Platzbon

Rutzenberg 41

39042

Brixen, Italy

Architect

Owner

Contact Details

Other Information

Use as residential house and holiday apartments - www.platzbon.it

http://itaspreis.gruppoitas.it/die-gewinner-2017/

Climate Zone F

Altitude 1330 m a.s.l.

HDD 3214

CDD 0

Conservation Area:

No

Level of Protection:

Year of last renovation:

2016

Year of previous renovation:

1970

Secondary use:

Agricultural & Fishery

Building occupancy:

Permanently occupied

Number of occupants/users:

4

Building typology:

Tenement (apartments)

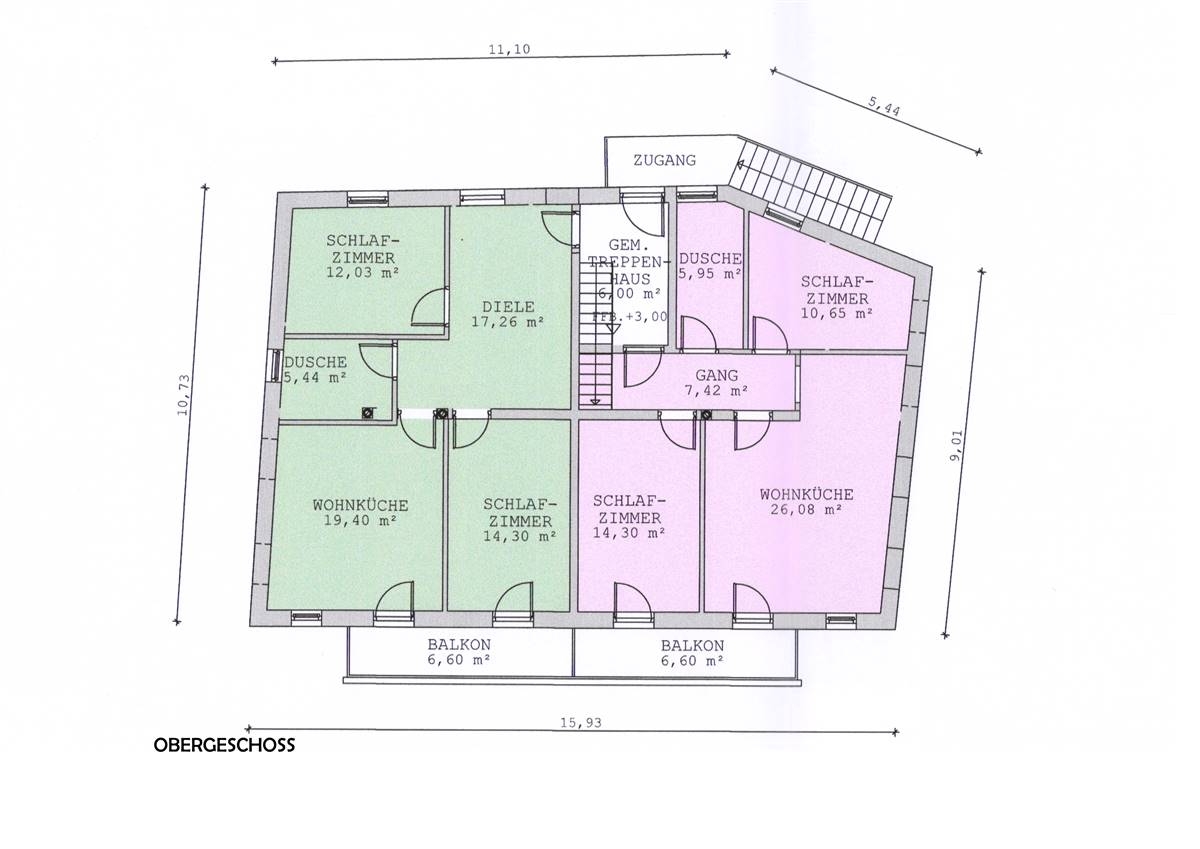

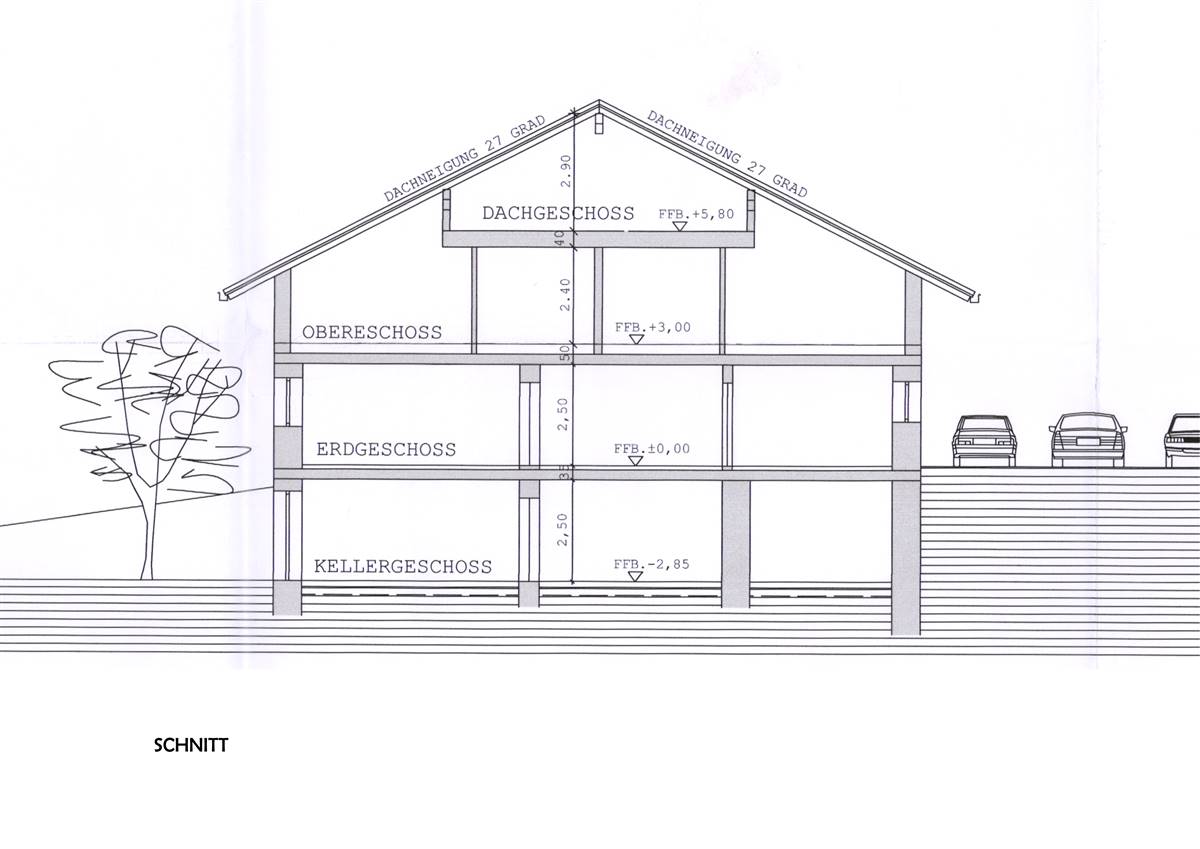

Number of floors:

