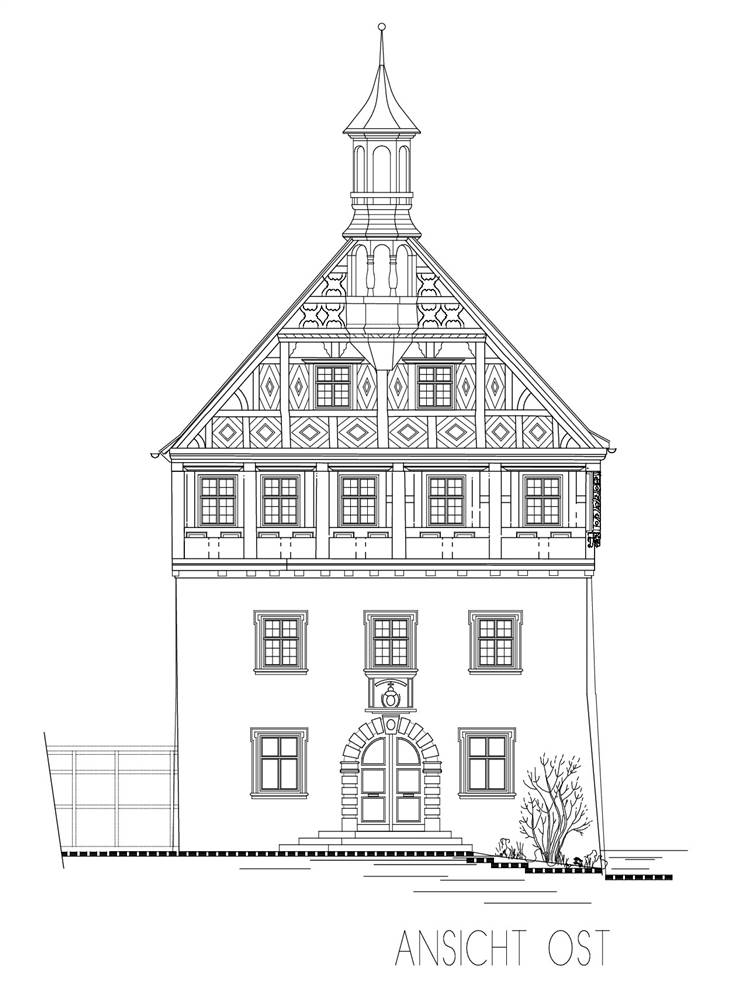

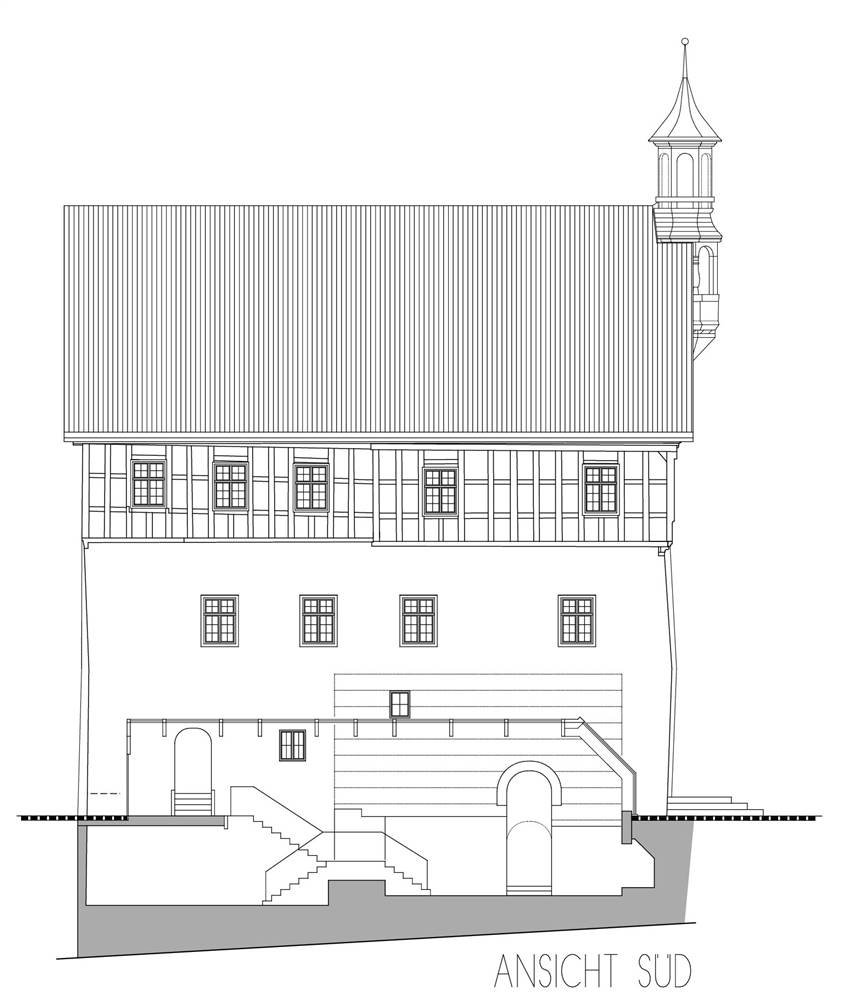

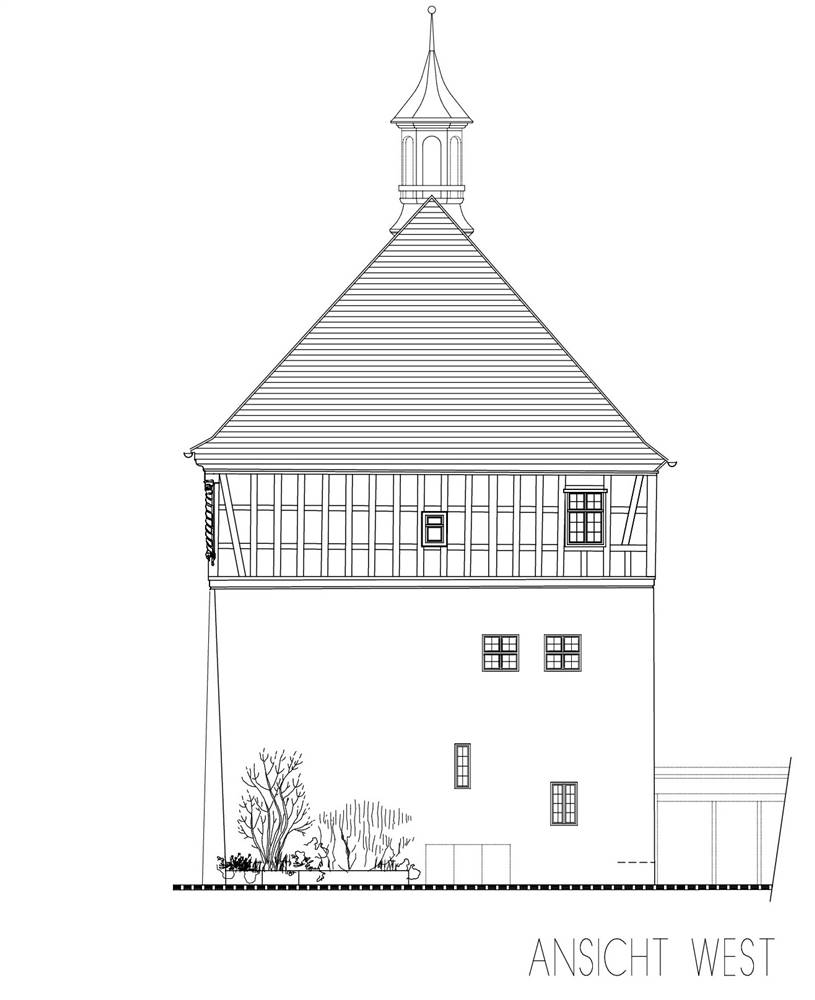

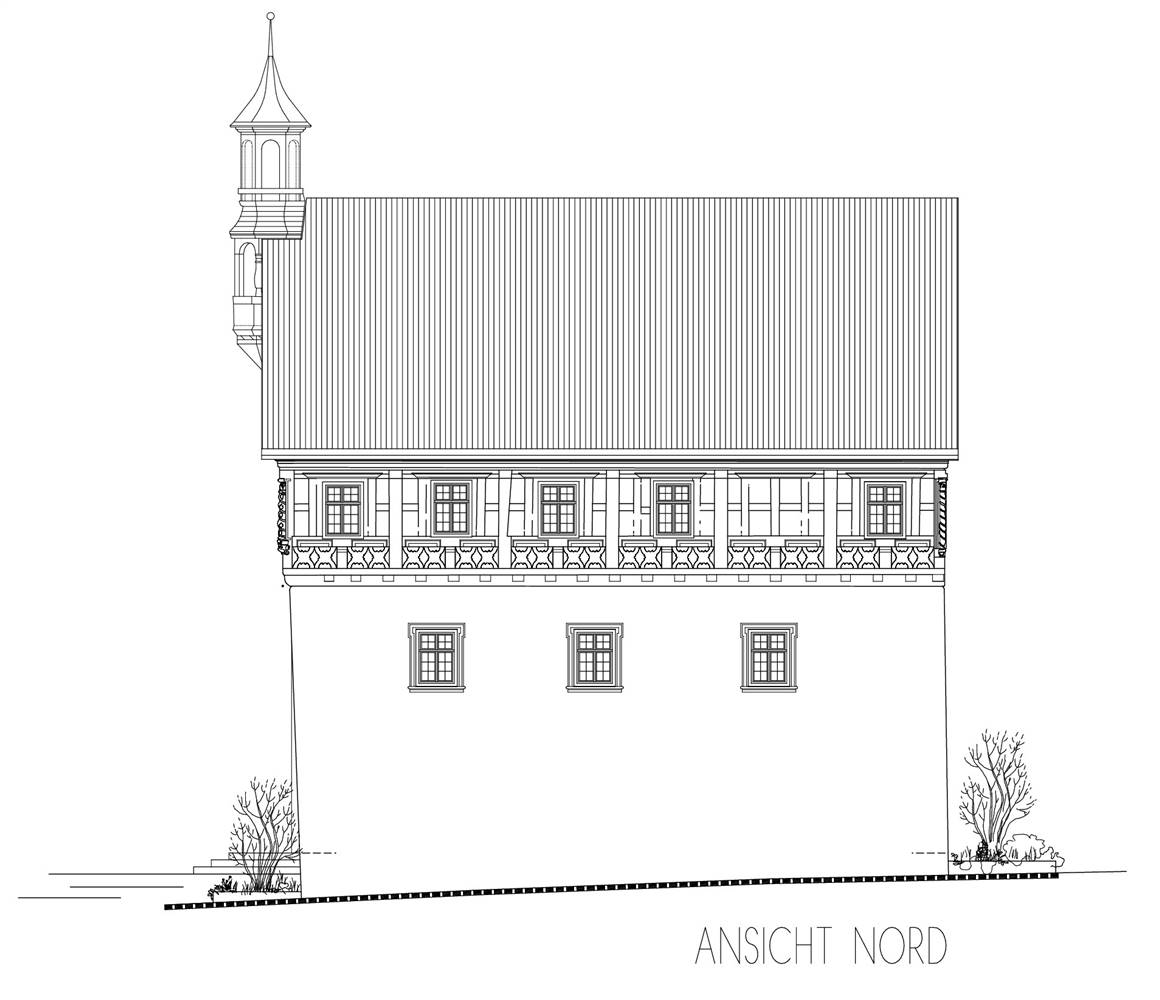

Town Hall Burgkunstadt

Vogtei 5

96224

Burgkunstadt, Allemagne

Architect

Owner

User

Contact Details

Other Information

opening hours: Mon+Wed 08:00-12:00 and 13:00-16:00, Thu 08:00-12:00 and 14:00-18:00, Fri 08:00-12:00

Climate Zone cfb

Altitude 306

HDD 2682

CDD 464

Conservation Area:

Oui

Level of Protection:

Year of last renovation:

2009

Year of previous renovation:

1979

Secondary use:

Offices

Building occupancy:

Permanently occupied

Building typology:

