House Moroder

Orazio street 7

39100

Bolzano, Italia

architetto

Owner

Contact Details

Climate Zone feucht-gemäßigtes Klima

Altitude 252 s.l.m.

HDD 3993

CDD 24

Conservation Area:

No

Level of Protection:

Year of last renovation:

1926

Building occupancy:

Permanently occupied

Building typology:

Detached house

Number of floors:

3

Basement yes/no:

Si

Number of heated floors:

3

Thermal envelope area [m²]:

734,0

Volume [m³]:

1261,0

NFA calculation method:

Useful area (it)

External finish:

Rendered

Internal finish:

Plastered (on hard)

Roof type:

Pitched Roof

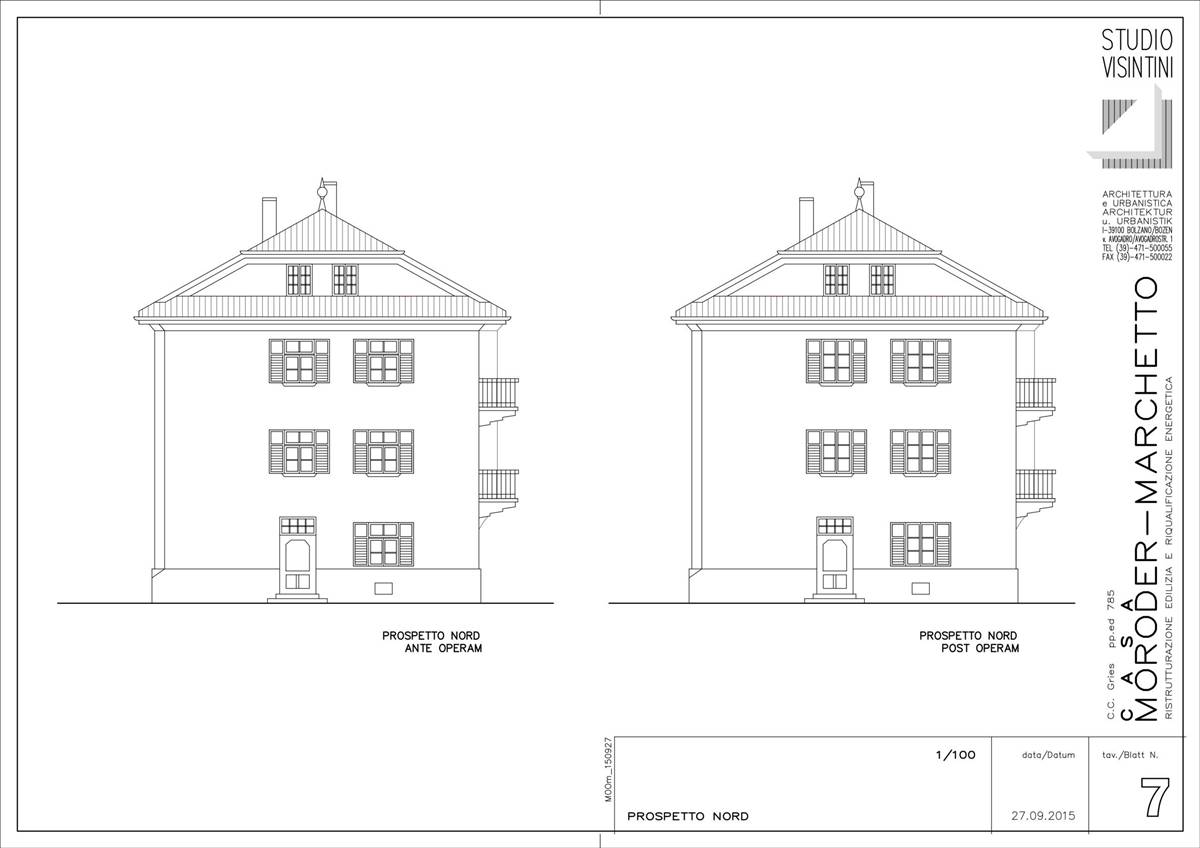

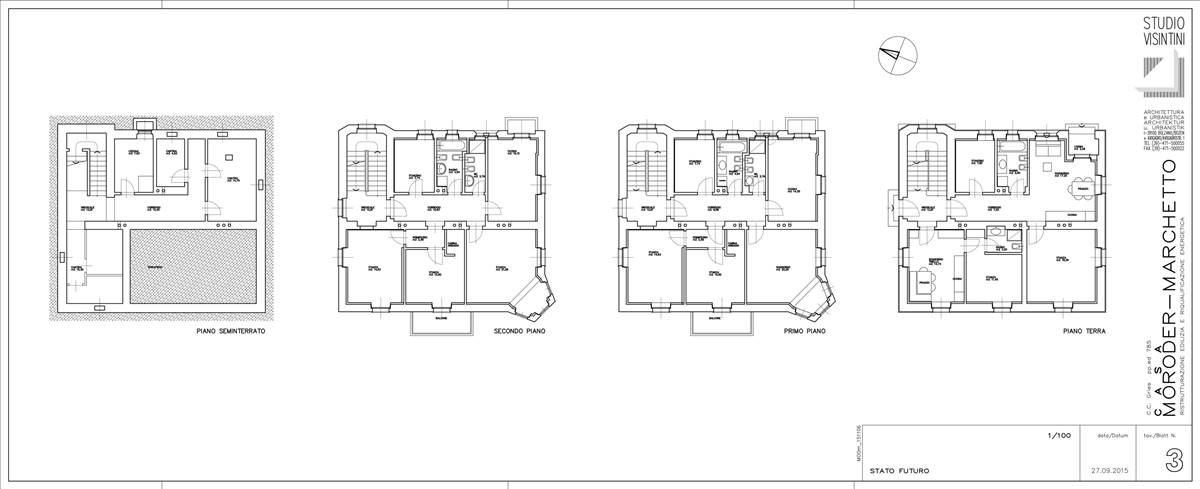

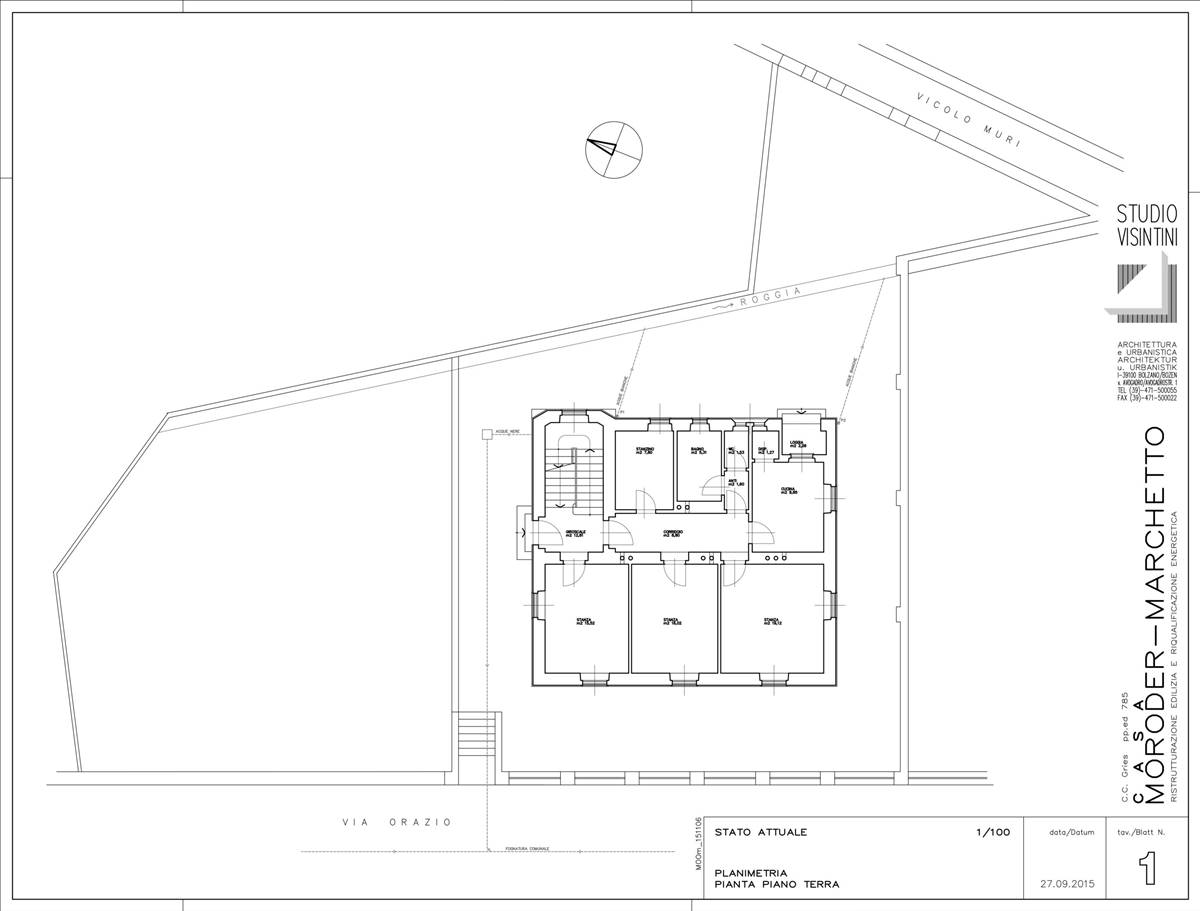

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Arch. Michael Tribus

Griesplatz 6/1 - Piazza Gries, 39011 Lana (Bz)