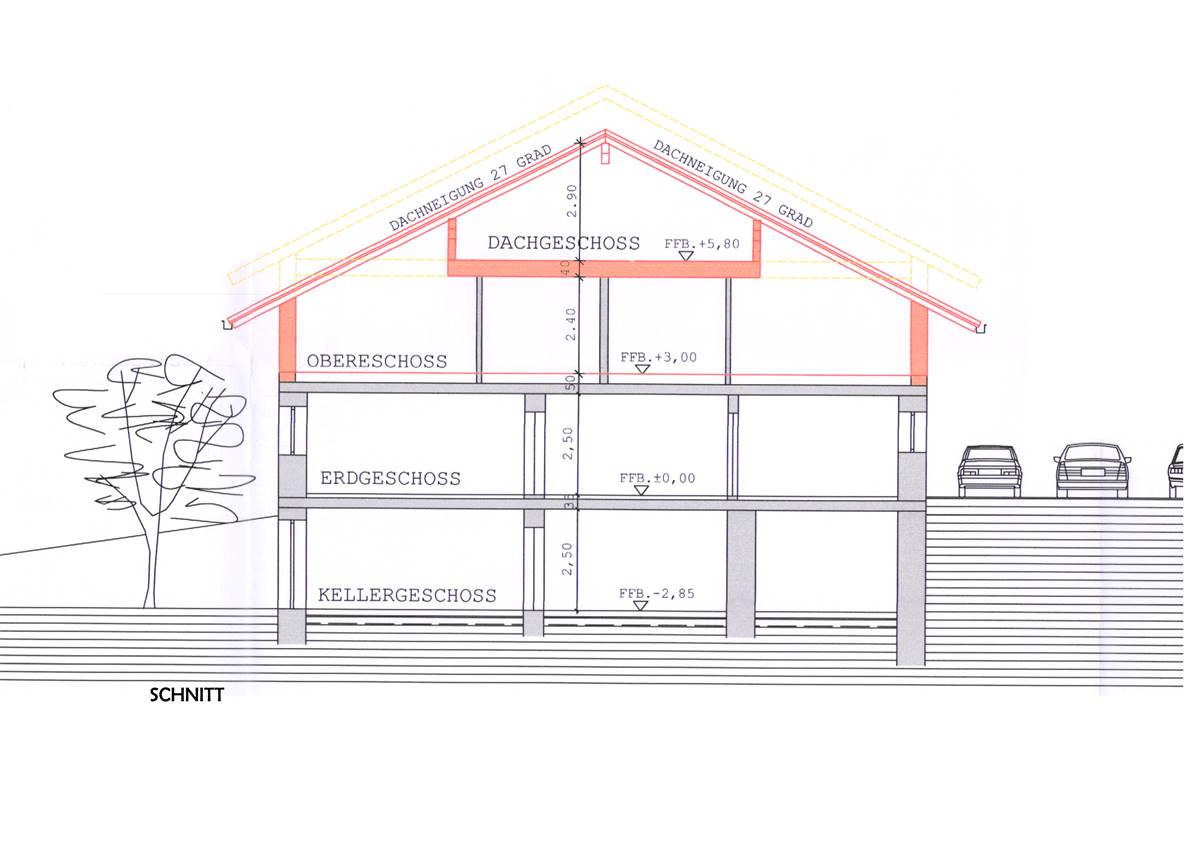

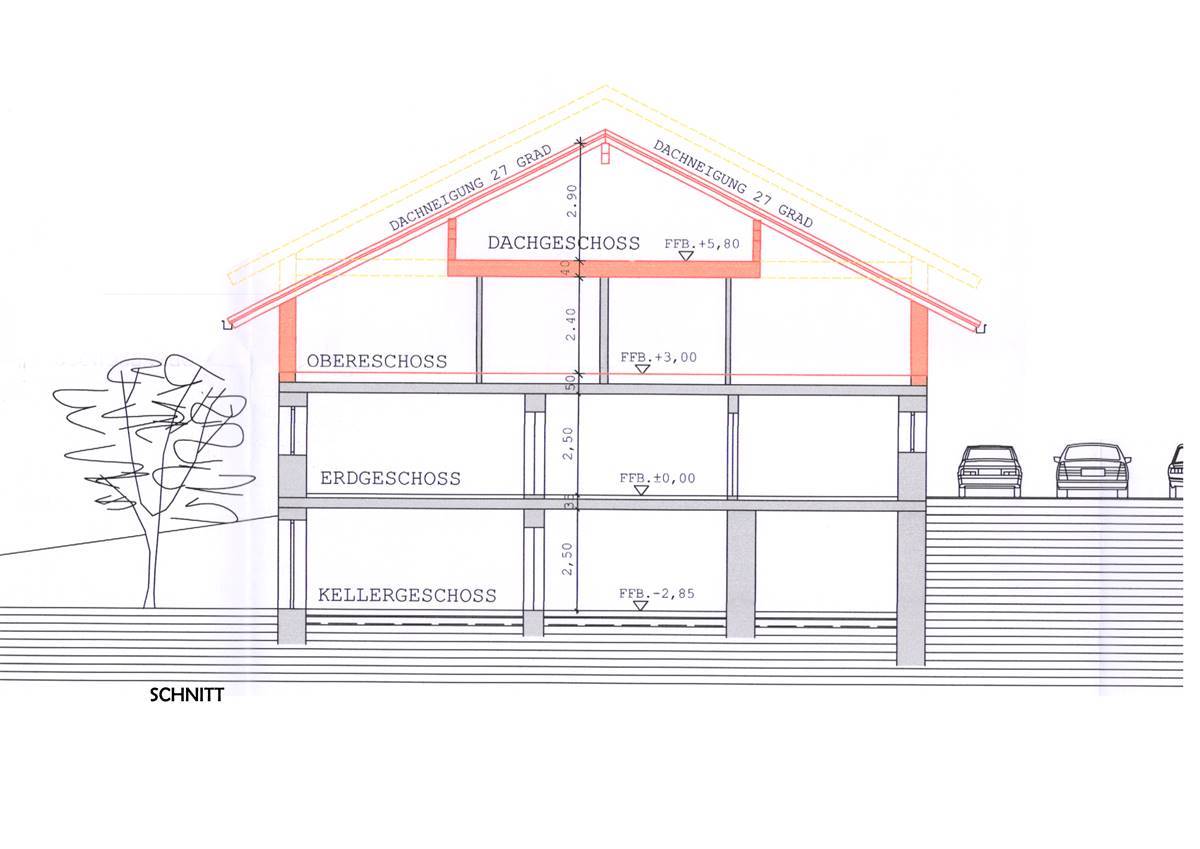

3

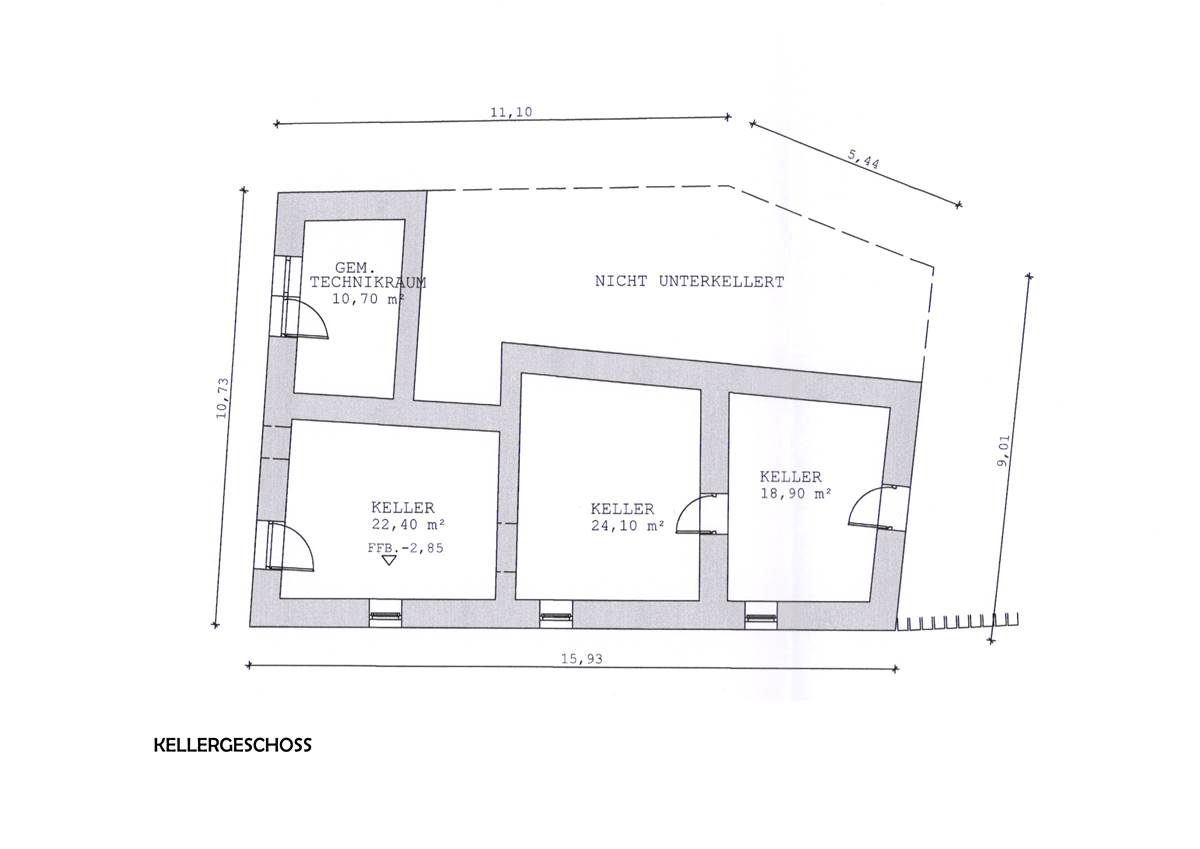

Basement yes/no:

Yes

Number of heated floors:

3

Gross floor area [m²]:

435,0

Thermal envelope area [m²]:

699,0

Volume [m³]:

1196,5

NFA calculation method:

NGF (de)