Detached house

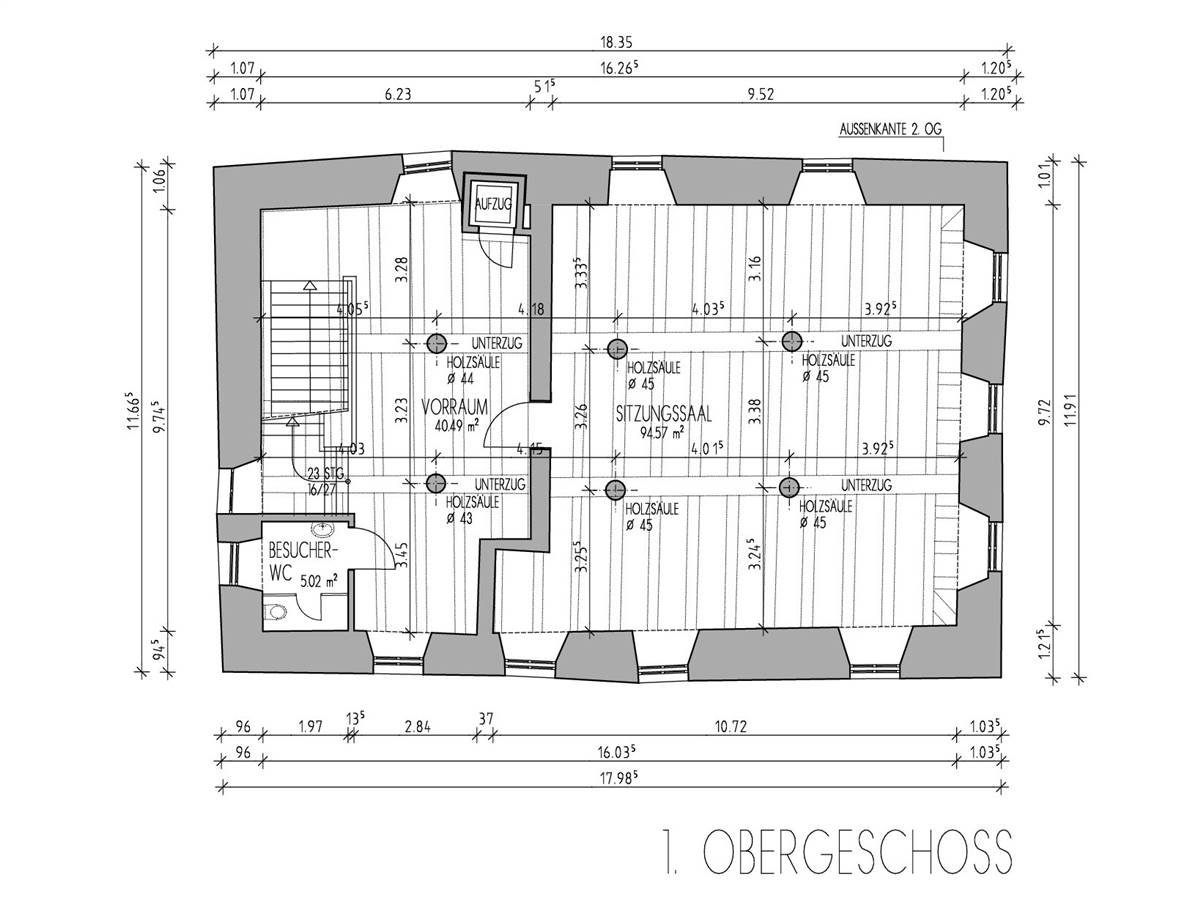

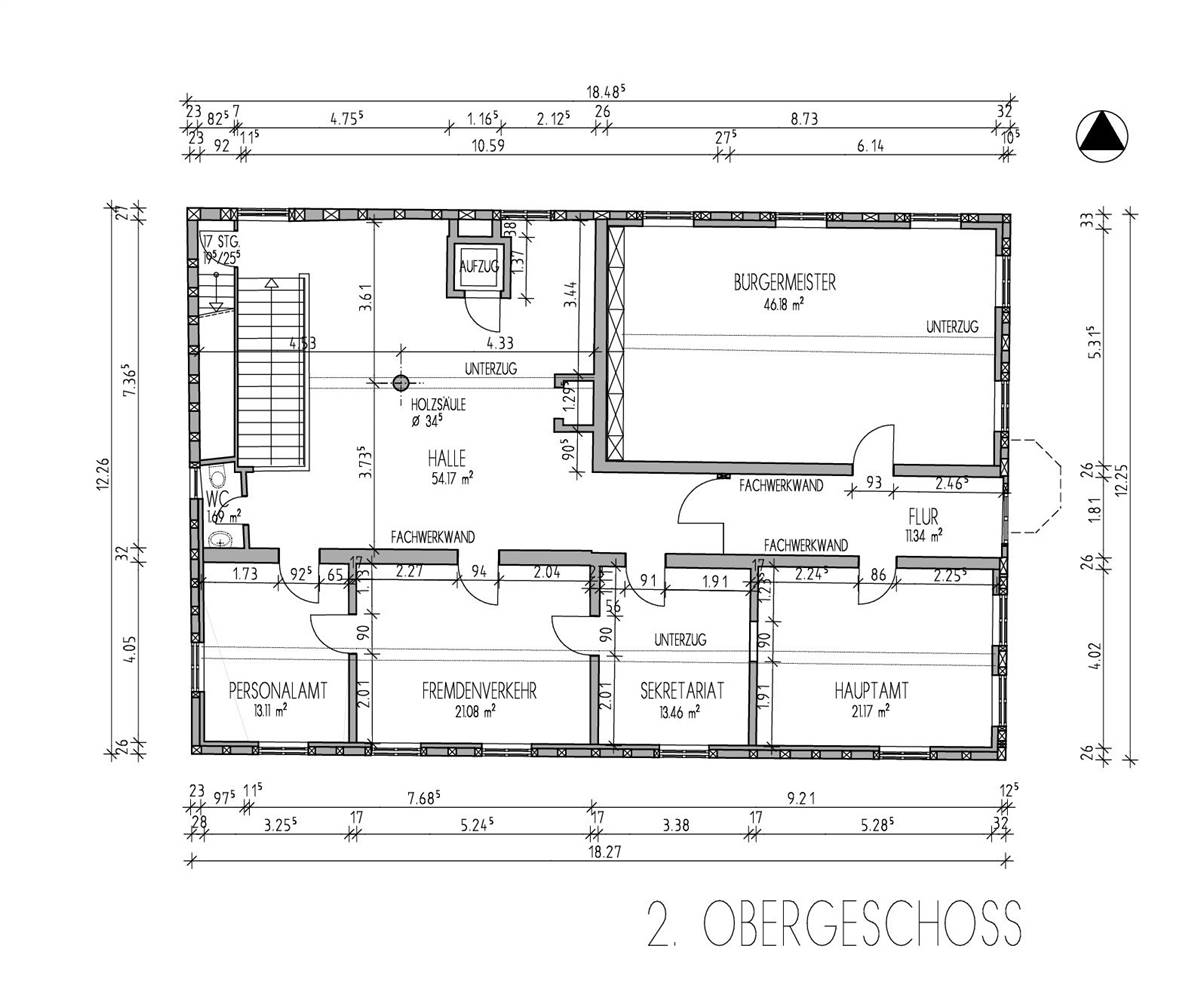

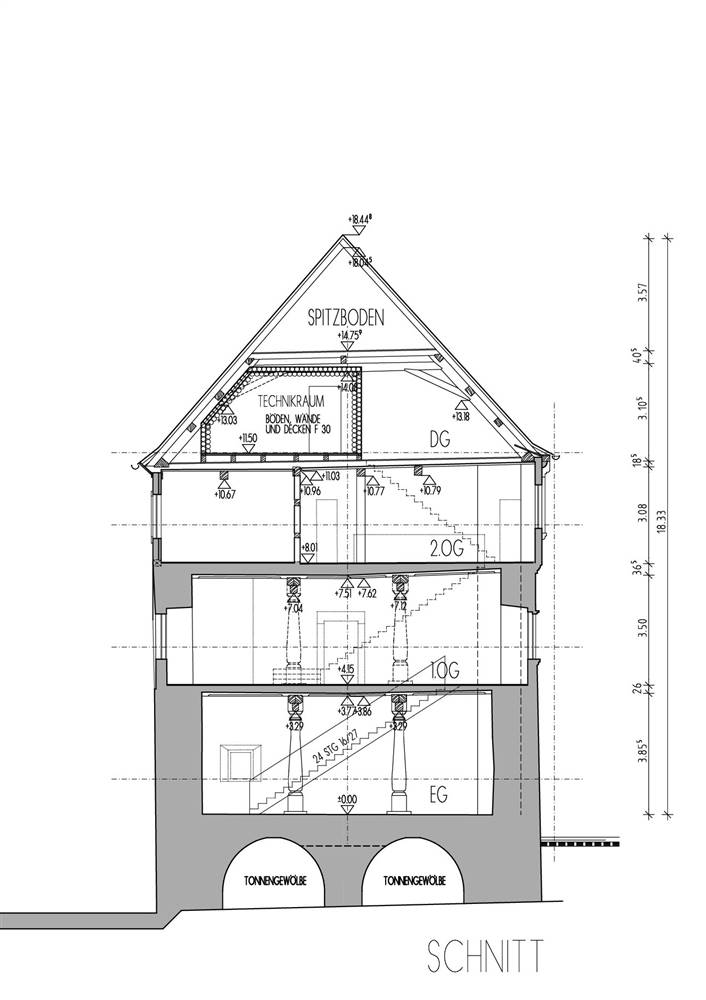

Number of floors:

6

Basement yes/no:

Oui

Number of heated floors:

3

Gross floor area [m²]:

1006,0

Thermal envelope area [m²]:

679,0

Volume [m³]:

1641,0

NFA calculation method:

NGF (de)

External finish:

Rendered

Internal finish:

Plastered (on hard)

Roof type:

Pitched Roof

.jpg)

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Stadt Burgkunstadt

Vogtei 5, 96224 Burgkunstadt

rathaus@burgkunstadt.de

Tel.09572 / 388 0

Hofmann Erhalten & Gestalten

Bergstr. 4, 96167 Königsfeld

info@hofmann-erhalten-gestalten.com

Tel.09207 / 9500

Architekturbüro Huth

Dr.-Baur-Siedlung 6a, 96224 Burgkunstadt

info@architektbuero-huth.de

Tel.09572 / 79 00 83

Bayr. Landesamt für Denkmalpflege

Schloss Seehof 1, 96117 Memmelsdorf

DST_Seehof@blfd.bayern.de

Tel.0951 / 4095 0

Ingenieurbüro Burges + Döhring

Schlehenbergstr. 1, 95448 Bayreuth

info-bt@bdingenieure.de

Tel.09209 / 982 0

Ingenieurbüro Reichenbach & Henkel

Tiefe Gasse 28, 96224 Burgkunstadt - Kirchlein

info@rh-ing.de

Tel.09572 / 3818 0

Institut für Gebäudeanalyse (Bauphysik)

