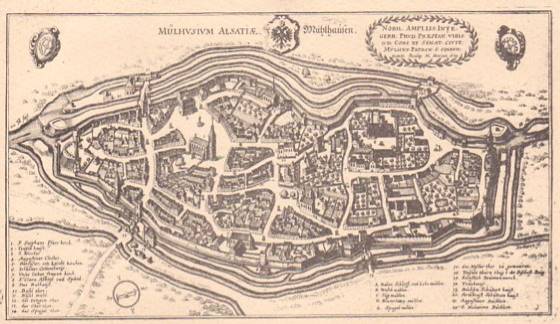

Elementary School in Mulhouse, France

21 Bis rue des Franciscains

68100

Mulhouse, France

Architect

Owner

Contact Details

Other Information

Please contact Ville de Mulhouse to visit the school outside of class hours.

The school is one of the case studies of the CREBA (French knowledge center for responsible retrofit of heritage building) website.

Climate Zone Cfb

Altitude 301 m a.s.l.

HDD 1961

CDD 719

Conservation Area:

No

Level of Protection:

The street-facing façade, the roof and two inner staircases are classified on the French supplementary historic monument list.

Year of last renovation:

2015

Year of previous renovation:

1980

Secondary use:

NA

Building occupancy:

Discontinuous occupancy (i.e. holiday home)

Number of occupants/users:

300

Building typology:

Detached house

Number of floors:

2

Basement yes/no:

Yes

Number of heated floors:

2

Gross floor area [m²]:

1925,0

Thermal envelope area [m²]:

5775,0

Volume [m³]:

5775,0

NFA calculation method:

SHON (fr)

External finish:

Rendered

Internal finish:

Lime coating

Roof type:

Pitched roof

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Ville de Mulhouse - Pôle Education et Enfance

11 avenue du Président Kennedy 68200 Mulhouse

education-enfance@mulhouse-alsace.fr

Tel.( 33)3 89 32 58 72

Pierre Lynde, Formats Urbains Architectes Associés

39 rue de Victor Schoelcher 68200 Mulhouse

contact@formats-urbains.fr

Tel. 33 (0)3 89 33 27 90

IBEO

39 rue de Victor Schoelcher 68200 Mulhouse

contact@ibeo.fr

Tel. 33 (0)3 89 33 27 98

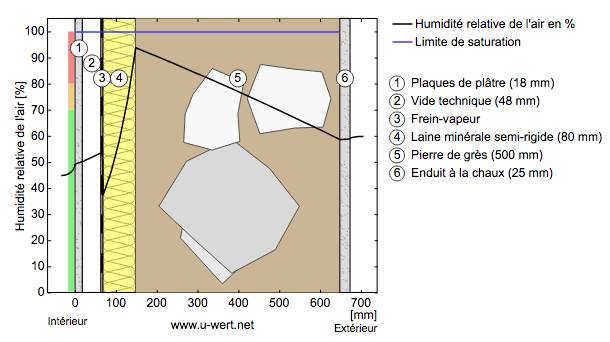

Hygrothermal assessment A dew point analysis was performed for walls.

Life Cycle Analysis (LCA) No life cycle analysis has been conducted.

Other BIM

RETROFIT SOLUTIONS

External Walls

Yellow sandstone and limestone rubbles

The original exterior lime coating was progressively replaced with of cement coating in the eighties. To put things back the way they were before and prevent more moisture-related damages, cement coating was removed and replaced with lime coating. In the interior, plaster coating was also removed and 8 cm of mineral wool and a humidity-variable vapour-retarder were installed and recovered with plasterboards. A technical space between the vapour-retarder and plasterboards was designed in order to pass the electrical network but also to prevent the piercing of the vapour-retarder. Biobased insulation was first chosen, but mineral wool was finally used because it was cheaper. A dew point analysis (see picture) was performed for walls to validate this choice.

The original exterior lime coating and some exterior decorations, like the lion's head, were restored. The colour of the lime coating is given by the local sand and close to the yellow limestone used to build the building. In the interior, there was no painting on walls or other elements to preserve. So there is no real issue about conservation compatibility

30 mm

500 mm

30 mm

25mm

500 mm

80 mm

1 mm

48 mm

18 mm

Windows

Double-glazed wooden windows

For cost reasons, only half of the windows was changed. There were already all double-glazed and some of them were replaced in 2010. The windows in bad state were replaced by wooden double-glazed windows with glazing bars. The others were repaired and adjusted and their seals were changed. The walls around the windows were not insulated because it was technical too difficult. So there are assumed thermal bridges between the walls and the windows.

