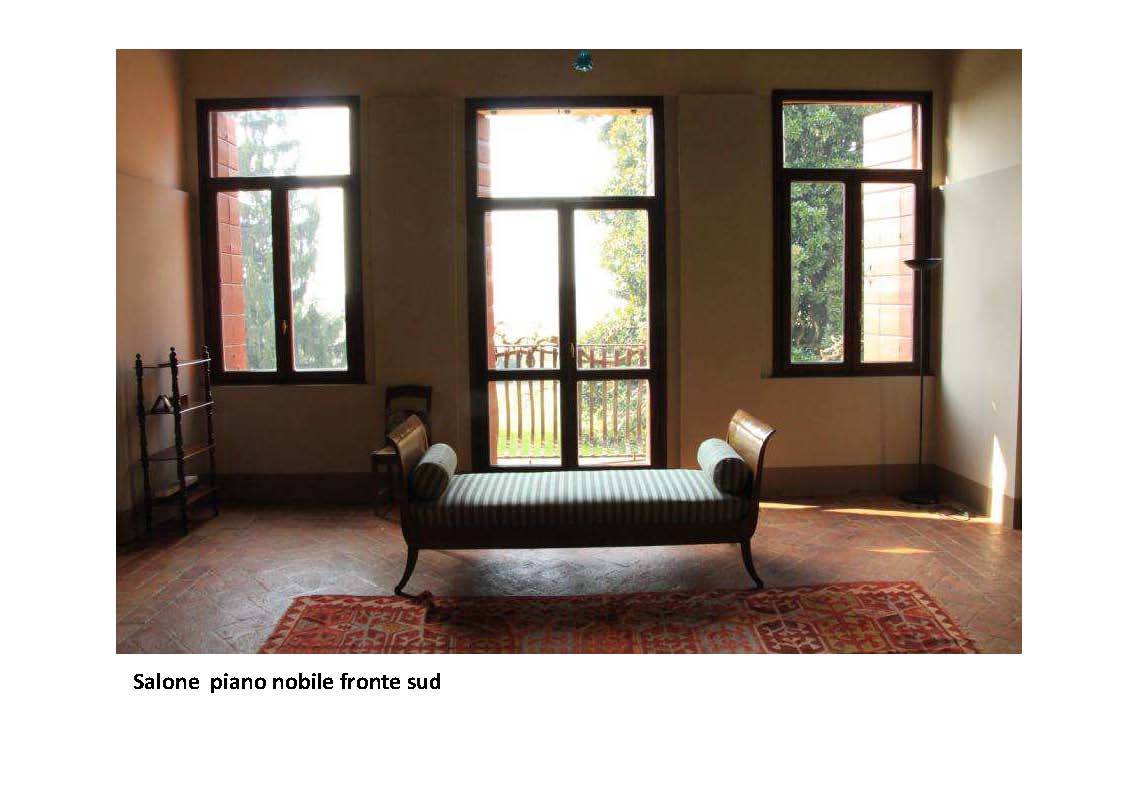

Villa Capodivacca

, Italie

Architect

Contact Details

Climate Zone Cfa

Altitude 20

HDD 2344

CDD 286

Conservation Area:

Oui

Level of Protection:

Decreto di vincolo 6/2/1076 ai sensi della legge 1089/39 - DLgs 42/2004

Year of last renovation:

2017

Year of previous renovation:

1970

Secondary use:

Residential (rural)

Building occupancy:

Discontinuous occupancy (i.e. holiday home)

Number of occupants/users:

8

Building typology:

Detached house

Number of floors:

