Glaserhaus - Affoltern im Emmental, Switzerland

Eggerdingen 7

3416

Affoltern im Emmental, Svizzera

architetto

Owner

Contact Details

Other Information

Contact the Owner

Climate Zone Cfb

Altitude 775 s.l.m.

HDD 171

CDD 0

Conservation Area:

No

Level of Protection:

Protected at cantonal level (Canton Bern)

Year of last renovation:

1980

Year of previous renovation:

1888

Secondary use:

NA

Building occupancy:

Permanently occupied

Number of occupants/users:

4

Building typology:

Detached house

Number of floors:

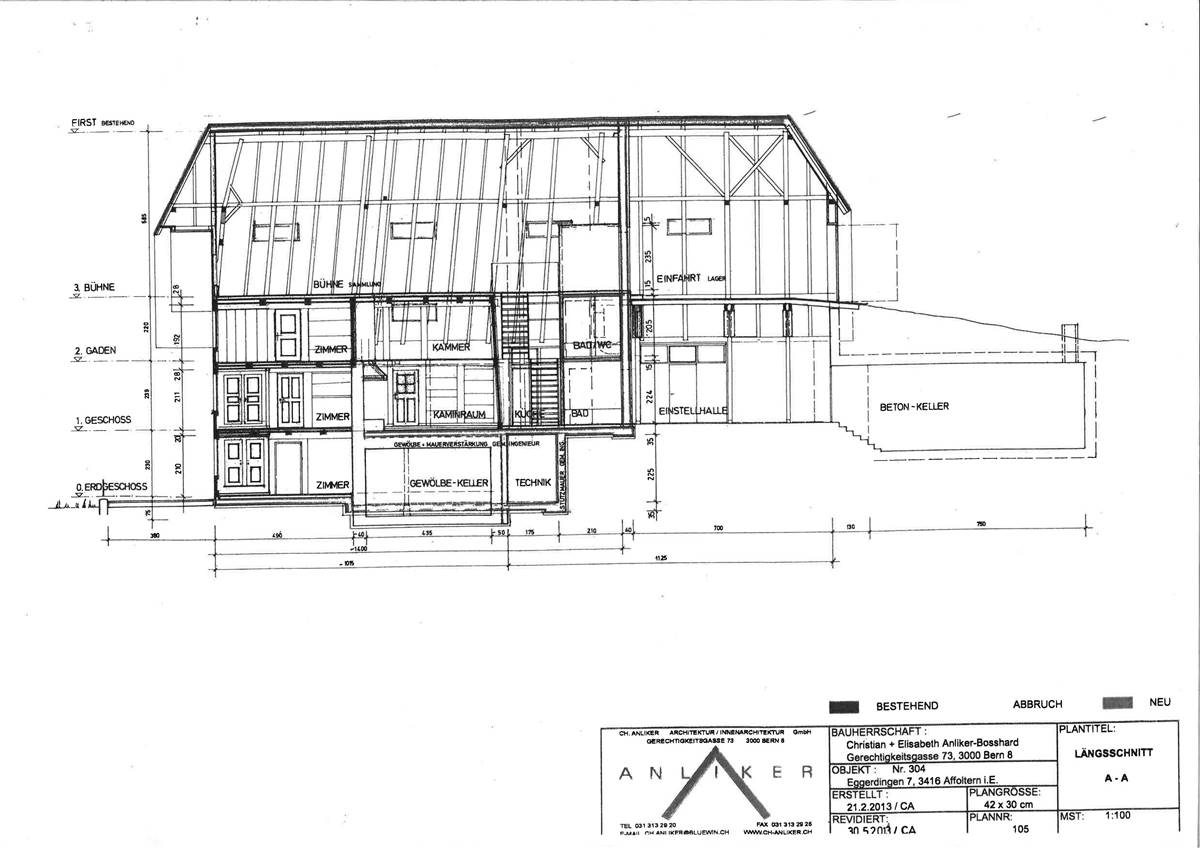

4

Basement yes/no:

Si

Number of heated floors:

2

Gross floor area [m²]:

1159,0

Thermal envelope area [m²]:

910,0

Volume [m³]:

1880,0

NFA calculation method:

SIA 416

External finish:

Exposed woodwork

Internal finish:

Exposed woodwork

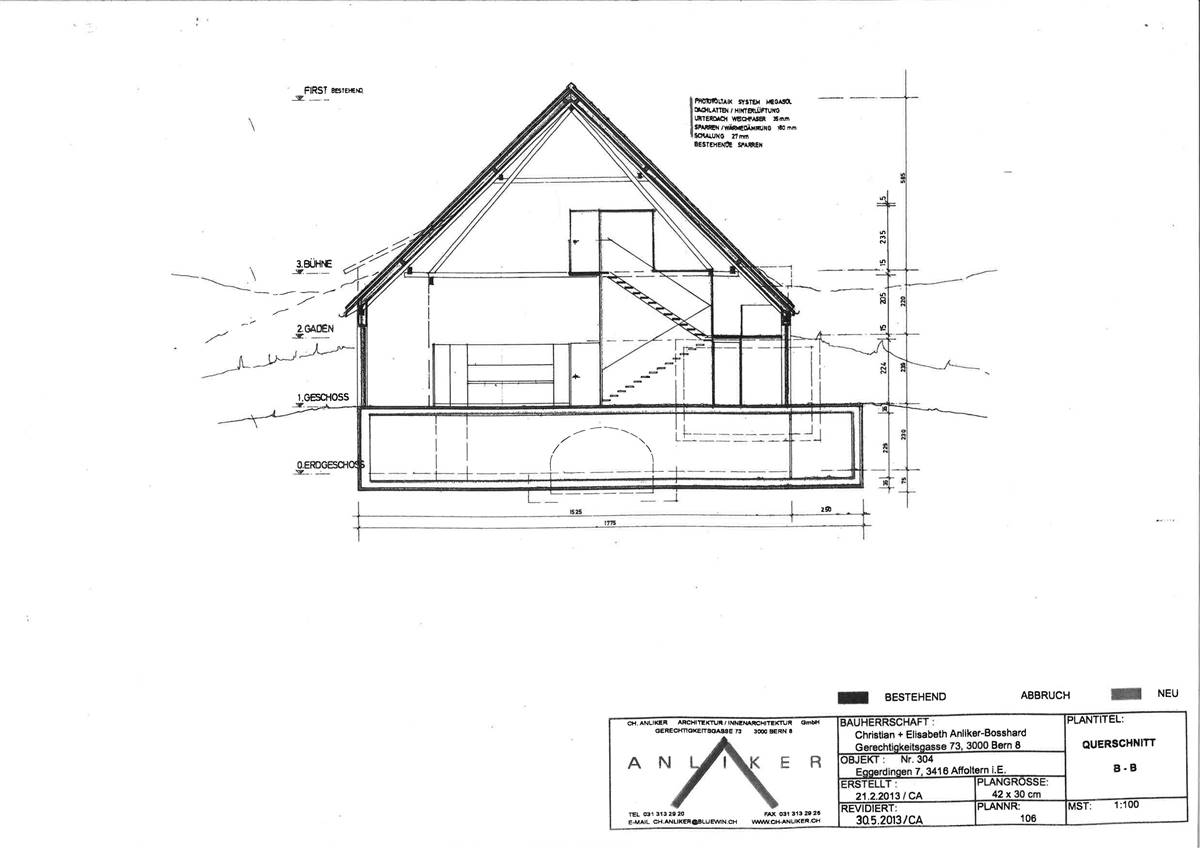

Roof type:

Pitched roof

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Denkmalpflege (Monument preservation office) Canton Bern

