

PalaCinema Locarno - Locarno, Switzerland

Piazza Remo Rossi 1

6600

Locarno, Suisse

Architect

Owner

Contact Details

Other Information

Is a public building.

Climate Zone Dfc

Altitude 200

HDD 1449

CDD 111

Conservation Area:

Oui

Level of Protection:

A (maximum level of protection)

Year of last renovation:

2017

Year of previous renovation:

1932

Secondary use:

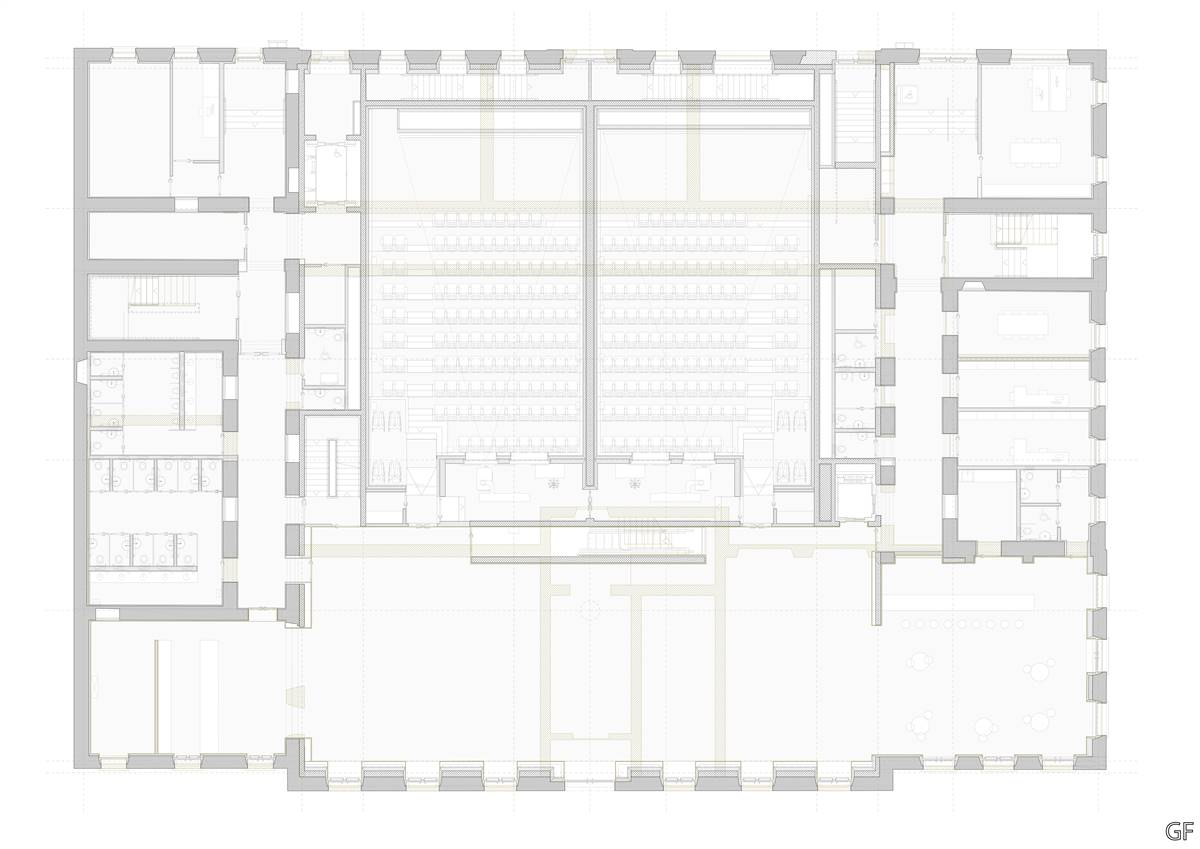

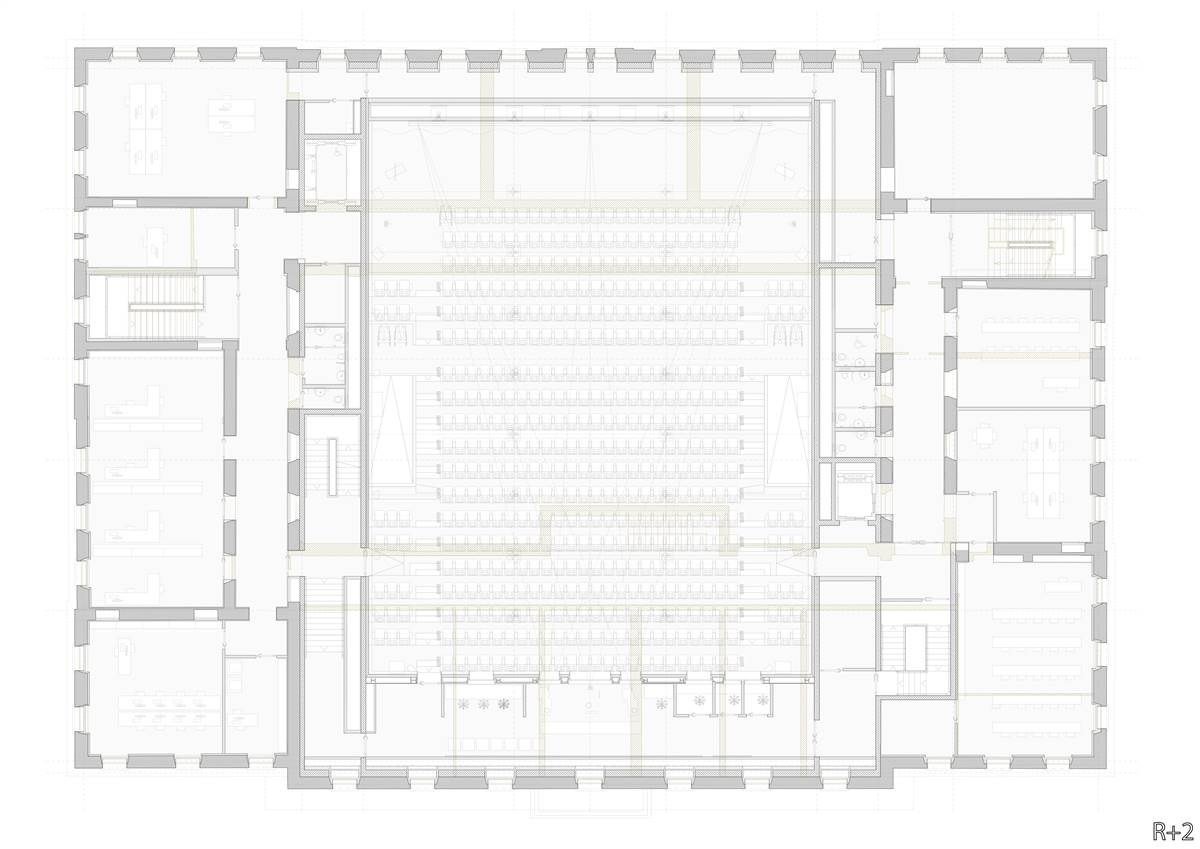

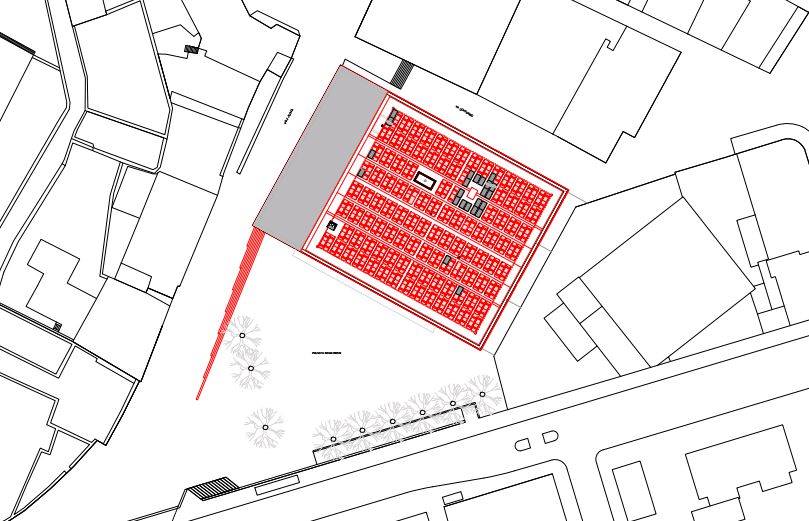

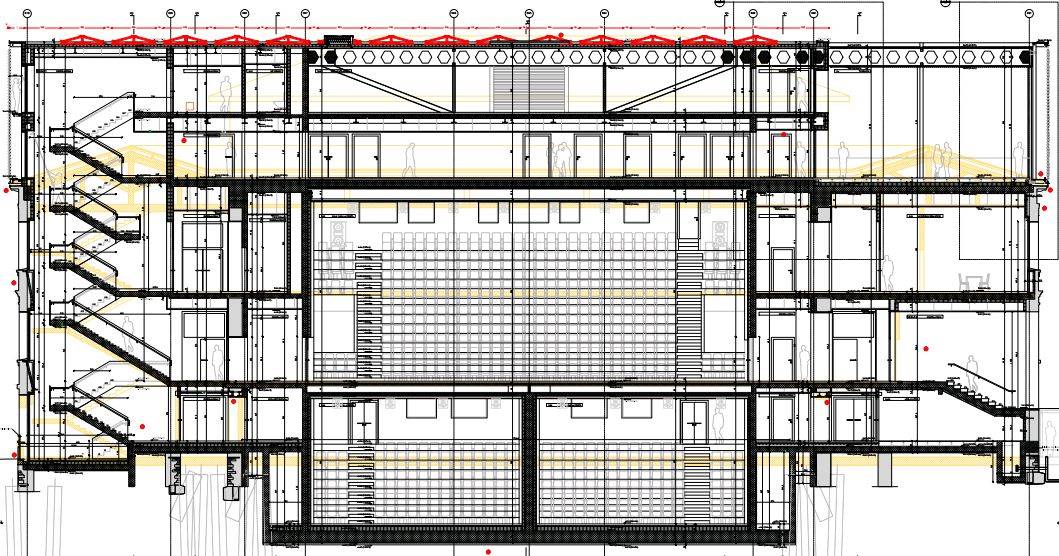

Educational and administrative facilities are located in the east and west wings of the building and connected with new multipurpose rooms and a terrace.

