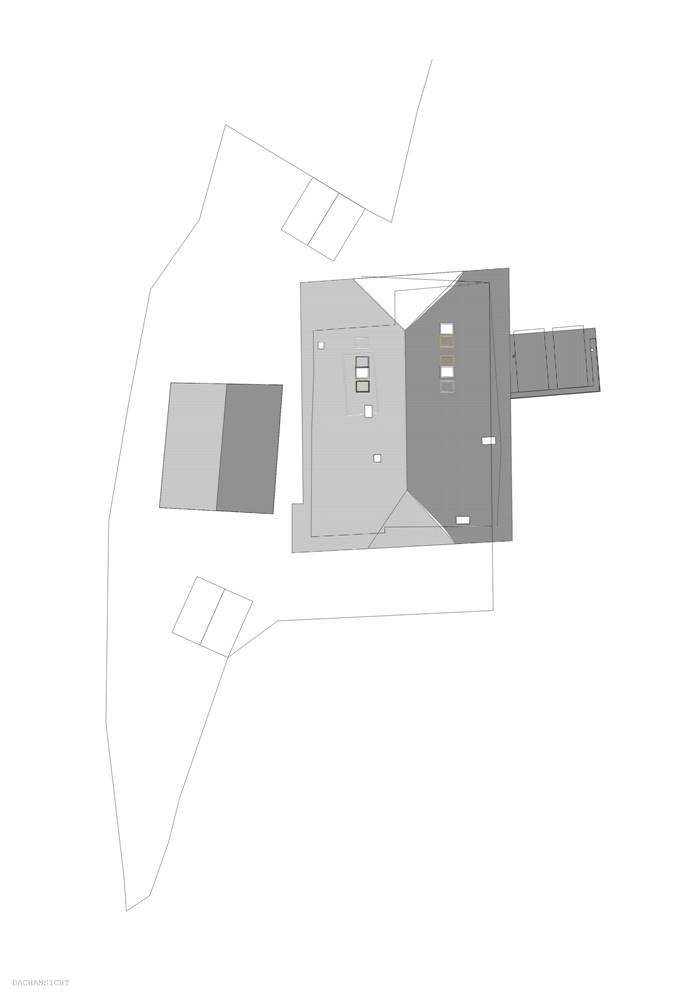

Oberbergerhof

Montagna - Montan, Italie

Architect

Contact Details

Other Information

https://atlas.arch.bz.it/de/oberbergerhof/

Climate Zone Cfb

Altitude 497

HDD 3113

CDD 0

Conservation Area:

No

Level of Protection:

denkmalgeschützt

Year of last renovation:

2016

Year of previous renovation:

0

Secondary use:

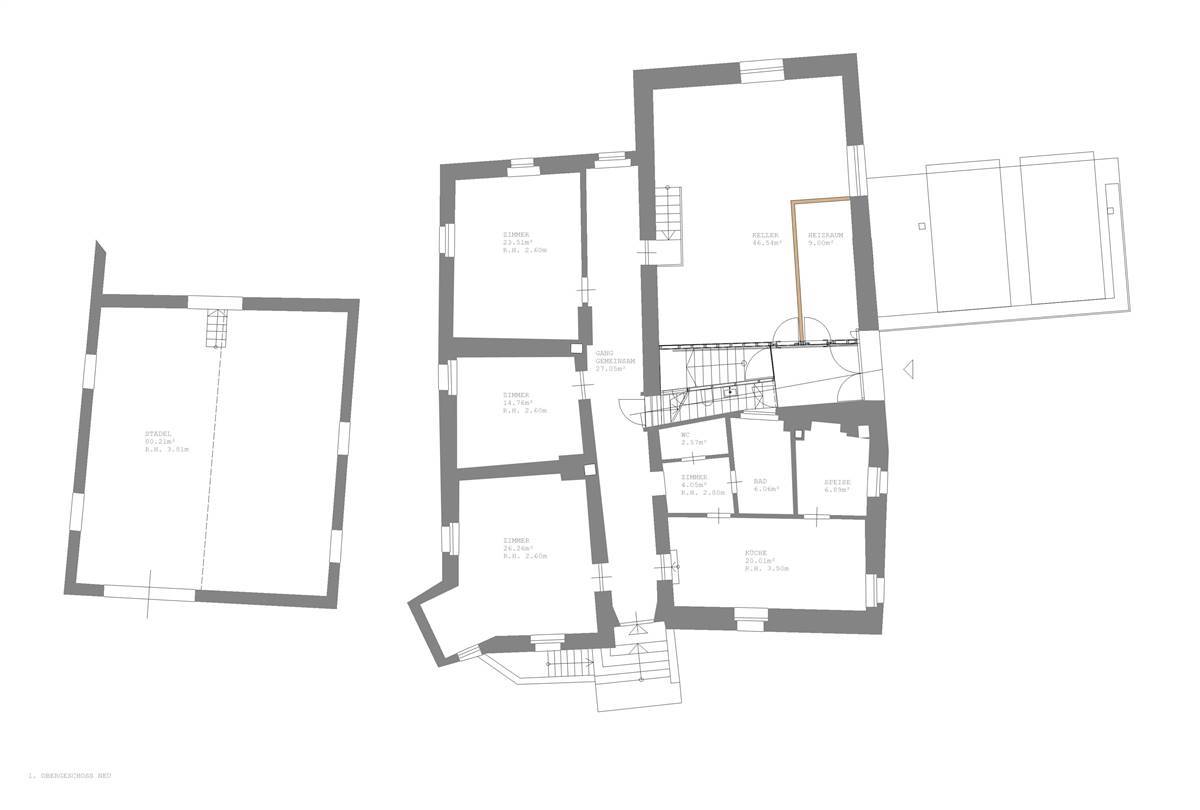

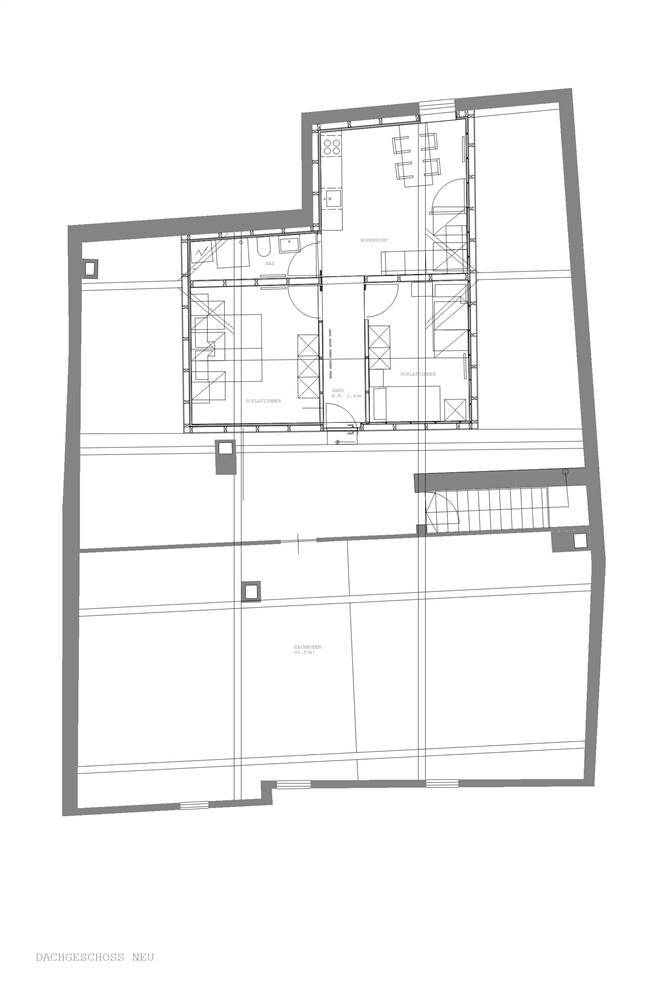

During the harvest season, the attic serves as accommodation for up to two workers.