info@michaeltribus.com

Tel.zusammen mit dem im Haus wohnenden Arch. Augusto Visintini

RETROFIT SOLUTIONS

External Walls

Brick masonry with internal insulation

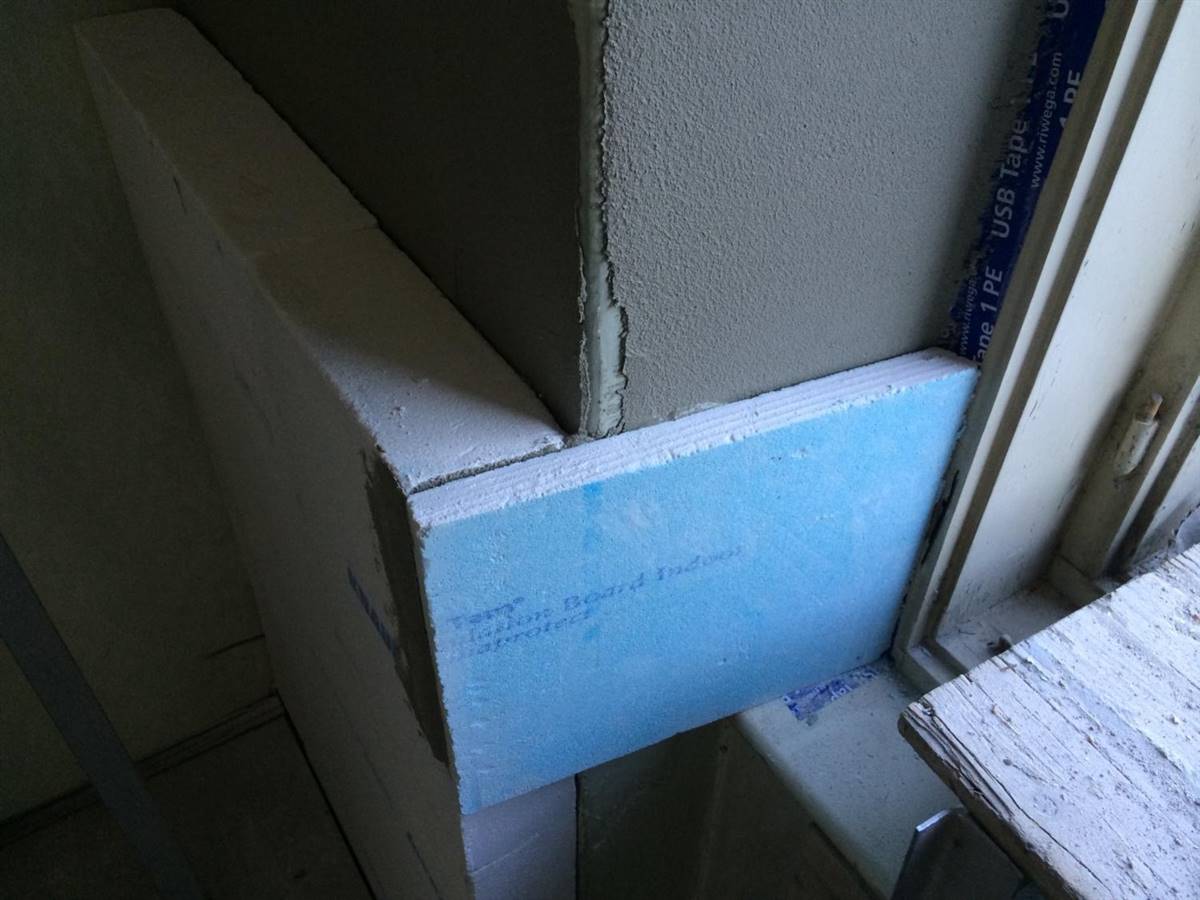