Building occupancy:

Permanently occupied

Number of occupants/users:

900

Building typology:

Public building with a compact volumetry.

Number of floors:

3

Basement yes/no:

No

Number of heated floors:

3

Gross floor area [m²]:

6740,0

Volume [m³]:

55755,0

NFA calculation method:

SIA 416

External finish:

Plaster and stonework.

Internal finish:

Plastered (on hard)

Roof type:

Pitched roof

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Municipality of Locarno - City of Locarno

Piazza Grande 18, 6601 Locarno, Switzerland

citta@locarno.ch

Tel.+41 91 756 31 11

PalaCinema Locarno SA

Piazza Remo Rossi 1, 6600 Locarno, Switzerland

info@palacinemalocarno.ch

Tel.+41 91 756 31 07

AZPML + DFN (architects consortium)

55 Curtain Road, London EC2A 3PT, UK

in@azpml.com

Tel.+44 (0) 2070336482

Greenkey Sagl

Via Ceresio 45, 6963 Pregassona, Switzerland

info@greenkey.ch

Tel.+41 91 630 64 91

WMM Ingenieure AG

Florenz-Strasse 1d, 4142 Münchenstein (Basel), Switzerland

bl@wmm.ch

Tel.+41 61 339 90 90

Marco de Carli engineer SA

Via Romerio 6, 6601 Locarno, Switzerland

info@ingdeca.ch

Tel.+41 91 751 07 51

Alsolis SA

Via Penate 4, 6850 Mendrisio, Switzerland

info@alsolis.ch

Tel.+41 91 640 90 80

Ecocontrol SA

Via Roveredo 16, 6604 Locarno, Switzerland

info@ecocontrol.ch

Tel.+41 91 290 12 00

Hygrothermal assessment No

Life Cycle Analysis (LCA) No

Other No

RETROFIT SOLUTIONS

External Walls

Stone masonry wall with concrete structure

Stone masonry wall with internal insulation

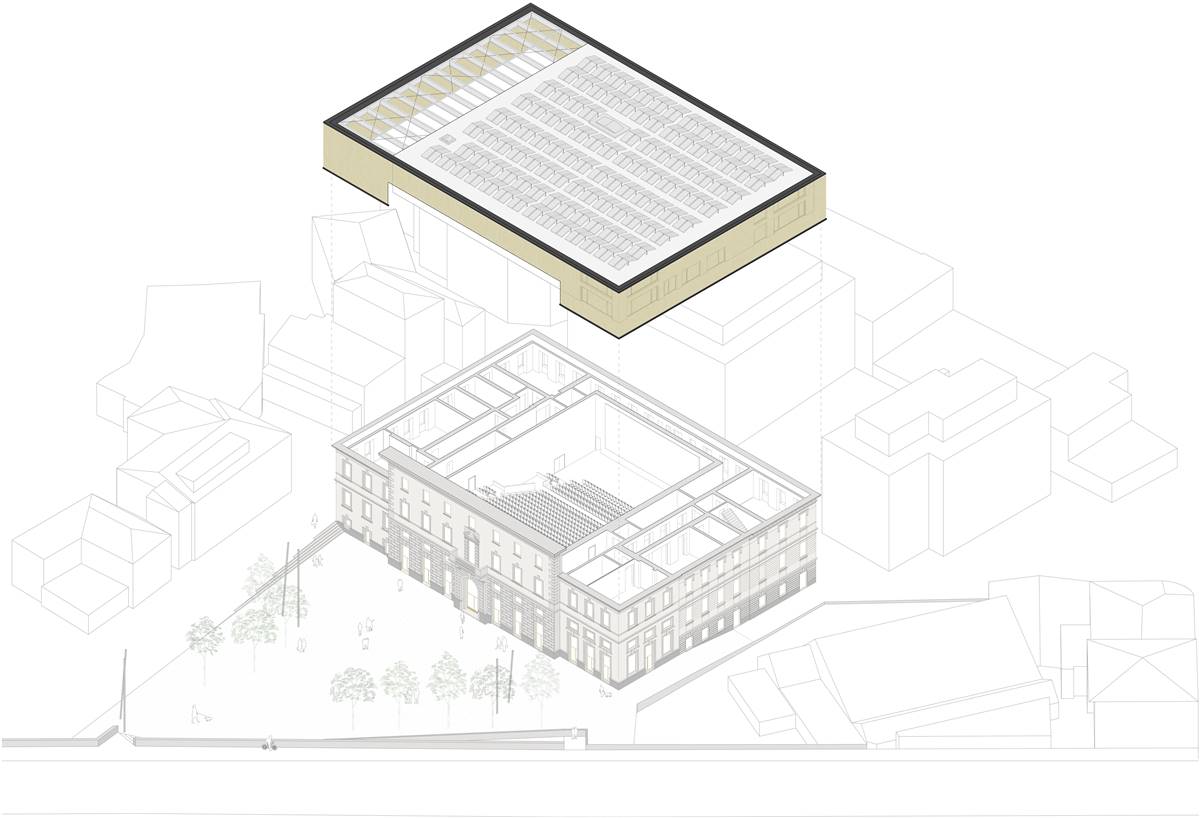

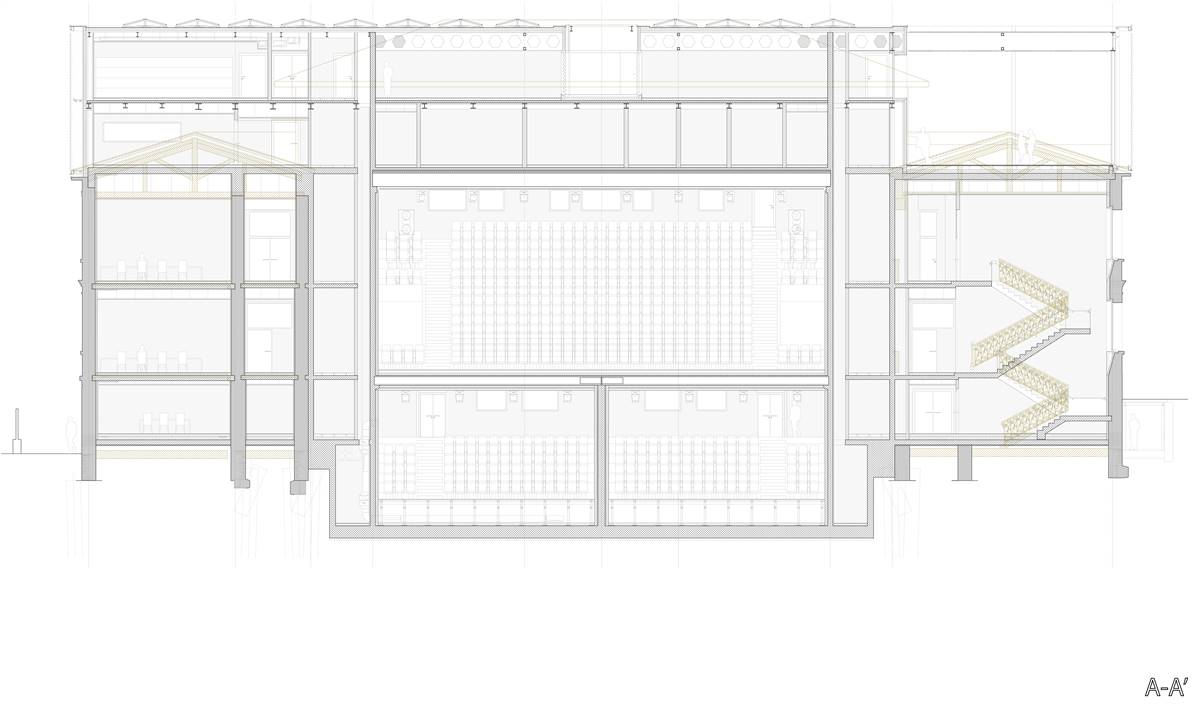

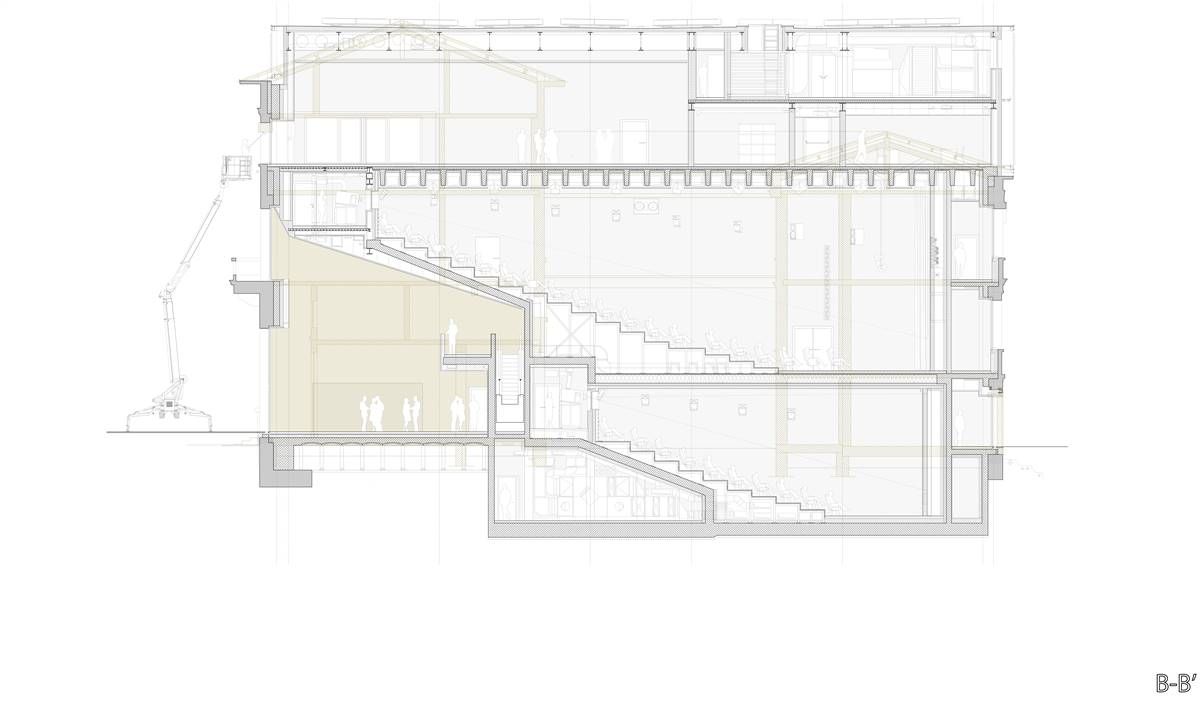

The original structure has been largely maintained as far as the outer ring of the building is concerned, while the central part has been demolished to make room for the cinemas. The new core has been inserted inside the old building to reinforce the external walls with a reinforced concrete structure.

