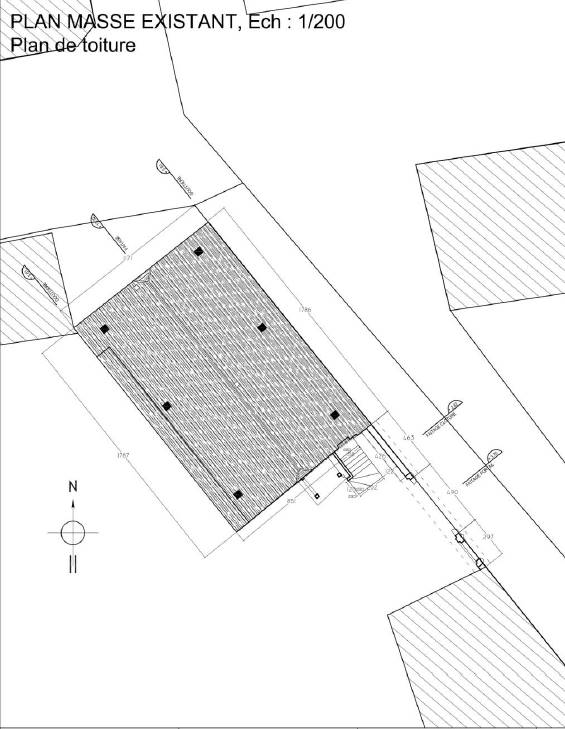

Timber-framed house in Alsace, France

67370

Schnersheim, France

Architect

Owner

Contact Details

Other Information

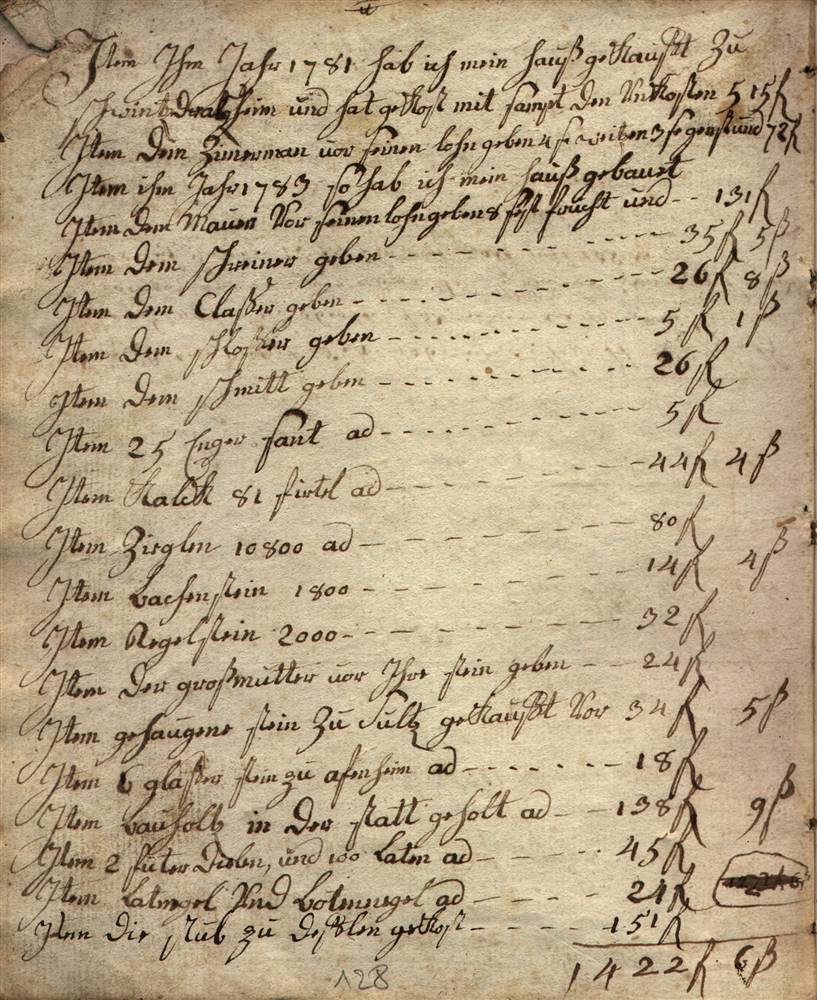

The owner is involved in a heritage protection association and often organises open house day for its members.