München

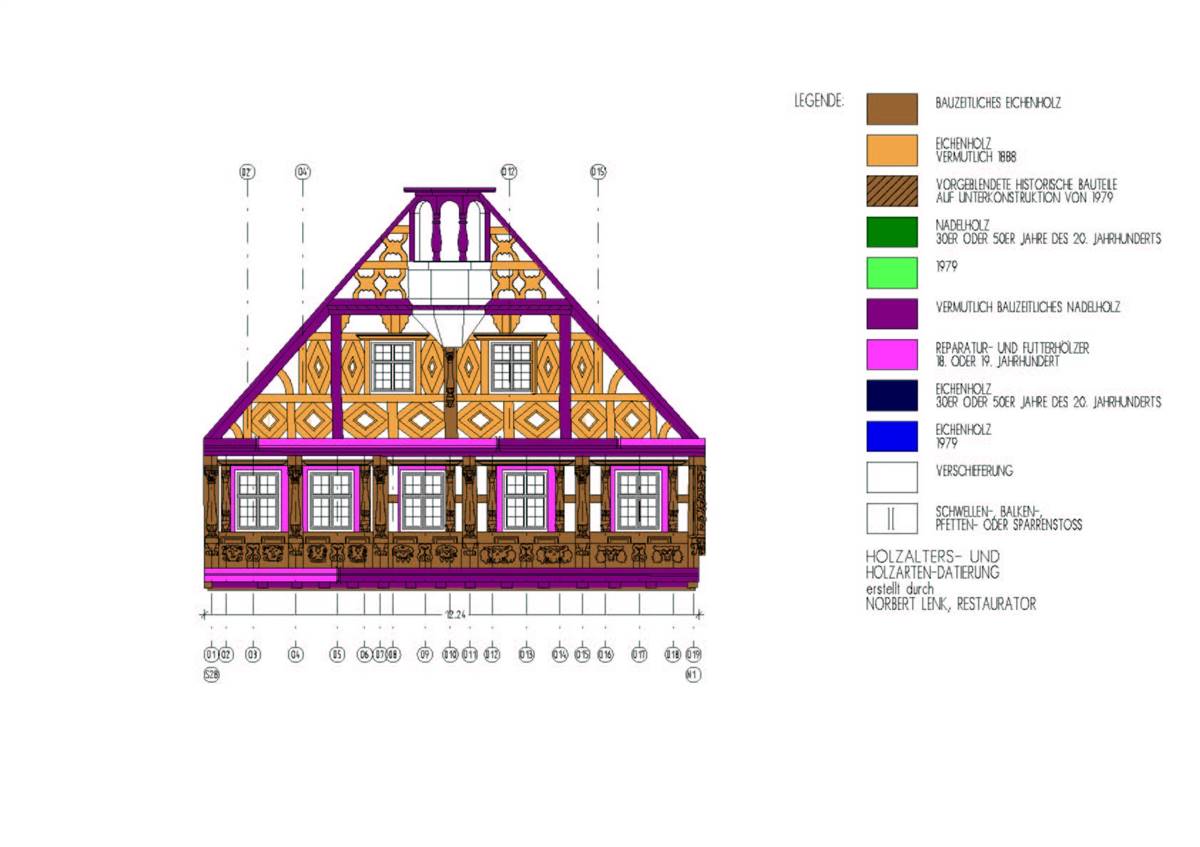

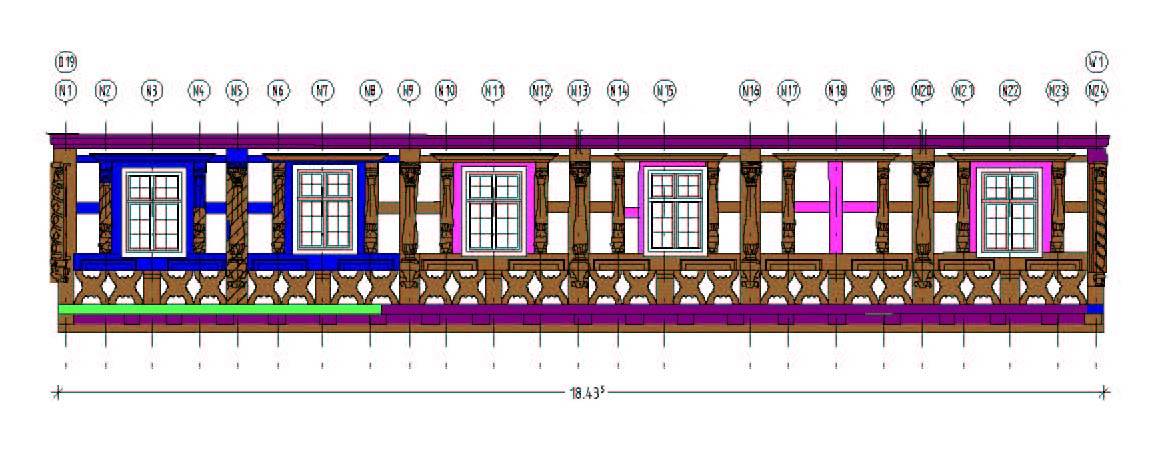

Restaurator Norbert Lenk

Langfeldstraße 23, 91077 Neunkirchen am Brand

n.lenk@t-online.de

Tel.09134 / 909012

RETROFIT SOLUTIONS

External Walls

half-timbering 2nd floor

massive masonry ground und first floor

In the course of the renovation, the previous infill was completely removed. Afterwards, the timber-work was repaired. The new infill was lined with special lightweight clay bricks from Claytec. In addition, internal lightweight clay insulation boards were installed to improve the insulation performance. Today, the wall temperature control is achieved by means of a wall heating system embedded in clay plaster. The wood carvings were repaired in a manner appropriate to the monument by filling them with a special wood crack paste from the Caparol company. Then all wooden elements were painted with a linseed oil paint.

During the refurbishment in 1970, a colour scheme in brown tones had been chosen. However, since the non-diffusion-open paint had caused some damage, it was completely removed in the course of the current renovation. In close cooperation with the monument conservation authorities and after an extensive research and investigations on the building, it was possible to determine the original colour shade applied by Jörg Hoffmann

0 mm

3mm

10 mm

20 mm

55 mm

70 mm

115 mm

20 mm

In order to improve the statics of the massive basement floor, the affected components were needled and grouted on the one hand. On the other hand, the floor slabs were structurally integrated. There were no energy-saving measures carried out on the masonry walls. Since the building was divided into different temperature zones and the ground floor only has a low temperature, the temperature losses are limited due to the poor U-value of the wall. The savings could not be taken into account in the standardized calculations according to the EneV, which is why the losses in the ground floor are relatively high in the verification. However, if one assumes that only a target temperature of 16° is reached there, the losses would be approx. 70% lower.

15 mm

1000 mm

20 mm

15mm

1000 mm

20 mm

0 mm

Windows

box window

The existing box-type windows were completely replaced in the renovation process. In addition, they were equipped with sun protection.

From an energy point of view, insulating glazing was to be installed, although this did not comply with the guidelines of the heritage office. For this reason, a classic drawn glass from the Schott company was used for the exterior panes of the insulating glass windows. This is characterised by its uneven surface, which is created by using the Fourcault method in the manufacturing process. So the original appearance of the façade could be retained.