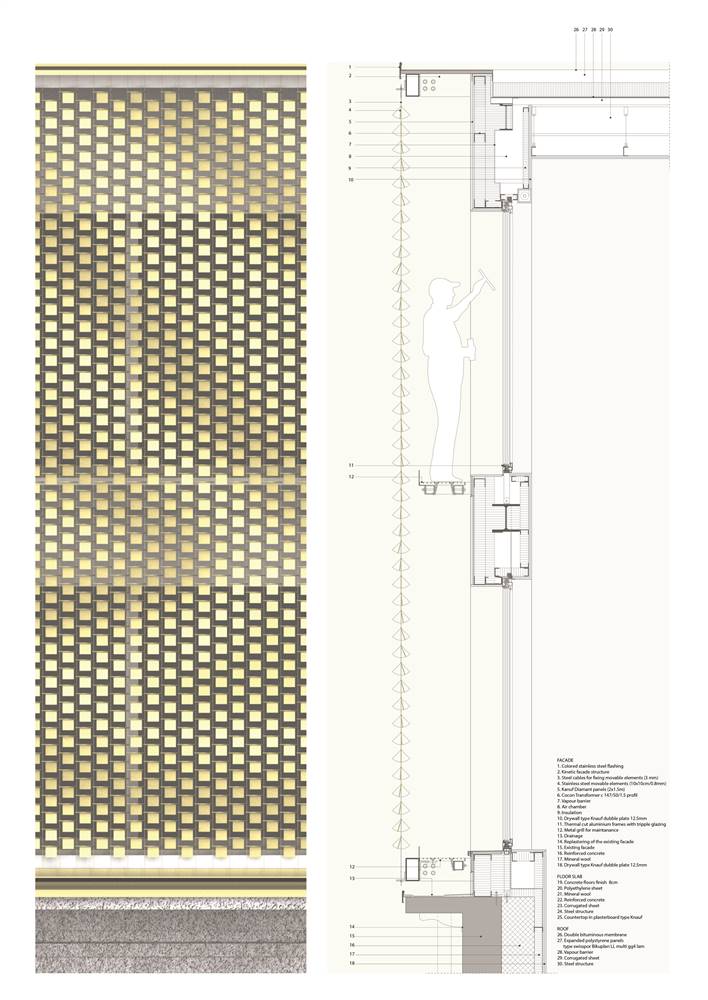

The building has been internally insulated with 18 cm on the new structure and new building. The minimum thickness necessary to reach the Minergie standard were selected both in the new part as in the old part, with the purpose to lose as little internal space as possible. This way the original façade remains exposed. As regards the renovation of the external surface, measures have been taken to allow images to be projected onto the façade. The plaster has in fact been carried out entirely in white. Initially the entire surface, including the ashlar, was to be plastered, but for conservation reasons this was not permitted. The intervention is already very invasive and completely covering the original façade would have ruined the intention of keeping part of its original expression alive.

20 mm

600 mm

20 mm

20mm

600 mm

300 mm

180 mm

12 mm

30 mm

The original structure has been largely maintained on the wings of the building. For them it was only necessary to add 8 cm of insulation on walls. Special attention was given to the verification and avoidant of thermal bridges.

The minimum thickness necessary to reach the Minergie standard has been inserted, with the purpose to lose as little internal space as possible. This way the original façade remains exposed. The external surface has been treated as well as the stone masonry wall with concrete internal structure: measures have been taken to allow images to be projected onto the façade. The plaster has in fact been carried out entirely in white. Initially the entire surface, including the ashlar, was to be plastered, but for conservation reasons this was not permitted. The intervention is already very invasive and completely covering the original façade would have ruined the intention of keeping part of its original expression alive.

20 mm

600 mm

20 mm

20mm

600 mm

80 mm

30 mm

Windows

Golden foil framed windows

The windows have been replaced by new ones that are not reproductions of the originals and a golden sheet has also been added to the intrados. The windows of the building were not original and were replaced in different periods. It was considered correct to avoid historical falsehoods by imitating period windows, also because they are difficult to reconstruct and in contrast with energy regulations. In origin, the reduced size of the glass depended on the technology of the time that did not allow the use of glass with larger surfaces while modern technology allows it, being able to use three-layer glasses to improve energy efficiency, which have a much lower brightness coefficient than the original glass, which if used with small surfaces would reduce the amount of light brought into the environment, a factor that must be avoided.