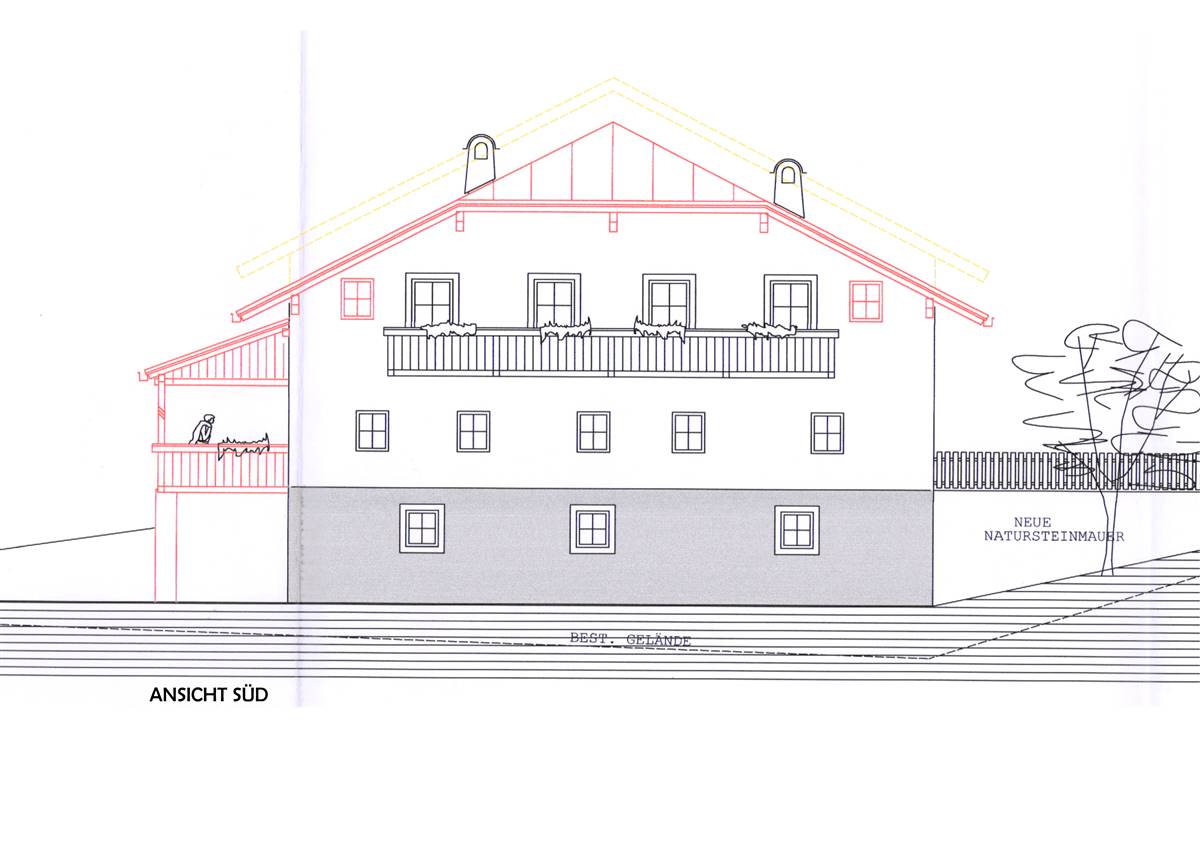

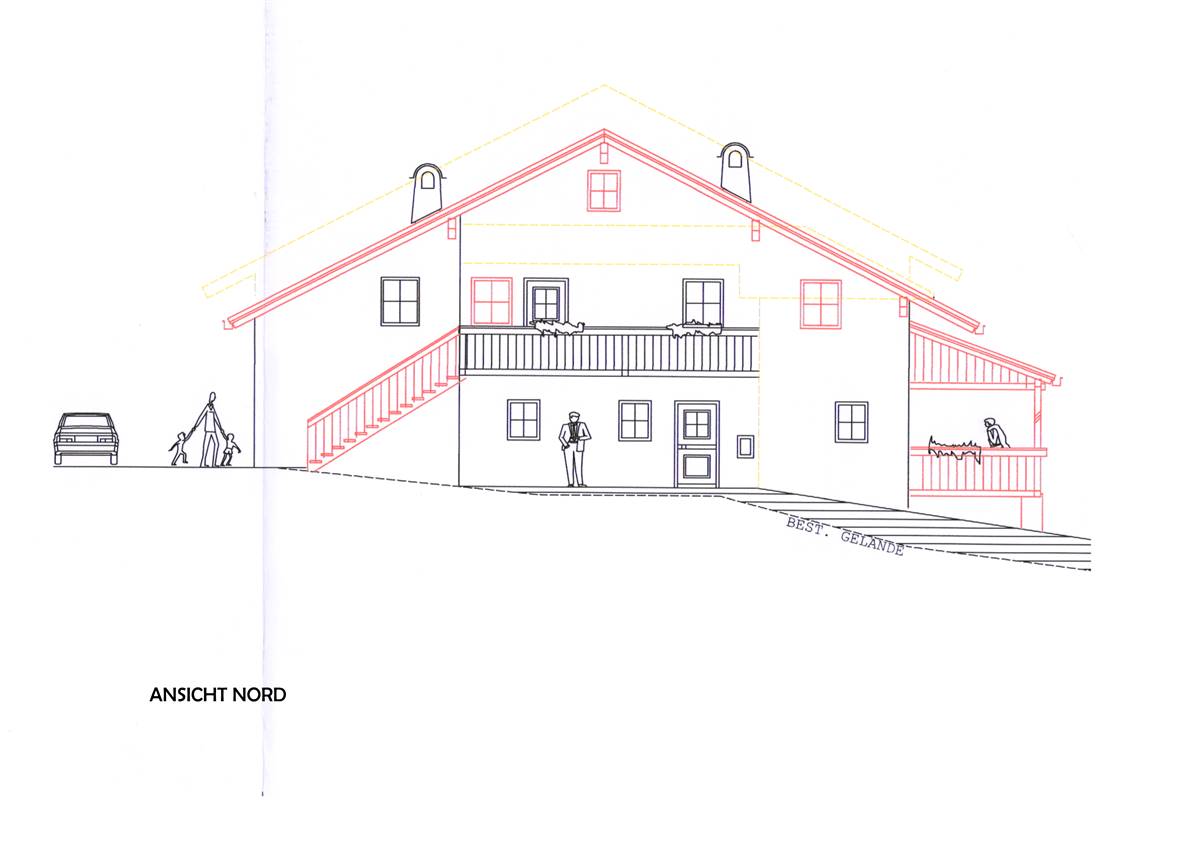

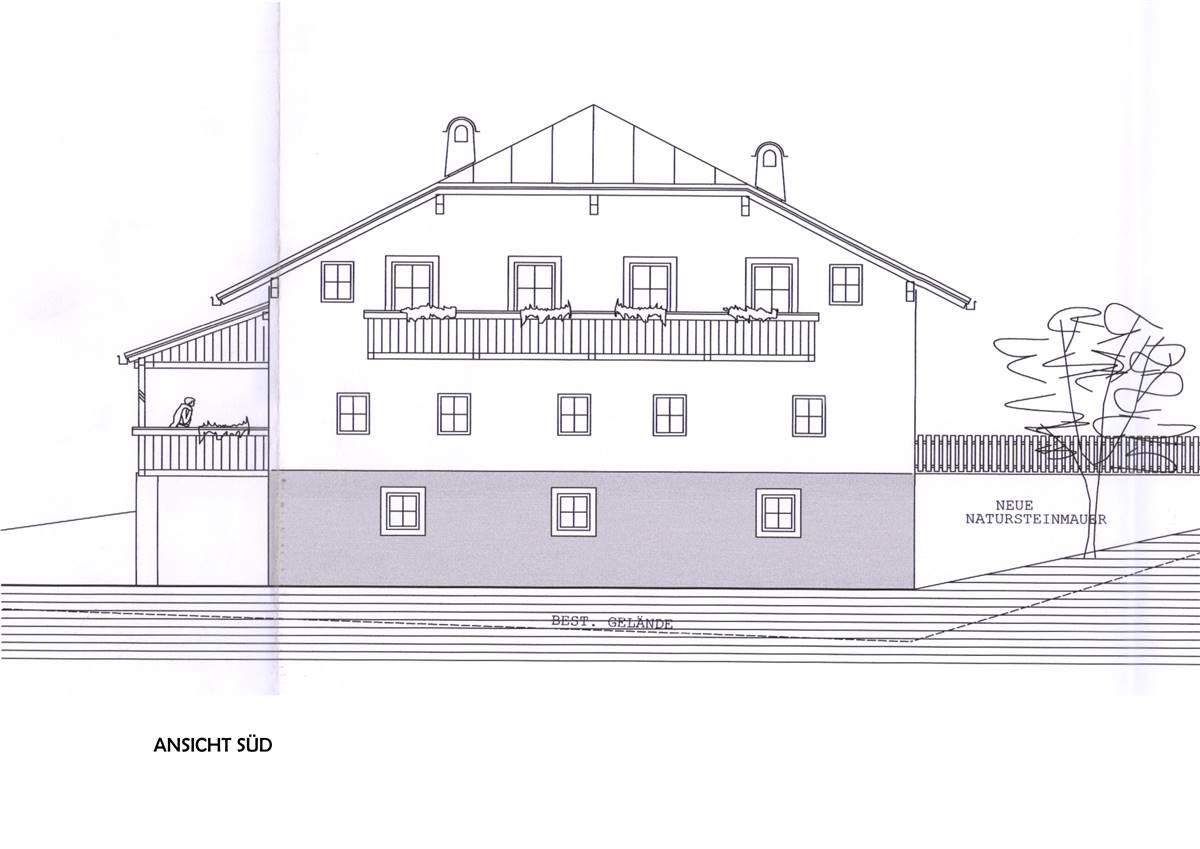

External finish:

Rendered

Internal finish:

Exposed woodwork

Roof type:

Pitched roof

.jpg)

.jpg)

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Fam. Markus Oberrauch

Rutzenberg 41, 39042 Brixen

info@platzbon.it

Tel. 39 334 18 40 958

Dr. Ing. Benno Graus

Rienzdamm 14, 39042 Brixen

ing.graus@gmx.net

Tel.+39 0472 835374

Klimahaus Energieberater - Geom. Thomas Graus

Am Hohen Feld 6, 39042 Brixen (BZ)