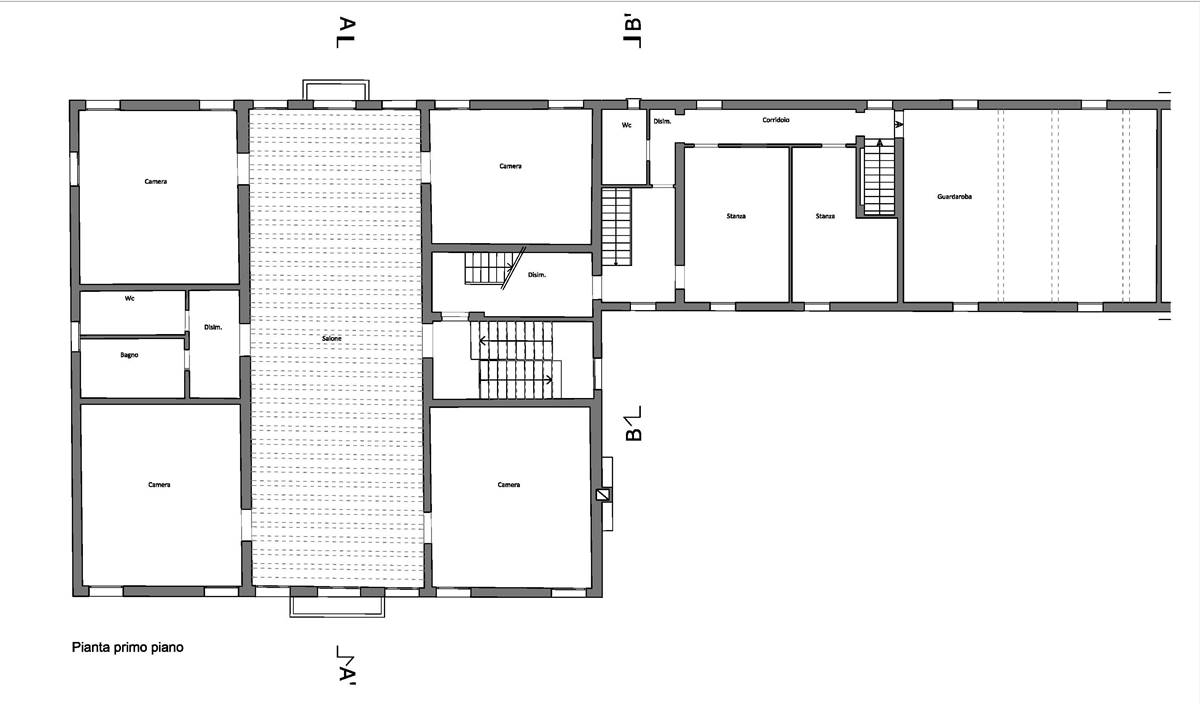

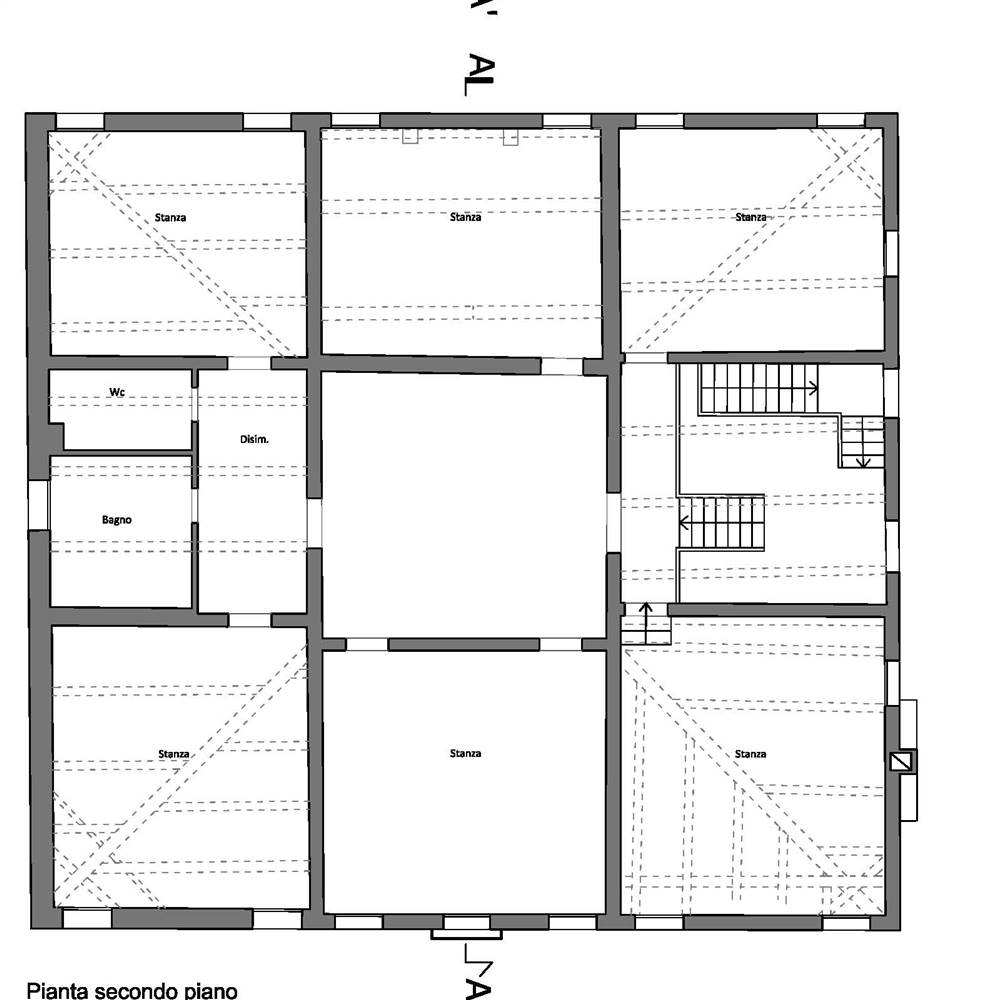