Building occupancy:

Permanently occupied

Number of occupants/users:

5

Building typology:

Detached house

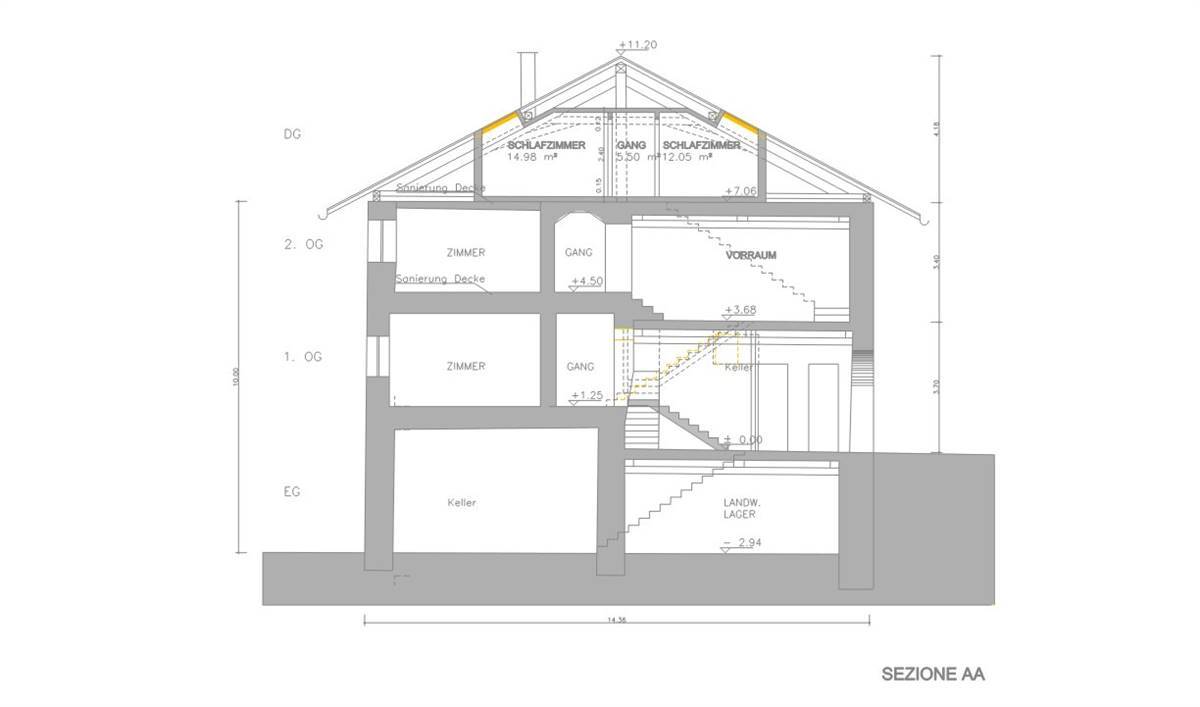

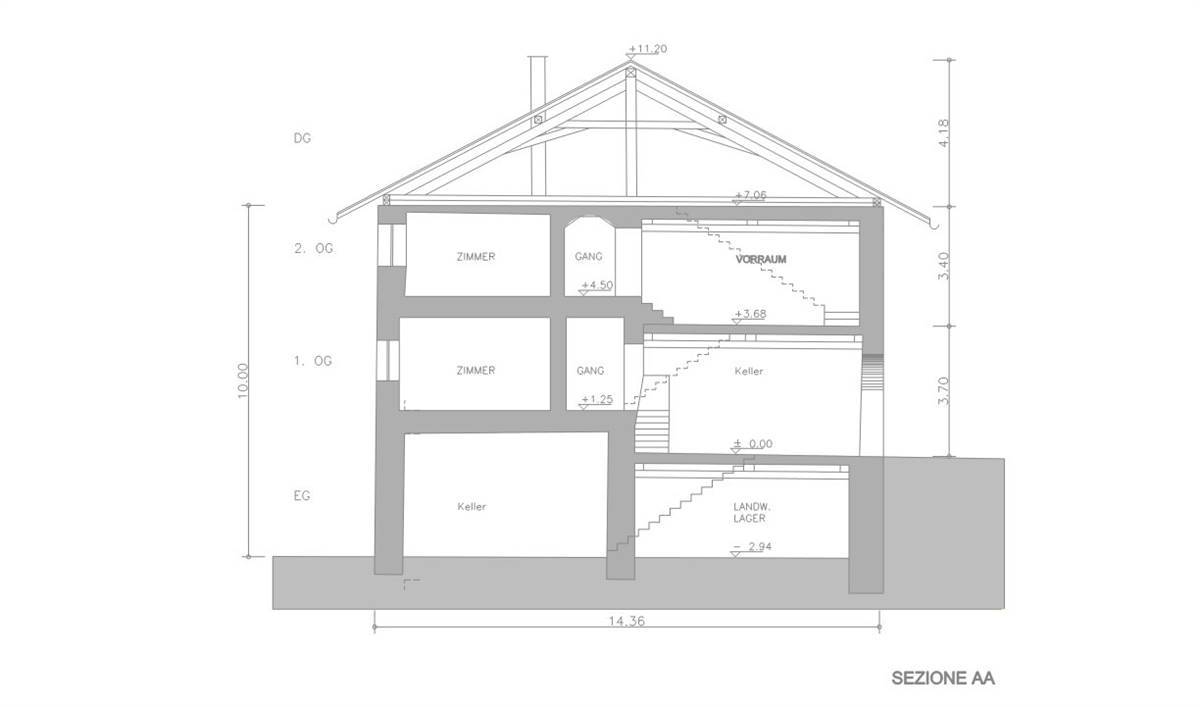

Number of floors:

2

Basement yes/no:

Oui

Number of heated floors:

2

NFA calculation method:

Useful area (it)