Schwarztorstrasse 31, 3001 Bern

denkmalpflege@be.ch

Tel.+41316334030

Anliker Christian, Arch/Innenarchitekt SWB

Gerechtigkeitsgasse 73, 3011 Bern

ch.anliker@bluewin.ch

Tel.+41 31 311 49 06

Anliker Christian, Arch/Innenarchitekt SWB

Gerechtigkeitsgasse 73, 3011 Bern

ch.anliker@bluewin.ch

Tel.+41 31 311 49 06

Lukas Meister, clevergie gmbh, Region Bern

Gemeindehaus 118, 4954 Wyssachen

info@clevergie.ch

Tel.+41 62 966 00 66

Lukas Meister, clevergie gmbh, Region Bern

Gemeindehaus 118, 4954 Wyssachen

info@clevergie.ch

Tel.+41 62 966 00 66

Habisreutinger Gebäudehülle GmbH

Brückenstrasse 6a, 4950 Huttwil

info@h-g.ch

Tel.+41 62 962 440

Hygrothermal assessment No

Life Cycle Analysis (LCA) No

Other No

RETROFIT SOLUTIONS

External Walls

Timber wall

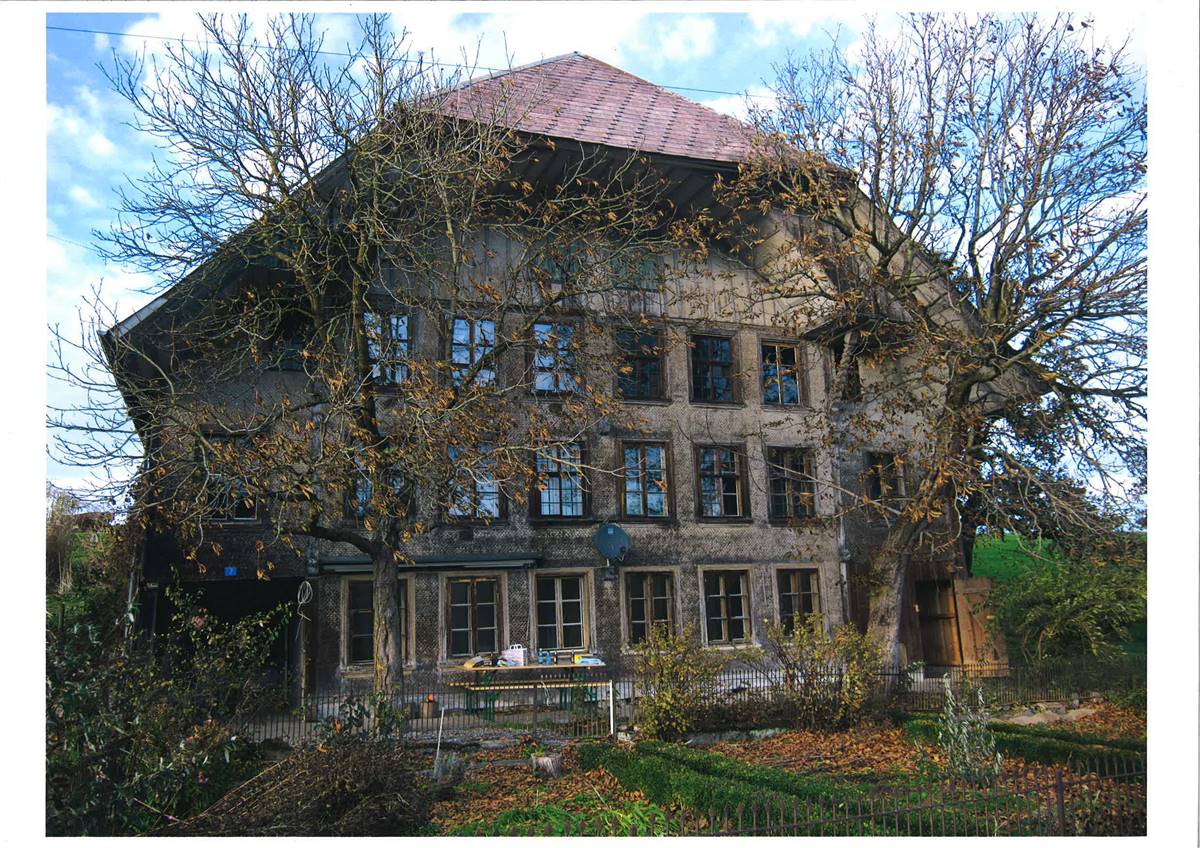

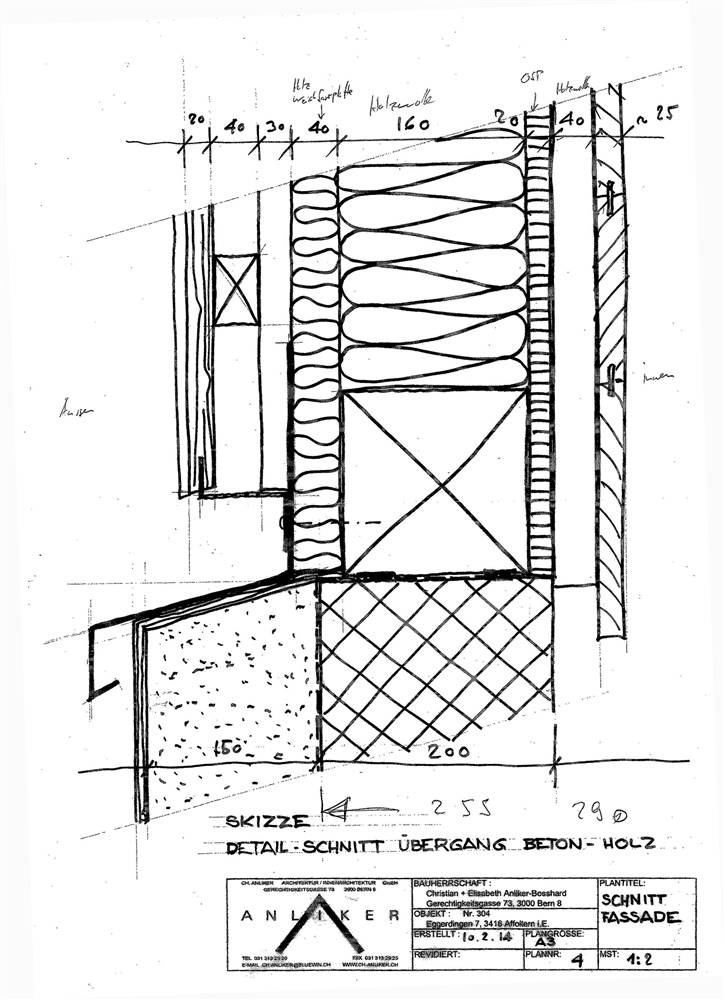

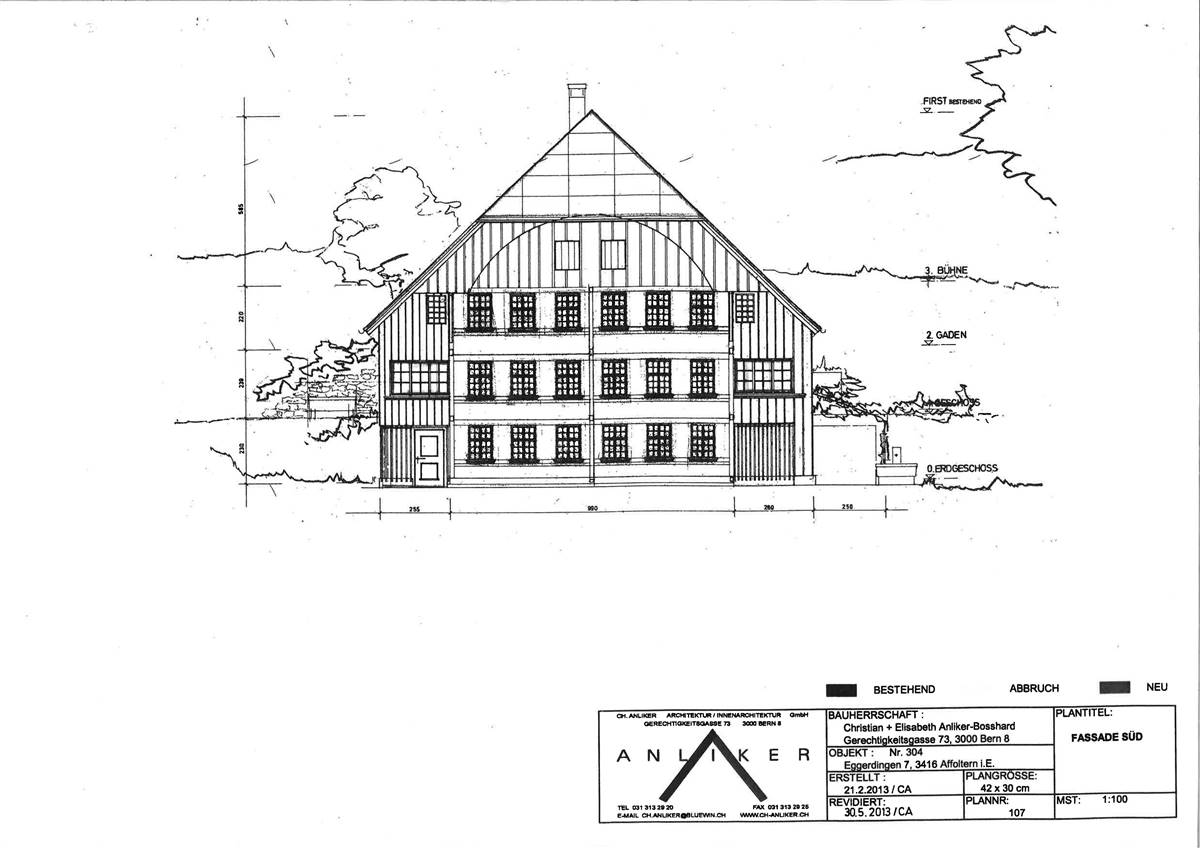

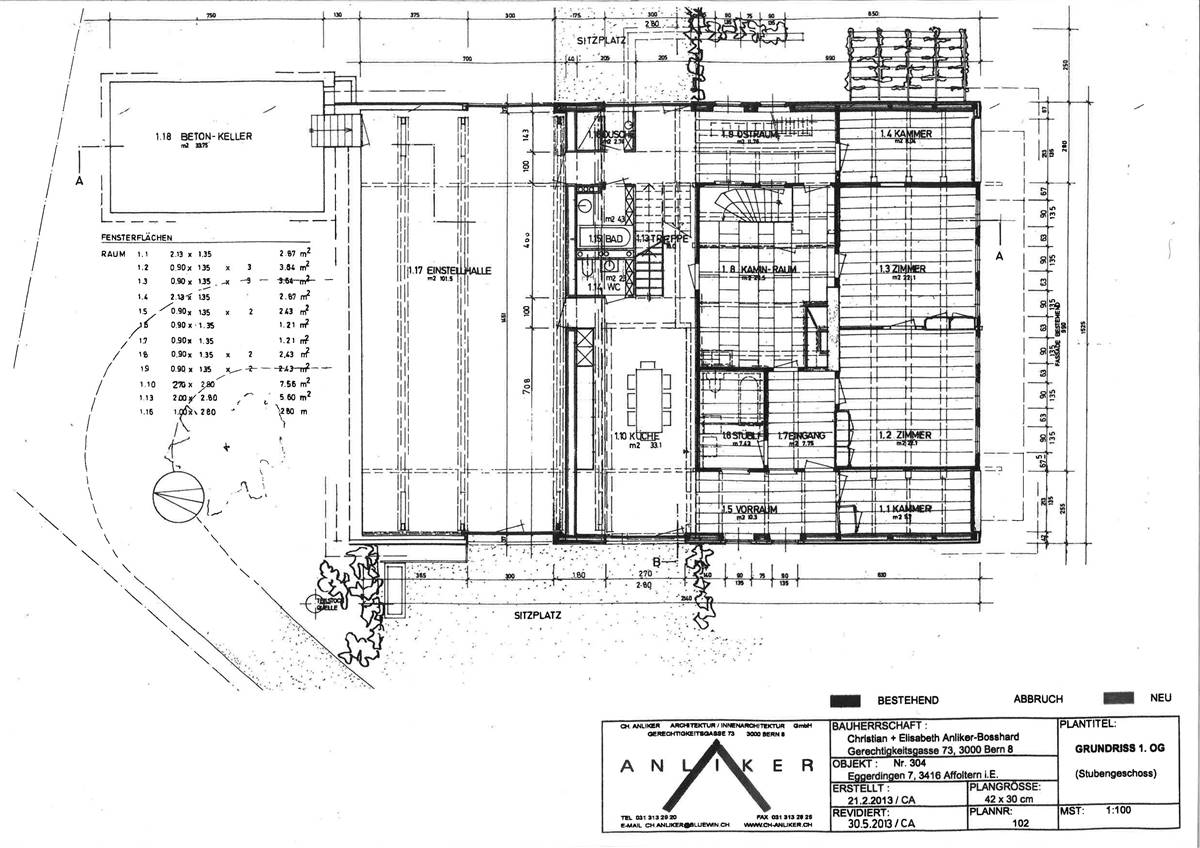

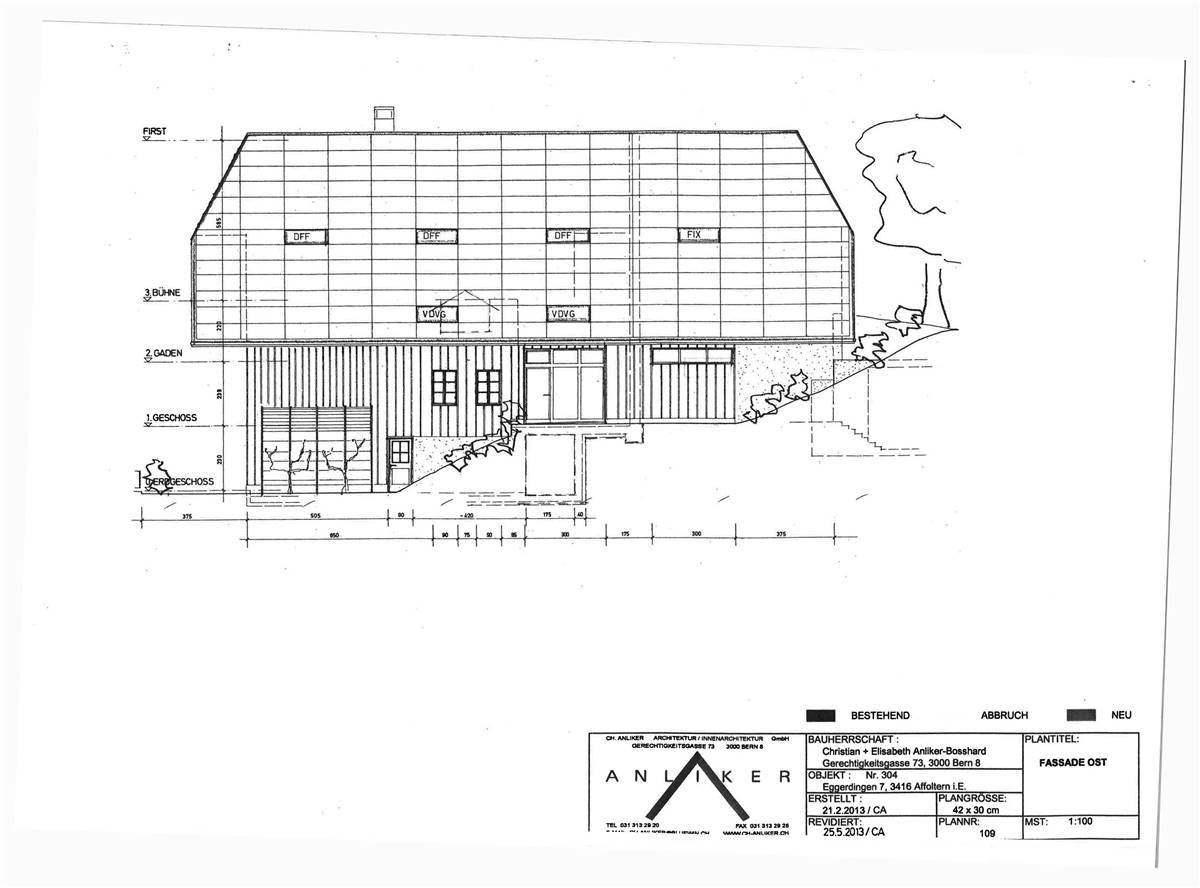

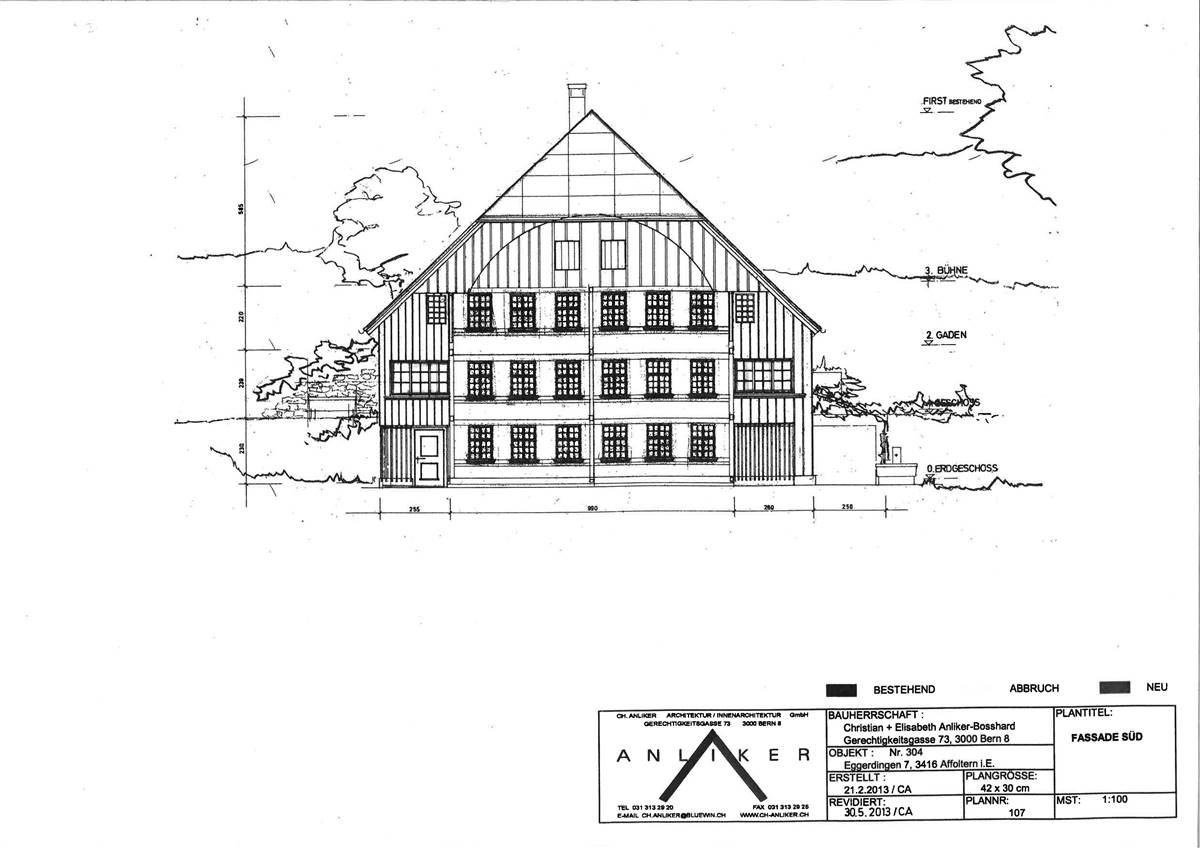

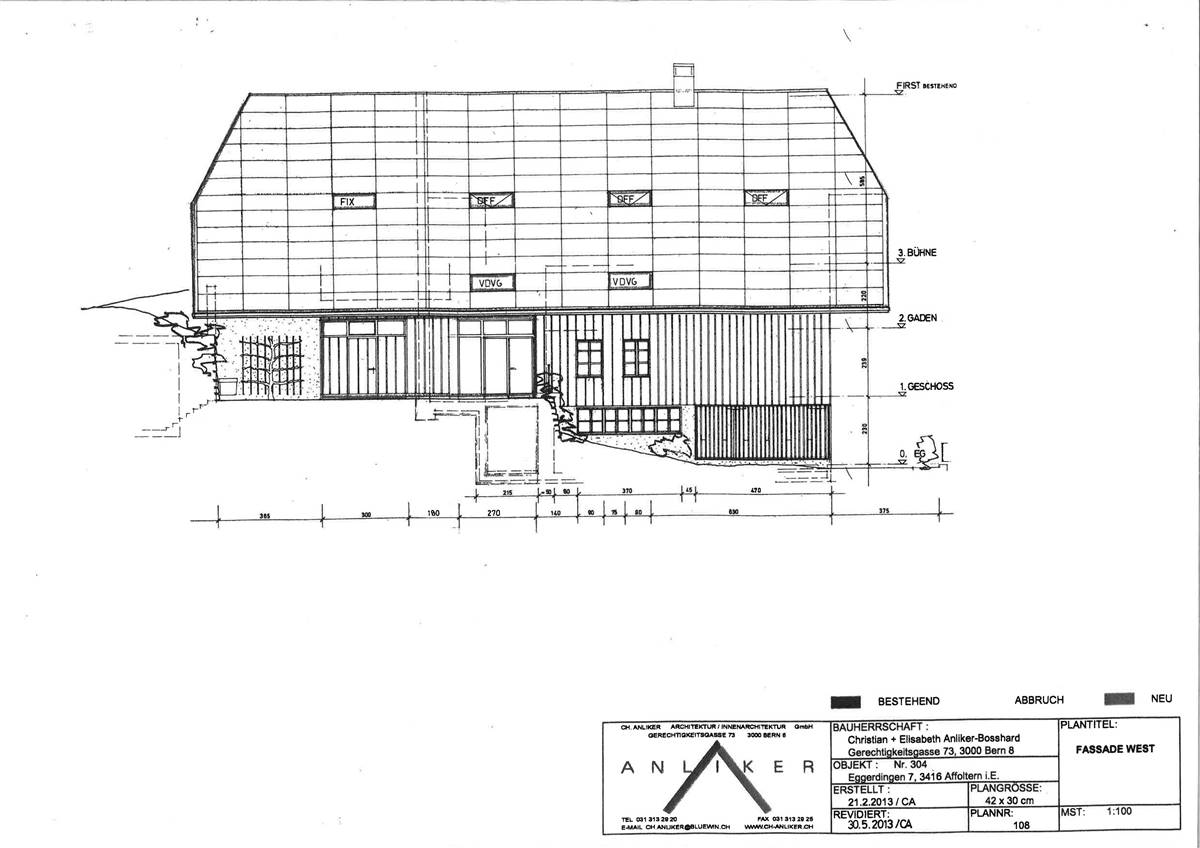

Facades have been restored to their very first appearance. The state right before the intervention presents a shingle cladding which has been added in a later intervention during the 250 years long life of this building. For this reason, the renovation shows a wood cladding that replicates the original one and that will turn grey in a few years, giving back to the house her old charm. Some parts, visible on the south facade, are actually