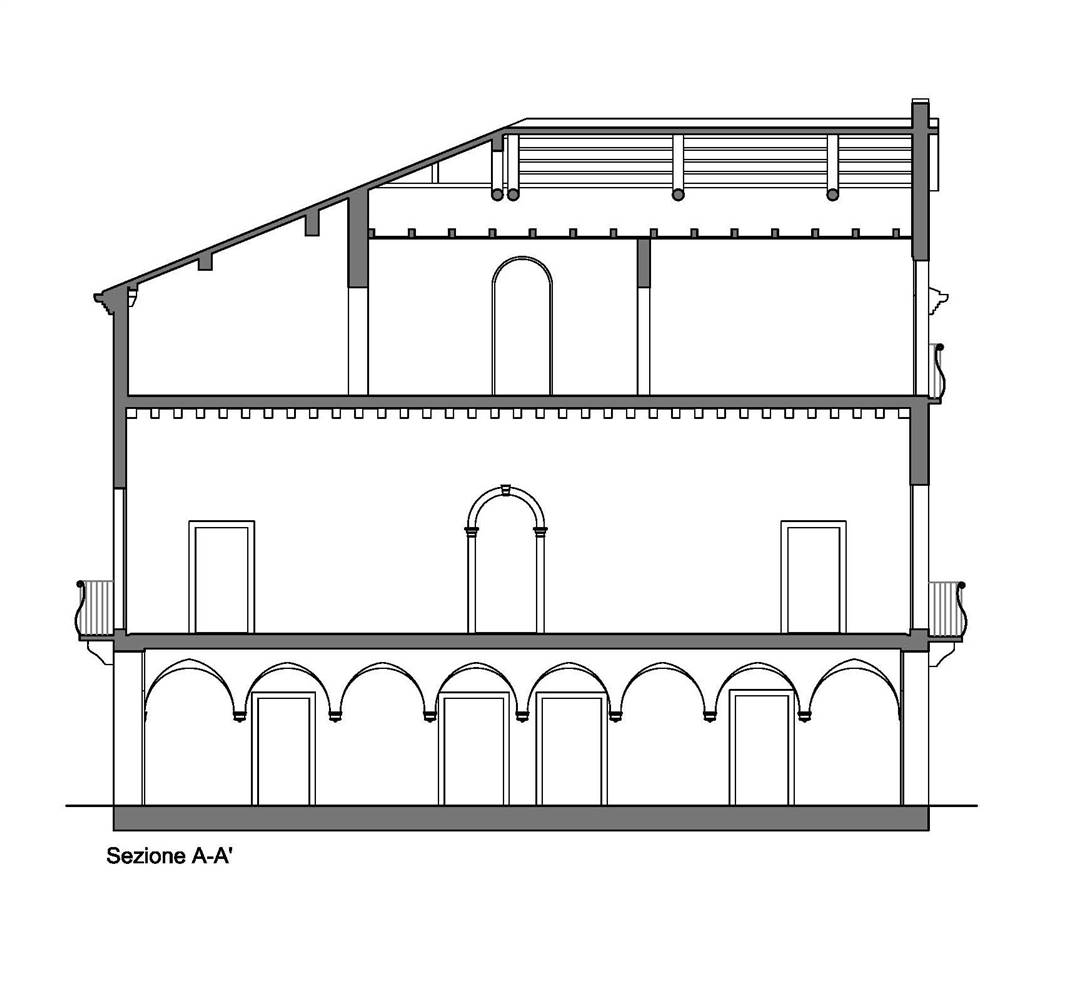

3

Basement yes/no:

No

Number of heated floors:

3

Gross floor area [m²]:

930,0

Thermal envelope area [m²]:

1453,95

Volume [m³]:

3502,93

NFA calculation method:

Useful area (it)

External finish:

Rendered

Internal finish:

Plastered (on hard)

Roof type:

Pitched roof

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Giulia Tissi, Federico Fioretta, Benedetta Tissi, Antonia de Besi, Alberta de Besi, Antonio Gallo, Matilde de Besi e Antonio Tissi .

Via Scapacchiò est n. 5, Saccolongo.

Lucia Corti

Laboratorio di Architettura Ecologica, Padova, Italy

Lucia.corti@architetturaecologica.net

In Enrico Pedretti Steping

VIA ARE 9, PESCANTINA (VR)

Ing. Stefano Dibiasi

Via Sabbadin 19, 35010, Limena (PD)

info@sheconsulting.it

Hygrothermal assessment Ediclclima

RETROFIT SOLUTIONS

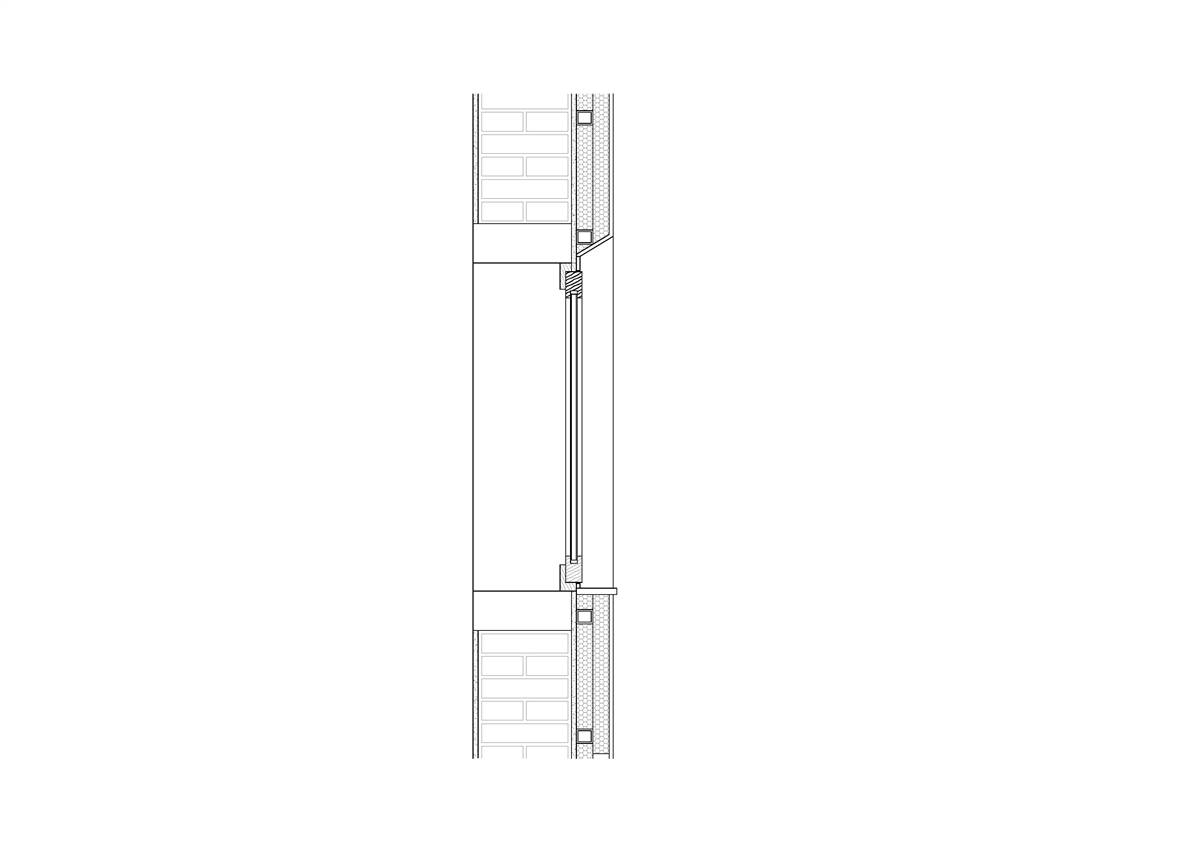

External Walls

brick masonry wall

The entire top-floor envelope was internally insulated with a coat of mineral insulating panels based on calcium silicate hydrates.