The house is one of the case studies of the CREBA (French knowledge center for responsible retrofit of heritage building) website.

Climate Zone Cfb

Altitude 184 m a.s.l.

HDD 3101

CDD 96

Conservation Area:

No

Level of Protection:

None

Year of last renovation:

2010

Year of previous renovation:

2015

Secondary use:

NA

Building occupancy:

Permanently occupied

Number of occupants/users:

2

Building typology:

Detached house

Number of floors:

2

Basement yes/no:

Yes

Number of heated floors:

2

Gross floor area [m²]:

350,0

Thermal envelope area [m²]:

875,0

Volume [m³]:

875,0

NFA calculation method:

SHON (fr)

External finish:

Rendered

Internal finish:

Lime and clay coating

Roof type:

Pitched roof

RENOVATION PROCESS

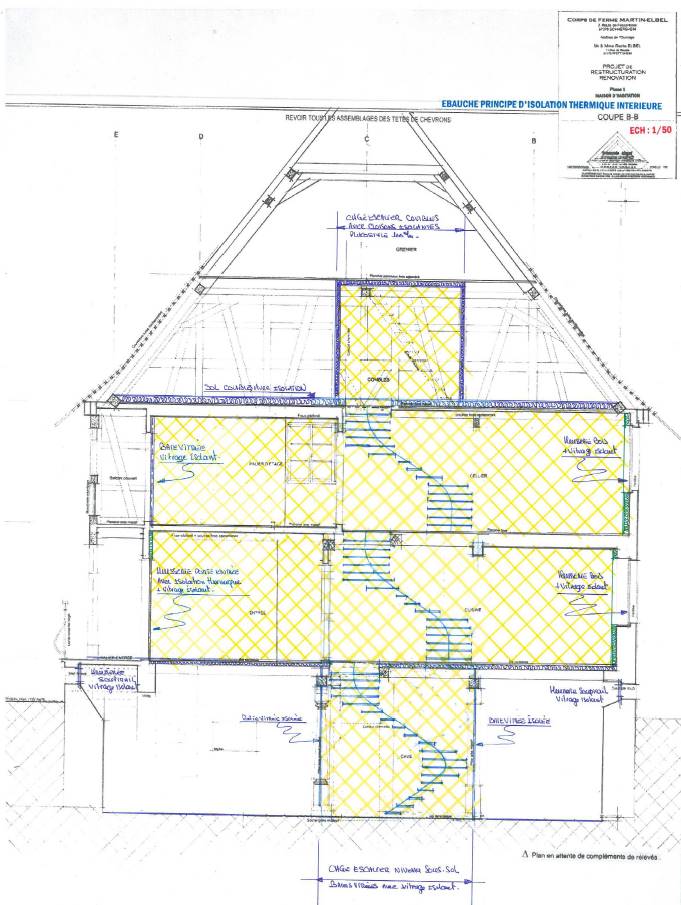

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

ELBEL Malou and Denis

Non applicable

Claude Eichwald, maître d'oeuvre

5 route de Weinbourg - 67340 Weiterswiller

claude.eichwald@wanadoo.fr

Tel.(33)3 88 89 55 65

Jean-Christophe Brua, atelier d'architecture JCBA Sarl

22 rue La Fayette 67100 Strasbourg

contact@jcba.fr

Tel.(33)6 87 41 42 09

Hygrothermal assessment A dew point analysis was performed for walls, basement ceiling and attic floor.

Life Cycle Analysis (LCA) No life cycle analysis has been conducted, but most of the materials that were used are biobased and not made from petrochemical products.