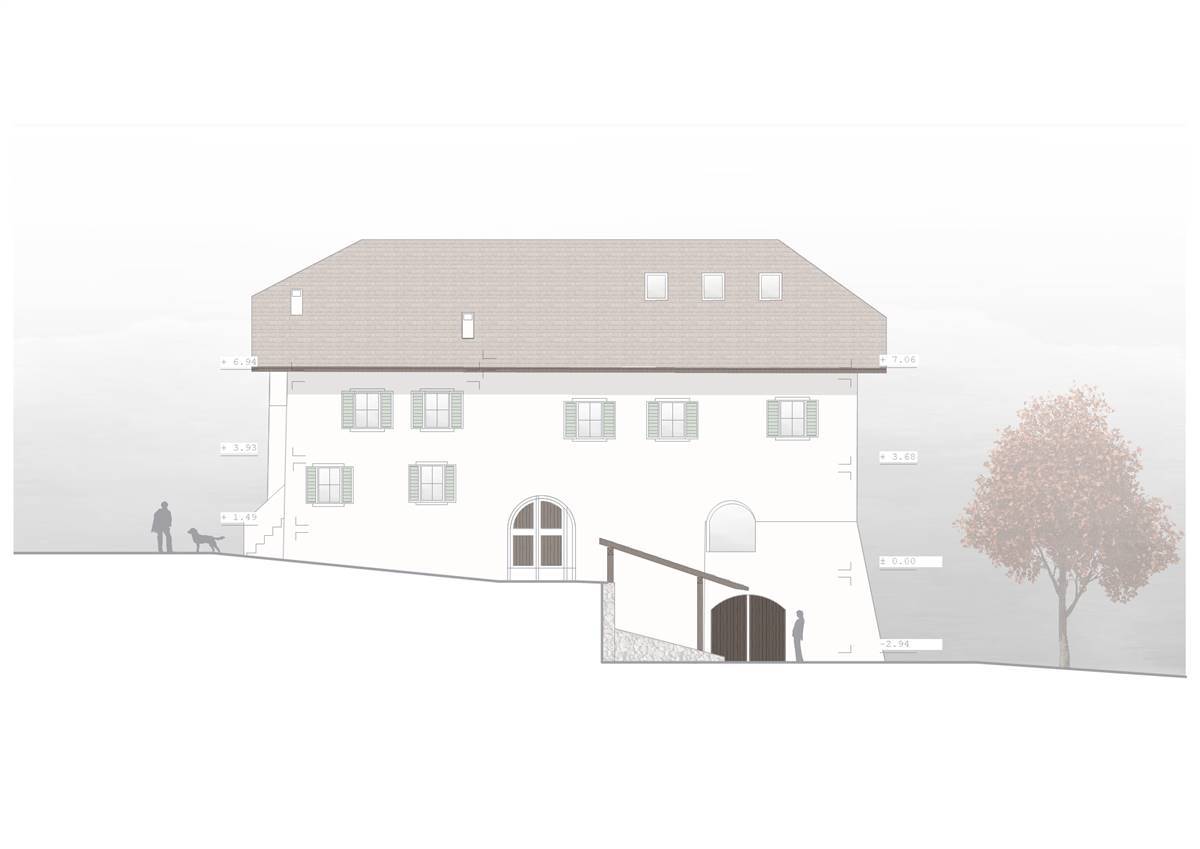

External finish:

Rendered

Internal finish:

Plastered (on hard)

Roof type:

Pitched roof

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

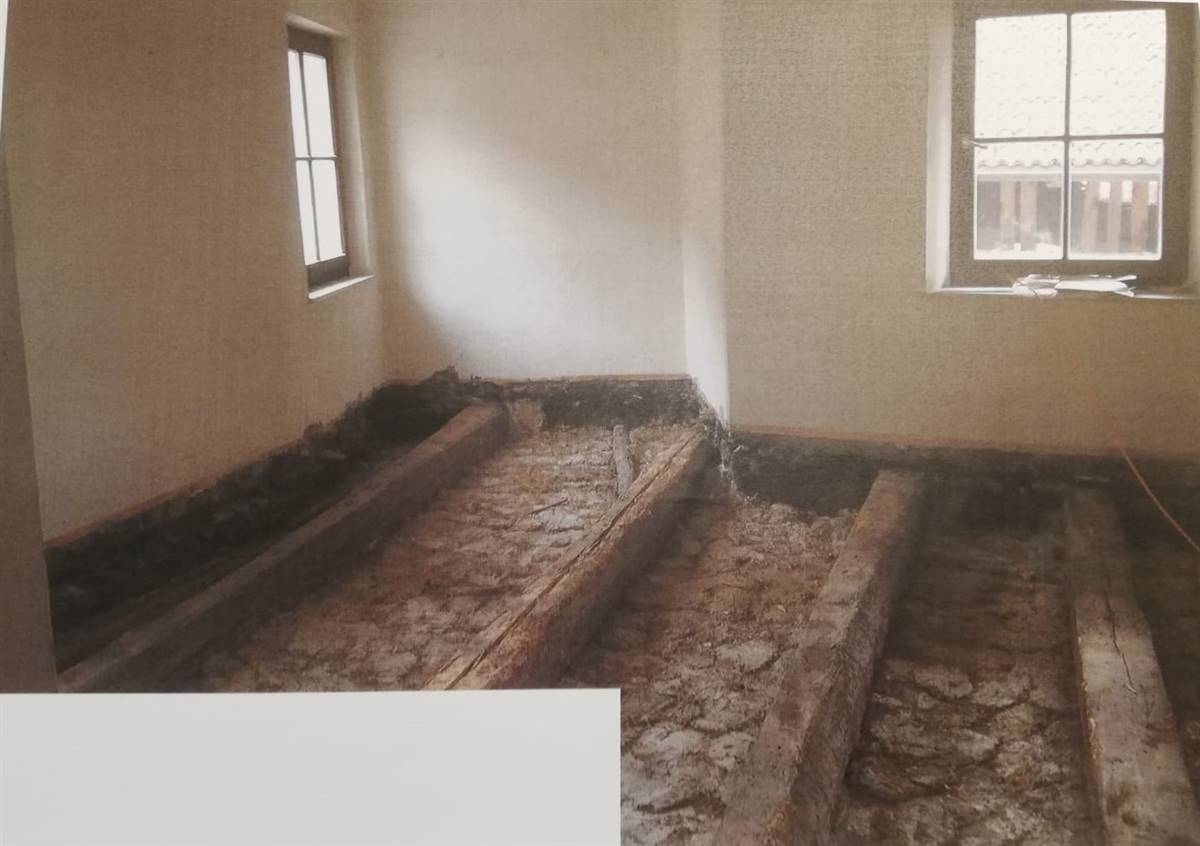

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Dr. Arch. David Stuflesser

Petlinstraße/Via Petlin 18, I-39046 St.Ulrich, Ortisei

Tel.T+F 0039 0471 786517

RETROFIT SOLUTIONS

External Walls

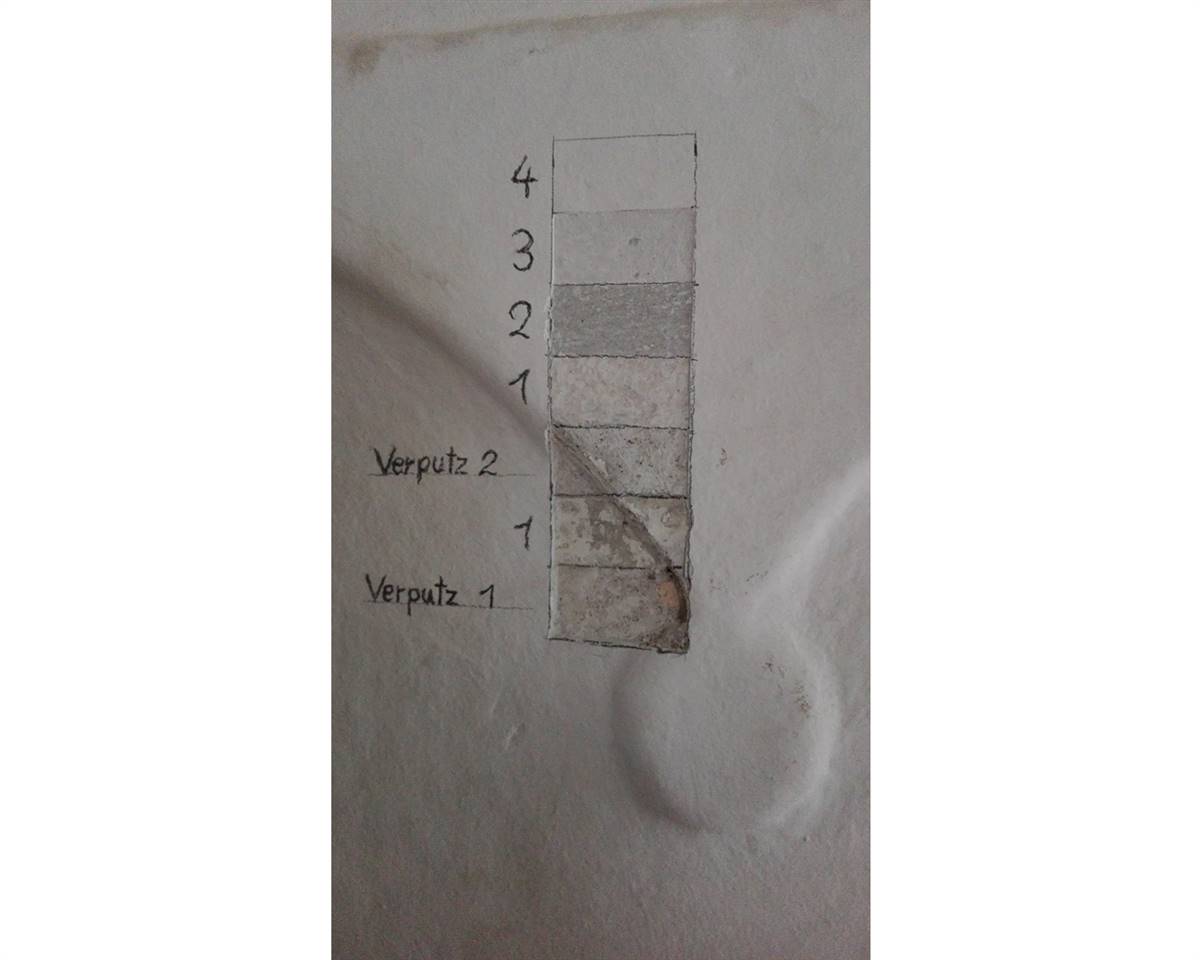

Stone masonry with lime plaster

House-in-House

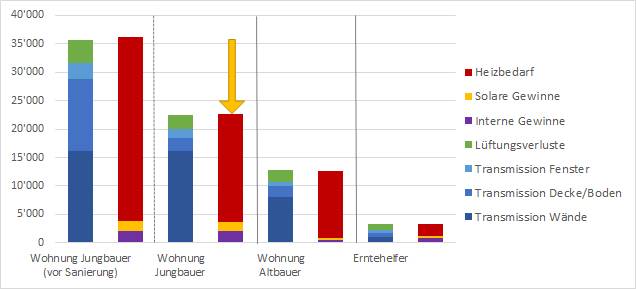

Since the farmhouse is located in a climatically favorable and sunny location, it was deliberately decided not to insulate the exterior walls, which are coated with beautiful, historic plaster, both inside and out. The users do guarantee a sufficiently dry indoor air with careful natural ventilation and avoid this the mould risk, which the relatively cold surfaces especially in corners would otherwise cause.

The U-value given is better than it would result purely mathematically from the thermal conductivity value of the natural stone and takes into account the mortar components and air inclusions. It was not measured on site, but is based on values from the literature and was indirectly verified with the consumption values.