The original double casement windows have been replaced by windows with a frame that is almost invisible from the outside. Previously all windows could be opened, while now a large part is fixed (this is possible thanks to mechanical ventilation that does not require natural ventilation). The intradoses of the windows were covered with gold foil, as if the new institutions housed in the building overflowed from the old envelope.

| Existing window type | Casement window |

| Existing glazing type | Single |

| Existing shading type | Roller blinds |

| Approximate installation year | 1932 |

| New window type | Fixed window |

| New glazing type | Triple |

| New shading type | NA |

| New window solar factor g [-] | 0,44 |

Other interventions

ROOF

GROUND FLOOR

OTHER

MEASURES TO INCREASE AIRTIGHTNESS

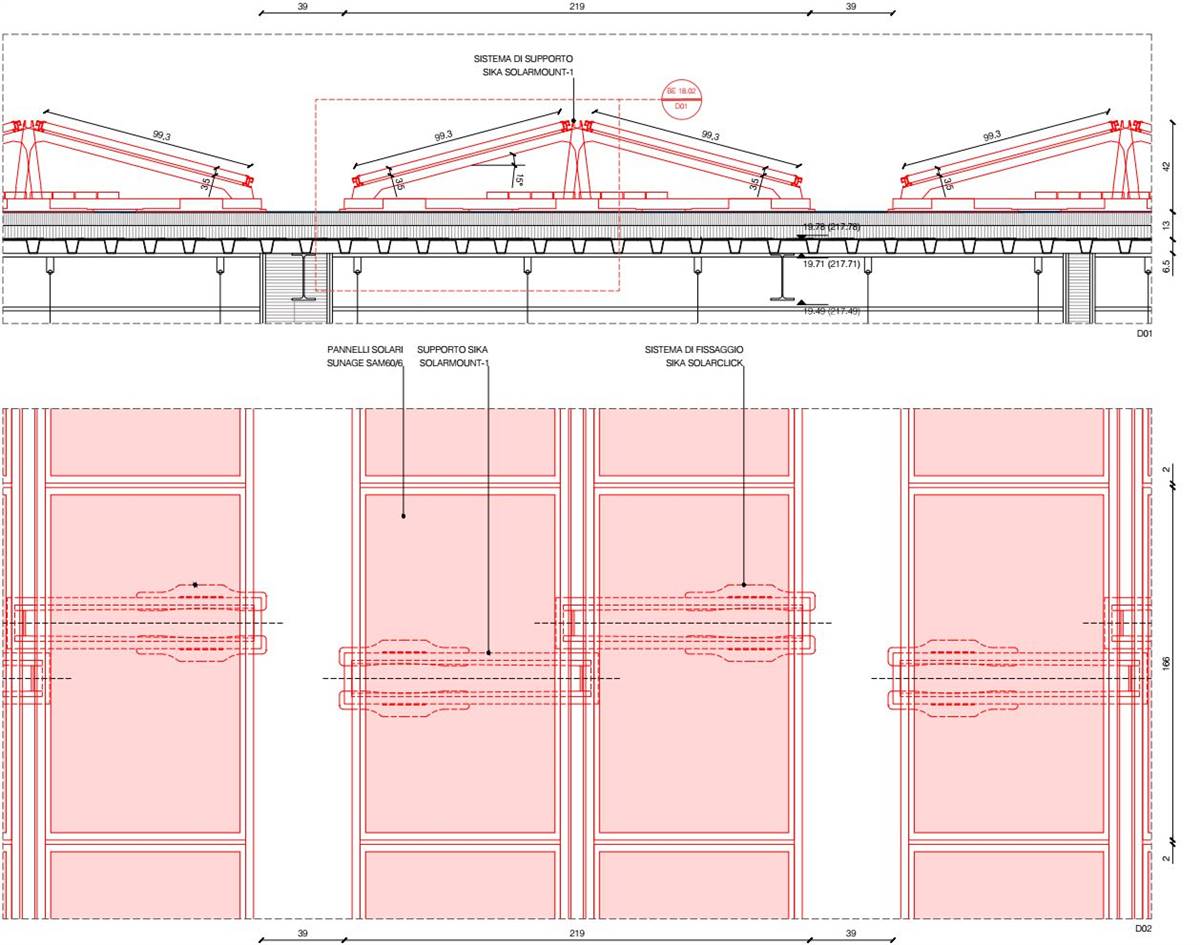

The extension of the building concerns the addition of an upper floor (besides the "filling" of the internal courtyard). The original pitched roof is therefore in no way recovered. The new roof is light, flat and houses the large photovoltaic system.

The roof is part of the extension of the building, so it is part of the new volume which is completely different and stands in contrast to the restored part. Its appearance and construction system therefore have no connection with the old building. The new roof is made of a light metal structure, while the old building had a classic pitched roof with wooden carpentry and roof tiles.

50 mm

250 mm

60 mm

40 mm

180 mm

20 mm

60 mm

900 mm

The ground floor has been completely replaced.

Due to the change of function, the needs of the structure and the space occupied by the cinema halls, the floor has been completely demolished to be rebuilt as needed.

20 mm

80 mm

200 mm

250 mm

50 mm

To complete energy efficiency, the lighting concept makes extensive use of LED technology. The installation of the safety systems was entrusted to Securiton AG. The entire building is protected by a SecuriFire 3000 fire detection system.