RETROFIT SOLUTIONS

External Walls

Timber-framed walls filled with cob and bricks

12 to 18 cm of lime-hemp concrete was sprayed on walls. A dew point analysis was performed for walls, as well as for basement ceiling and attic floor, to validate the choice of this insulating material. The project team was aware that the post-intervention U-value was not as good as it should be, but decided to compensate on other elements. Lime-hemp concrete was chosen because it is permeable to vapour and that it has so a similar behaviour to cob. Besides, lime-hemp concrete increases the sensation of comfort of the occupants, what was one of the objective of the owner. To avoid air leakages and thermal bridges, the flooring from the second storey was removed in order to spray the lime-hemp concrete in a continuous way through the storeys. Some pieces of the wooden-frame were missing because they had been sawed for convenience, to install a window for example. They were reinstated to prevent structural damages. The "Brandwand", that caused the differential settlement because it was too heavy, was replaced by a timber-framed wall, filled with lime-hemp concrete and a with a steel beam on its top. The whole structure was cut by 7 tonnes. To prevent an other structural damage, a reinforced concrete footing was poured in the basement. There differentiel settlement of 12 cm is still visible but the structure has been stabilized.

There was no painting on walls or other elements to preserve and the "Stub" has been repositionned after the works. So there is no real issue about the conservation compatibility, although the lime-hemp concrete is not a reversible intervention. The interior render was coloured with natural pigments from the local lime-burner. The plastic coating and the exterior organic render were removed, as the multiple layers of wallpaper and interior coating. No tiling and no wallpaper were put on the new interior lime render, to let vapour freely transit through the walls. The walls are indeed permeable to vapour from the exterior to the interior, thanks to the materials that were used.

20 mm

160 mm

20 mm

20mm

160 mm

180 mm

20 mm

Windows

Double-glazed wooden windows dedicated to heritage buildings

All the original single-glazed wooden windows were replaced by double-glazed ones. Thanks to pictures from the beginning of the 20th century, it was possible to restore the windows as they were originally. The doors were replaced by more traditional ones. The outside shutters are the original ones. A loggia was created in the second storey by removing cob from timber-frame and installing a double-glazed fixed window against the interior surface of the wall. This brings light to the house, knowing that these traditional houses are often depreciated because of their lack of light. The windows are all in oak and some are arched. They are made of four casements that can be opened independently.

The windows were all replaced, but the new ones are identical to the original ones, except the glass, which is a double-glazing dedicated to heritage buildings. The windows were made to measure by a local joiner. This was the only exterior work related to heritage for which the Alsatian architectural review board, charged for validating these works not by regulation but because of a grant application, had to be convinced. They thought indeed that double-glazing, even dedicated to heritage buildings, would be too thick and that it would be impossible to maintain the original proportions of the windows. So the owner and the joiner had to produce a prototyp, that finally convinced the board.