original. The building was in a very decadent state before renovation. For this reason, the structure has been largely renovated, whereas all the internal cladding consists in original reused wood.

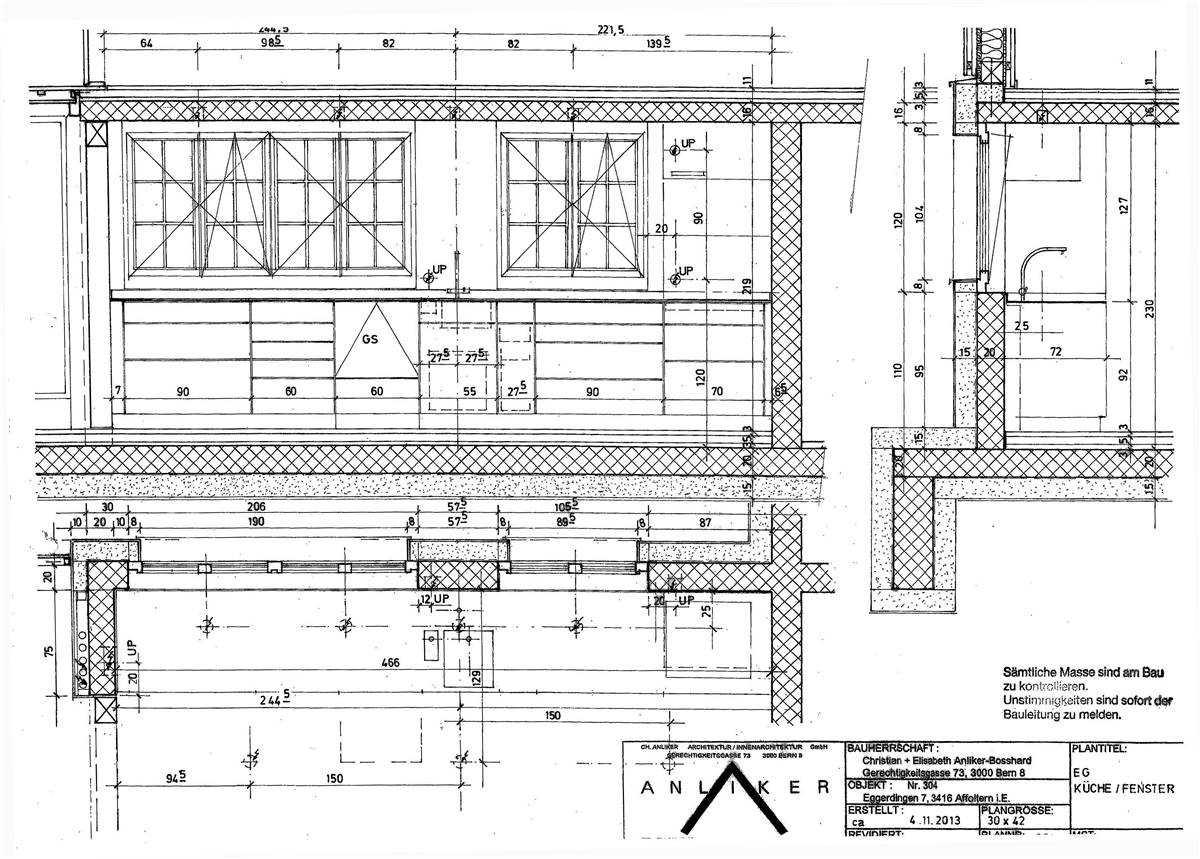

As far as the energetic improvement is concerned, only the southern front was not thermally insulated due to protection constraints of historic buildings, that in this case were severe regarding the maintaining of the window front as close as the original as possible (the intervention was possible directly on windows, as described in the dedicated part of this article). Other facades improved with the insertion of the solar thermal insulation between the wooden rafters, reaching the Minergie-P standard.