thomas.graus@gmail.com

Tel.+39 347 7448812

Dr. Ing. Benno Graus

Rienzdamm 14, 39042 Brixen

ing.graus@gmx.net

Tel.+39 0472 835374

RETROFIT SOLUTIONS

External Walls

Ground floor

Upper floor

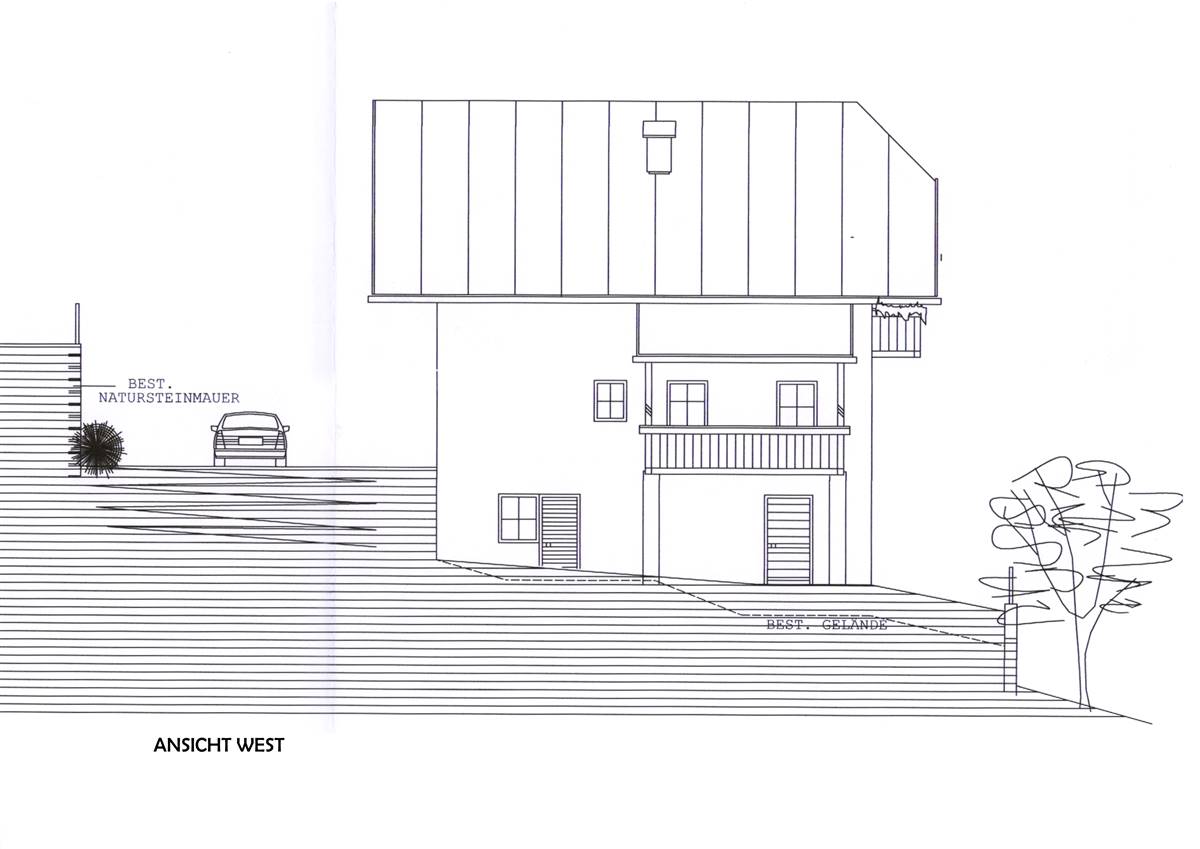

The 70cm thick, repaired existing wall of quarry stones was provided with a 12cm thick layer of lime-based insulating plaster. Röfix CalceClima Thermo (with a lambda value of 0.067 W/mK)and CalceClima Fino were used for the exterior plaster. For the interior plaster, Röfix CalceClima Ambiente and Röfix Smooth Lime were chosen. With these building measures, Climate House Standard B was achieved.

The existing walls on the ground floor were only insulated on the outside, as they were worth preserving on the one hand, and on the other hand, parts of the interior should be visible. This becomes clear from the exposed window lintels.

20 mm

700 mm

20 mm

20mm

700 mm

120 mm

20 mm

On the upper floor a complete demolition of the walls, renovated in the late 1960s, took place. Only the quarry stone wall on the uphill side was preserved. The walls were rebuilt with "insulating bricks" (Unipor W08 Plan bricks, 0.08 W/mK), which allowed to increase the thermal performance considerably.

This was possible, since the walls from the 1960s were not considered worth preserving.

20 mm

365 mm

50 mm

20mm

425 mm

20 mm

Windows

Three sectioned muntin window

New triple-glazed wooden sash bar windows were installed throughout the building. The insulation plaster was pulled up to the window jambs, the window jambs and blind jambs were replaced and airtightly sealed.

The heritage was taken into account mainly by the choice of material - wood - and the traditional division. The windows were completely replaced, only the lintel remained.