| Existing window type | Box-type window |

| Existing glazing type | Single |

| Existing shading type | NA |

| Approximate installation year | 1979 |

| New window type | Casement window |

| New glazing type | Double |

| New shading type | Inner shutter |

| New window solar factor g [-] | 62,2 |

Other interventions

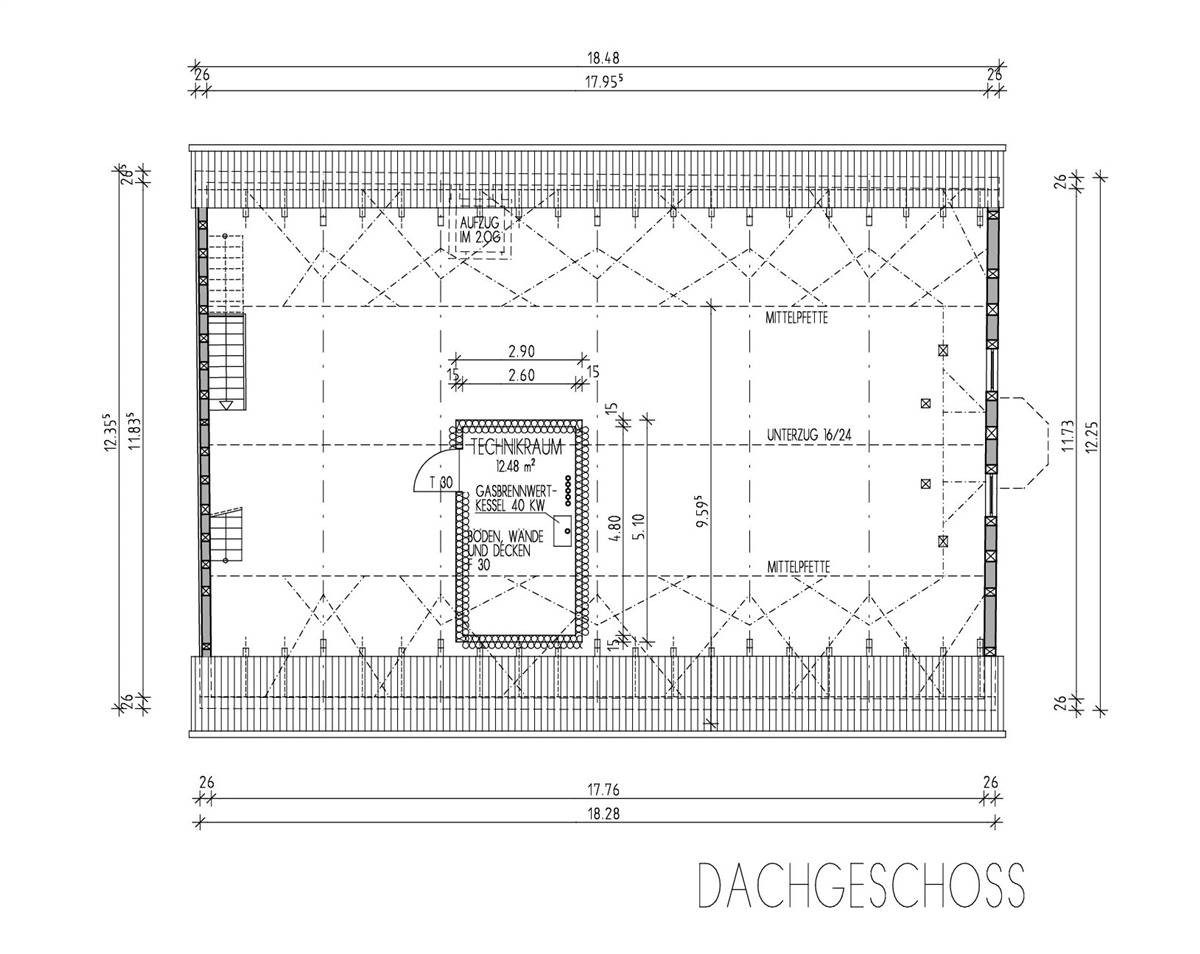

ROOF

GROUND FLOOR

OTHER

MEASURES TO INCREASE AIRTIGHTNESS

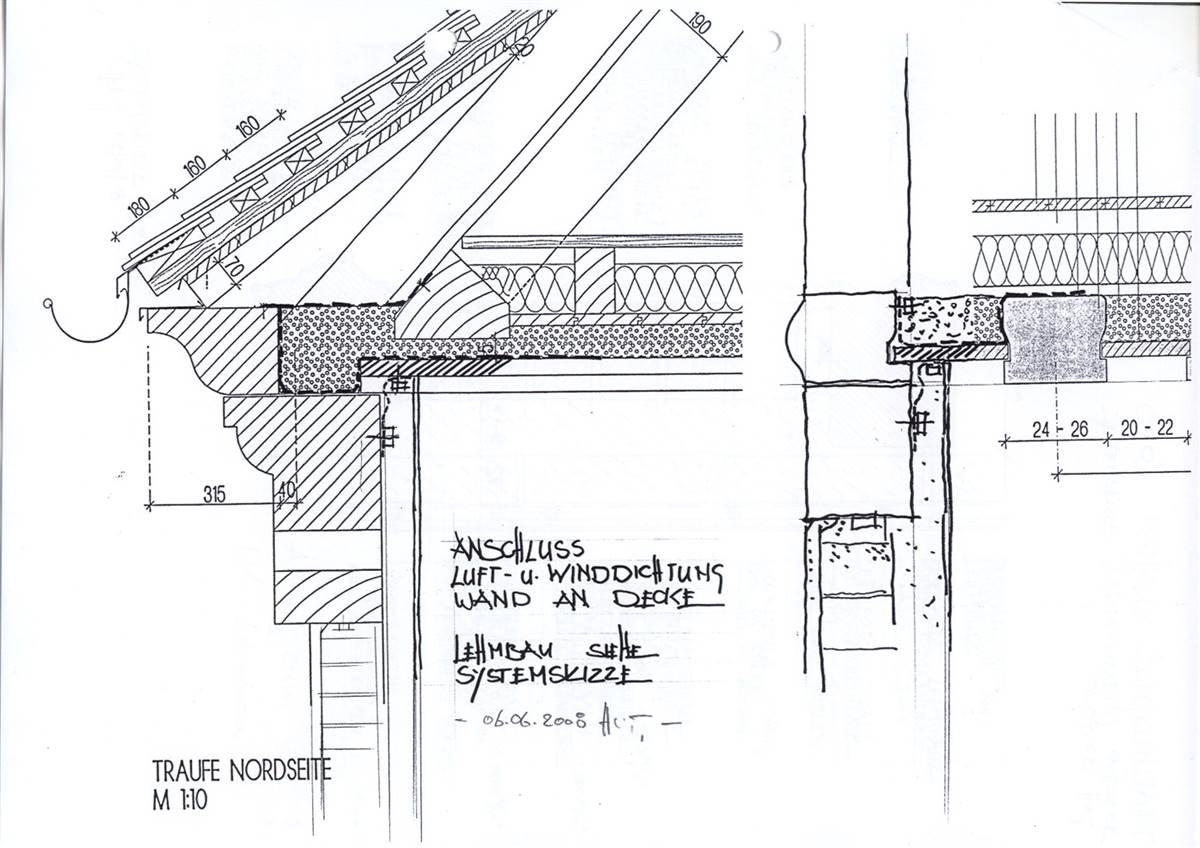

Due to the existing damage and the lack of static stability, the affected components were removed and supplemented or completely replaced. Furthermore, the connections between the roof and the wall were strengthened in order to sufficiently reinforce the supporting structure. Yet, energetic measures were not implemented at the truss. Hence, the new ceiling above the 2nd floor serves as the upper finish of the thermal envelope. Since the attic is not used, the floor structure here could be ventilated to prevent moisture damage.