40 mm

200 mm

20mm

70 mm

40 mm

160 mm

20 mm

40 mm

25 mm

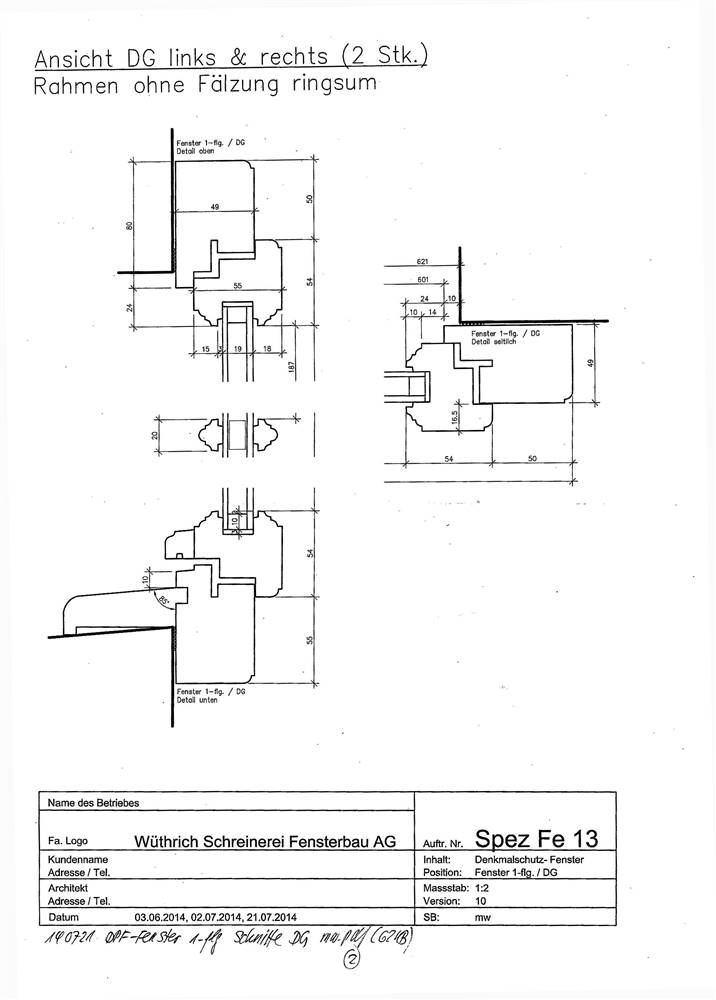

Windows

Wood windows

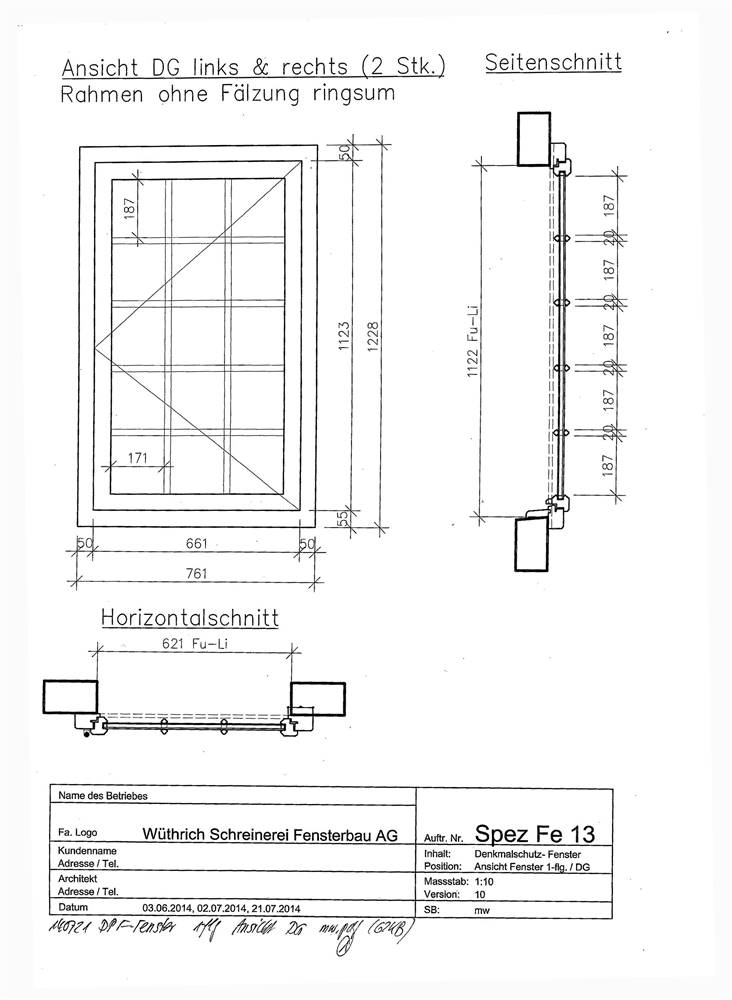

Replica windows with the same characteristics and dimensions as the previous ones were made, but which could accommodate a triple glazing (reproduction of the frame and crossbar profiles). For reasons of monument protection, the traditional window front with wooden bars remained without insulation. Only the other windows received new insulating glazing. The hand-made window panes installed by the master glazier in the 18th century found a new use in the interior.

Most of the windows are located on the large south front and due to protection constraints their appearance could not be changed: for this reason replica windows with the same characteristics and dimensions as the previous ones were made, but which could accommodate a triple glazing (reproduction of the frame and crossbar profiles).

