Single family House - Bern, Switzerland

Luisenstrasse 30

3005

Bern, Suisse

Architect

Owner

Contact Details

Other Information

Swiss Solar Price 2014 (German and French)

Climate Zone Cfb

Altitude 542

HDD 198

CDD 0

Conservation Area:

Oui

Level of Protection:

High

Year of last renovation:

2015

Secondary use:

NA

Building occupancy:

Permanently occupied

Number of occupants/users:

5

Building typology:

Detached house

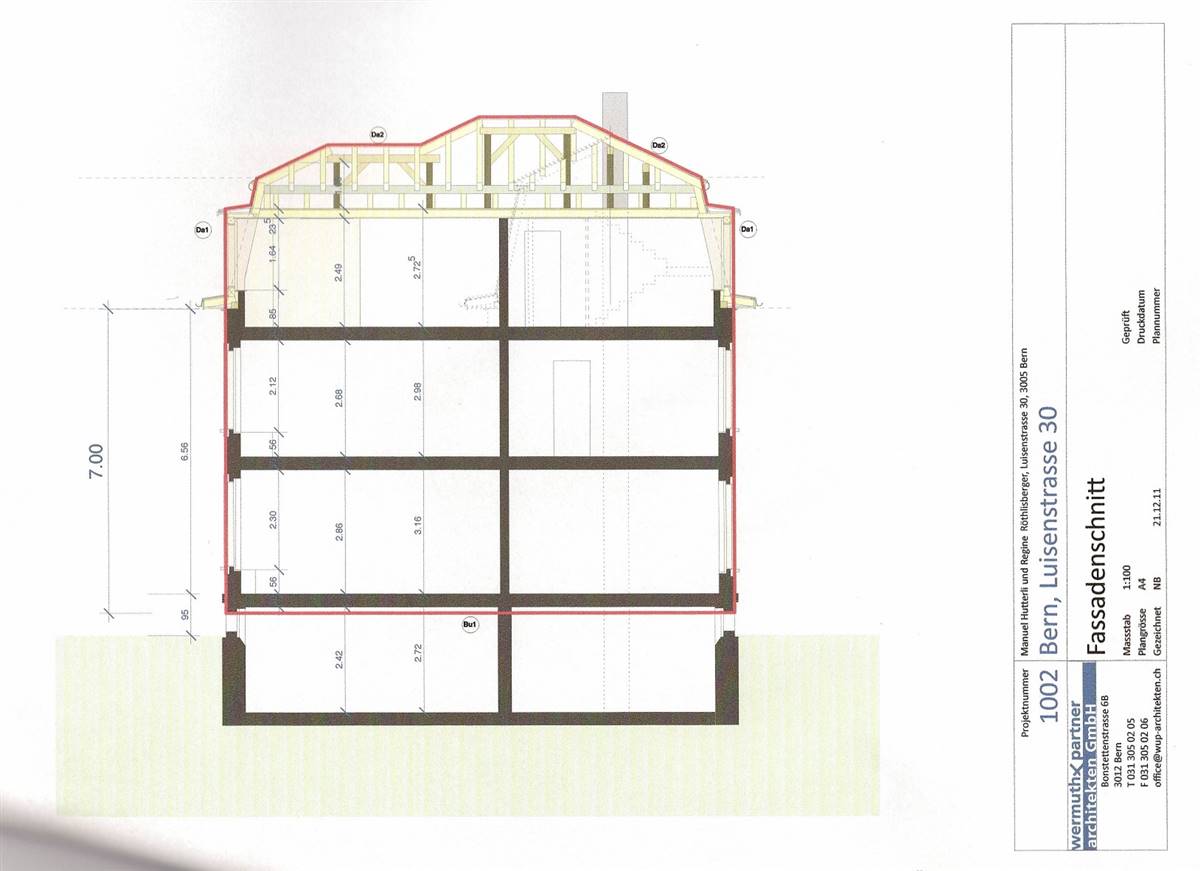

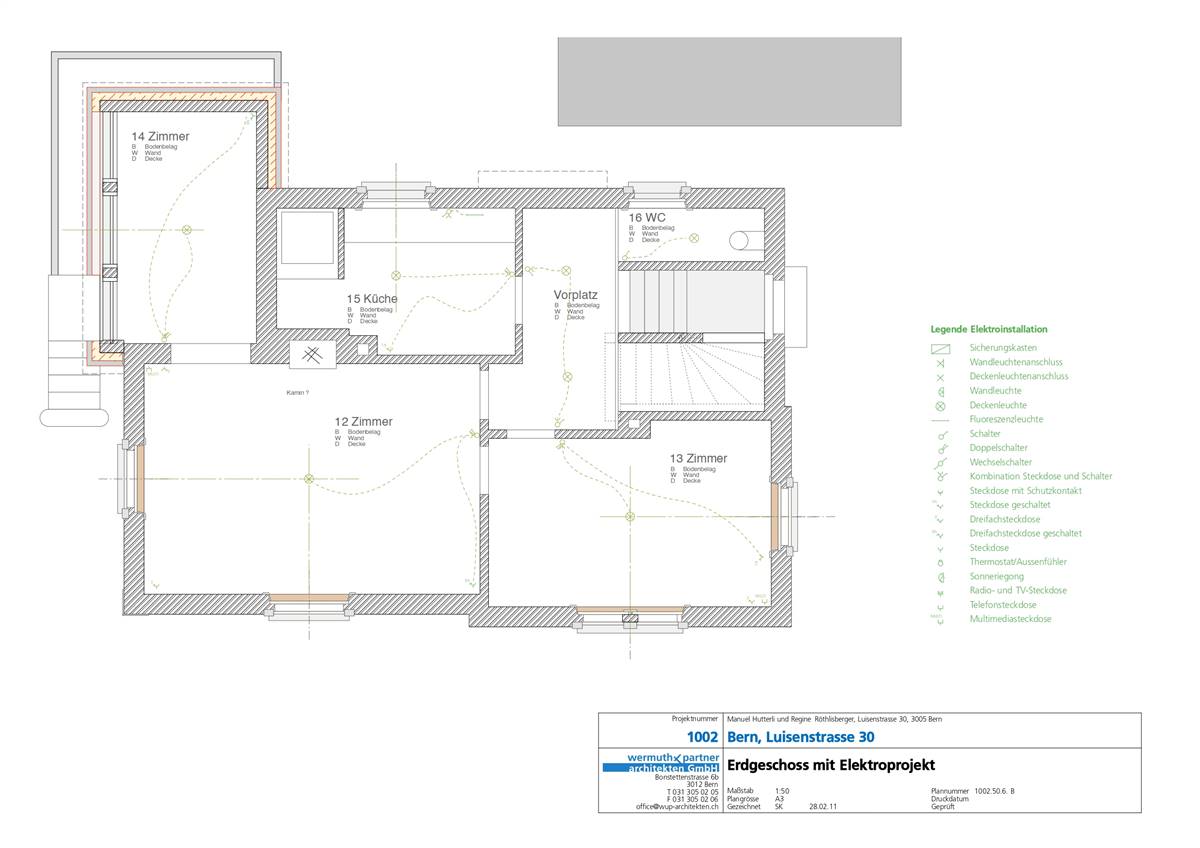

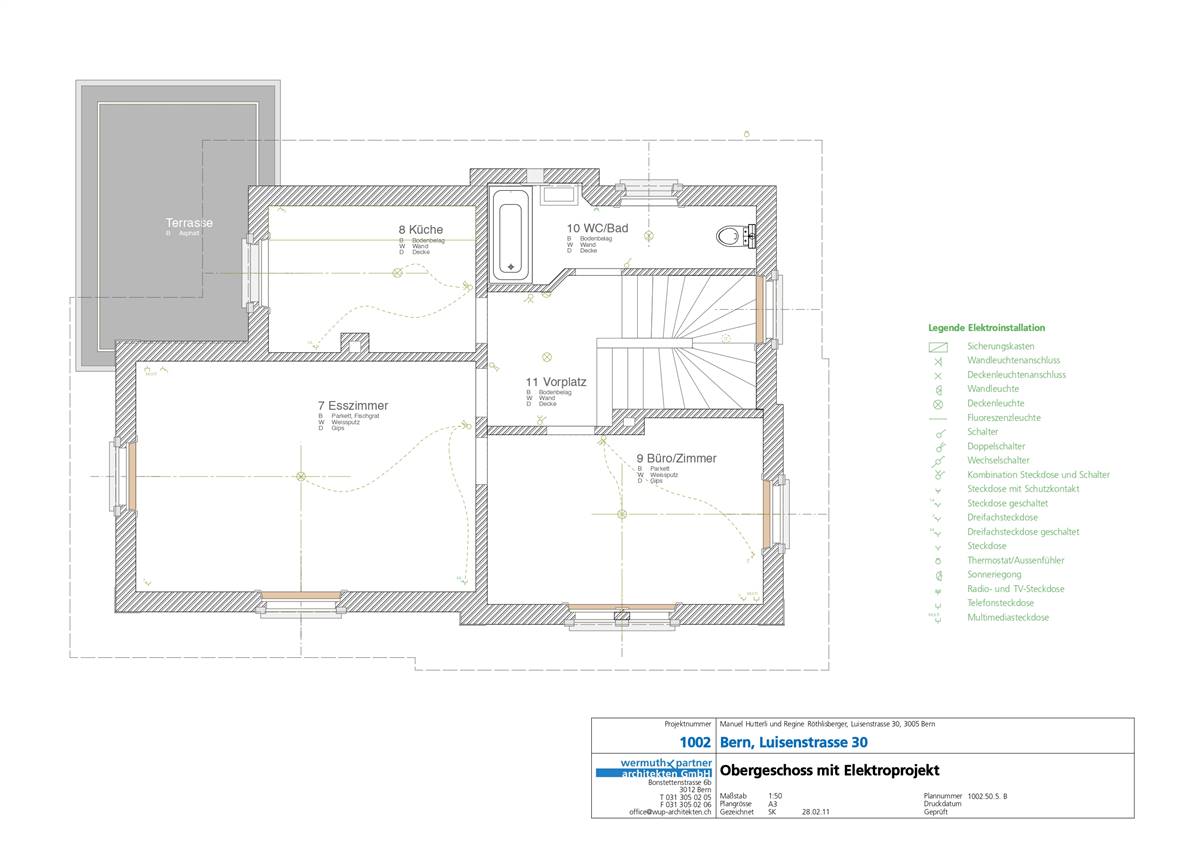

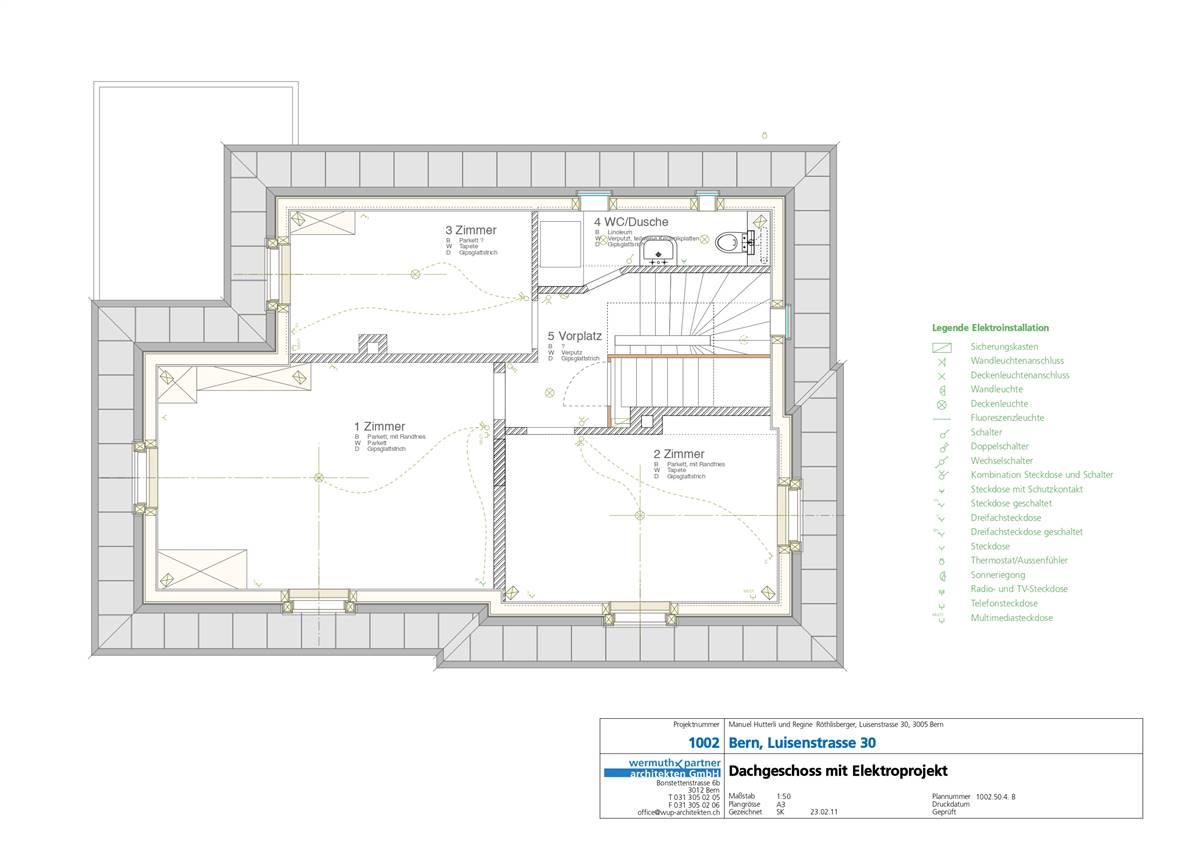

Number of floors:

2

Basement yes/no:

Oui

Number of heated floors:

3

Gross floor area [m²]:

258,0

Thermal envelope area [m²]:

570,0

Volume [m³]:

1250,0

NFA calculation method:

SIA 416

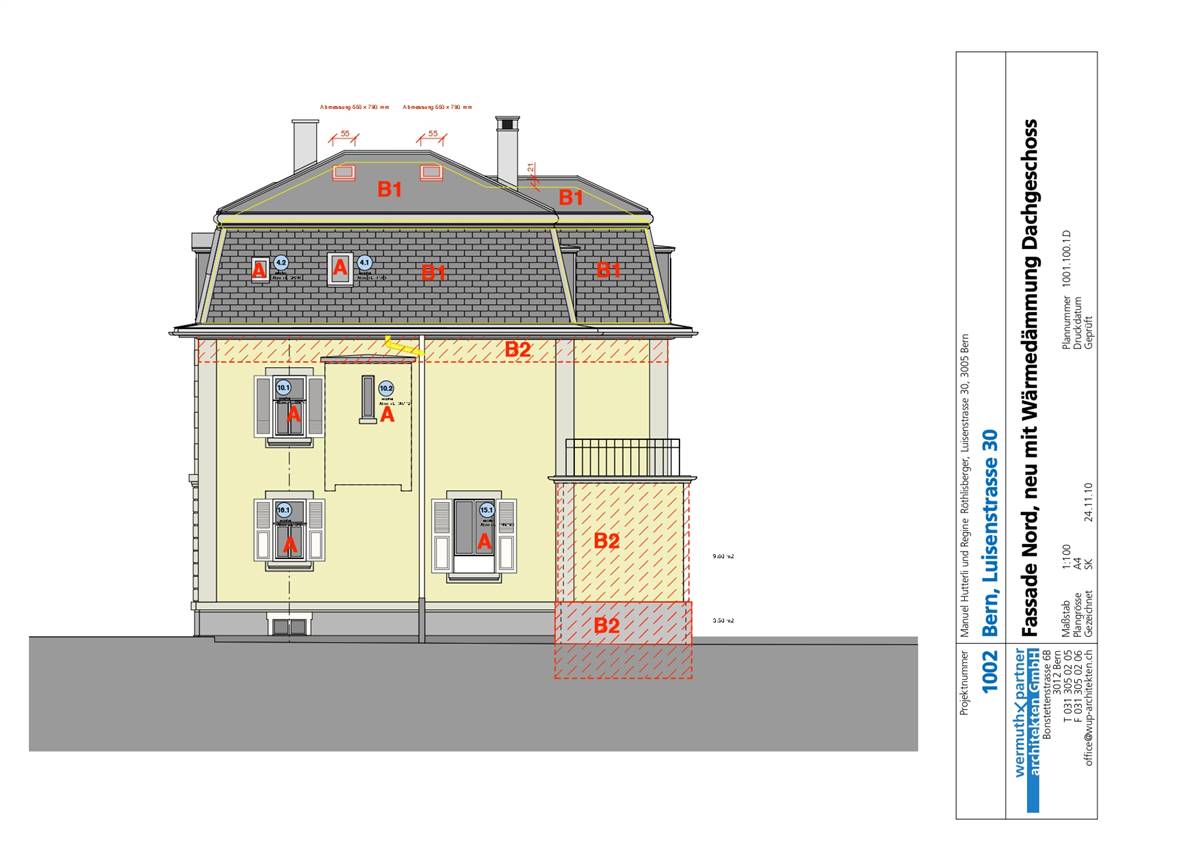

External finish:

Rendered

Internal finish:

Plastered (on hard)

Roof type:

Pitched roof

RENOVATION PROCESS

Architecture

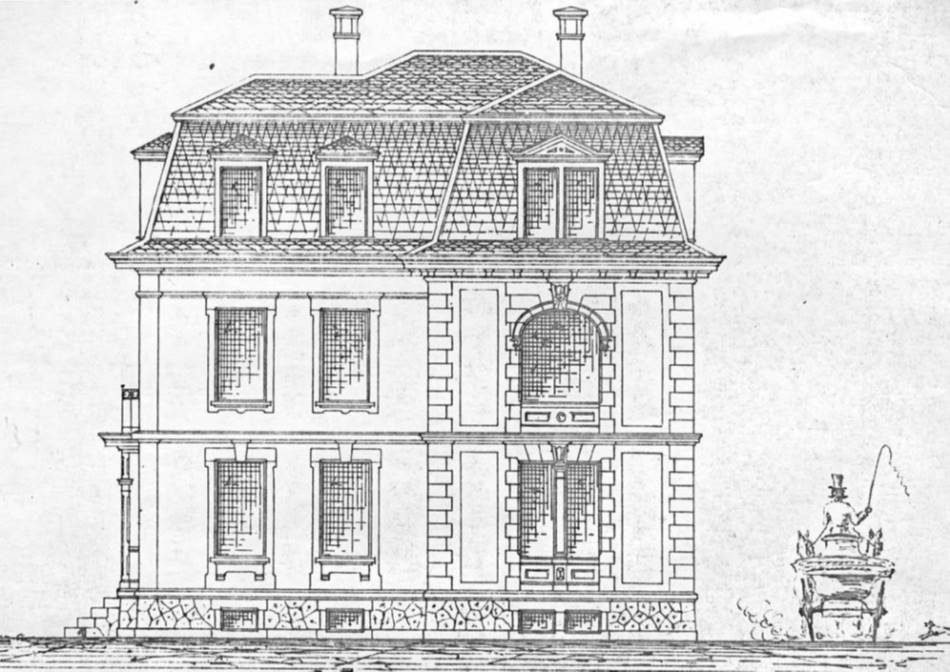

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Bauinspektorat der Stadt Bern