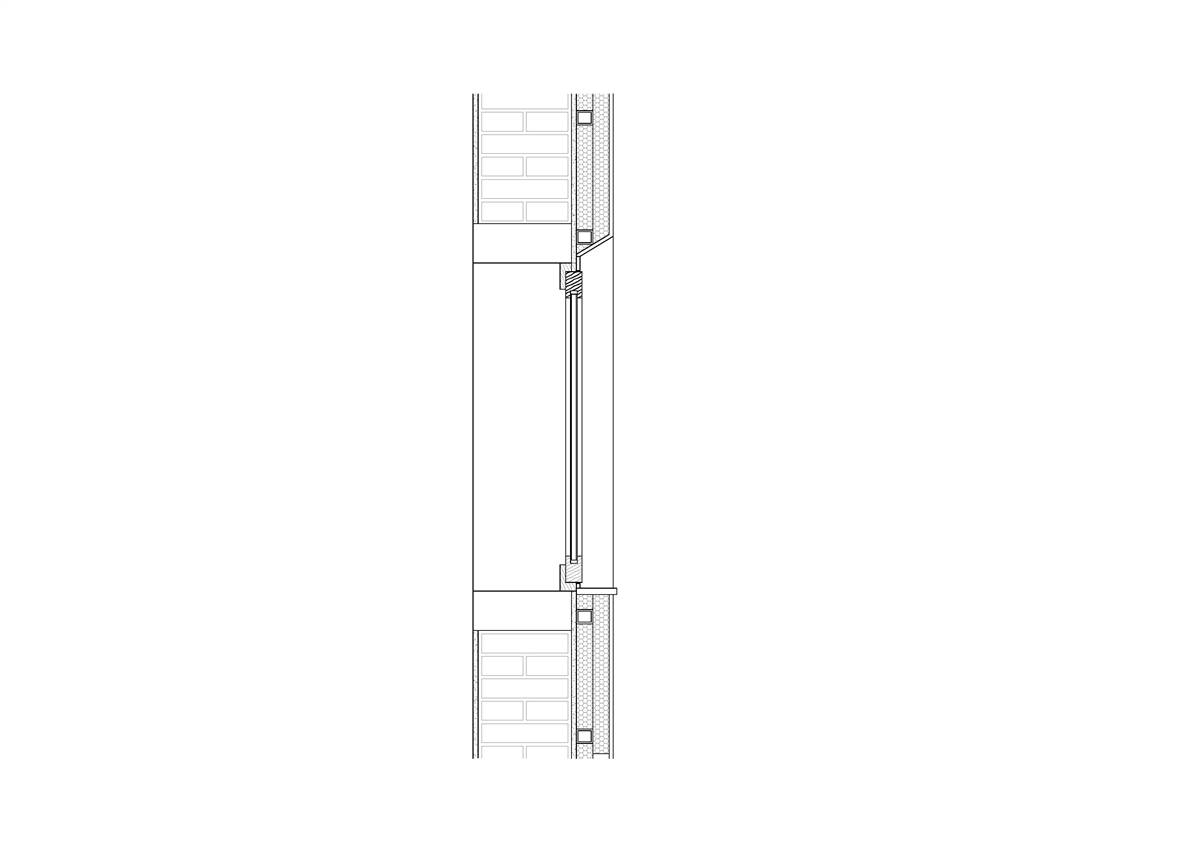

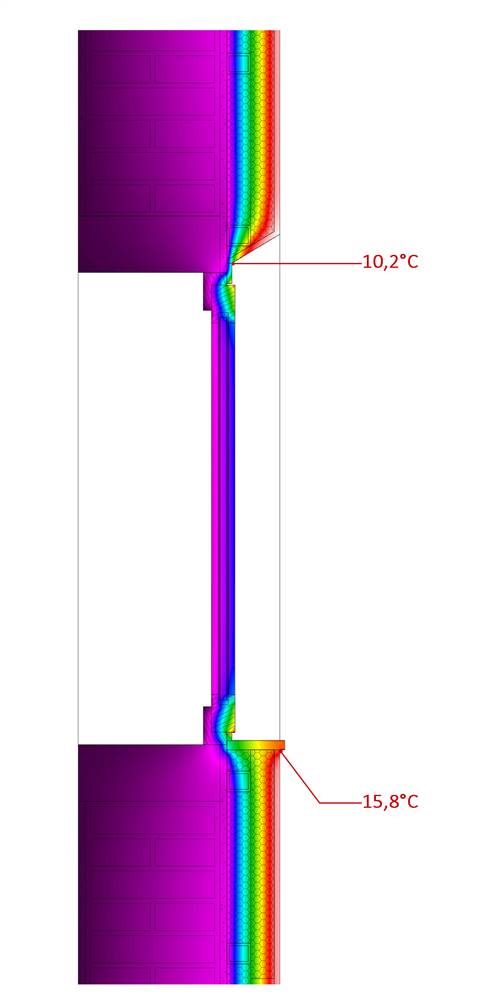

Application of a reversible insulation layer in the internal surface of the walls and new finishing

30 mm

250 mm

30 mm

30mm

250 mm

80 mm

30 mm

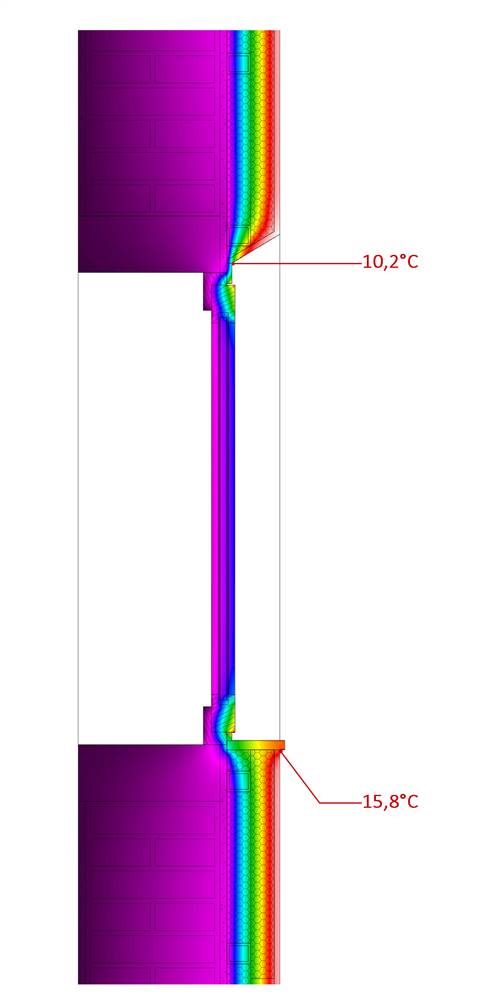

Windows

timber frame and double glazing dating around 1970

The new windows have similar shape and materials to the existing frames (timber). The frames are in lamellar larch wood and the double low emissive glass (3 + 3) has argon gas in the air gap.

The new windows, recurring to traditional materials (wood) have a better performance; their replacement is approved by the protection bodies because existing windows the existing windows had already been replaced around the 1970s and therefore did not constitute elements of historical and architectural character to be protected. The choice was to keep a frame made of traditional, natural material (wood) with better energy performance (it was not a question of preserving seventeenth-century frames). In this case it was not the material degradation that justified the replacement of the elements but rather the low historical value combined with poor environmental performance.