The original single-glazed windows were replaced long ago. As there was no regulatory requirement on them, they were not replaced with identical ones. However, the windows are still in wood and with glazing bars.

| Existing window type | Casement window |

| Existing glazing type | Double |

| Existing shading type | NA |

| Approximate installation year | 1980 |

| New window type | Casement window |

| New glazing type | Double |

| New shading type | Inner curtains |

| New window solar factor g [-] | 0,5 |

Other interventions

ROOF

GROUND FLOOR

OTHER

MEASURES TO INCREASE AIRTIGHTNESS

The attic floor was insulated by the interior with 26 cm of mineral wool. A vapour-retarder was installed between the insulation and the ceiling cladding. The attic floor is suspended to the roof with iron fittings. This is the traditional technique, dating from the 18th century. But it does not comply with fire safety and every iron fitting had to be shuttered with plaster and wood. To even more security, a fire detector was installed in the attic. The tiles dated from the thirties. Only the ones in bad state were replaced.

Original tiles were replaced long ago. Dormers, that had been removed, were rebuilt in a more contemporary style. They today hide the exhaust and air intake stacks of the two dual-flow air handling units of the building. All these works were validated by the Regional commissioner for historic monuments, as the roof is a listed part of the school. Therefore, there is no issue about conservation compatibility.

20 mm

200 mm

20 mm

20 mm

200 mm

260 mm

20 mm

The ground floor sits on a concrete slab. It was insulated with 8 cm of polyurethane and an underfloor heating was installed above.

Original ground floor were replaced long ago. Therefore, there is no real issue about conservation compatibility. Regarding the high ceilings, adding insulation on the ground floor did not have a noticeable impact on floor level.

200 mm

1 mm

200 mm

80 mm

50 mm

1 mm

To prevent moisture accumulation in the lower sections of the buildings, a paved strip of 1 m 40 was managed between the walls and the bituminous surfacing of the backyard (see picture). Almost all the joists ends of the intermediate floors were mouldered. It was decided to completely replaced these floors (see picture). The new floors, consisting in hollow-care slabs, have several advantages : they have a better fire resistance, provide a better acoustic comfort and strengthen more effectively the structure than wooden floors. Because of the foundations that had subsided from several centimeters, concrete screeds were poured on the new intermediate floors in order to have a right horizontal surface. The peripherical edges of the new floors were not insulated so there are assumed thermal bridges between the walls and the intermediate floors. Thanks to the construction of the new building in the backyard, the canteen and the technical room were removed from the ground floor of the existing building. This resulted in a space saving and the school can now welcome 18 classes instead of 13 before. The interior design was also rearranged, in order to comply with the accessibility requirements. An elevator and new staircases were installed.

In the second floor, the ceiling of the rococo style lounge was preserved and reinforced from above with steel beams. A derogation was delivered for the two listed staircases, as they could not be brought up to regulatory accessibility standards. There is no issue about conservation compatibility.

The carriage entrance was very leaky. On the other hand, it was not used any more as an entrance for pupils. So the solution was to install in the inside a glazed door, more airtight, in front of the carriage entrance (see picture). An airtightness test was conducted, even if it is not required for French low energy building label for existing non-residential buildings, and lead to a good value, even lower than what is required for new non-residential buildings. To improve this value, some adjustments on windows and on the door giving in the attic were done. NB : the only available value was the French airtightness indicator Q4Pa,surf, which can not be converted in n50 without some other values, that are unfortunately missing.

HVAC

HEATING

VENTILATION

The technical room was shifted from the existing building to the new one. It shelters two condensing gas boilers of 224 kW each, that cover 200 % of the heating demand. This is a specific requirement of the city of Mulhouse, in case of failure of one of the boilers. A underfloor heating was installed in the entire ground floor. The intermediate floors are heated with new radiators. The cost of the reuse (checkup, cleaning, painting and storage) of the existing ones was judged too expensive. Temperature is being controled in each classroom by the city's technical services, to the nearest 0,1 degrees Celsius, thanks to a building management system (BMS). This BMS was also installed in the new building and energy consumptions of both buildings are monitored. The BMS needed several months to be fully operational.

There are few remainings of the interior design and the existing radiators were installed in the 20th century. Therefore, there is no issue about conservation compatibility.

| New primary heating system | New secondary heating system | |

|---|---|---|

| New system type | Boiler | Condensing |

| Fuel | Gas | Gas |

| Distribuition system | Radiators | Radiating floor |

| Nominal power | 0 kW | 244 kW |

There was no mechanical ventilation. Improving indoor air quality, even above the French regulatory standards, was one of the objective of the retrofitting. As natural ventilation hardly meet the regulation, a mechanical system was installed. Two dual-flow air handling units were installed in the attic (see picture) and the exhaust and air intake stacks were hidden in the new dormers. They are only functioning during the class hours, in order to save energy. In winter, the fresh air is filtered to eliminate fine particles, then preheated by the heat exchanger and a hot water battery and finally distributed all over the classrooms at a temperature of 21 °C. The air flow is calculated from the number of pupils in the classroom and the exhaust and air intake vents are located on both sides of the classroom to ensure an effective ventilation. In mid-seasons, the heat exchanger by-pass is activated and the fresh air is not preheated anymore.