Bundesgasse 38, 3001 Bern

bauinspektorat@bern.ch

Tel.+41 31 321 65 45

Beat Wermuth und Partner Architekten GmbH

Bonstettenstrasse 6b, 3012 Bern

office@wup-architekten.ch

Tel.+41 31 305 02 01

Manuel Hutterli

Luisenstrasse 30, 3005 Bern

mhutterli@gmail.com

Tel.+41 31 352 82 12

Manuel Hutterli

Luisenstrasse 30, 3005 Bern

mhutterli@gmail.com

Tel.+41 31 352 82 12

Hans Dürig AG, Markus Dürig, Ing. HTL

Hintere Gasse 11, 3132 Riggisberg

info@hans-duerig.ch

Tel. 41 31 809 02 50

Meyer Burger AG, PV Systems

Schorenstrasse 39, 3645 Gwatt

mbtinfo@meyerburger.com

Tel.+41 33 221 24 07

INNOVAR, Christian Käsermann

Route des Genevrés 35, 1784 Courtepin

Tel.+41 26 684 10 87

Hygrothermal assessment No

Life Cycle Analysis (LCA) No

Other No

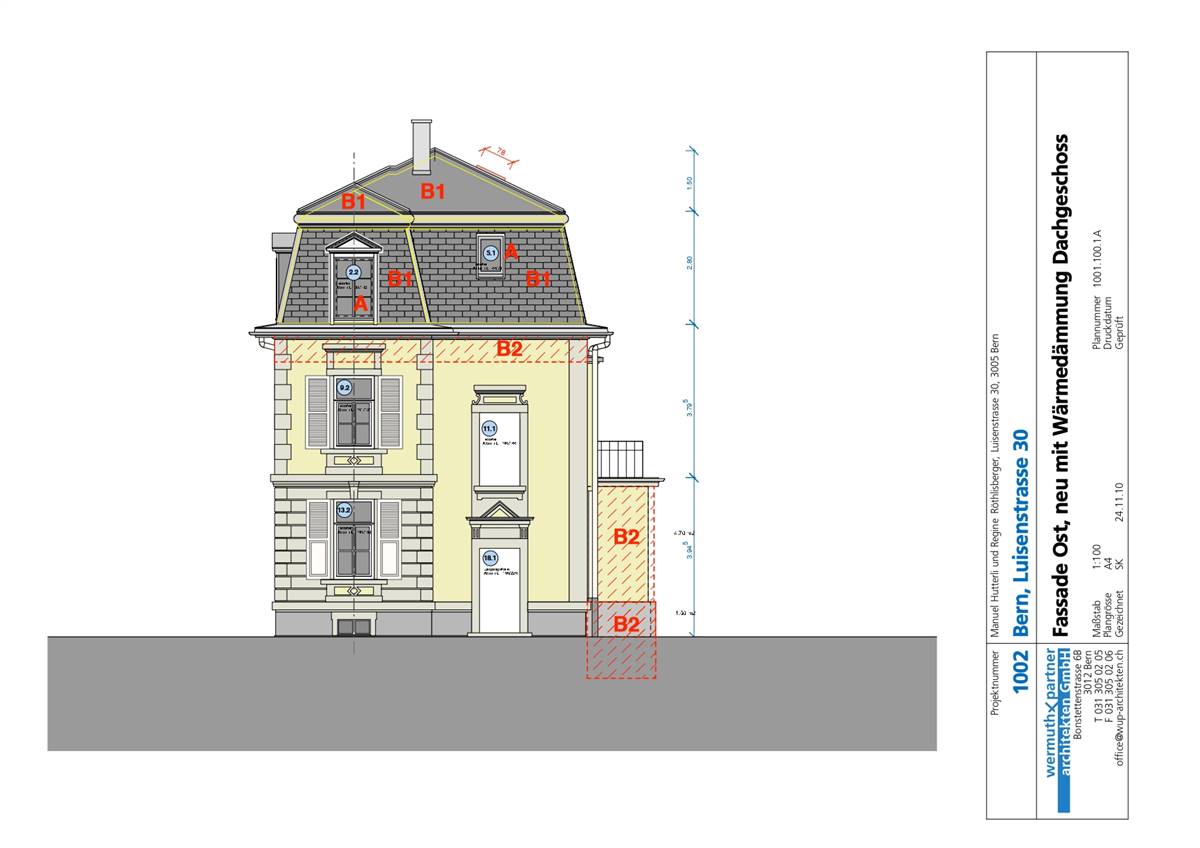

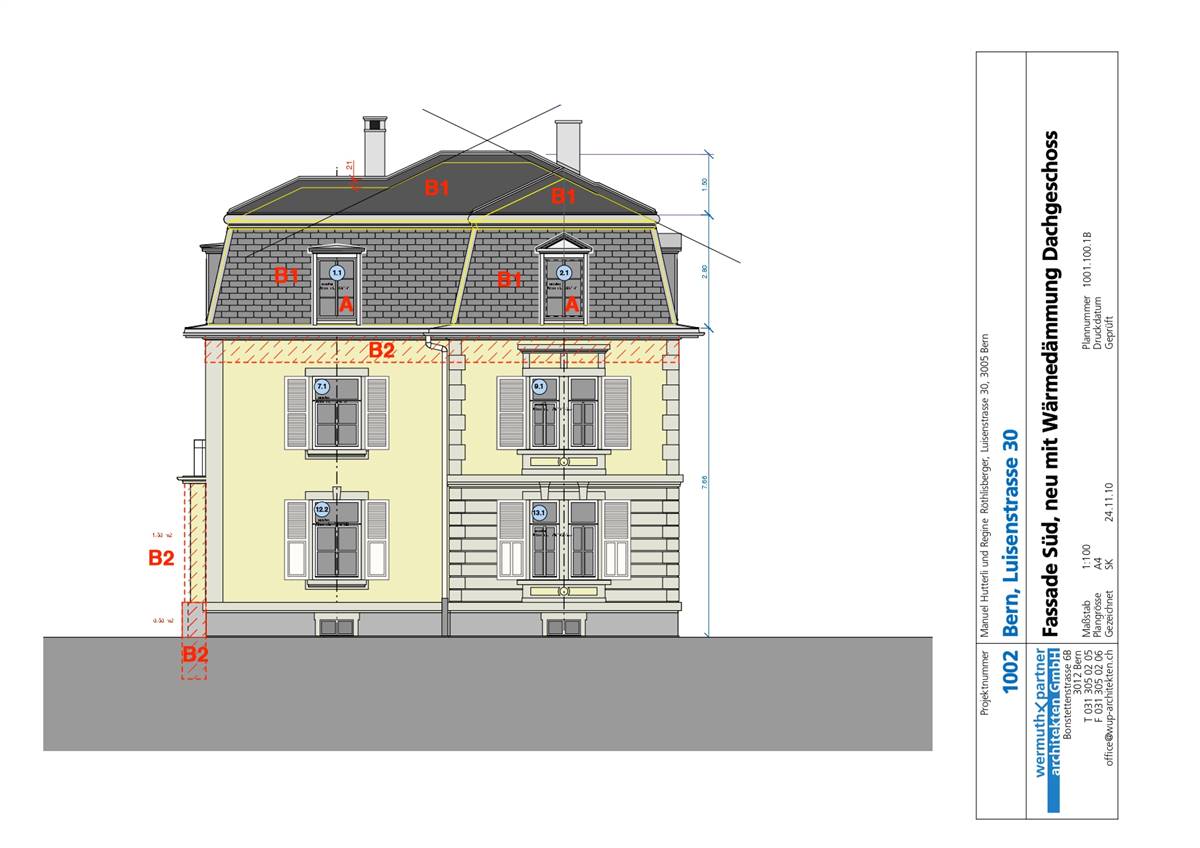

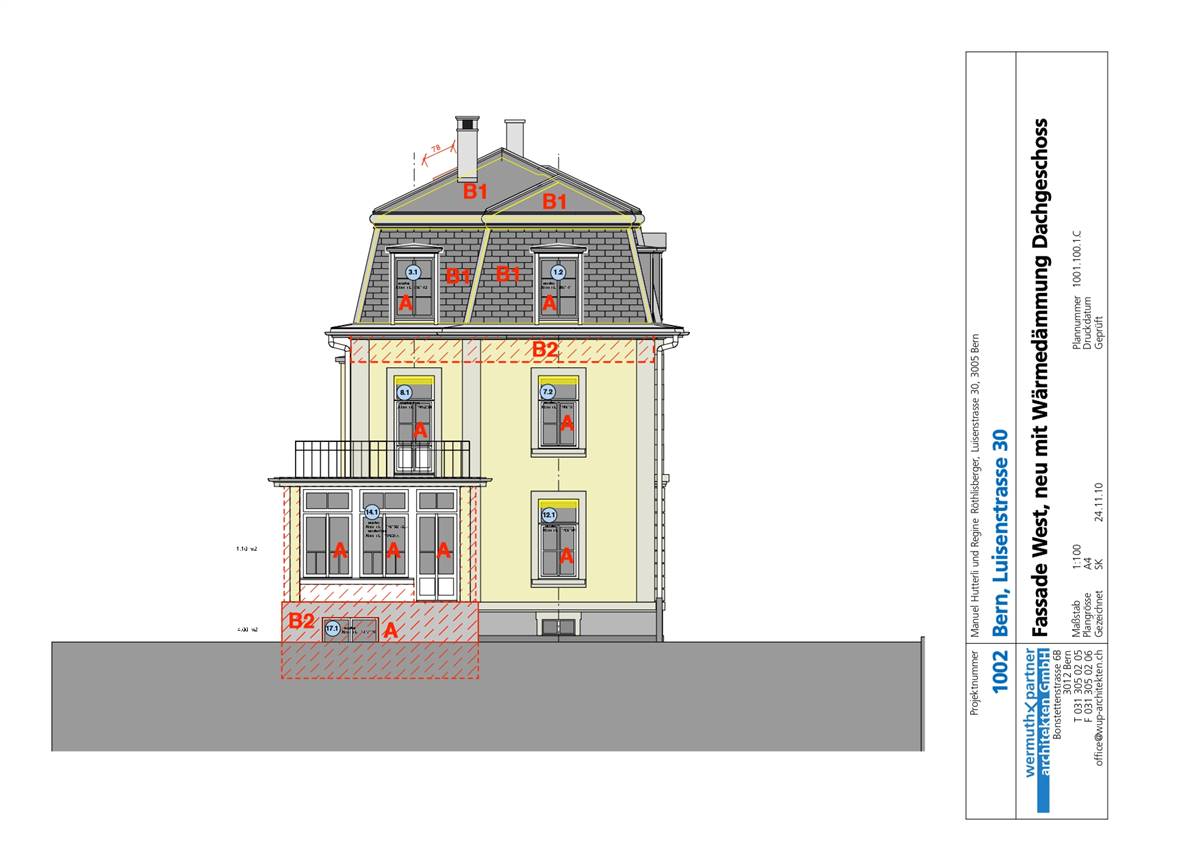

RETROFIT SOLUTIONS

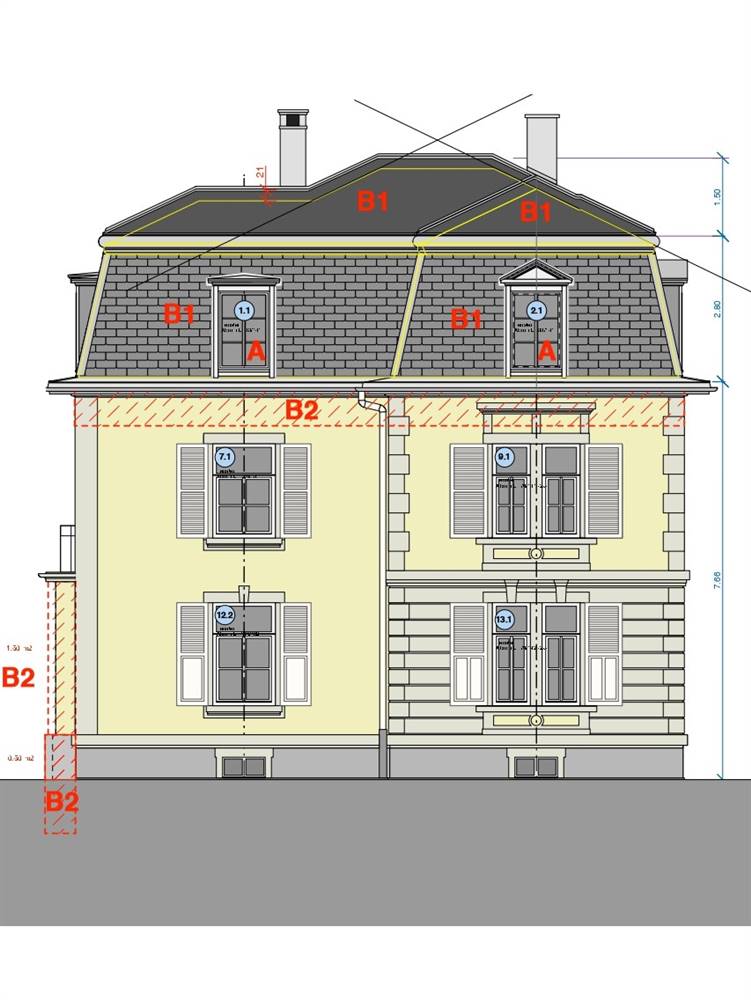

External Walls

Double-shell masonry wall

The external wall was insulated with a double-shell blowing system with Isofloc H2Wall. This is the best possible insulation for an external wall, as reported in the cantonal buildings inventory. This was a premiere in Bern. In addition, it has been included on the inside a wall heating with 1cm aerogel insulation (corresponds to 3cm of conventional isolation).

