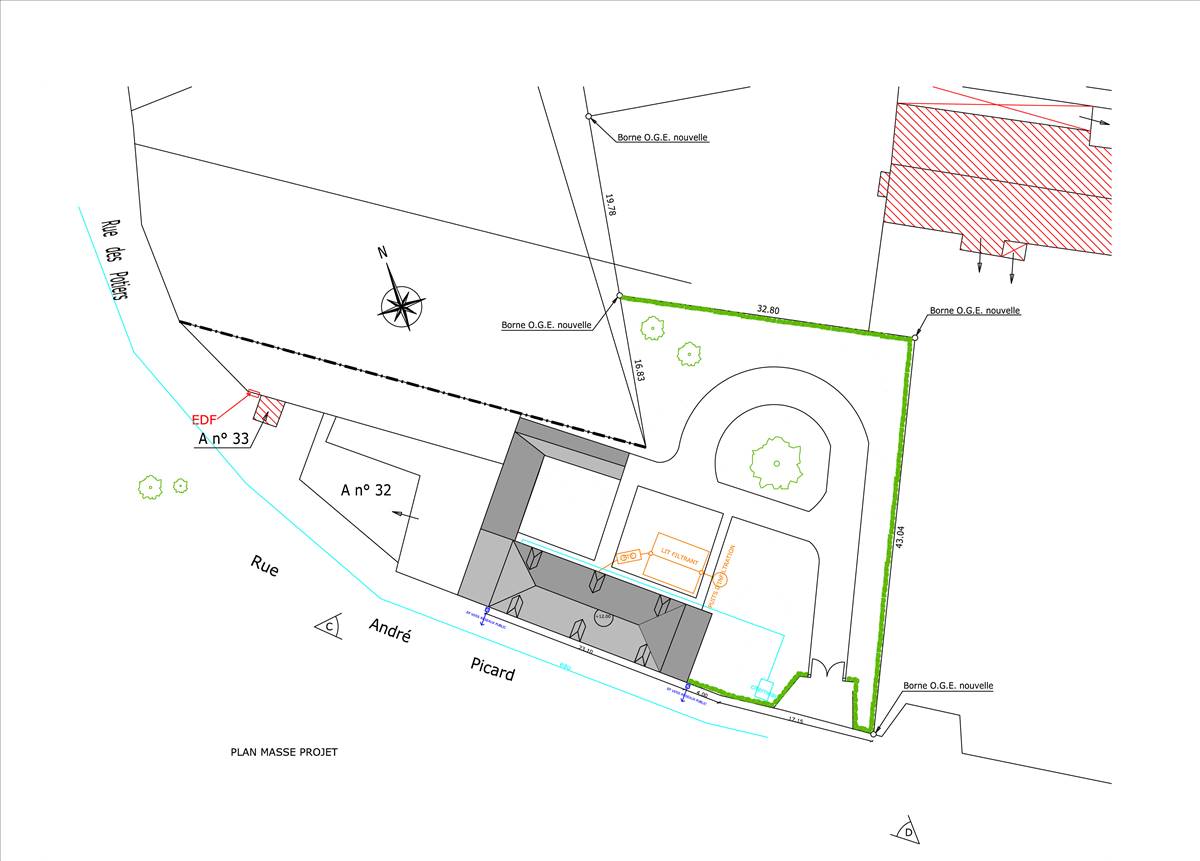

Timber-framed barn in the north of France

60220

SAINT-SAMSON-LA-POTERIE, France

Owner

Contact Details

Other Information

http://www.rehabilitation-bati-ancien.fr/fr/retours-d-experiences/reconversion-dune-grange-seigneuriale-en-logement-performant-0

Climate Zone Cfb

Altitude 198 m a.s.l.