| Existing window type | Double window |

| Existing glazing type | Single |

| Existing shading type | Moveable shading |

| Approximate installation year | 1970 |

| New window type | Double window |

| New glazing type | Triple |

| New shading type | Moveable shading |

| New window solar factor g [-] | 0,55 |

Other interventions

ROOF

GROUND FLOOR

OTHER

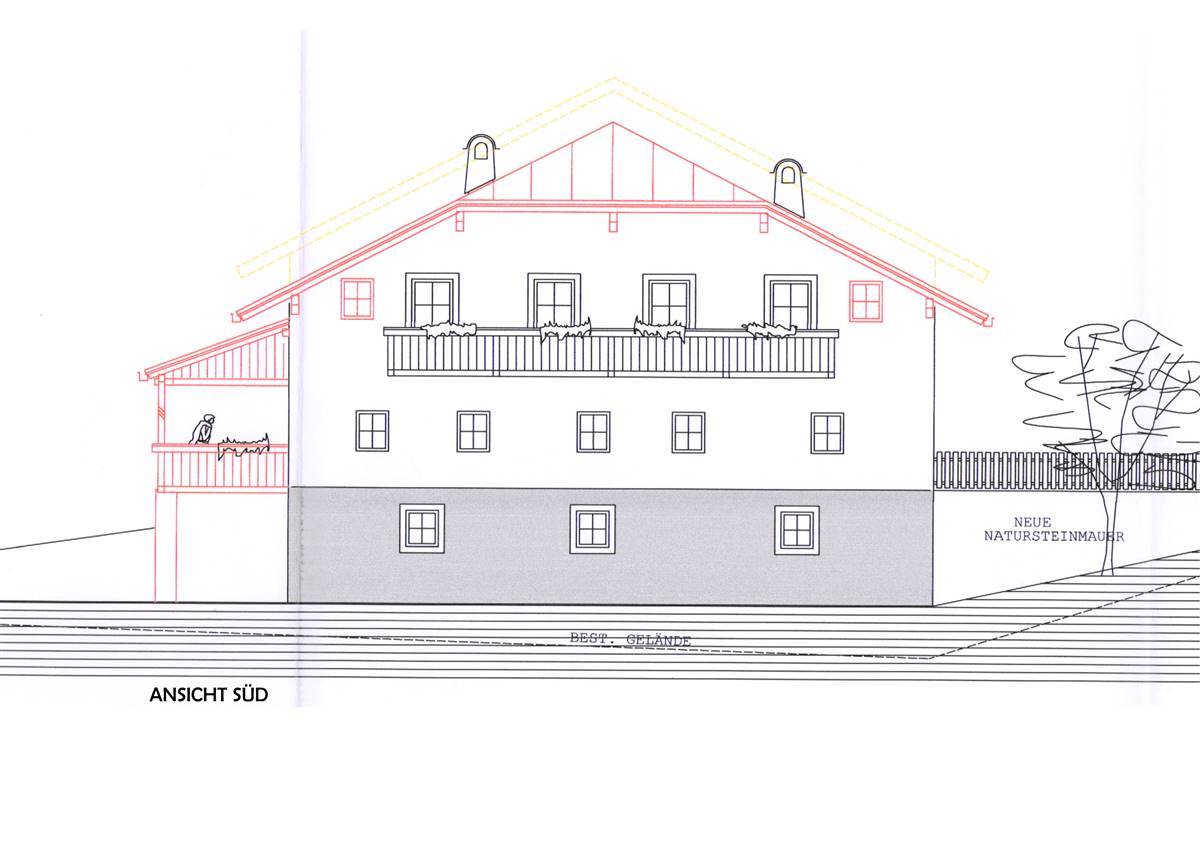

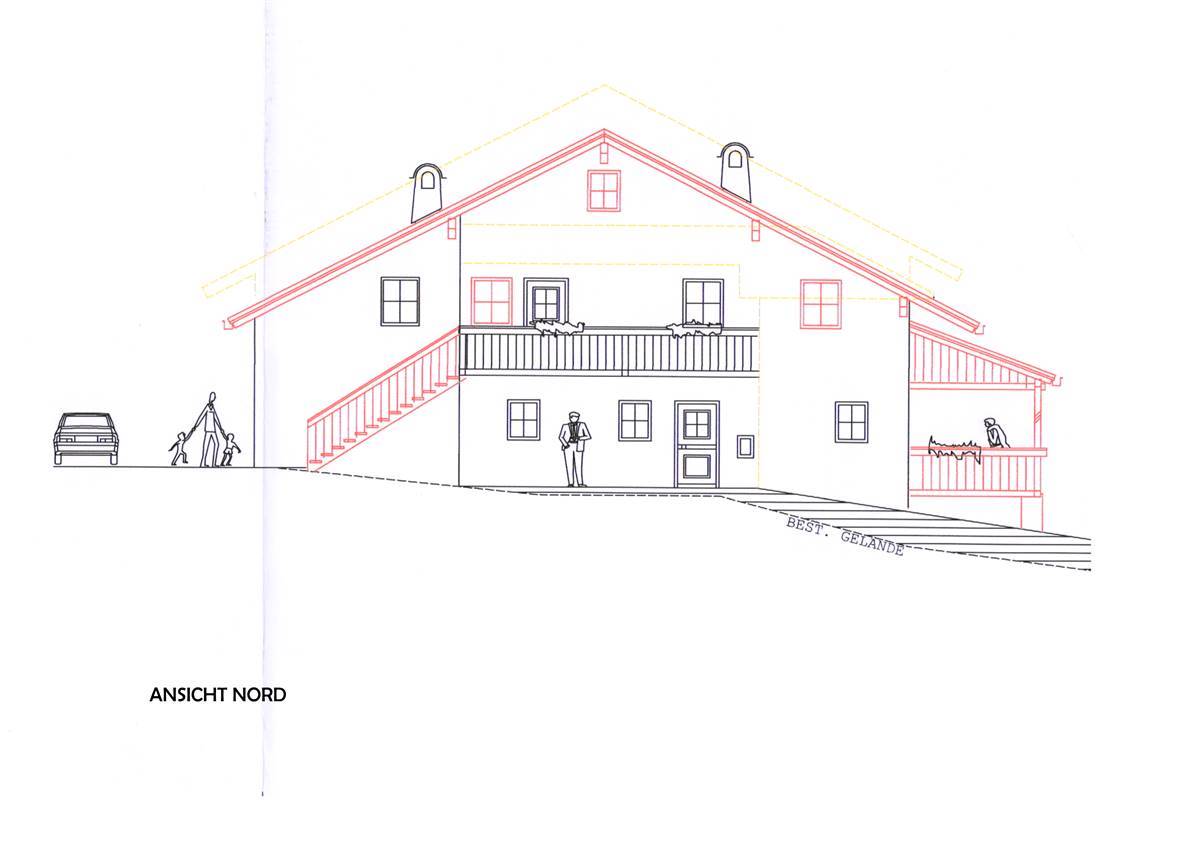

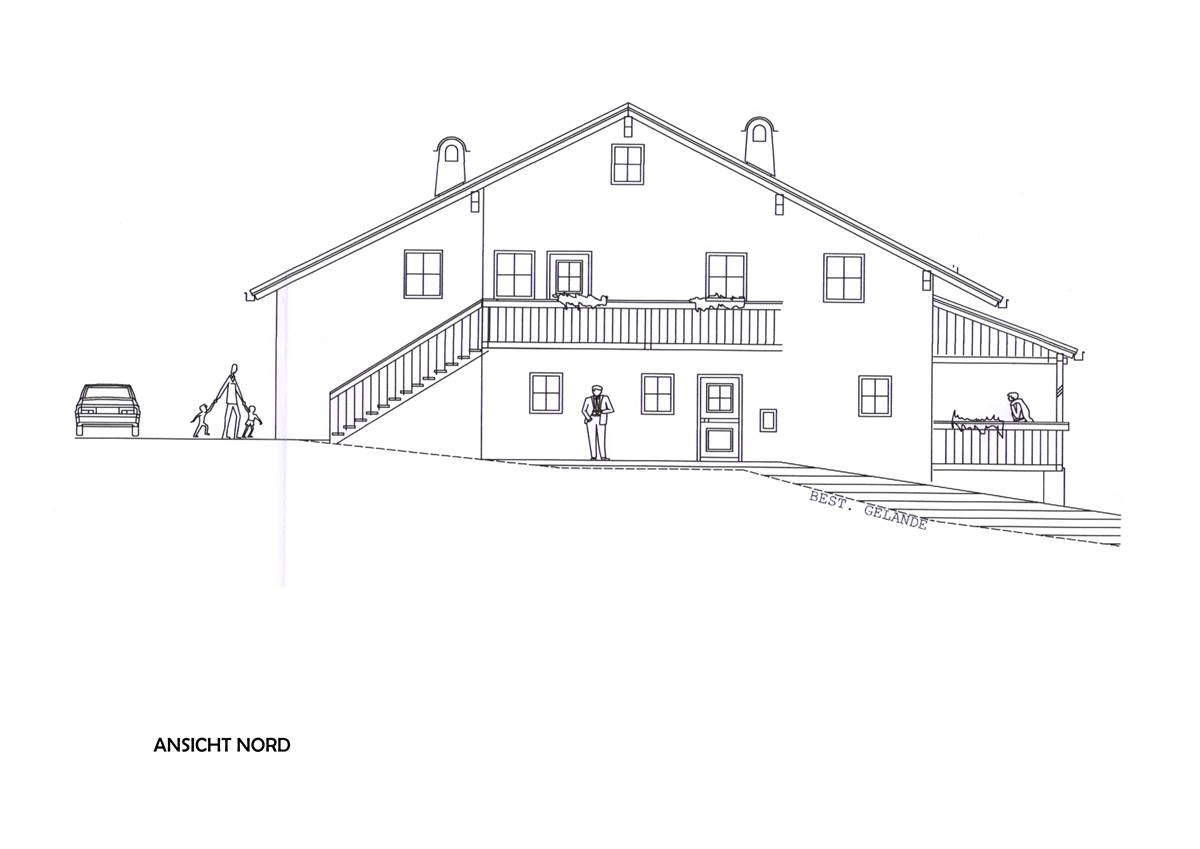

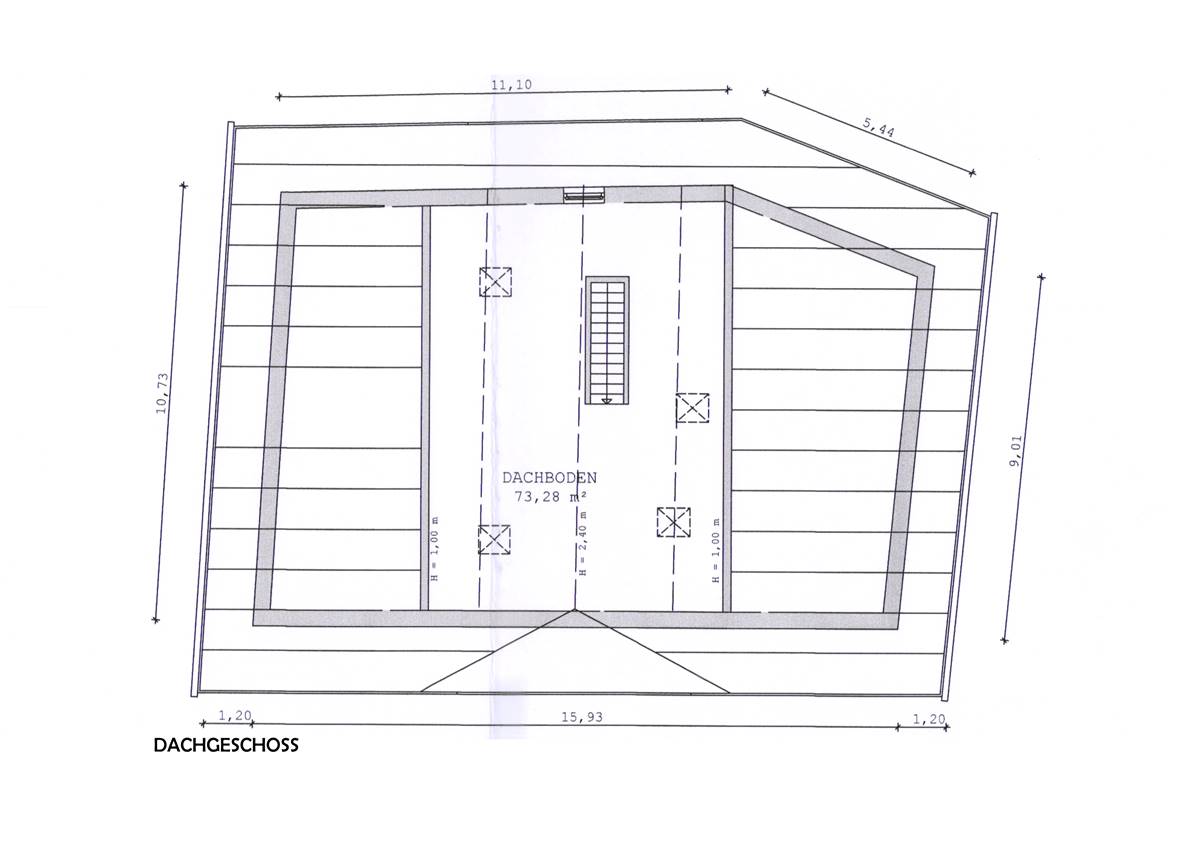

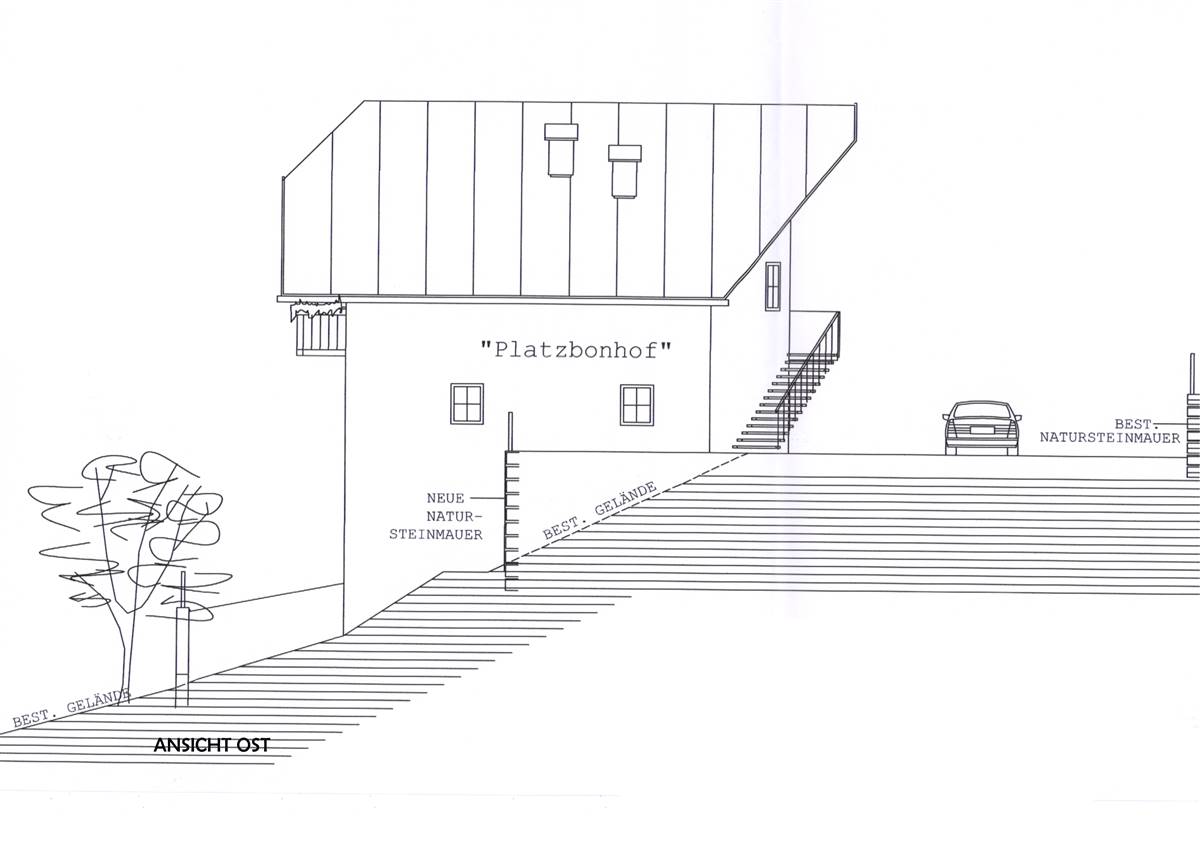

The building was partly demolished from the 1st floor onwards, renewed and the roof construction was raised to such an extent that another habitable floor was created.