20 mm

500 mm

20 mm

20mm

500 mm

20 mm

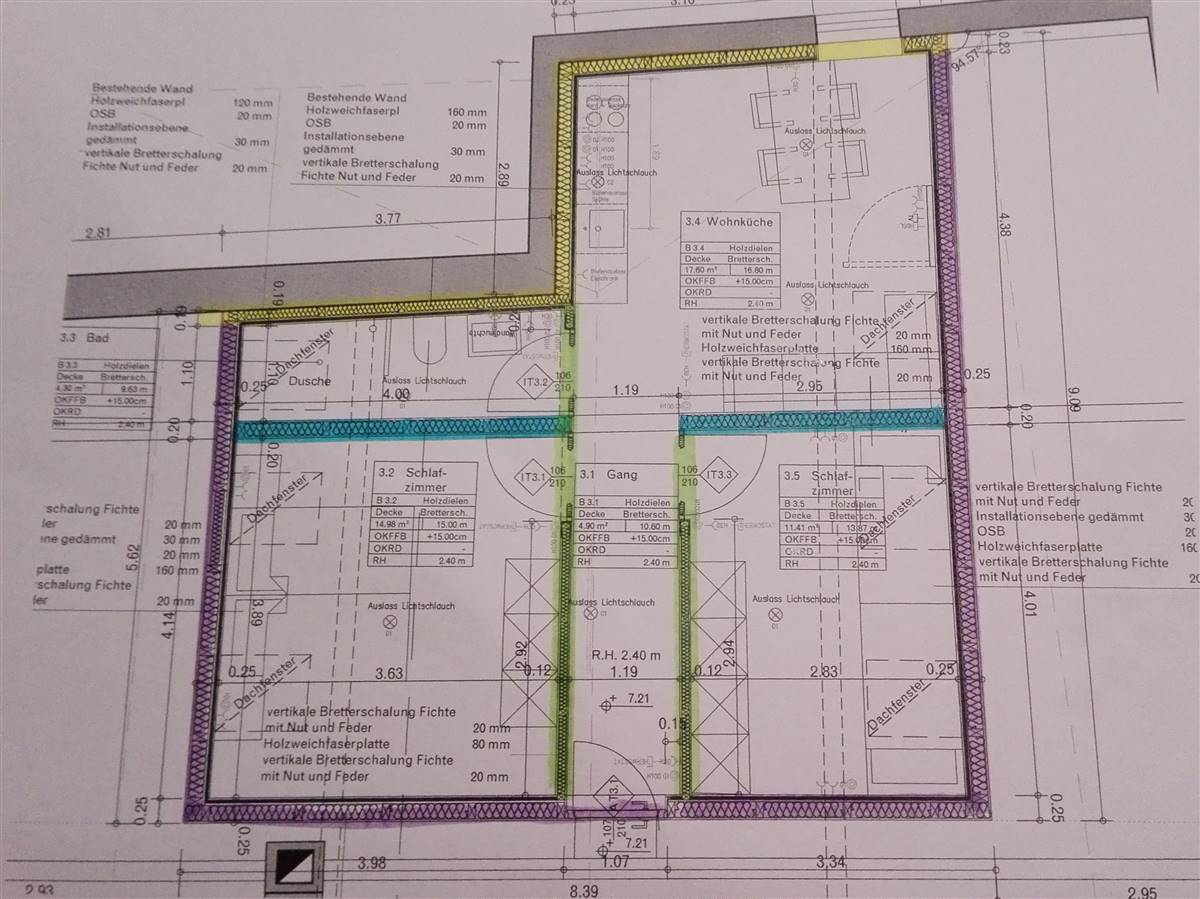

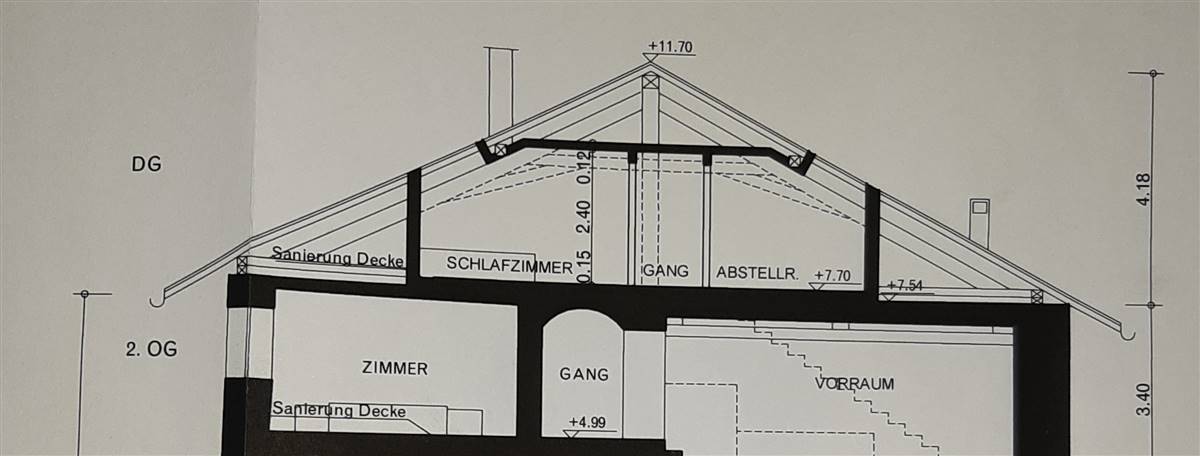

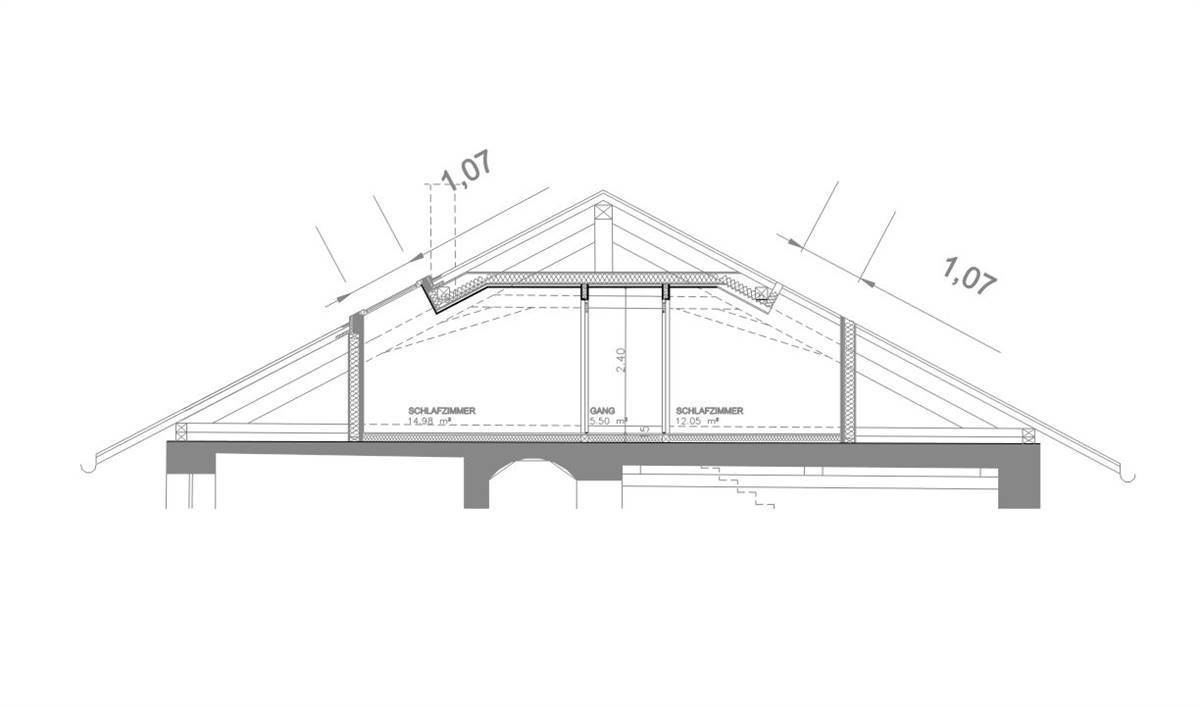

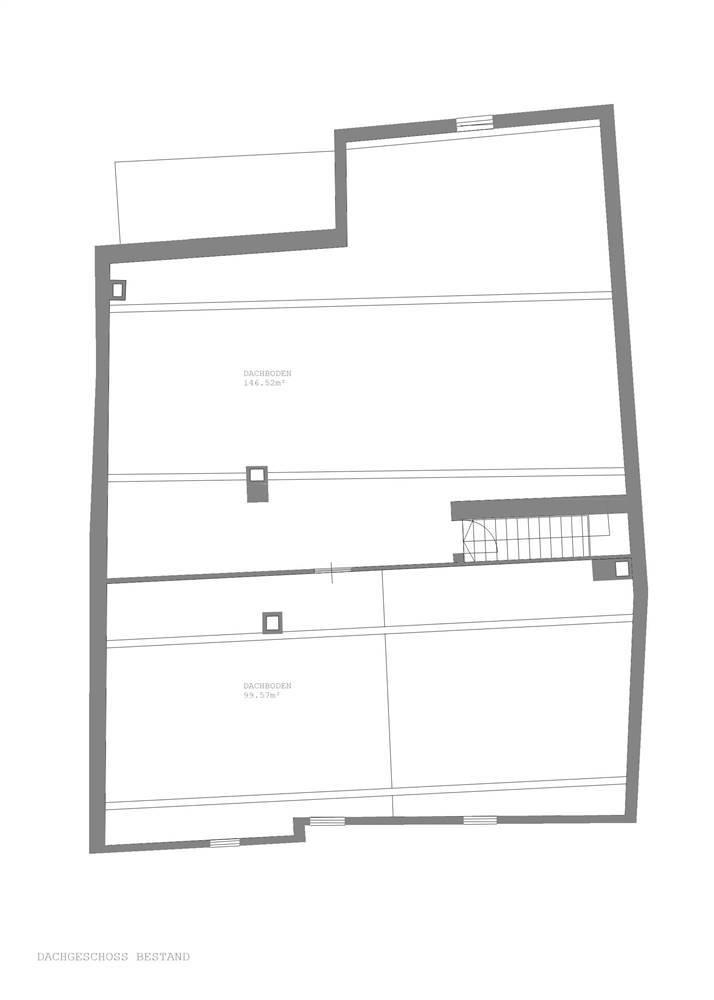

In the attic, that was not renovated as such, an additional residential unit was installed for the harvest workers. 55m ² divided into living room, two bedrooms and bathroom,. The external walls were built as drywall with 16cm soft wood fiber board - two thirds are "inner walls" (towards the attic), one third real outer walls .

In purely mathematical terms, the unit has an "efficiency of the building envelope" according to the Klimahaus of 37 kWh / m² - in fact, the unit is only used from May until the end of November.