| Existing window type | Casement window |

| Existing glazing type | Double |

| Existing shading type | Outer shutter |

| Approximate installation year | 1970 |

| New window type | Casement window |

| New glazing type | Double |

| New shading type | Outer shutter |

| New window solar factor g [-] | 0,51 |

Other interventions

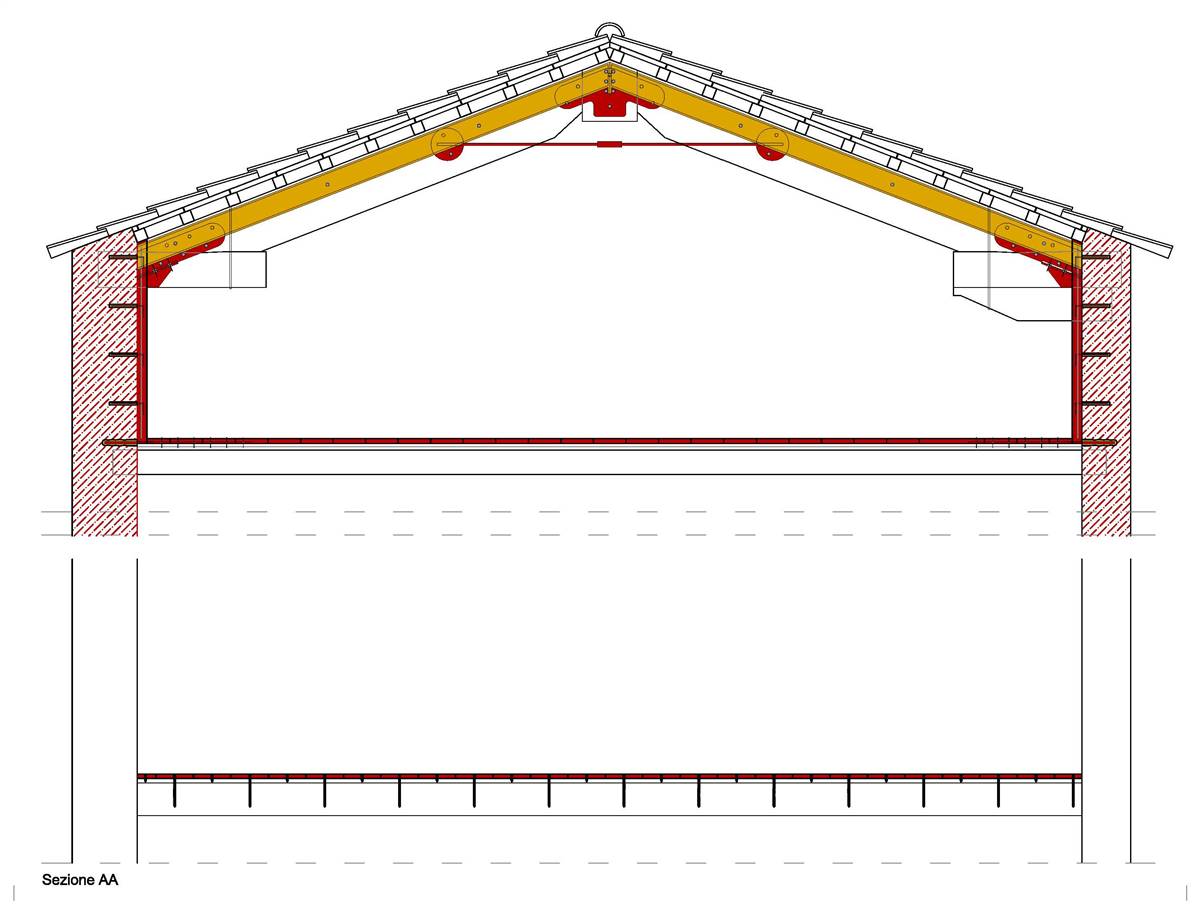

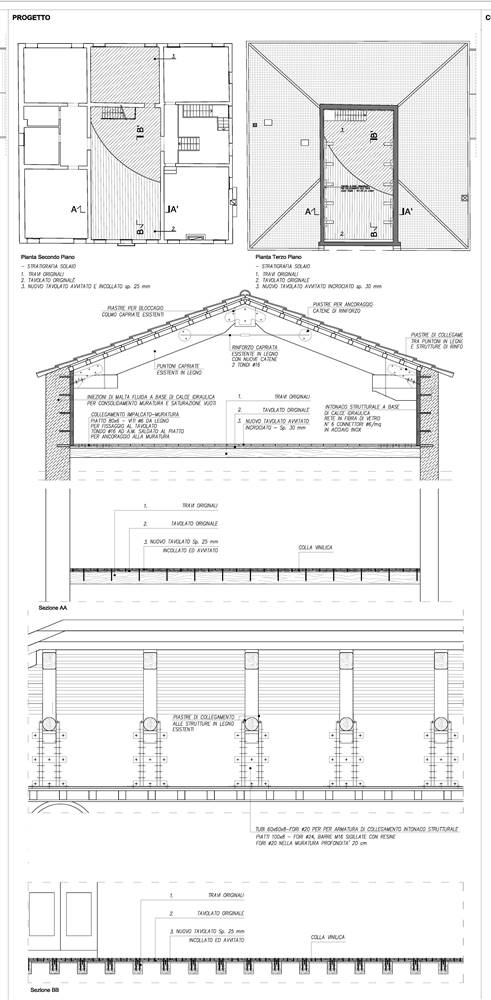

ROOF

OTHER

The roof insulation work was preceded by a careful analysis of the healthiness of the primary and secondary wooden structure, especially with regard to the main beam heads. Although they appeared to be healthy and intact, the internal analysis revealed that the upper part of the beams in contact with the tiles was damaged and suffering. The consolidation of the beam heads took place by inserting steel blades into the deteriorated portion and, in some cases, by adding concrete to the parts of the beams that had been cleaned from the deteriorated portions. Once the structure had been restored, the roof was insulated. Here, the need to combine summer comfort, using a material of sufficient thickness and low thermal conductivity, with the safeguarding of the aesthetic prerogatives of the façade and its elements, led us to withdraw the wood fibre insulation package and replace it, near the cornice, with light, thinner insulation.

The soluton was compatible because of the nature of insulation material (fibre wod) and not alteration of the external shape, even conservation of old tiles

30 mm

30 mm

30 mm

200 mm

The consolidation of the roof, prior to all others, was carried out by means of: - the installation in the attic of new planking screwed and glued to the existing one; - the connection between the new planking and the wall structures using bolted metal plates; - the installation of new metal tie-rods in a raised position with respect to the original; - the application, on the internal side of the vertical walls of the attic, of reinforced structural plaster based on hydraulic lime with suitable connectors.

From the intersection between the differentiated use of the three floors of the villa, the problems encountered and the constraints imposed by the Superintendence, an articulated project of restoration, static restoration and plant and energy requalification was born, which has been developed in different ways on the various levels.

HVAC

HEATING

VENTILATION

AIR CONDITIONING

DOMESTIC HOT WATER