The intervention does not affect the conservation of the building's substance.

To achieve the Minergie® certificate specific attention were paid to control of the air change throughout the year and to good air tightness.

HVAC

HEATING

VENTILATION

AIR CONDITIONING

DOMESTIC HOT WATER

100% indirect Ground Water Heat Pump (GWHP) for heating/cooling and domestic hot water in combination with the solar PV plant in the roof of the building. The production of thermal energy is guaranteed by a water-water heat pump with a primary medium of groundwater with 450 kW of thermal power capacity, while the refrigerating energy necessary for the air conditioning, of about 1'050 kW cooling power capacity, is ensured by a pumping station of water from the lake. In consideration of the fact that the lake water has a significant temperature difference depending on the seasonal trend and the depth of collection, in order to obtain an enough constant temperature and to allow an integral free-cooling function (10ºC at the point of use and 7ºC at the sampling point) it was necessary to go to a depth of 45 m due to the considerable length of the pipeline (approx. 1'000 ml.) This solution presupposed an accurate analysis of various aspects such as: maintenance of the pumping station; periodic cleaning of collection hoods, housing and anchoring pipes, operating pressures in the pipes and power supply. Taking these reasons into account, it was decided to adopt an "under head" suction pump system (booster system). After the renovation, the building was certified Minergie® for buildings with low energy consumption (energy index between 30 - 38 kWh / m2y) respecting some fundamental requirements: 1) Attention to the insulation of the building envelope and thermal bridges; 2) Control of the air change throughout the year; 3) Verification of summer thermal comfort; 4) Additional requirements regarding lighting, industrial refrigeration systems and heat production; 5) Limitation of additional costs up to a maximum of 10%, compared to conventional buildings.

Geothermal power can be generated throughout the year on twenty-four-hour basis as it is not much dependent on ambient temperature and weather conditions exploitation low enthalpy geothermal (aquifers) resources for heating and cooling. There is lower environmental impacts due to the exploitation of such geothermal resource.

| New primary heating system | |

|---|---|

| New system type | Geothermal Ground Water Heat Pump (GWHP) |

| Fuel | Electricity |

| Distribuition system | |

| Nominal power | 450 kW |

Comfort is achieved by maintaining high technical and quality standards of the casing and by the renewal of the air guaranteed by controlled ventilation systems. The HVAC and ventilation systems have been divided according to the different sectors of use, in order to adapt the thermal loads to the thermo-hygromectic conditions and to the actual activities (cinema halls, foyer, multipurpose room and theater, administration rooms and audio-video CCD archive rooms) for a volume total treated air of 89'500.00 m3 / h.

To achieve the Minergie® certificate specific attention were paid to control of the air change throughout the year and to good good performances and verification of summer thermal comfort.

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | |

| Type flow regime | Air handling unit 89,500 m3 / h. |

| Heat recovery | Oui |

| Humitidy recovery | |

| Nominal power | kW |

| Electric power | kW |

| Control system | Si |

The new cooling systems consist in a Groundwater Heat Pump (GWHP) system. GWHP with 450 kW of thermal power capacity and 1050 kW of cooling capacity. GroundWater Heat Pump systems (GWHPs) extract water from one or more wells, pass it through a heat exchanger or a heat pump, which either extracts heat from, or rejects heat, and discharge water back into the aquifer or nearby surface water. To achieve the Minergie® certificate additional and high requirements regarding industrial refrigeration systems and heat production must be complied (HVAC systems).

For the purposes of Minergie certification it is important that the whole building is considered as an integrated system: the building envelope, but also the domestic systems. For the domestic technology with heating, ventilation and hot water preparation, not many additional additions are required, but rather reasonable combinations of systems.

| New cooling system | |

|---|---|

| Type | Heat pump |

| Distribuition system | Radiating floor |

| Nominal power | 252 kW |

| Electric power | 1050,0 kW |

A new DHW systems have been implemented in combination with the HVAC system.

The old building has been totally modified to meet the new needs for changes in use (school building to cinema and cultural building) and for the configuration spaces' needs to follow the distribution program required by the tender competition.

| New DHW system | |

|---|---|

| Type | with heating system |

| Hot_water_tank | Oui |

| With heat recovery | Oui |

RENEWABLE ENERGY SYSTEMS

Photovoltaic

Geothermal

A photovoltaic system has been installed on the roof. With a nominal power of 135.7 kWp, the production is about 130'000 kWh/y. The total cost is 178'000 CHF.

The intention is to guarantee the best possible integration from an aesthetic and architectural point of view. For this reason, the system has been inserted on the roof. Initially the intent was to install an integrated PV system, but after a cost comparison it was decided to continue with a standard black/blue monocrystalline cell system. The inverter is installed in the technical room on the top floor.