The two dual-flow air handling units are installed in the attic. The integration of the exhaust and air intake stacks in the new dormers was validated by the Regional commissioner for historic monuments. In the interior, the ducting needed for the air handling system resulted in lowered ceiling. But as there was no painting on walls or other elements to preserve, there is no real issue about conservation compatibility.

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Centralized |

| Type flow regime | Cascade |

| Heat recovery | Yes |

| Humitidy recovery | No |

| Nominal power | Unknown kW |

| Electric power | 0,0 kW |

| Control system | Yes |

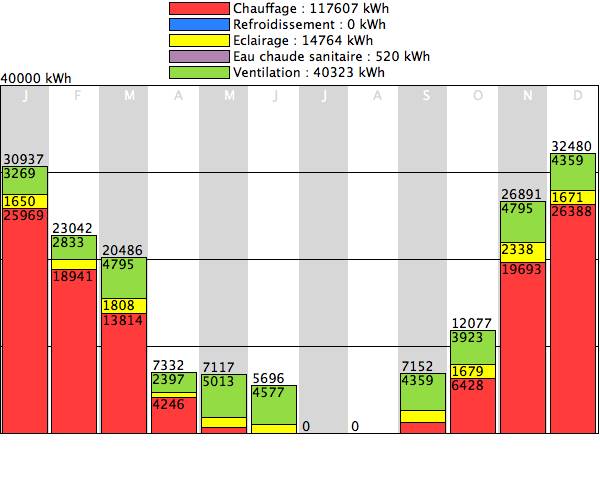

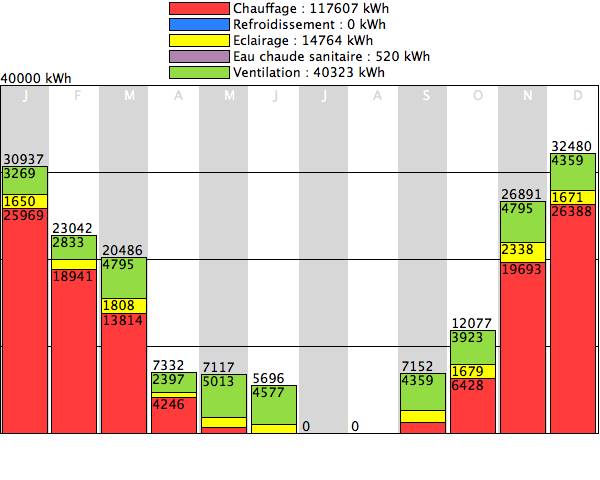

Energy Efficiency

Voluntary certificates: The retrofitted school obtained the French low energy building ("Bâtiment basse consommation") label. To obtain this label, the consumption for heat, domestic hot water, ventilation, lighting and pumps must be calculated with a State approved calculation software and be lower than 40% compared to a calculated reference. The energy consumption detail can be find in the energy use section. It shows that heating is the largest energy user in the building, followed by ventilation.

Primary Energy 69 kWh/m2.y

Consumption_estimation_Before: 214 kWh/m2.y

Consumption_estimation_After: 69 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: Steady state simulation (e.g. EPC, PHPP)

Consumption_estimation_Before: 214 kWh/m2.y

Consumption_estimation_After: 69 kWh/m2.y

Type_of_monitoring: Continuous

Description: The classrooms temperature and air flow are constantly monitored by the building management system and adjusted.

Internal Climate

The classrooms temperature is constantly monitored by the building management system and adjusted. Overheating was reported at the end of the school year in 2017. The dual-flow air handling units were programed to provide a constant indoor temperature. This probably means that the windows were opened although they were supposed to remain closed for the good functioning of the units.

Improving indoor air quality, even above the French regulatory standards, was one of the objective of the retrofitting. Two dual-flow air handling units include fine particles filters and the classrooms air flow is constantly monitored by the building management system and adjusted.

Visual comfort was also studied. Indirect lighting and white-coloured paints were favored in the classrooms. LEDs and presence detectors were also installed, as lighting is a major energy consumer in non-residential buildings.

Acoustic comfort is very important in a school. Acoustic suspended ceiling were installed both in the classrooms and in the circulations.

Costs

In the first version of the project, achieving the French low energy building ("Bâtiment basse consommation") label was not an objective. But thermal simulations showed that it was technically possible. Thanks to a grant from the Alsace Region and the French environment and energy management agency, the label was also financially achievable.

No