HDD 1901

CDD 524

Conservation Area:

No

Level of Protection:

Year of last renovation:

1700

Year of previous renovation:

1700

Secondary use:

NA

Building occupancy:

Permanently occupied

Number of occupants/users:

4

Building typology:

Detached house

Number of floors:

3

Basement yes/no:

No

Number of heated floors:

3

Gross floor area [m²]:

400,0

Thermal envelope area [m²]:

1000,0

Volume [m³]:

1000,0

NFA calculation method:

SHON (fr)

External finish:

Rendered

Internal finish:

Plastered (on substructure)

Roof type:

Pitched roof

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Guillaume ALGLAVE

60220 SAINT-SAMSON-LA-POTERIE

Other Studies were conducted in order to choose the heating system, including geothermal heating.

RETROFIT SOLUTIONS

External Walls

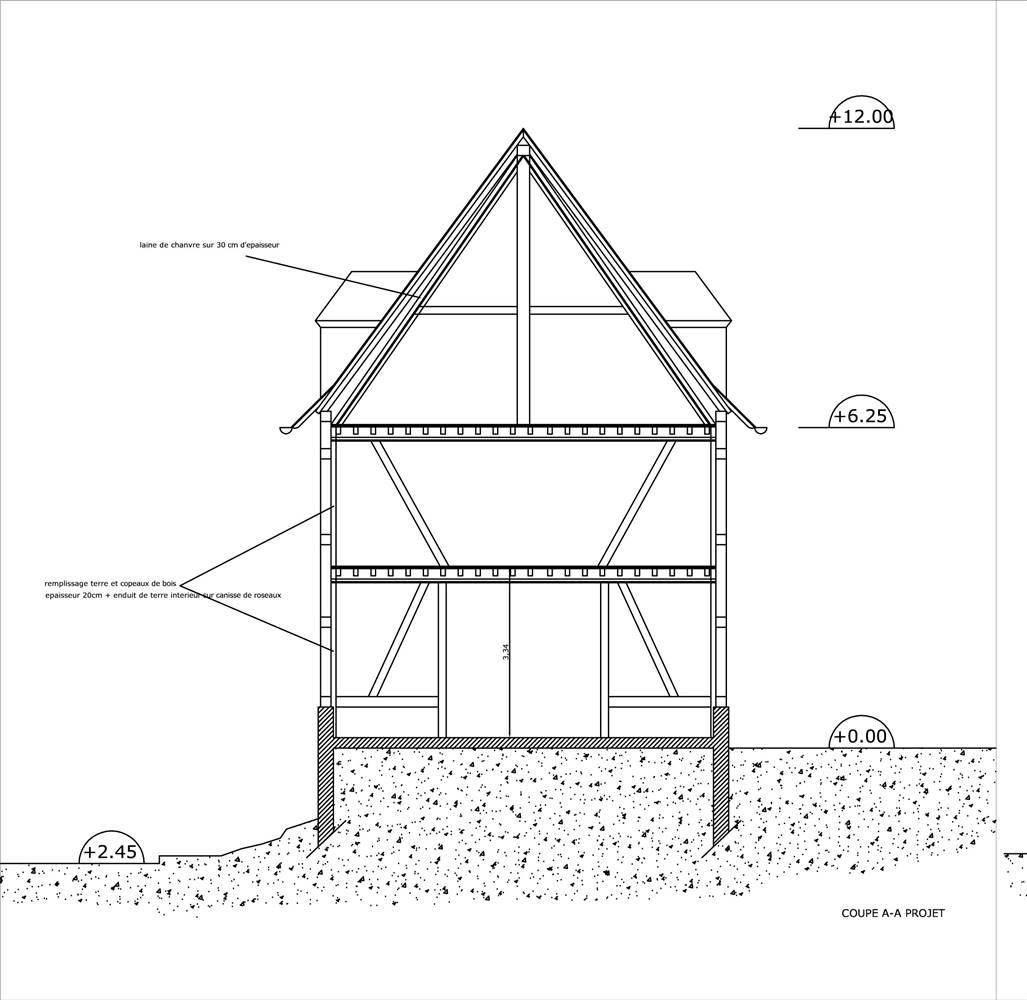

Timber-framed walls filled with cob

The ground floor and the first storey were insulated from the interior with 20 cm of hemp wool on wood frame. The insulation was rendered, as traditionally, with the earth from the manufacture, clay rich, on chestnut laths. No airtightness membrane was installed because the render is naturally airtight when well dosed and well executed. Besides, the render was assumed by the owner to be a sufficient vapour barrier. In fact, it is not the case and the installation of a vapour barrier or the use of another insulations solutions could have avoided internal condensation in the walls. The exterior façades were rendered with a lime and clay plaster. Between the wooden frame and the render, the plaster is being processed at 45° to the outside. This allows the wind-driven rain to be evacuated away from the wooden frame. All renders were executed in Spring, in order to let them dry long enough.