| Existing window type | Casement window |

| Existing glazing type | Double |

| Existing shading type | Outer shutter |

| Approximate installation year | 1970 |

| New window type | Casement window |

| New glazing type | Double |

| New shading type | Outer shutter |

| New window solar factor g [-] | 0,5 |

Other interventions

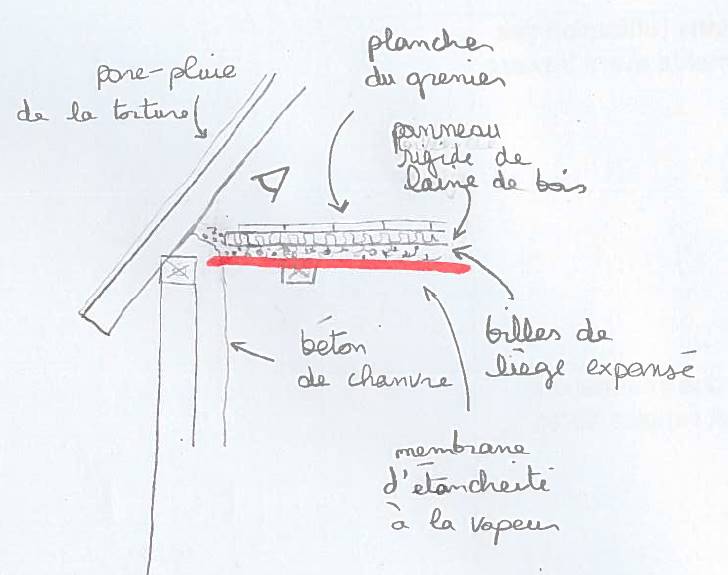

ROOF

GROUND FLOOR

OTHER

MEASURES TO INCREASE AIRTIGHTNESS

The tiles were replaced by traditional ones, called "Biberschwanz" (beaver tails). A rain screen, that was not originally present, was installed. The roof windows were replaced by dormers, which shape is more traditional. Modern roof vents were also replaced by more traditional ones in copper. After installing a vapour retarder, the attic floor was insulated with about 9 cm of granulated cork (in order to get the floor horizontal) and with two cross-coats of wood-fibre panels of 10 cm. The top of the stairwell was insulated with 20 cm of granulated cork and 4 cm of woodwool.

Original details like dormers were restored. Others interventions like installing a rain screen or insulating the floor of the attic are invisible to the occupants and reversible. Therefore, there is no issue about conservation compatibility.

20 mm

200 mm

25 mm

100 mm

90 mm

1 mm

20 mm

200 mm

The basement is only located under a half of the first storey. Before retrofitting, there was a lot of moisture in the basement, because of : - the use of materials which were not permeable to water vapour, like concrete ; - the lack of ventilation ; - a naturel high moisture load due to the location of the house on a light slope. The basement concrete slab was removed and replaced by different layers of pebbles and sand to ensure drainage. A new flooring with reused terracotta tiles was created. The joists of the floor separating the basement from the first storey were mouldered because of the high moisture load of the basement. They were replaced and the floor was insulated between the new joists with 13 cm of lime-hemp concrete. Where there was no basement, a technical room was excavated by underpinning in order to shelter the boiler, the pellet silo and the ventilation system. The new floor consists in a reinforced concrete slab and a lime screed with expanded clay balls. The first storey is covered with parquet or with traditional flooring of wood and reused terracotta tiles.

Original details like the traditional flooring were restored. Others interventions like installing the ventilation system or insulating the floor are invisible to the occupants, but not really reversible because of the concrete and the screed. Therefore, there is no real issue about conservation compatibility.

200 mm

20 mm

200 mm

30 mm

The house is constructed on a light slope. In order to reduce the water pressure on the highest external wall and to lower moisture load in the basement, a gutter was dug and paved at the exterior side of the wall.

There is no issue about conservation compatibility.

The heated envelope was clearly defined in order to avoid air leakages. The central stairwell, that goes from the basement to the attic, is separated from the basement by double-glazing bay windows and by a door from the attic. Besides, the intermediate floor was dismantled in order to realize complete hemp-lime concrete spraying, avoiding thermal bridges and air leakages between the floors. Despite taking all possible care, the wooden joists and the heating distribution network between the technical room and the first storey were still not perfectly airtight.

HVAC

HEATING

VENTILATION

DOMESTIC HOT WATER

A 25 kW pellet boiler of an efficiency of 95 % was installed in the technical room. It provides heating and domestic hot water thanks to two storage tank (300 and 800 L respectively). The pellet silo is also stored in the technical room. The worm screw usually used to convey pellets to the boiler was replaced by an aspiration system. Indeed, worm screw can cause ignition and the owner did not want to take this risk in a timber-framed house. At the beginning of the project, a geothermal heat pump was first considered but rapidly abandoned because of the high cost of it and technical issues. A traditional stove, called "Kachelofe", was installed in the heated envelope as an additonal heating. This kind of stove was the principal heating system in Alsatian houses before the 20th century. It is supplied by logs and takes its air supply directly from the outside. The owner did not want to have imposing radiators in his home, so he opted for an innovative distribution system by baseboards.