| Existing window type | Casement window |

| Existing glazing type | Single |

| Existing shading type | NA |

| Approximate installation year | 1888 |

| New window type | Casement window |

| New glazing type | Triple |

| New shading type | NA |

| New window solar factor g [-] | 45,0 |

Other interventions

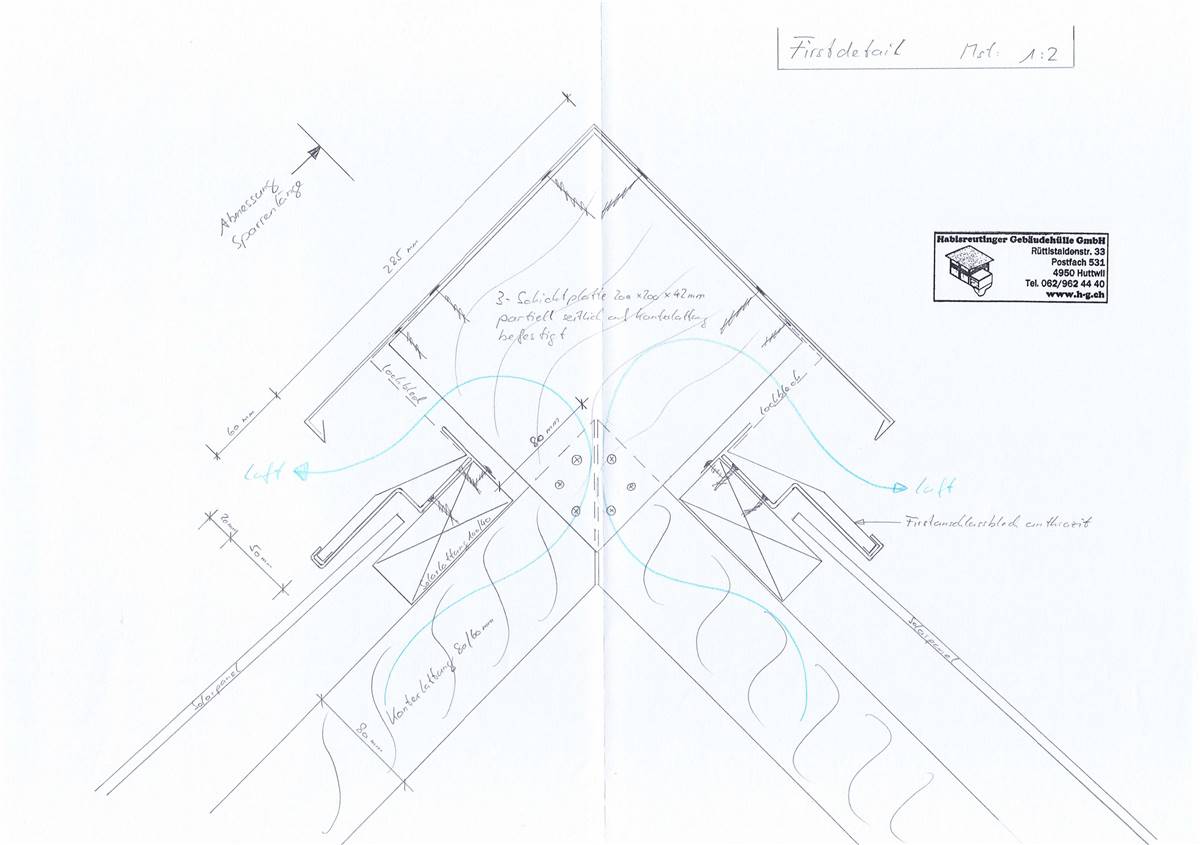

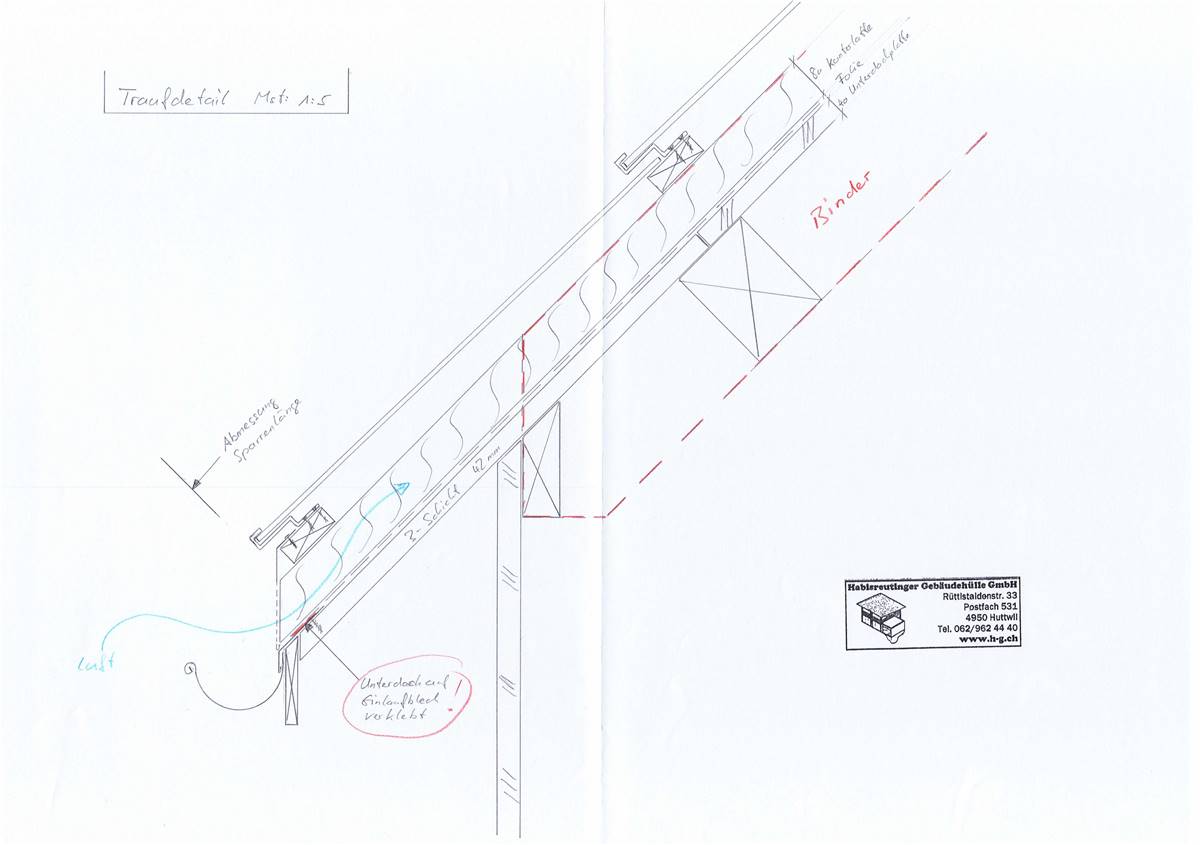

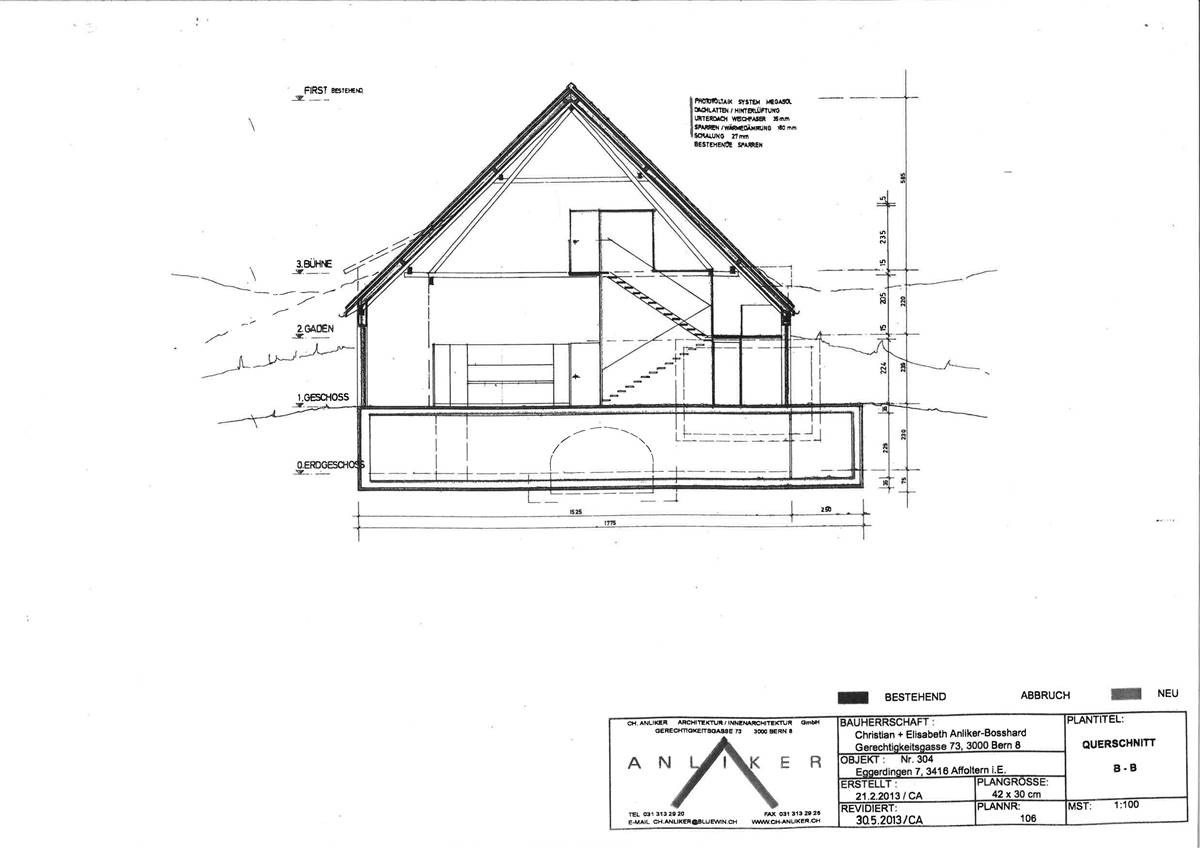

ROOF

GROUND FLOOR

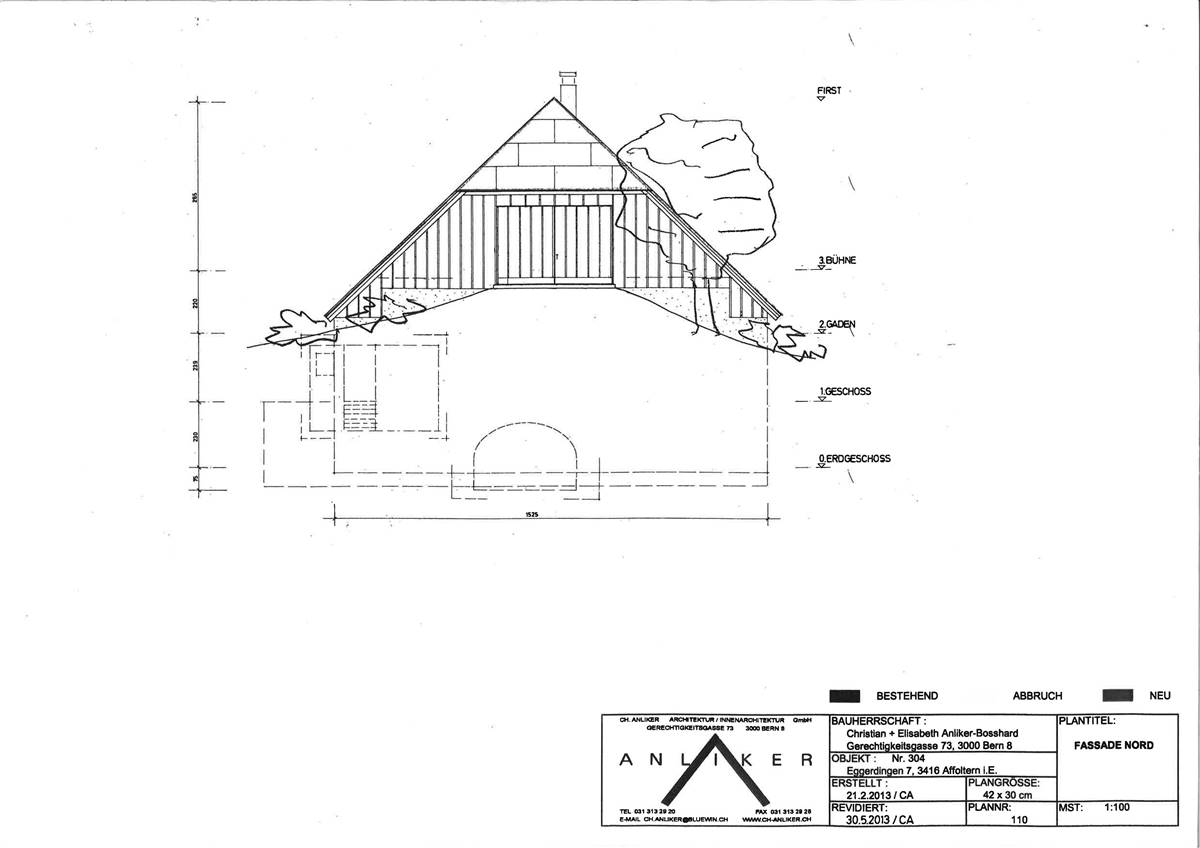

The roof construction shows deformations caused by subsidence, in some places it is defective. The deformations are straightened, the defectiveness is remedied, especially by straightening the existing purlins and rafters. The existing roof structure is supplemented by a new rafter layer and wooden formwork to ensure the load-bearing capacity and rigidity of the entire system and to achieve the required insulation thickness. The roof is insulated throughout, which is indispensable in the cross-section to avoid energy inefficiency and to avoid areas of potential cold bridges. In addition, the existing storage use of the platform above the core building does not require any heating for energy reasons, but nevertheless a certain constancy with regard to room temperature and air humidity.

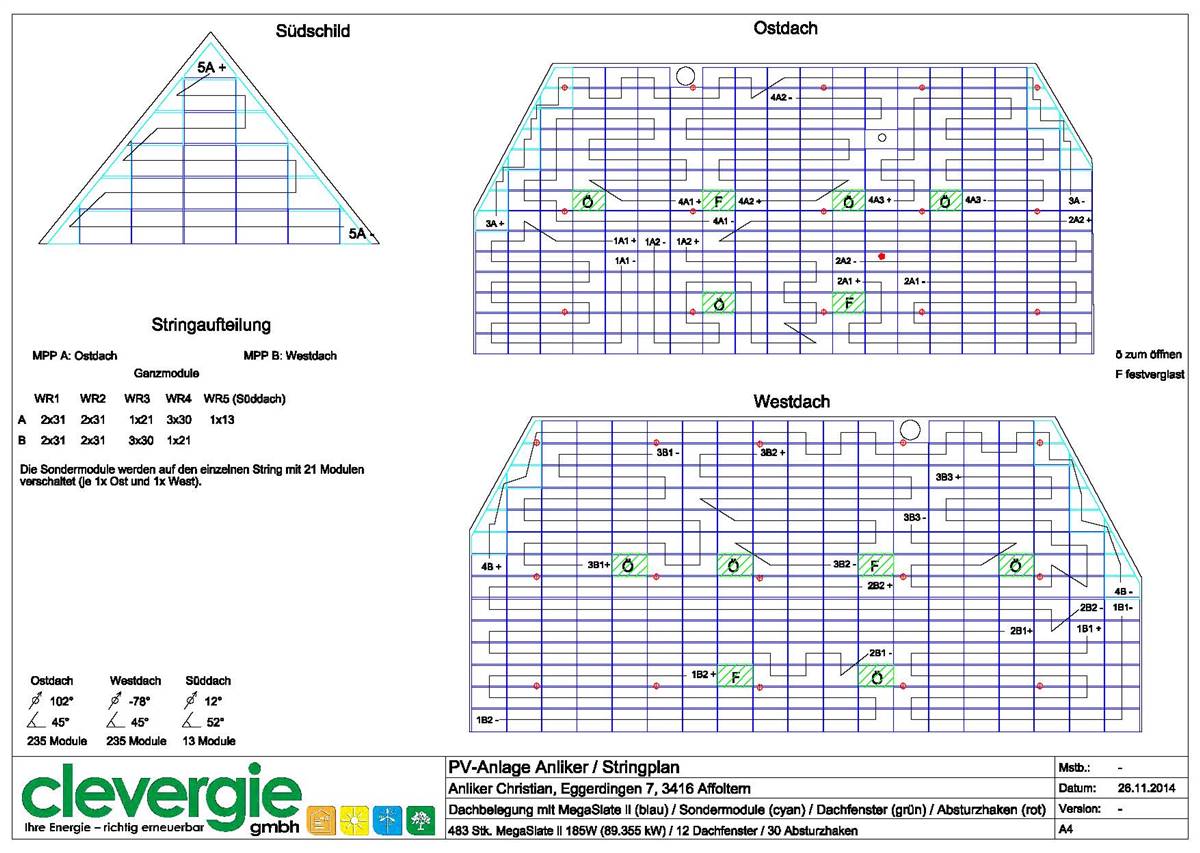

The roof shape is returned to its original simple form by removing the 20th century skylight and the roof elevation above the entrance to the storage room. The roof consists in a matt black slate-like photovoltaic system.

15 mm

80 mm

200 mm

20 mm

110 mm

42 mm

180 mm

27 mm

180 mm

Without thermal insulation and without sound insulation, board cladding of approx. 40 mm, partly on the ground and partly on wooden beams. Totally renovated.

The details were discussed with the cantonal office taking into account the height problems of the premises.

400 mm

40 mm

150 mm

200 mm

30 mm

30 mm

HVAC

HEATING

VENTILATION

AIR CONDITIONING

DOMESTIC HOT WATER

The heat is generated using two geothermal boreholes made of polyethylene pipes which are laid in the ground with a deep bore hole. The heat for the heating system is generated with a water heat pump. The hot water preparation is carried out by a 1'000l combi storage system. The heat pump, the heating group, the free-cooling function and the DHW preparation are regulated or controlled by the projected regulation. The heat load occurring in summer is extracted from the building with the floor heating pipes and released into the ground via the geothermal probe. For room heating in winter and cooling in summer, a separately controllable and shut-off underfloor heating group is provided on the ground floor, 