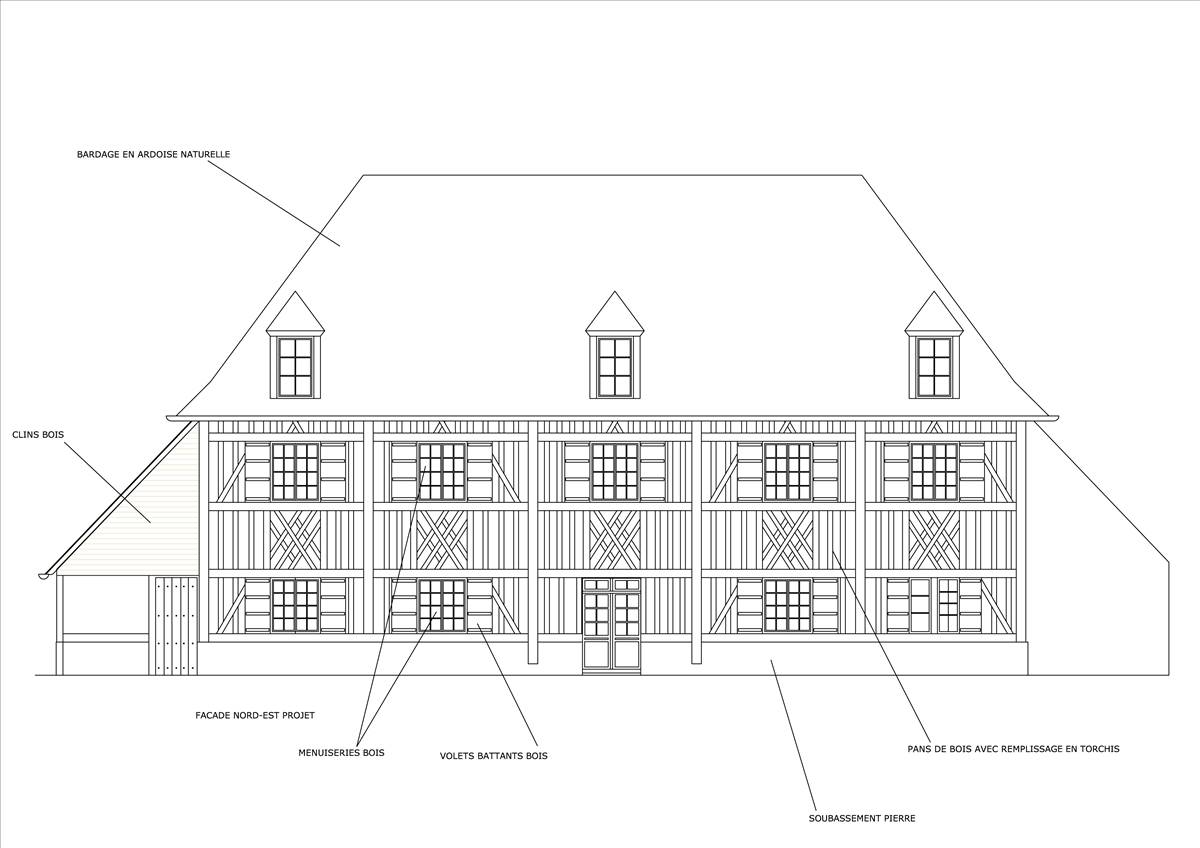

The stone substructure and some part of the wooden frame were cleaned and repaired. The street facing façade was rebuilt as it was before. The main entrance, on the east façade, had been enlarged for the passage of tractors. It was narrowed in order to look like it was, thanks to old drawings. All the old cob was removed and replaced by new one, made of clay, sand and straw and laid on laths nailed in the wooden frame. The wooden frame was painted in a raspberry red colour, that was advised by the Oise council of architecture, urban planning and the environment (CAUE), a non-profit consulting organisation present in every French department. All the interior renders were coloured with natural pigments. More than ten different pigments were used in the housing. Wooden panels are covering the lower part of the walls.