The intervention maintains the original aesthetics of the wall and the the increase in wall thickness is minimal. This way, the interior space of the building remains practically unchanged.

20 mm

180 mm

60 mm

180 mm

15 mm

20mm

180 mm

40 mm

180 mm

50 mm

25 mm

Windows

Wood windows

Most of the existing windows have been renovated and only a few have been replaced with a copy, due to the bad state of conservation.

The existing windows have been improved. The original single glazing was replaced with the thin, krypton filled double glazing and seals for airtightness. Where improvement was not possible, the windows have been replaced with a reproduction (west facade). The historical front windows have also been renovated.

| Existing window type | Casement window |

| Existing glazing type | Single |

| Existing shading type | Outer shutter |

| Approximate installation year | 1898 |

| New window type | Casement window |

| New glazing type | Double |

| New shading type | NA |

| New window solar factor g [-] | 45,0 |

Other interventions

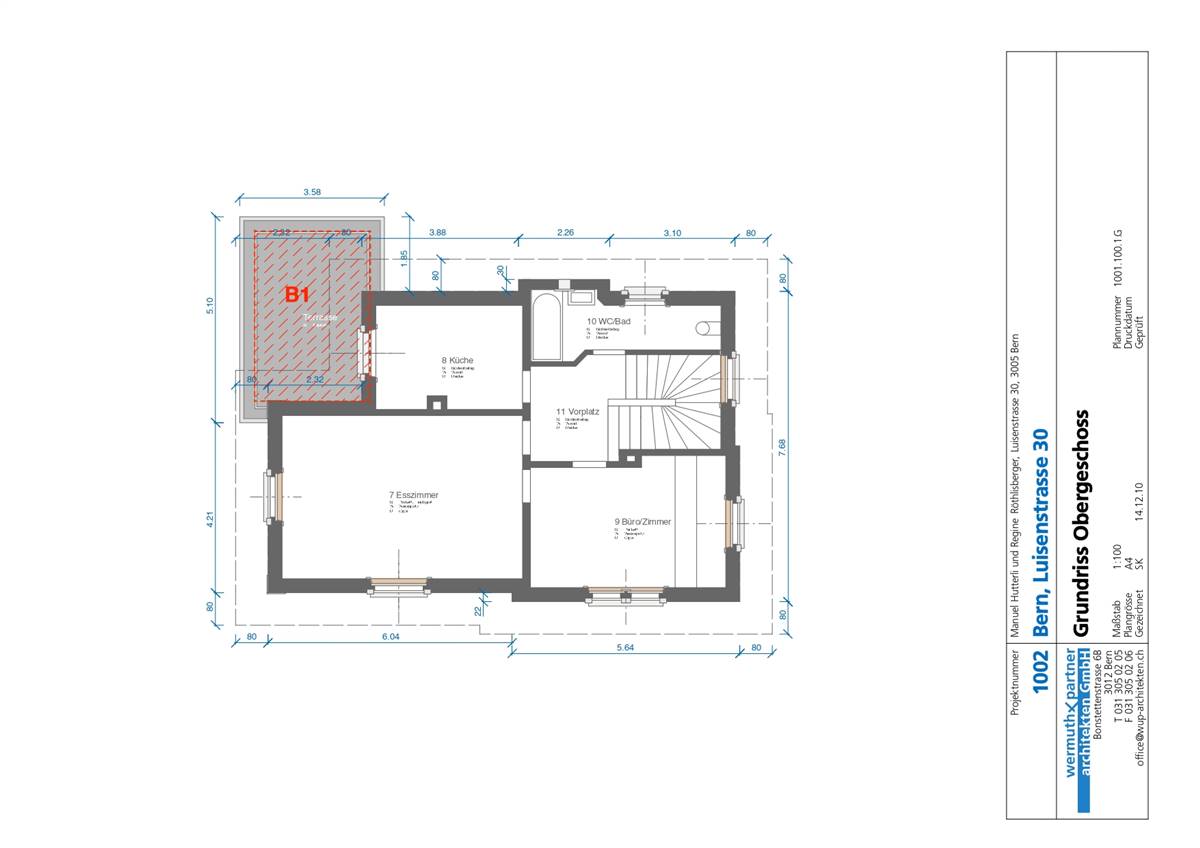

ROOF

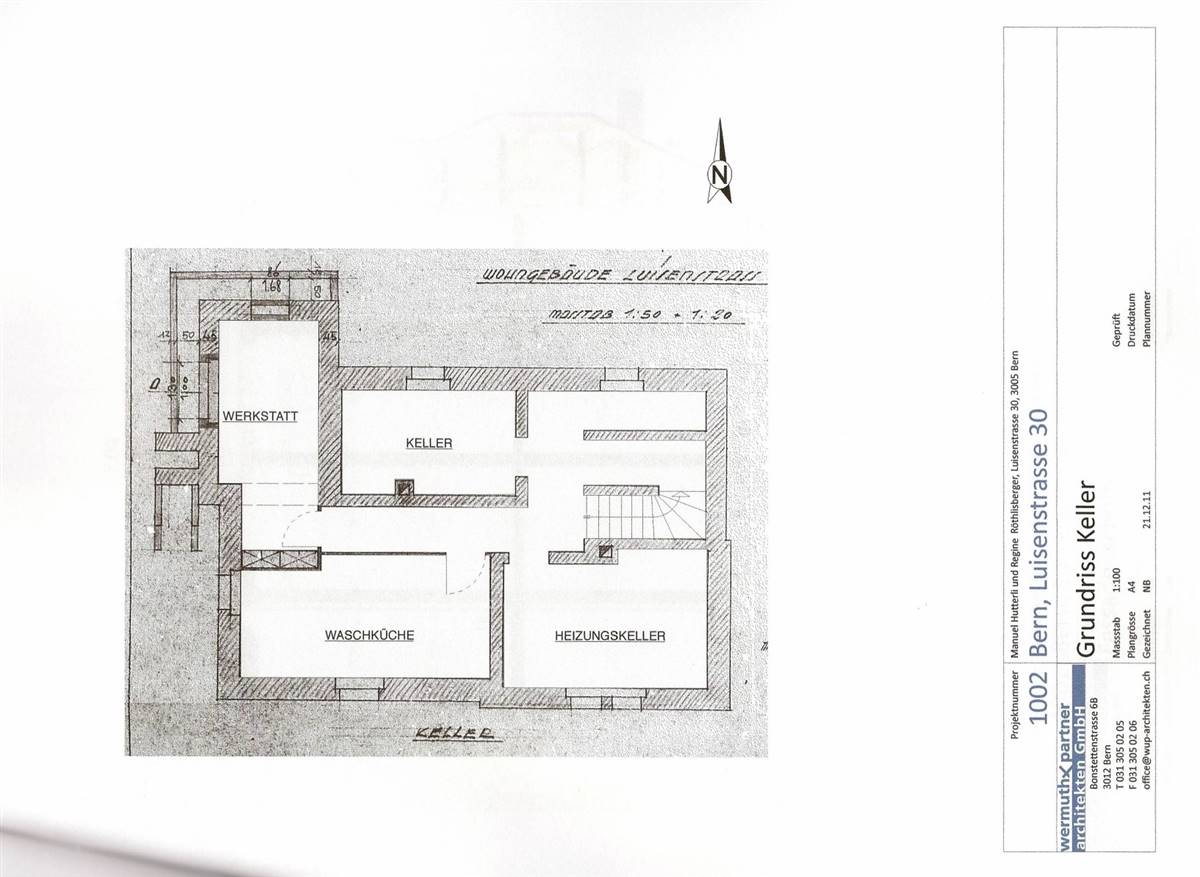

GROUND FLOOR

The roof has been improved with cellulose insulation and also used to place a PVT and an hybrid system. The roof structure has been improved both statically and thermally. Originally the building had a U-value of 1.36 W/m2K for the roof, which was very high (as expected). The intervention made possible to reach a U-value of 0.19 W/m2K.

Thanks to the aesthetic integration of the PVT hybrid system, the compatibility is assured. The natural slate hides the collectors in the steeply sloping roof, making them invisible from the outside. The production of heat is therefore less efficient and more third-party energy is required, but it is a good compromise to maintain the original appearance of the building.

10 mm

22 mm

160 mm

60 mm

10 mm

22 mm

240 mm

12 mm

The intervention consists in the installation of thermal insulation under the ceiling of the cellar to keep the floor covering intact.

The intervention was carried out in the cellar where it was not necessary to pay particular attention to conservation.

40 mm

120 mm

40 mm

120 mm

140 mm

HVAC

HEATING

VENTILATION

DOMESTIC HOT WATER

The original gas heating system has been replaced with a heat pump, a solar thermal system and a geothermal system. The main source is the water heat pump, which is supplied partly by geothermal probes and partly by the PVT and the natural slate collector systems. Both systems are used to support the heat pump by increasing the water temperature into the heat pump whenever possible and thus to improving the COP. The heat is distributed through radiators and through a stove. Historical radiators were not changed during the renovation (except newly painted). The solar thermal system is well implemented in the building.

The system has been designed to perfectly integrate with the construction. Wall radiators have been fitted to the wall with a minimal intervention in terms of space, while the PVT system (as well as the hybrid) has been built to adapt perfectly to the shape, colour and materials of the roof.

| New primary heating system | New secondary heating system | |

|---|---|---|

| New system type | Heat pump | Stove |

| Fuel | Electricity | Biomass |

| Distribuition system | Radiators and radiators wall | Air |

| Nominal power | 8 kW | 10 kW |

A Zehnder comfort ventilation system with heat recovery has been introduced.