0 mm

0 mm

20mm

30 mm

20 mm

160 mm

20 mm

Windows

Wooden windows from the local carpenter

additional windows in the roof

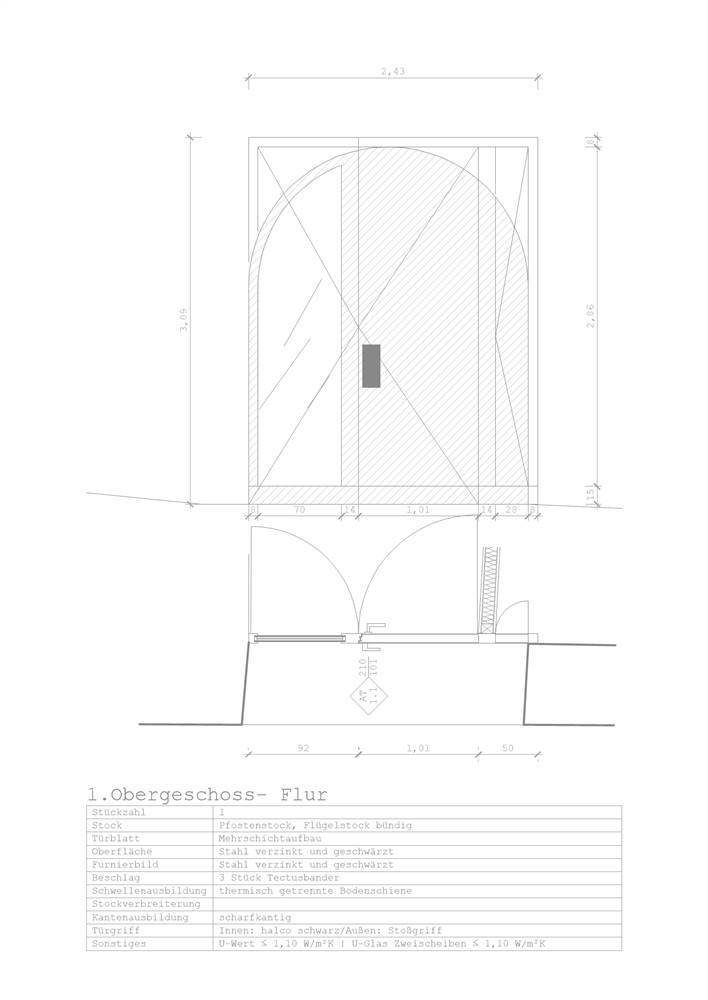

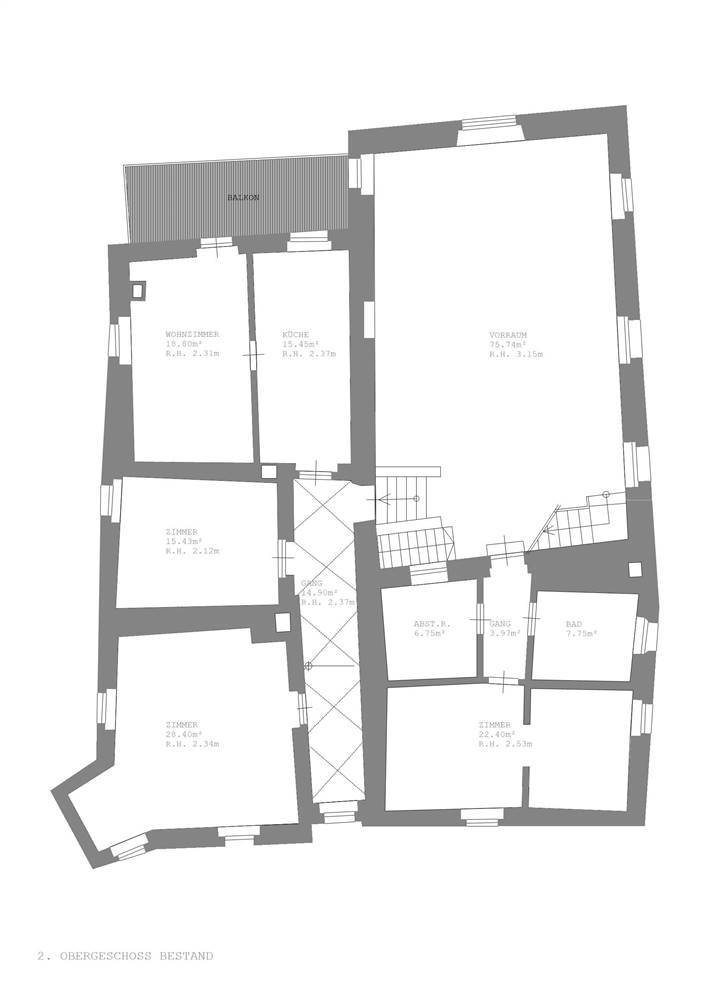

The windows in the young family's apartment were renewed. When replacing the windows, special care was taken not to change the view of the courtyard: The decision was therefore made to use two-sash double-glazed windows, what allowed the very narrow, historical-looking frames. The windows were built by the local carpenter and replace 20 year old one-sash windows.

The historic Bifora windows from the late Renaissance in the Rittersaal on the 2nd floor were not changed. However, the room is not in constant use.

| Existing window type | Casement window |

| Existing glazing type | Double |

| Existing shading type | Outer shutter |

| Approximate installation year | 1995 |

| New window type | Casement window |

| New glazing type | Double |

| New shading type | Roller blinds |

| New window solar factor g [-] | 0,6 |

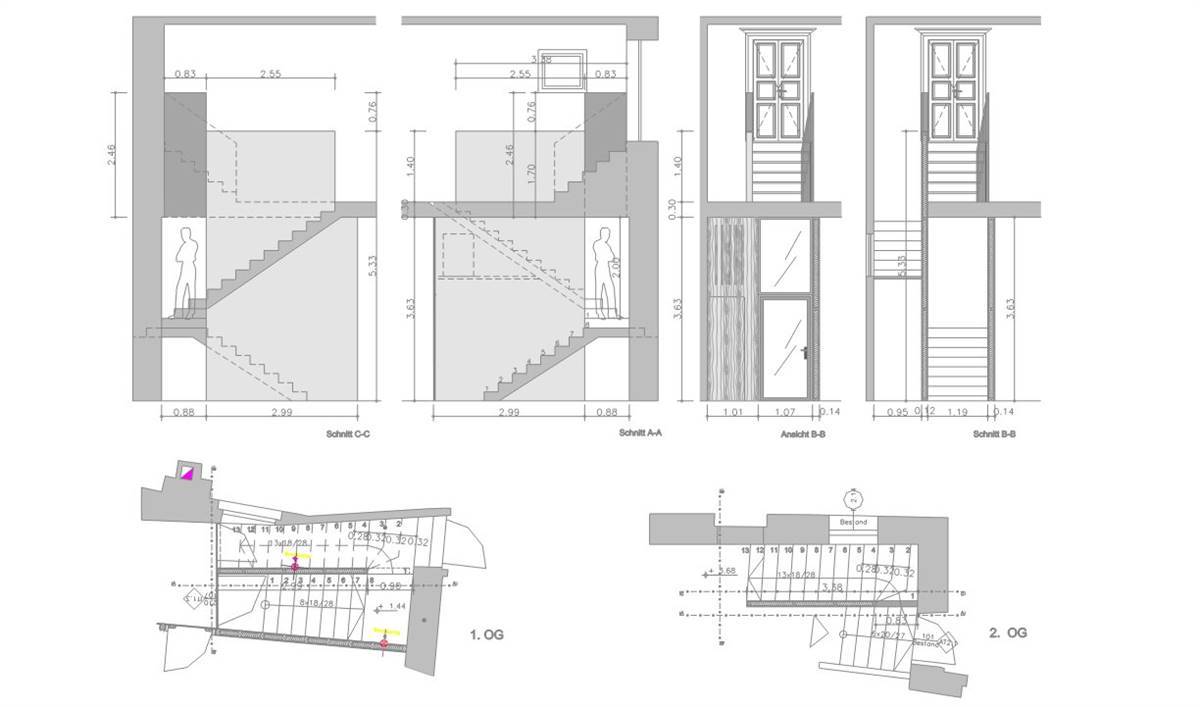

Four additional windows were used to illuminate the house-in-house box on the top floor in accordance with the preservation authorities.

Apart from that, the roof remains untouched.

| Existing window type | no window |

| Existing glazing type | none |

| Existing shading type | NA |

| New window type | Casement window |

| New glazing type | Double |

| New shading type | NA |

| New window solar factor g [-] | 0,7 |

Other interventions

ROOF

GROUND FLOOR

OTHER

The ceiling to the attic was mostly insulated with ~25cm insulation during the renovation - this reduced the losses from the apartment to the attic (which originally accounted for 25% of the apartment's heat losses) from ~8'500 kWh/year to ~1'500 kWh/year, i.e. to less than one fifth.