20 mm

140 mm

20 mm

20mm

200 mm

140 mm

20 mm

Windows

Wooden double-glass window

The barn did not originally have windows. About twenty openings were created on both façades, respecting dimension, location and rythm that can be found in other similar buildings.

The windows are all wooden double-glass windows. The wooden front door was tailor-made by a local craftsman.

| Existing window type | No window |

| Existing glazing type | No window |

| Existing shading type | NA |

| Approximate installation year | 1700 |

| New window type | Box-type window |

| New glazing type | Double |

| New shading type | Outer shutter |

| New window solar factor g [-] | 0,63 |

Other interventions

ROOF

GROUND FLOOR

OTHER

To be repaired by the carpenters, the framework was entirely lifted with jacks.

The dormer windows were dismantled then reassembled as they were. The second storey with its slopping ceilings was insulated with 30 cm of hemp wool with a vapour barrier and covered with classic plasterboard. A ventilated and high vapour permeable rainscreen was installed between the insulation and the slate, with an air gap of 4 cm.

3 mm

400 mm

3 mm

40 mm

1 mm

300 mm

1 mm

13 mm

On the ground, a polyane film was spread in order to form a moisture barrier. Polystyrene was installed above and goes up the wall until it reaches the wall insulation, in order to avoid thermal bridges. Then a classic concrete slab was poured and a radiant floor heating was installed.

A new flooring of 3 cm thickness with reused terracotta tiles, slate from the Touraine region, bricks and wooden floor was created. Some of the tiles unfortunately cracked because of an application failure.

20 mm

20 mm

30 mm

100 mm

20 mm

100 mm

100 mm

1 mm

An intermediate floor was created with local wood. The wooden beams are not embedded in all the depth of the wall, so there are few thermal bridges.

The interior was very carefully designed and honours reused materials (tiles but also doors and furnitures). To access the second storey, a wood and zinc stairwell was created.

HVAC

HEATING

VENTILATION

Studies were conducted in order to choose the heating system, including geothermal heating. But the studied systems were beyond budget. The owner simply opted for a second-hand oil-fired boiler, that provides both heating and domestic hot water.

There are no radiator since the only heat emitter is the radiant floor heating from the ground floor. As the intermediate floor is not insulated and features a large hopper, the warmth from the ground floor can rise in the upper storeys and the radiating floor heating turns out to be sufficient to heat the 400 m² of the housing.

| New primary heating system | |

|---|---|

| New system type | Boiler |

| Fuel | Oil |

| Distribuition system | Radiating floor |

| Nominal power | kW |

The owner planned to install a single flow ventilation system : laying of ducting and air inlets in the windows. Until it is put into service, the housing is ventilated by opening windows, which is not satisfactory regarding the ventilation law in France. Indeed, it requires a permanent ventilation, even for retrofitted buildings.

Earth render also helps to keep indoor air quality to an acceptable level, as it can absorb water up to 7 % of his weight.

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Centralized |

| Type flow regime | Overflow |

| Heat recovery | No |

| Humitidy recovery | No |

| Nominal power | kW |

| Electric power | kW |

| Control system |

Energy Efficiency

Voluntary certificates: No

Primary Energy

Internal Climate

The owner and his family are fully satisfied of the thermal comfort of their housing in both summer and winter.

Costs

Works extended over six years and were mostly carried out by the owner himself. A cost estimation is indeed very difficult to make. The restoration obtained a national grant that funded 1 % of the total costs of the exterior works related to heritage (tiles, roofs, framework, exterior render, etc) and that allowed the owner to get a tax credit amounting 25 % of these costs.

2000 € (total)

(includes DHW) Yes