The boiler, the pellet silo and the storage tank are installed in the technical room. The stove is a traditional one. The distribution system is hidden in the baseboards. Therefore, there is no issue about conservation compatibility.

| New primary heating system | New secondary heating system | |

|---|---|---|

| New system type | Boiler | Stove |

| Fuel | Biomass | Biomass |

| Distribuition system | Radiating baseboards | No distribution system |

| Nominal power | 25 kW kW | Unknown kW |

A balanced ventilation with heat recovery was installed in the first storey and a simple mechanical ventilation in the first storey. The air exchange unit was installed in the technical room, where the temperature is always higher than 20 °C in winter. The owner did not want to see the exhaust and air intake vents on the roof, so he hid them behind shutters and near an exterior staircase. The ventilation distribution system consists in smooth semi-flexible conduits. A maintenance contract was signed between the owner and the ventilation system supplier : the conducts will have to be cleaned every 4 years and the filters changed every 6 months. The owner also wanted the ventilation distribution network to be invisible. So the air supply units were installed between the joists and covered with lime-hemp concrete and the air extract unit in load-bearing walls or even in pieces of furniture. All these units where made to measure and were placed in order to guarantee a good flushing of the air. In order to avoid a high moisture load in the basement and in the technical room, the windows are always opened in summer. In winter, they are closed but a simple mechanical ventilation is turned on.

The ventilation system is installed in the technical room. The ventilation distribution system is hidden in load-bearing walls, pieces of furniture or covered with lime-hemp concrete. The exhaust and air intake stacks are hidden behind a shutter and near an exterior staircase. Therefore, there is no issue about conservation compatibility.

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Centralized |

| Type flow regime | Cascade |

| Heat recovery | Yes |

| Humitidy recovery | No |

| Nominal power | Unknown kW |

| Electric power | 0,0 kW |

| Control system | No |

RENEWABLE ENERGY SYSTEMS

Biomass

The boiler uses pellets and the traditional stove logs.

Non applicable

| Biomass System | |

|---|---|

| Type | |

| Storage size | |

| Origin of biomass | |

| Overall yearly production | 0,0 kWh |

Energy Efficiency

Voluntary certificates: The retrofitted house obtained the French low energy building ("Bâtiment basse consommation") label. To obtain this label, the consumption for heat, domestic hot water, ventilation, lighting and pumps must be calculated with a State approved calculation software and be lower than 104 kWh.m2.year in primary energy.

Primary Energy 94 kWh/m2.y

Consumption_estimation_Before: 352 kWh/m2.y

Consumption_estimation_After: 94 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: Steady state simulation (e.g. EPC, PHPP)

Consumption_estimation_Before: 352 kWh/m2.y

Consumption_estimation_After: 94 kWh/m2.y

Internal Climate

On a hot day (36 °C at the exterior), with shutters and windows closed, the interior temperature was 25 °C at midday.

The glazed loggia brings light to the house, knowing that these traditional houses are often depreciated because of their lack of light.

Costs

The owner spared no expense on the retrofitting of his house. The energy retrofitting awarded a regional grant of 10 000 €, according by the Alsace Region and the main electricity supplier in Alsace. The grant also paid the airtighness tests and the visit of a building control office. The restoration obtained a national grant that funded 1 % of the total costs of the exterior works related to heritage (tiles, roofs, framework, exterior render, etc) and that allowed the owner to get a tax credit amounting 25 % of these costs. As the building is not located in a conservation area, this was the only works were the validation of the Alsatian architectural review board was required.

Cost of energy related interventions:

150 000 € (pre-tax prices) (total)

Amount includes: The whole energy retrofitting of the house costs 150 000 € (pre-tax prices). It includes labour and supplies. It does not include either the restoration costs or the windows, made to measure. To this is added a 280 €/year (pre-tax prices) maintenance contract for the balanced ventilation and a 216 €/year maintenance contract for the heating system. 50 % of these costs was for the heating and domestic hot water system ; 17 % for the walls insulation with lime-hemp concrete ; 15 % for the ventilation system.

With a 9 tonnes pellets consumption, the annual heating cost amounts to 2500 €. (total)

Lifecycle cost

No