On the top floor, the supply air is routed via the screed into the built-in cupboards: apart from the inconspicuous supply air grilles in the cupboard walls (usually behind furniture), no architectural intervention in the rooms (pipes) is necessary. No audible ventilation noises.

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Centralized |

| Type flow regime | Overflow |

| Heat recovery | Oui |

| Humitidy recovery | No |

| Nominal power | NA kW |

| Electric power | 0,0 kW |

| Control system | Customized |

The hot water preparation is carried out by the 2’840l tank, which is mainly supplied by the heat pump and the PVT system.

The system doesn't need conservation compatibility.

| New DHW system | |

|---|---|

| Type | with heating system |

| Hot_water_tank | Oui |

| With heat recovery | Oui |

RENEWABLE ENERGY SYSTEMS

SolarThermal

Photovoltaic

Biomass

Geothermal

Two different types of STh have been used: special system on the lower part, PVT on the top of the roof (cfr. section PV)

Due to preservation orders, no conventional collectors were allowed. The collectors of the special system (lower part of the roof) are integrated in the underroof (layer battens and counter battens). External layer of the roof is natural stone plates, and the system is not visible at all.

Since originally no conventional solar system was possible due to monument preservation regulations, a collector that is not visible from the outside has been developed, with which the heat can be efficiently extracted from the natural slate roofing. 13m2 of natural slate collectors were installed, which corresponds to an output of about ~5kWp. The collector consists of copper lamellas, which are clamped between the slate plates. The heat is conducted via the fins into a soldered copper tube, through which it is dissipated via a glycol solution, as in conventional collectors. Due to possible condensation moisture and to increase efficiency, a 1 cm aerogel insulation, covered by a sub-roof foil, was placed between the roof battens and the slate. PVT and the natural slate collector systems are used to support the heat pump by increasing the water temperature into the heat pump improving the COP. The PVT and natural slate collector systems are also used to regenerate the geothermal probes/ground temperatures with excess heat available from the PVT and the slate collectors on multi-day to seasonal time scale (on diurnal time scale the solar tank is the heat storage). The regeneration thus increases the net solar electricity production and at the same time prevents the ground to cool down over time, assuring a constantly high COP over the lifetime of the geothermal probes. In addition, the cooled roof helps the rooms of the top floor to remain cooler in summer. This renovation deserved the Swiss Solar Prize 2014.

| SolarThermal System | |

|---|---|

| Type | Natural slate collectors |

| Collector area | 13,0 m² |

| Elevation angle | 80,0 |

| Azimuth | 5,0 |

| Overall yearly production | 10000,0 kWh |

| Heating_contribuition | 6242,0 kWh |

| DHW contribuition | 1330,0 kWh |

| Cooling contribuition | 0,0 kWh |

Roof-integrated PVT (13 m2) + roof integrated PV (5.5 m2) + STh natural slate collectors (13 m2)

Due to the high level of protection, solar panels are slightly visible from the street, leaving part of the original slate roof intact. During the refurbishment, the requirements of the preservation of historic monuments were somewhat softened, so that both PV+PVT system was possible on the flat (upper) part of the roof.