Due to the pollution burden, most of the ceilings were dismantled and replaced by new constructions. Elements important for the preservation of monuments, such as the planks of the plank ceiling and the exposed formwork, were retained. After cleaning, these components were given a special coating that traps the pollutants, but otherwise remains vapour-permeable. In the general process, as much as possible of the historical structure was preserved during the constructional interventions.

28 mm

60 mm

120 mm

35 mm

80 mm

2 mm

45 mm

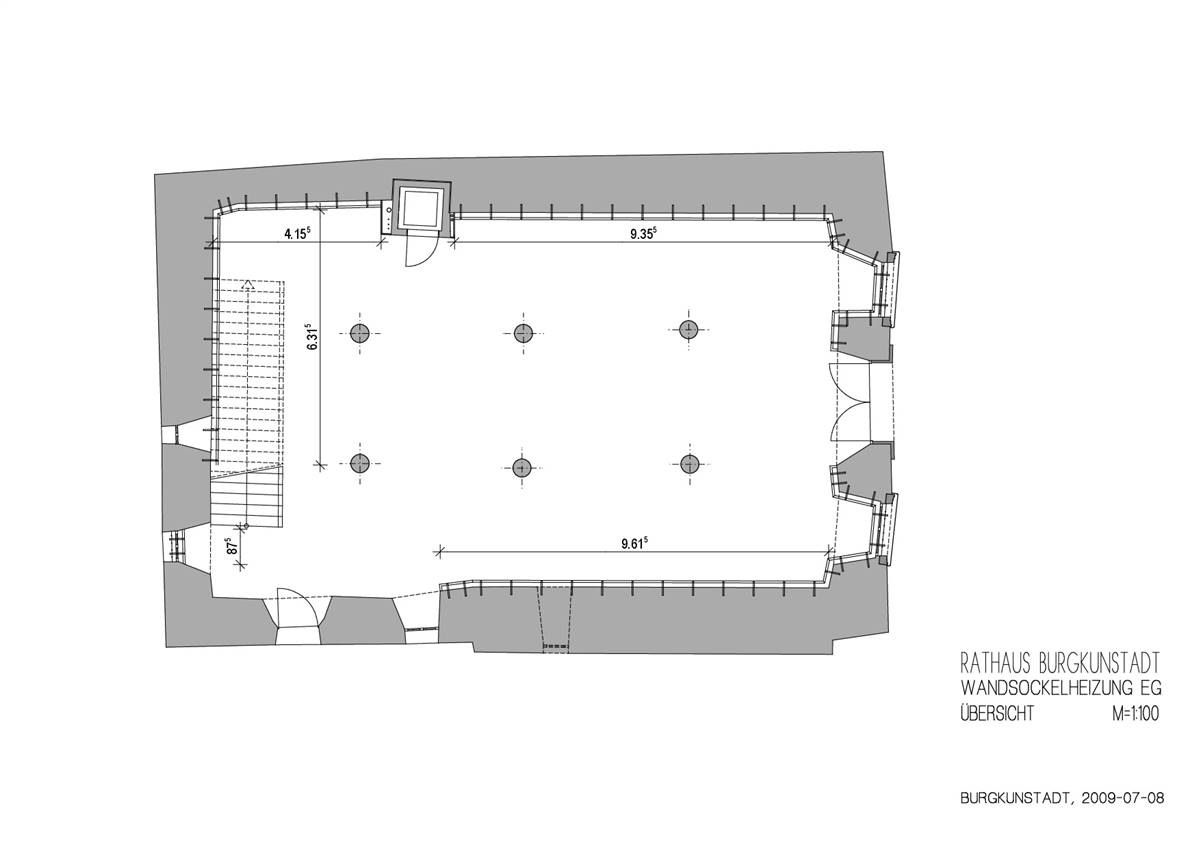

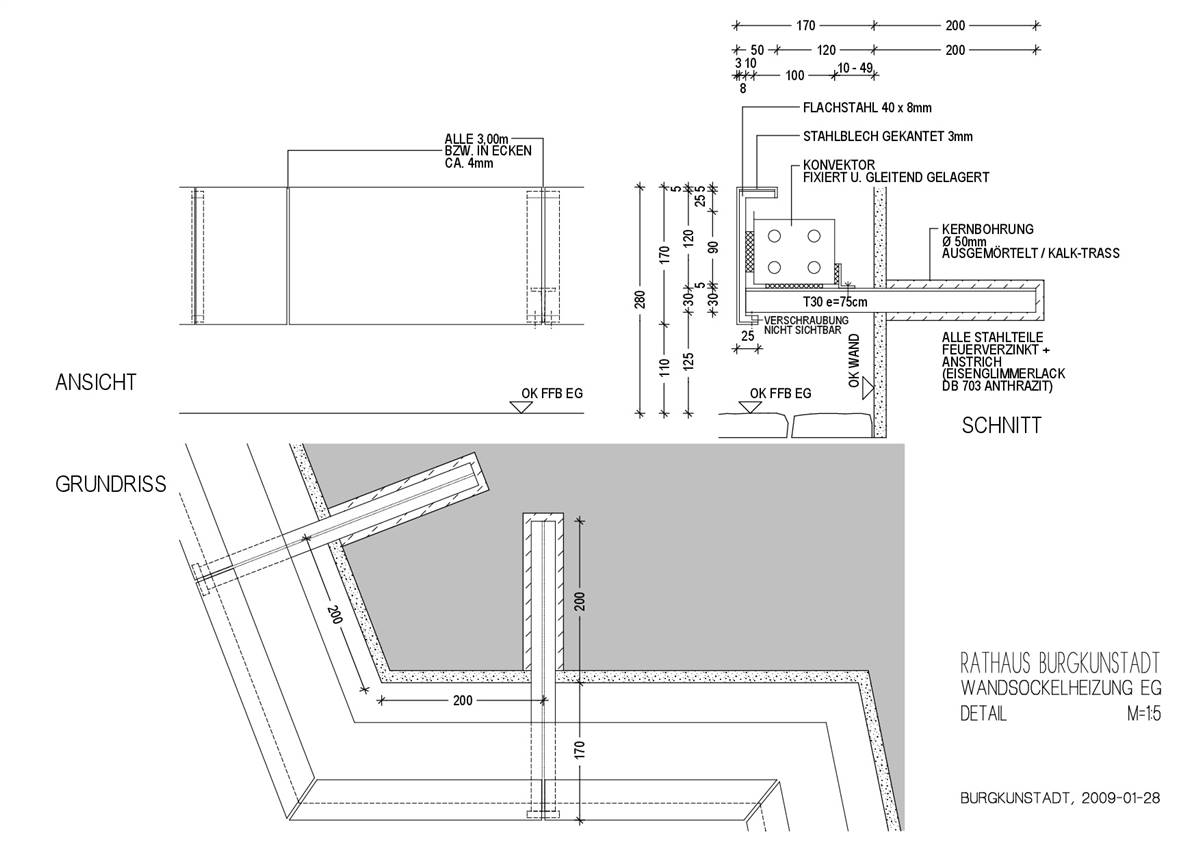

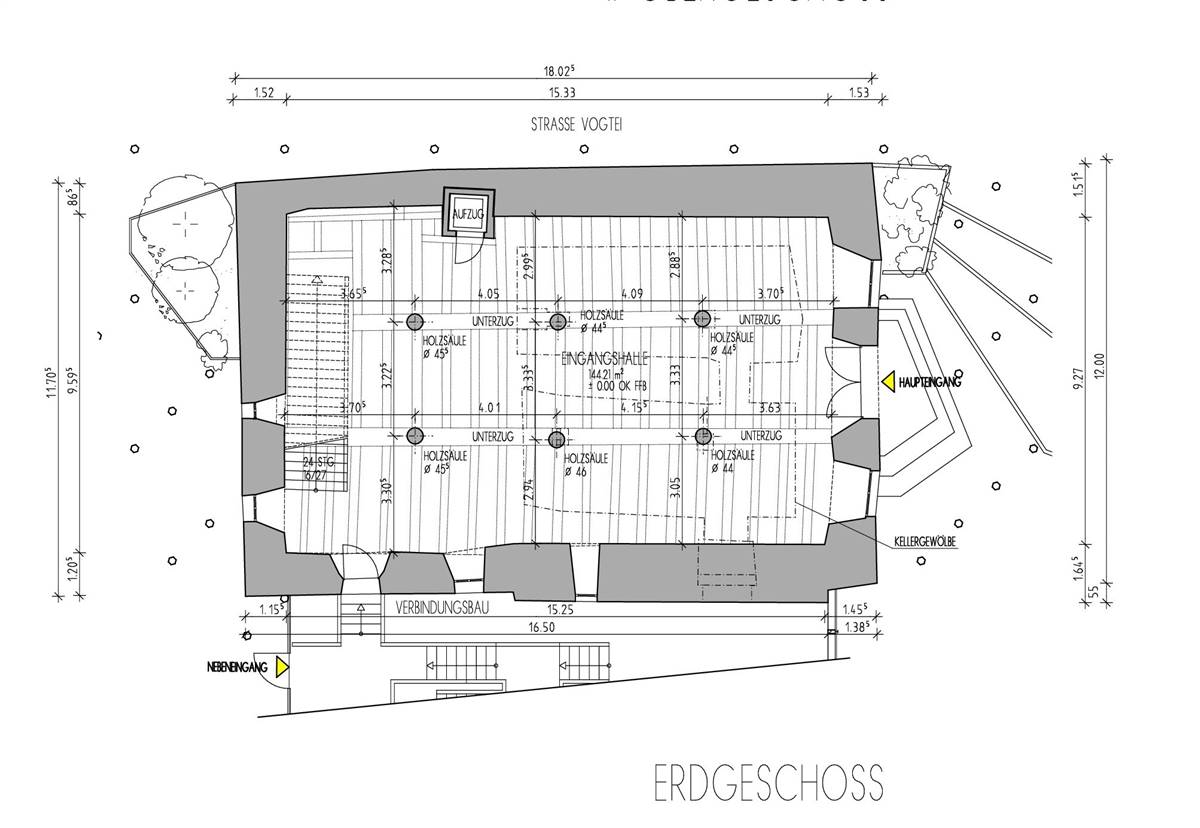

The floor structure was retained. However, since the existing underfloor heating was very sluggish due to the high floor construction, the entrance hall was supplemented with a baseboard heating system.

-

Another energy-saving measure was the differentiation of the building into its various usage zones. The individual areas, such as the entrance hall, conference room and administrative rooms, were divided into different temperature zones. This classification was then used to develop appropriate energy-related measures.

So unused areas, such as the roof truss and the vaulted cellar, could be preserved in their original form.

To ensure better airtightness, all new constructions were made airtight and the corresponding joints were specially sealed. The connections were sealed with sealing tapes.

HVAC

HEATING

VENTILATION

DOMESTIC HOT WATER