The attic itself was preserved as a cold room - except for the built-in house-in-house box for the harvest helpers

10 mm

300 mm

20 mm

130 mm

60 mm

24 mm

1 mm

130 mm

12 mm

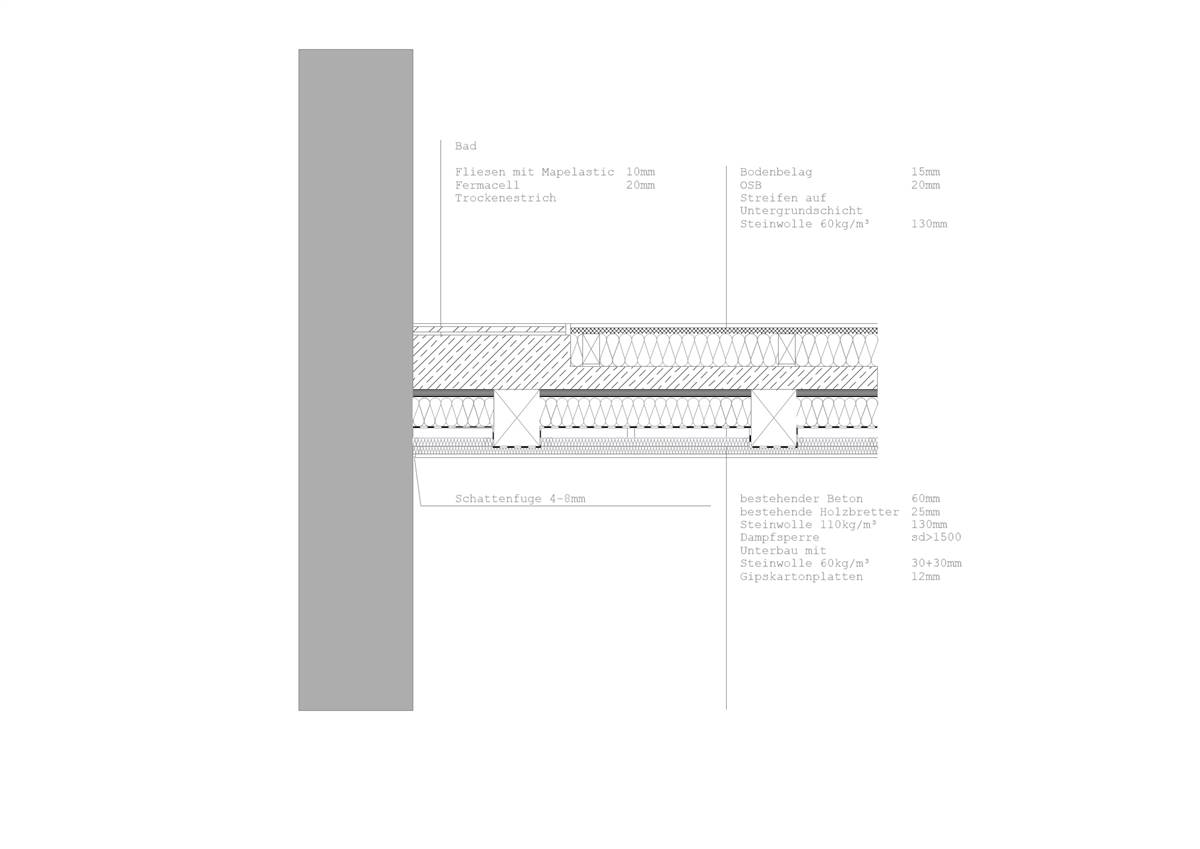

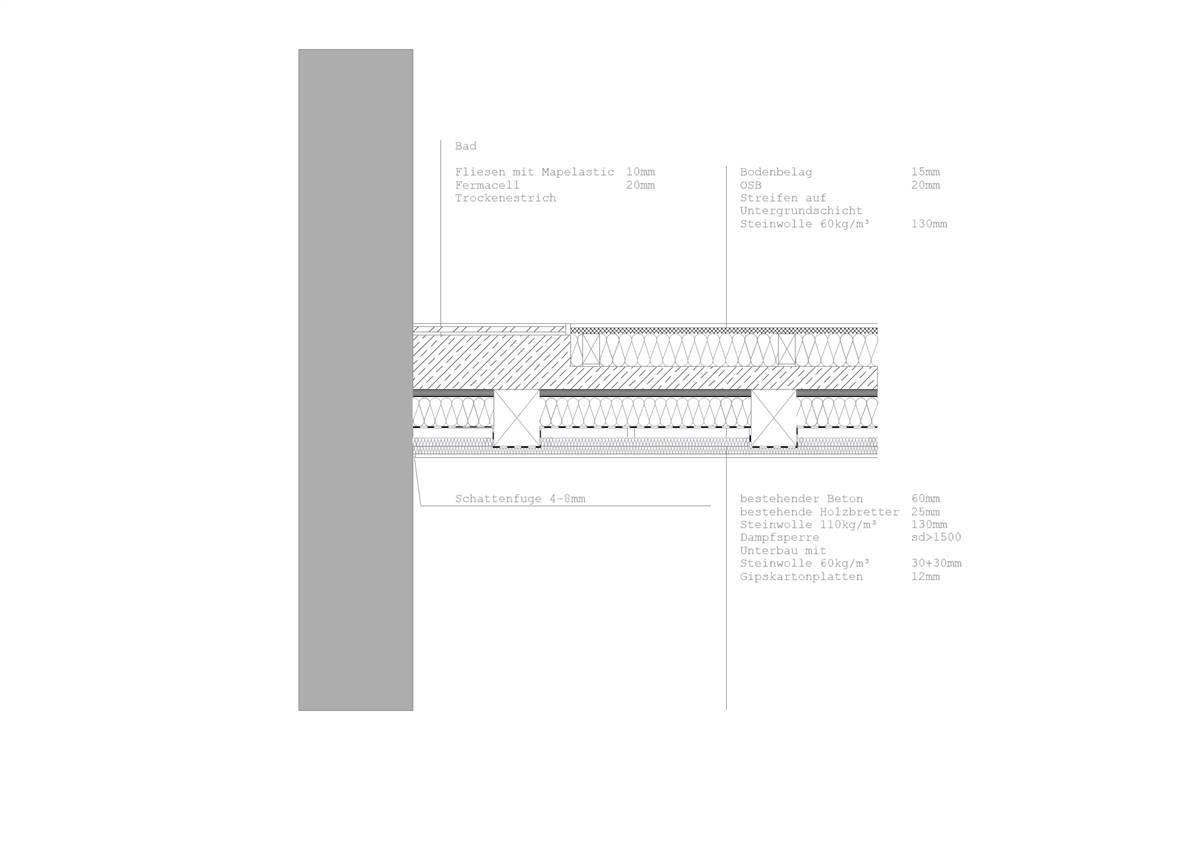

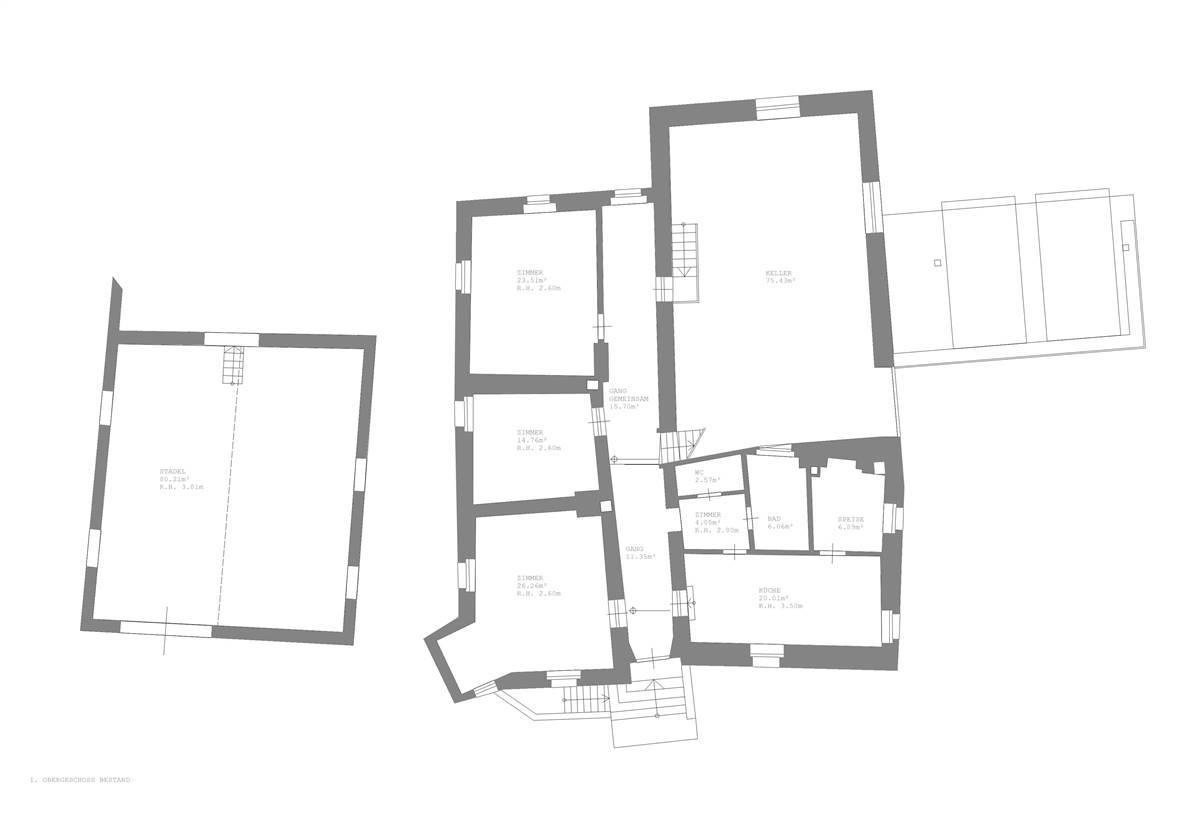

The ground floor structure was changed fundamentally due to the underfloor heating that was inserted in every room, except for the cross vault and the central hall. The original terrazzo floor was imitated in the vaulted entrance. In the remaining rooms, the original wooden floorboards were sanded down to ensure that the historic doors were opened.

both aspects of monument preservation and sustainability were taken into account.

15 mm

25 mm

42 mm

20 mm

20 mm

24 mm

190 mm

25 mm

60 mm

130 mm

20 mm

15 mm

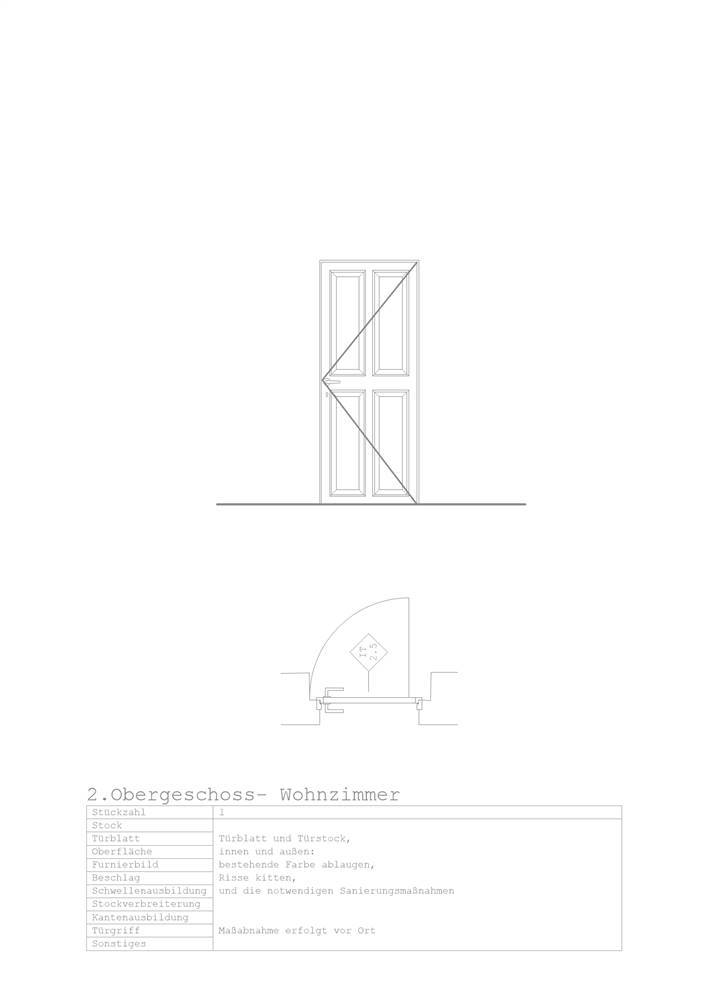

The historic interior doors were removed and repaired with skilled craftsmanship.

The existing paint of the interior doors was leached and the cracks were puttyled.

HVAC

HEATING

DOMESTIC HOT WATER

The old room stoves were replaced by a central pellet / wood stove. In the living room, the existing stove got a new look, which integrates well into the general concept.

In the apartment of the old farmers only kitchen and bathroom are heated (about 30m² of the total 140m²), the accommodation for the harvesters in the attic is used only until the end of November - but here the hypothetical heating demand for a whole winter is shown.

| New primary heating system | New secondary heating system | |

|---|---|---|

| New system type | Stove | Stove |

| Fuel | Wood and Pellets | Stückholz |