The arrangement of solar panels on triangular pitched roofs approaches solves the critical points with tailored solar modules with attention to detail and fixing systems. First 'optical' roof-integrated system with 3S Hybrid 900/240 modules. Optically' integrated into the roof, because the installation is integrated into the roof and flush with the eaves, but the solar system is not a completely tight roof skin. The actual dense and back-ventilated roof skin lies underneath, i.e. the installation is hybrid roof-integrated and 'on roof'. - Eight hybrid collector modules (13 m2) and 12 purely photovoltaic special modules (5.5 m2) on the southern, 25° inclined roof surface. - Electrical output: 2,728 kWp. Active cooling of the modules increases the annual electrical yield by up to 10%. - The thermal output of the hybrid collectors is at least 7.2 kWp (manufacturer's specifications).

| Photovoltaic System | |

|---|---|

| Type | Monocrystaline |

| Collector area | 18,5 m² |

| Total nominal power | 2,7 kW |

| Elevation angle | 28,0 |

| Azimuth | 170,0 |

| Overall yearly production | 3207,0 kWh |

| Heating contribuition | 0,0 kW |

| DHW contribuition | 0,0 kW |

| Cooling contribuition | 0,0 kW |

| Lighting contribuition | 3537,0 kW |

Stove

In the building there was already a fireplace/stove whose only element visible from the outside was a chimney that came out in the north-west part of the roof. This chimneypot remained intact, while the gas boiler chimneypot was removed. The new stove is located in the living room and is connected to the central heating system.

The new heating system includes several interventions. The main source is the water heat pump, which is supplied partly by geothermal probes and partly by the PVT and the natural slate collector systems. Both systems are used to support the heat pump by increasing the water temperature into the heat pump whenever possible and thus to improving the COP. The water is stored in a 2840 L tank. It also works thanks to the stove. In addition, a 'Frischwasserstation' which contains a small heat exchanger to provide warm water (Brauchwasser) on demand have been installed which prevents the formation of legionella. The hot water of the solar tank is used to heat up the 'Brauchwasser' in the Frischwasserstation when required. From the tank the water is then distributed to the radiators and wall radiators.

| Biomass System | |

|---|---|

| Type | Logs |

| Storage size | Normal cellar in the basement |

| Origin of biomass | Kanton Bern |

| Overall yearly production | 2798,0 kWh |

Heat pump with bore holes

The execution in a geothermal heat pump is not very invasive for any building, in fact all the pipes coming out of the building are underground, while inside the building there will be a presence of greater pipes due, in this case, to the complexity of the system that combines several energy carriers. The use of more vectors allows a better management because it gives priority to the vector that has production potential at any specific moment.

The new heating system includes several interventions. The main source is the water heat pump, which is supplied partly by geothermal probes and partly by the PVT and the natural slate collector systems. Both systems are used to support the heat pump by increasing the water temperature into the heat pump whenever possible and thus to improving the COP. The PVT and natural slate collector systems are also used to regenerate the geothermal probes/ground temperatures with excess heat available from the PVT and the slate collectors on multi-day to seasonal time scale (on diurnal time scale the solar tank is the heat storage). This regeneration is a win-win situation: By cooling the PVT panels and transferring the excess heat (up to 12 kW) into the ground e.g. in summer, the PVT panels produce significantly more electricity (up to 500 W) than the pump required to transfer the heat into the ground (~50W). The regeneration thus increases the net solar electricity production and at the same time prevents the ground to cool down over time, assuring a constantly high COP over the lifetime of the geothermal probes. In addition, the cooled roof helps the rooms of the top floor to remain cooler in summer. The water is stored in a 2840 L tank. It also works thanks to the stove. In addition, a 'Frischwasserstation' which contains a small heat exchanger to provide warm water (Brauchwasser) on demand have been installed which prevents the formation of legionella. The hot water of the solar tank is used to heat up the 'Brauchwasser' in the Frischwasserstation when required. From the tank the water is then distributed to the radiators and wall radiators. The geothermal system includes two probes of 150 m each.

| Geothermal System | |

|---|---|

| Type | Vertical loop |

| Exchange area | 33,6 m² |

Energy Efficiency

Voluntary certificates: In this case Minergie it corresponds to the EPC cathegory B

Consumption_estimation_Calculation_method: Steady state simulation (e.g. EPC, PHPP)

Consumption_estimation_Before: 43312 kWh/y

Consumption_estimation_After: 35,22 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: Steady state simulation (e.g. EPC, PHPP)

Consumption_estimation_Including_DHW: Oui

Consumption_estimation_Before: 46867 kWh/y

Consumption_estimation_After: 11109 kWh/y

Type_of_monitoring: Punctual

Description: Complexity of the plant requires performance and flexibility, which is not available in typical control systems of individual components. Temperature and flow rate data should not only be used for monitoring and control, but also be recorded as a basis for optimisation. The control system was put together and programmed from inexpensive components.

External Climate

Type_of_monitoring: Continuous

Description: The strategy of monitoring ist to follow the temperature of the solar systems (sloping, PV, PVT) according to the external air temperature. This is the link: https://grovestreams.com/singleDash.html?org=2776f02c-f718-3407-83e0-78bc4c61ecda&itemUid=10f024e4-0cf4-37df-a184-79853932b9d6&api_key=f66a4104-ad33-3159-90e6-10bd46a26c29

Construction

Type_of_monitoring: Continuous

Description: The strategy of monitoring is to follow the temperature of the solar systems (sloping, PV, PVT) according to the external air temperature. Information available: https://grovestreams.com/singleDash.html?org=2776f02c-f718-3407-83e0-78bc4c61ecda&itemUid=10f024e4-0cf4-37df-a184-79853932b9d6&api_key=f66a4104-ad33-3159-90e6-10bd46a26c29

UserBehavior

Type_of_monitoring: Punctual

Description: Thanks to the ventilation control, the temparture is monitored, and the ownership wishes to have light reduced temperature. The automatically change of air doesn't require other minotoring.

Internal Climate

The thermal comfort of the occupants improved thanks to the new walls and roof insulation and the new heating system.

Indoor air quality improved thanks to the new ventilation system. The automatically change of air guarantees the necessary hygienic exchange.

Daylight does not change compared to pre-intervention due to the original size of the openings which was determined by the existing structure. In some rooms where the size of the windows are large in comparison to the surface of the room itself, the deepening has been done to avoid overheating in summer.

The change of glazing windows improved the acoustic comfort of the house. The introduction of a ventilation system has been well elaborated, in fact there are no audible noises.

NA

Costs

The roof intervention cost is around CHF 45,000. The estimation costs were made on the basis of the annual CHF savings due to the renovation. An interesting aspect is that many of the interventions were carried out with the help of the owners. As well as being very involved and enthusiastic about the renovation, the owners were able to keep some costs down.

Cost of energy related interventions:

about 200'000.- CHF (total)

Amount includes: Roof, walls, doors and windows, insulation cellar,

No

Environment

Inside the building there are water-saving taps/mixers.