The preliminary analysis showed an open horizon on the roof, with good sunshine throughout the year. For this reason it was decided to work with modules inclined at 15° with a bidirectional east-west system that allows energy production to be better distributed throughout the day. The lower inclination results in lower profitability, but the covered surface area can be increased in the absence of shading, thus compensating for this factor.

| Photovoltaic System | |

|---|---|

| Type | Monocrystaline |

| Collector area | 759,0 m² |

| Total nominal power | 135,7 kW |

| Elevation angle | 15,0 |

| Azimuth | 90,0 |

| Overall yearly production | 130000,0 kWh |

GroundWater Heat Pump system (GWHP) were used for heating and cooling purposes and also for the domestic hot water (DHW), in combination with the solar PV plant in the roof of the building. The production of thermal energy is guaranteed by a water-water heat pump with a primary medium of groundwater with 450 kW of thermal power capacity, while the refrigerating energy necessary for the air conditioning, of about 1'050 kW cooling power capacity, is ensured by a pumping station of water from the lake. Geothermal power can be generated throughout the year on twenty-four-hour basis as it is not much dependent on ambient temperature and weather conditions exploitation low enthalpy geothermal (aquifers) resources for heating and cooling. Lake catching: 2 pumps x 180 m3 / h; capturing headphones placed at a depth of 45 meters; Water transport line approx. 1'000 linear meters (of which 250 ml in the DN 250 lake).

Exploitation of low enthalpy geothermal resources for geothermal space heating and cooling for domestic hot water applications. No requirements as the old former building were totally renovated.

GroundWater Heat Pump systems (GWHPs) are used in this building to extract water from one or more wells, pass it through a heat exchanger or a heat pump, which either extracts heat from, or rejects heat, and discharge water back into the aquifer, in this case, acquifers exploiting lake Maggiore catchment. In consideration of the fact that the lake water has a significant temperature difference depending on the seasonal trend and the depth of collection, in order to obtain an enough constant temperature and to allow an integral free-cooling function (10ºC at the point of use and 7ºC at the sampling point) it was necessary to go to a depth of 45 m due to the considerable length of the pipeline (approx. 1'000 ml.) This solution presupposed an accurate analysis of various aspects such as: maintenance of the pumping station; periodic cleaning of collection hoods, housing and anchoring pipes, operating pressures in the pipes and power supply. Taking these reasons into account, it was decided to adopt an "under head" suction pump system (booster system).

| Geothermal System | |

|---|---|

| Type | Vertical loop |

| Exchange area | 0,0 m² |

| Overall yearly production | 205200,0 kWh |

Energy Efficiency

Voluntary certificates: Minergie 2017, certificato num TI-480 This certificates implies a limitation of additional costs up to a maximum of 10%, compared to conventional buildings.

Consumption_estimation_Calculation_method: Minergie® Certification

Consumption_estimation_After: 38 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: Minergie® Certification

Consumption_estimation_Including_DHW: Oui

Consumption_estimation_After: Estimation of energy demand: 205200 kWh/y

Internal Climate

Thermal comfort was improved as the building was no longer used due to poor energy and environmental conditions. After the renovation, the building obtained the Minergie® Certification for low energy consumption buildings, which is the Swiss brand that certifies the sustainability of new or redeveloped buildings, with particular attention to living comfort. Comfort is achieved by maintaining high technical and quality standards of the casing and by the renewal of the air guaranteed by controlled ventilation systems.

Comfort and Indoor Air Qualiy is achieved by maintaining high technical and quality standards of the casing and by the renewal of the air guaranteed by controlled ventilation systems.

Special attention was given to internal lighting and to the daylight factor. The windows have been replaced by new ones which are not reproductions of the originals and a gold foil has also been added to the intrados. Originally, the small size of the glass in the original windows depended on the technology of the time that did not allow the use of glass with larger surfaces. The three-layered glass used in the renovation improves energy efficiency, but has a lower brightness coefficient than the original glass, reducing the amount of light introduced into the environment. The gold foil in the edge of the window increases the reflection coefficient by decreasing the natural light in the building. It was created in the extension of the volume of the original facade wiht a Kinetic facade structure using steel cables for fixing movable elements (3 mm) in stainless gold steel movable elements (10x10 cm / 0.8 mm) which provide light diffusion and shadow on the terrace of the top floor. A mockup was recreated on a scale to verify the effect of the wind and the sound of moving elements.

Special attention was paid to the acoustics and sound insulation of the 3 new cinemas inside the building. The correct performance has been verified by a specific sound studio with verification and testing of acoustic insulation and verification of architectural acoustics. A mockup was recreated on a scale to verify the effect of the wind and the sound of moving elements of the Kinetic facade structure of the raised floor.

No

Costs

The following financing arrangements have been made for the intervention: Tourism and cultural sector: 5'000'000 CHF Stella Chiara Foundation: 10'000'000 CHF City of Locarno: 6'000'000 CHF Cantonal contributions: 6'000'000 CHF Municipalities, sponsors and other sources: 5'200'000 CHF

33'660'000 CHF (total)

Amount includes: Fund: 235'000 CHF Preliminary works: 3'998'000 CHF Building: 23'672'000 CHF Operating equipment: 1'300'000 CHF External works: 190'000 CHF Secondary expenses and VAT: 2'465'000 CHF Reserves: 1'500'000 CHF Costs of HVAC, DHW and ventilation system (GWHP with lake water collection system): 5'000'000 CHF Fairly precise estimate of the main cost positions (before the intervention), the actual costs after the intervention are not available.

No

.jpg)