| Distribuition system | Radiating floor | Since the wood stove is in the living room, this room is heated. The heat therefore only reaches the other rooms via the air distribution. |

| Nominal power | NA since for the whole building, not just the refurbished flat kW | In general, the nominal output of the furnace cannot be specified. It is primarily defined by the user and his own feeling of comfort. kW |

RENEWABLE ENERGY SYSTEMS

Biomass

In summer, mainly pellets are used for the preparation of domestic hot water.

In winter for heating wood from their own forest.

| Biomass System | |

|---|---|

| Type | Logs from their own forest and pellets |

| Storage size | |

| Origin of biomass | own woods |

| Overall yearly production | 44000,0 kWh |

Energy Efficiency

Voluntary certificates: No

Primary Energy 181 kWh/m2.y

Consumption_estimation_Before: 230 kWh/m2.y

Consumption_estimation_After: 135 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: see "energy efficiency", here DHW included

Consumption_estimation_Including_DHW: Oui

Consumption_estimation_Before: 260 kWh/m2.y

Consumption_estimation_After: 181 kWh/m2.y

Type_of_monitoring: Continuous

Description: The user is able to monitor the energy and regulate it if necessary.

Internal Climate

The temperature is kept relatively constant due to the underfloor heating. However, there are different temperatures in different rooms.

Costs

There were no financial reasonings important for the renovation, decisions were made mostly based on the user needs. The total cost of the renovation was approx. 340,000 €.

No

Environment

emissions_at_use_stage_before_intervention: 18 per m2

emissions_at_use_stage_after_intervention: 11.3 per m2