As each floor of the villa is subject to different uses, comfort requirements and cost expectations were also different. On the ground floor, intended for occasional use, new radiators were simply installed in place of gas stoves, radiant terminals with better performance. These measures have increased efficiency with a considerable improvement in energy production and storage. On the second floor, where a family home was located, it was necessary to obtain a good level of air conditioning both in winter and summer. For this reason an autonomous thermal power station was installed with a hybrid system (boiler and heat pump) that produces both hot and cold water. To guarantee humidity levels compatible with summer air conditioning, a centralised controlled mechanical ventilation system with built-in dehumidifier was installed.

Conservation of all the significative materials and characters

| New primary heating system | |

|---|---|

| New system type | Heat pump |

| Fuel | Gas |

| Distribuition system | Radiating wall |

| Nominal power | 102,43 kW |

Finally, to guarantee humidity levels compatible with summer air conditioning, a centralised controlled mechanical ventilation system with built-in dehumidifier was installed.

As already specified

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | NA (Natural) |

| Type flow regime | NA (Natural) |

| Heat recovery | No |

| Humitidy recovery | No |

| Nominal power | 0,10 kW |

| Electric power | 0,0 kW |

| Control system | on/off |

On the second floor, where a family home was located, it was necessary to obtain a good level of air conditioning both in winter and summer. For this reason, an autonomous heating plant was built with a hybrid system (boiler and heat pump) that produces both hot and cold water.

As altredy written

| New cooling system | |

|---|---|

| Type | Heat pump |

| Distribuition system | Radiating wall |

| Nominal power | 9,25 kW |

| Electric power | 1,5 kW |

Energy Efficiency

Voluntary certificates: No

Primary Energy 361,88 kWh/m2.y

Consumption_estimation_Before: 338 kWh/m2.y

Consumption_estimation_After: 319 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: Steady state simulation (e.g. EPC, PHPP)

Consumption_estimation_Including_DHW: Oui

Consumption_estimation_After: 361,88 kWh/m2.y

Internal Climate

On the first floor, with very significant inter-floor heights (up to 4.50 metres), winter air conditioning with low temperature terminals (radiant wall panels) to lower consumption at the same time achieve greater indoor comfort thanks to the radiant effect of the panels, which work by radiating their heat right at the right at the human body.

Costs

Private financing

No