1st floor and first floor. The heat is emitted or extracted with a conventional underfloor heating system, inserted in the underlay floor. The individual room regulation is ensured by electric room sensors. Rooms with minimum room heights are heated with radiators, the wet areas are additionally heated with a towel radiator. The heat distribution takes place via a radiator heating group which can be separately regulated and switched off from the heat generator or storage tank. A Step oven under preservation order, with built-in heating register is also operated via the radiator heating group. The individual room regulation is ensured by thermostatic valves.

The only element of the heating system that touches on the protection of historical monuments is the step oven on the ground floor, whose model was chosen according to the requirements of historical monuments. An existing traditional tiled stove with a heated bench - a so-called Swiss step stove - was incorporated into the heating circuit via a subsequently installed heating register.

| New primary heating system | New secondary heating system | |

|---|---|---|

| New system type | Heat pump | Stove |

| Fuel | Electricity | Biomass |

| Distribuition system | Radiating floor | Air |

| Nominal power | 17 kW | NA kW |

The building has ventilation with opening of windows, no mechanical ventilation

The airtightness of the windows has been largely improved while maintaining the appearance in accordance with the historical monuments.

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | NA (Natural) |

| Type flow regime | NA (Natural) |

| Heat recovery | No |

| Humitidy recovery | No |

| Nominal power | 0 kW |

| Electric power | 0,0 kW |

| Control system | No |

The heat load occurring in summer is extracted from the building with the floor heating pipes and released into the ground via the geothermal probe. In summer, the building can also be passively cooled with the system. The water circulating in the underfloor heating absorbs excess heat and transfers it via a heat exchanger to the brine circuit and then to the ground.

The cooling system is integrated in the heating distribution (radiating floor) and doesn’t involve any intervention that requires conservation compatibility.

| New cooling system | |

|---|---|

| Type | Heat pump |

| Distribuition system | Radiating floor |

| Nominal power | 13.4 kW |

| Electric power | 3,62 kW |

The heat is generated using two geothermal boreholes made of polyethylene pipes which are laid in the ground with a deep bore hole. The heat for the heating system is generated with a water heat pump. The hot water preparation is carried out by a 1'000l combi storage system.