However, the historical roof form was reconstructed - even if the construction from 1970 itself was not worth preserving. Actually, the roof was renovated at least 3 times in the last 150 years (1880, 1927 and 1967), but not completely, it was always just pieced up and repaired. The uninsulated roof truss would in no way have met the requirements of energy insulation, let alone the requirements of statics. During the renovation, the intermediate ceilings were also acoustically insulated (thickness approx. 50 cm), and the roof was consequently raised somewhat in order to still create sufficient living space on the upper floor.

70 mm

80 mm

240 mm

20 mm

70 mm

80 mm

20 mm

240 mm

20 mm

240 mm

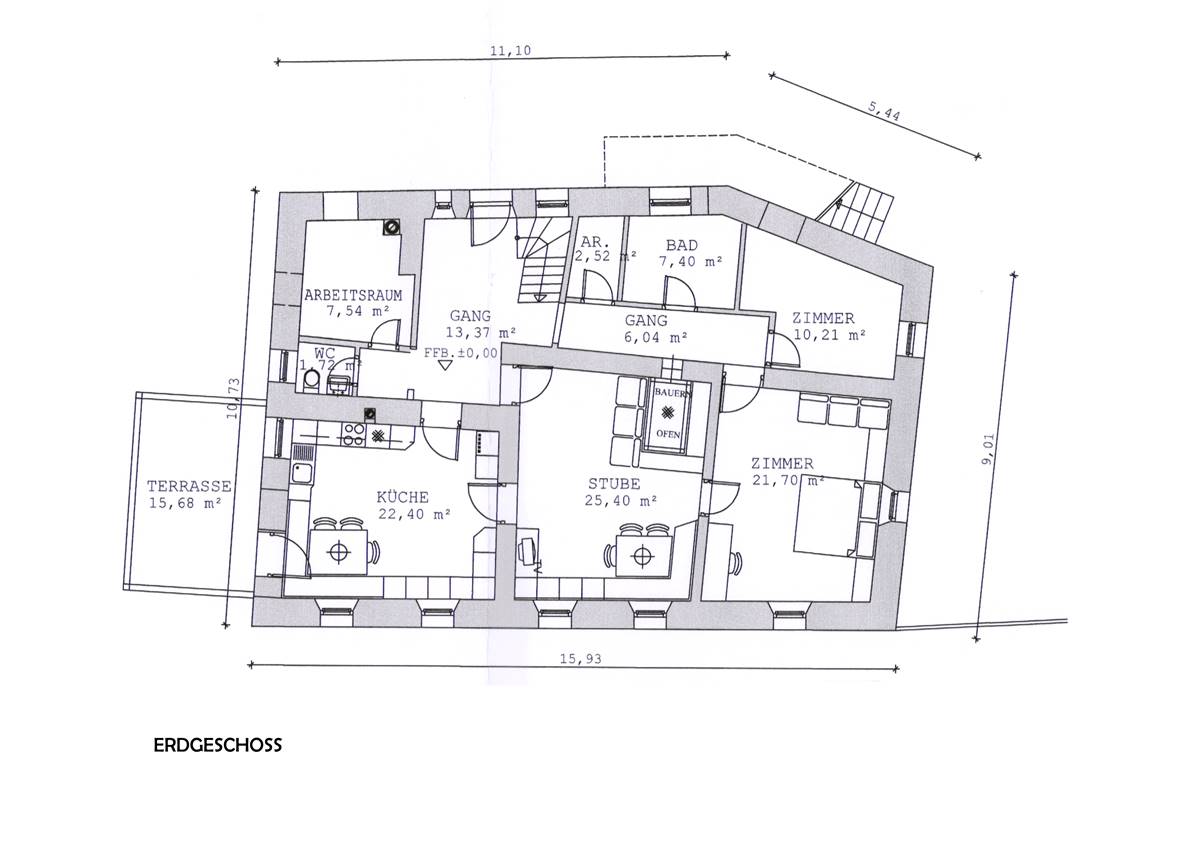

The floor covering was removed, partially repaired and reinstalled. Above the basement the wooden beam ceiling was reinforced, insulated and provided with a new floor construction. The part without cellar was replaced with additional reinforcement and gravel fill. In the area of the kitchen and the bathroom an underfloor heating was installed.

During the renovation, stone slabs of Brixner quartz phyllite were rediscovered. These were reused in the kitchen and the "Labe".

1000 mm

50 mm

785 mm

150 mm

100 mm

15 mm

The parlour and the parlour chamber from 1834 as well as the old panelling of the upper floor were expertly removed, restored and reinstalled.

Since the building had been energetically improved with insulating plaster, there was also no need for coordination conservation - energy.

HVAC

HEATING

DOMESTIC HOT WATER

Before the renovation, heating was only provided by the oven in the parlour and the stove in the kitchen. A boiler was installed, which is fired with wood chips and emits the heat mainly via radiators and partially via underfloor heating.

The historic oven in the parlour is still in operation, alongside the modern heating systems.

| New primary heating system | New secondary heating system | |

|---|---|---|

| New system type | Heizkessel | Stove |

| Fuel | Biomass | Biomass |

| Distribuition system | Radiators | Radiating surface |

| Nominal power | 30 kW | 7 kW |

RENEWABLE ENERGY SYSTEMS

Photovoltaic

Biomass

Two photovoltaic systems of 19 kWp each are installed on the roof of the nearby barn. One serves to generate electricity for the residential house and the other for agricultural use. Exchange with the electricity net takes place in both systems.

In order not to disturb the historical building apperance, the photovoltaic system was installed on the roof of the newly built barn.

| Photovoltaic System | |

|---|---|

| Type | Polycrystalline |

| Collector area | m² |

| Total nominal power | 38,0 kW |

The heating system is fired with wood chips. It consumes 120m³ per year - for hot water and heating for the house, but also hot water for the barn (milking machine cleaning and cattle watering).

The wood from the adjacent forests can be used, thus keeping the ecological footprint low.

The boiler and wood chip silo found a place under the entrance of the hayrick - additional soil had to be excavated for this purpose. The 2000-liter buffer storage is located in the cellar of the house and accessible via an external staircase.

| Biomass System | |

|---|---|

| Type | Chips |

| Storage size | |

| Origin of biomass | Holz aus anliegenden Wäldern |

| Overall yearly production | 30,0 kWh |

Energy Efficiency

Voluntary certificates: No

Consumption_estimation_Calculation_method: Steady state simulation (e.g. EPC, PHPP)

Consumption_estimation_After: 74 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: Steady state simulation (e.g. EPC, PHPP)

Consumption_estimation_Including_DHW: Yes

Consumption_estimation_After: 39 kWh/m2.y

Internal Climate

The interior temperature is described by the residents as comfortable. The different heating systems - underfloor heating, radiators and the parlour oven - can be used independently of each other and according to your well-being.

Due to the natural ventilation, the air quality is perceived as pleasant. In turn, the residents must contribute to a pleasant indoor climate by regularly airing the rooms through the windows.

The rooms are all sufficiently lit and give a pleasant feeling.

The acoustics have been significantly improved by installing impact sound insulation in the ceilings and the windows are now soundproofed.

Costs

NA

No

Environment

emissions_at_use_stage_after_intervention: 4 per m2

emissions_before_use: NA

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)