Before the renovation, the town hall was supplied with electric storage heating. The two new gas condensing boilers heat both the historic old building and the new extension. The heating system is located in the technical room on the first floor together with the ventilation system.

-

| New primary heating system | |

|---|---|

| New system type | Condensing |

| Fuel | Gas |

| Distribuition system | Radiating wall |

| Nominal power | 45 kW |

As a result of the renovation, the town hall received a ventilation system that supplies the administrative rooms on the 2nd floor.

-

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Centralized |

| Type flow regime | |

| Heat recovery | Oui |

| Humitidy recovery | |

| Nominal power | kW |

| Electric power | kW |

| Control system |

Hot water is generated by decentralized instantaneous water heaters.

-

| New DHW system | |

|---|---|

| Type | decentral boiler |

| Hot_water_tank | No |

| With heat recovery | No |

Energy Efficiency

Voluntary certificates: No

Primary Energy 112,5 kWh/m2.y

Consumption_estimation_After: 51,222 kWh/y

Primary Energy

Consumption_estimation_Calculation_method: NA

Consumption_estimation_Including_DHW: Oui

Consumption_estimation_After: 112,5 kWh/m2.y

Costs

The renovation of the old building and the construction of the extension were financed with the help of various grants: Städtebauförderung: 200.000€ E-Fond (Denkmalpflege): 230.000€ Oberfrankenstiftung: 266.000€ Bayer. Landestiftung: 150.00€

3 Mio. € (total)

Amount includes: The investment costs include both the €1.8 million for the renovation of the old building and the €1.2 million for the new building.

No