The DHWsystem is integrated in the heating that doesn’t involve any intervention that requires conservation compatibility. An existing traditional tiled stove with a heated bench - a so-called Swiss step stove - was incorporated into the heating circuit via a subsequently installed heating register.

| New DHW system | |

|---|---|

| Type | with heating system |

| Hot_water_tank | Si |

| With heat recovery | No |

RENEWABLE ENERGY SYSTEMS

Photovoltaic

Geothermal

This intervention demonstrates the potential PV implementation in a protected building and within a sensible landscaping heritage. The solar tiling completely replace the roof surface. The homogeneous solar cladding, extended to the whole roof area, creates a clear recognizability/expression of PV respecting the general lines and the morphology of the pre-existing building typology. Twelve skylights that can be opened are integrated into the solar roof to increase daylighting inside the building and to allow natural ventilation. The project was awarded with the swiss solar price 2016.

On the roof of the special craftsmen's house, which is a listed building, a fully integrated photovoltaic system was installed. The modules take over the function of the water-bearing layer, therefore it is an in-roof system.

The frameless modules of the Swiss company Meyer Burger were used. In order to be able to actively cover the edges of the roof, so-called "Crea modules" from Meyer Burger (made to measure) were also added. In order to maintain a homogenous black appearance of the roof surface, solar-look printed single-pane safety glass was used on the northern mitre sign.

| Photovoltaic System | |

|---|---|

| Type | Monocrystaline |

| Collector area | 550,0 m² |

| Total nominal power | 85,0 kW |

| Elevation angle | 45,0 |

| Azimuth | 85,0 |

| Overall yearly production | 90493,0 kWh |

| Heating contribuition | 12300,0 kW |

| DHW contribuition | 0,0 kW |

| Cooling contribuition | 0,0 kW |

| Lighting contribuition | 13940,0 kW |

Two geothermal probes placed at a depth of 180 meters extract heat from the ground, which is raised by the heat pump to a temperature level suitable for space heating and hot water preparation. In summer, the building can also be passively cooled with the system. The heat is generated using two geothermal boreholes made of polyethylene pipes which are laid in the ground with a deep bore hole. The heat for the heating system is generated with a water heat pump. The hot water preparation is carried out by a 1'000l combi storage system. The heat pump, the heating group, the free-cooling function and the DHW preparation are regulated or controlled by the projected regulation.

The only element of the heating system that touches on the protection of historical monuments is the step oven on the ground floor, whose model was chosen according to the requirements of historical monuments.

The heat is emitted or extracted with a conventional floor heating system, inserted in the underlay floor. The individual room regulation is ensured by electric room sensors. Rooms with minimum room heights are heated with radiators, the wet areas are additionally heated with a towel radiator.

| Geothermal System | |

|---|---|

| Type | Vertical loop |

| Exchange area | 696,0 m² |

| Overall yearly production | 26000,0 kWh |

Energy Efficiency

Voluntary certificates: The owners renovated the building strictly in accordance with the Minergie-P standard (but without an official label). This construction standard corresponds to Passivhaus in DE or CasaClima Gold in Italy. Spread over all sides of the roof, the 89.4 kW and 550 m2 PV installation produces 90,500 kWh/y. Until the full completion of the semi-detached dwelling, only two people live and work in the building, which explains the effective surplus of 80'800 kWh/y injectable into the public grid. The high quality of PEB (Plus Energy Building) renovation ensures 345% self-production.

Consumption_estimation_Calculation_method: On-stie monitoring

Consumption_estimation_Before: 180000 kWh/y

Consumption_estimation_After: 26,64 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: Steady state simulation (e.g. EPC, PHPP)

Consumption_estimation_Including_DHW: Si

Consumption_estimation_Before: 273100 kWh/y

Consumption_estimation_After: 77932 kWh/y

Type_of_monitoring: Punctual

Description: The building before the renovation was not at all airtight, considering the gaps between the wooden boards that make up the previous shell. The realisation of the new shell in accordance with the SIA 180 standard, which requires airtightness, improves radically the quality of internal climate. The heating system is reversible and permits to cool the inside spaces during the hot summers.

Construction

Type_of_monitoring: Continuous

Description: No construction or indoor air quality monitoring is performed. For the temperature there are modern systems with sensors (hot-cold). Monitoring of performances of PV systems and energy improvements are available at: https://www.energie-cluster.ch/de/deklariert-ch/plusenergiegebaeude/efh-anliker-sanierung-eggerdingen-7-3416-affoltern-im-emmental-3495.html

Internal Climate

The building is divided in two different heating zones: the normal one in the core and the rest. The existing storage use of the platform above the core building does not require any heating for energy reasons, but nevertheless a certain constancy with regard to room temperature and air humidity.

The building before the renovation was not at all airtight, considering the gaps between the wooden boards that make up the previous shell. The realisation of the new shell in accordance with the SIA 180 standard, which requires airtightness, improves radically the quality of internal climate. The heating system is reversible and permits to cool the inside spaces during the hot summers. For the temperature there are modern systems with sensors (hot-cold). Twelve skylights that can be opened are integrated into the solar roof to allow natural ventilation and to increase daylighting inside the building.

The lighting in the building is largely provided by natural light, thanks to the arrangement of the windows, especially those on the south front, where the fully inhabited and heated part of the building is located, which bring plenty of light inside. In the semi-heated/unheated areas of the roof level, the skylights integrated in the photovoltaic roofing bring the necessary light without having to use electricity during the day.

The sound insulation has been significantly improved compared to the previous situation, with a minimum of impact insulation but within certain limits due to the local height.

The wooden planks, used for the previous casing, were cut from whole trees and had widths of up to 84 cm (tree trunk). These were replaced and some of them with paintings, 1m x 50 cm, were given to the Landesmuseum.

Costs

The goal of the refurbishment was to re-use these building that was in a really bad estate. Costs includes all the action to do this.

2.8 mio CHF (total)

Amount includes: Building and surroundings

Cost of energy related interventions:

745'000.- CHF (total)

Amount includes: Insulation floor, walls, roof, windows, PV, heat pump and borholes

180.- per month (about 2160 CHF/year) (total)

Annual heating cost

about 1500.- CHF (total)

(includes DHW) Si

Annual electricity cost

about 660.- CHF (total)

Lifecycle cost

No

Environment

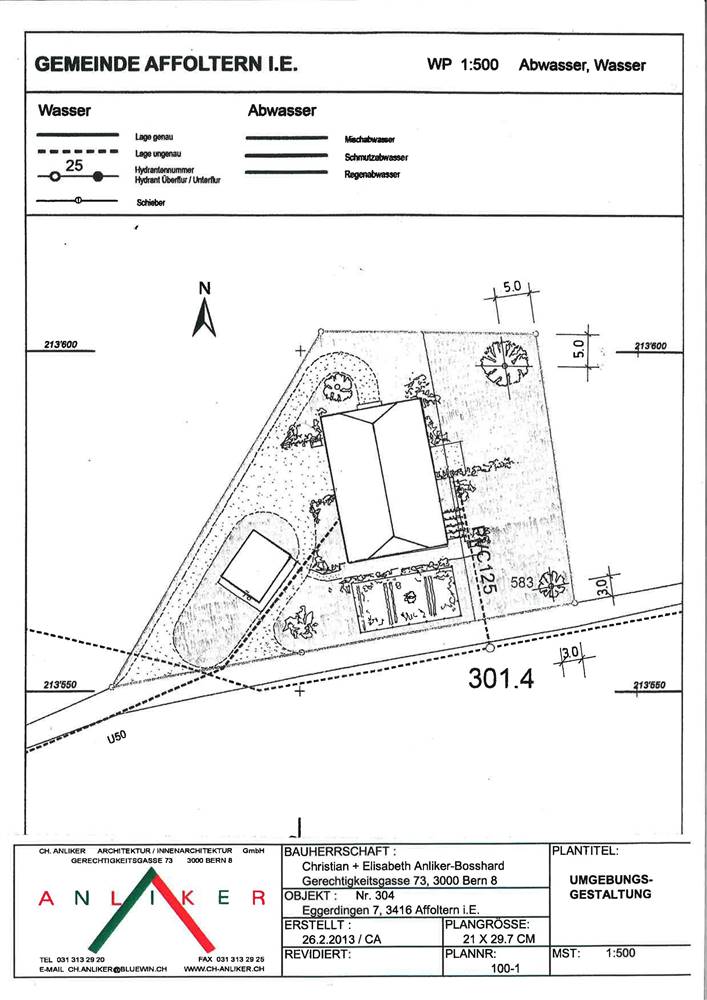

A cistern has been built that takes both rainwater and water from a small spring in the ground (used approx. 8l/min). An overflow brings the excess water to a nearby stream.

It is planned to build a charging station for electric cars, at the moment that the owners will change vehicles (private car as they live in the countryside). There is a place to lay batteries but they are not yet laid. The batteries would be used to store electricity both for domestic use and for the electric car.