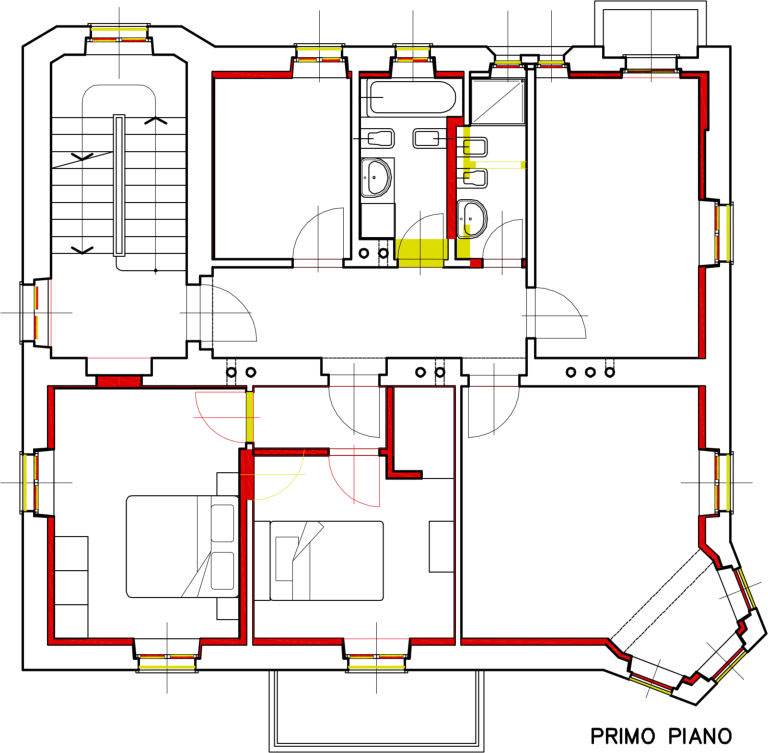

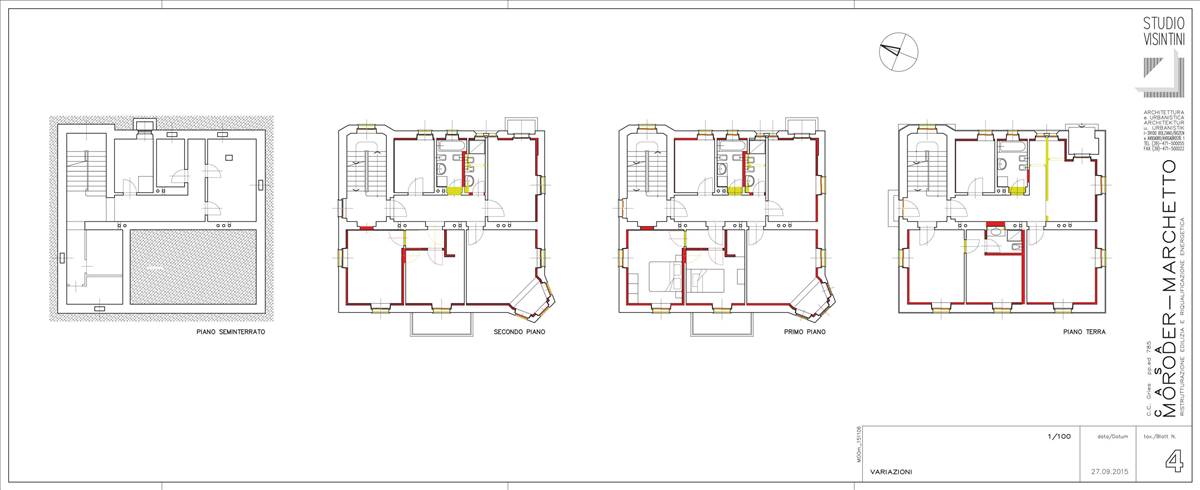

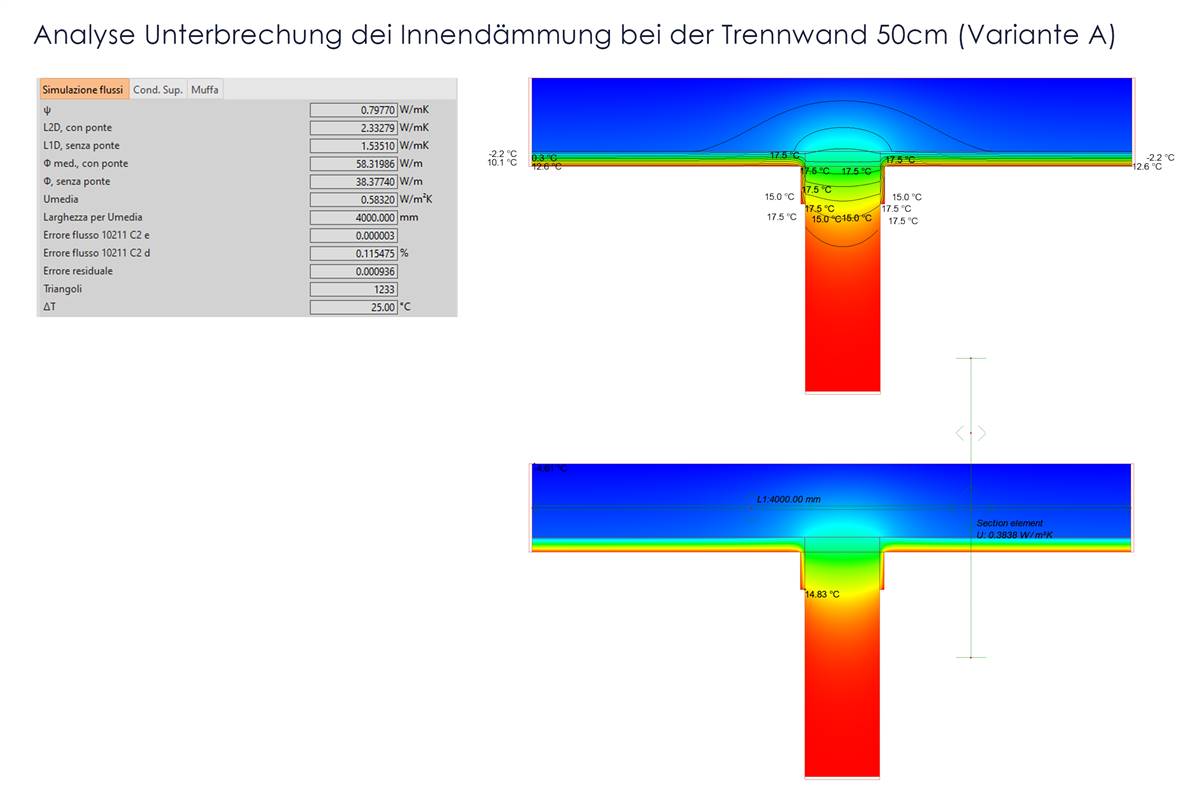

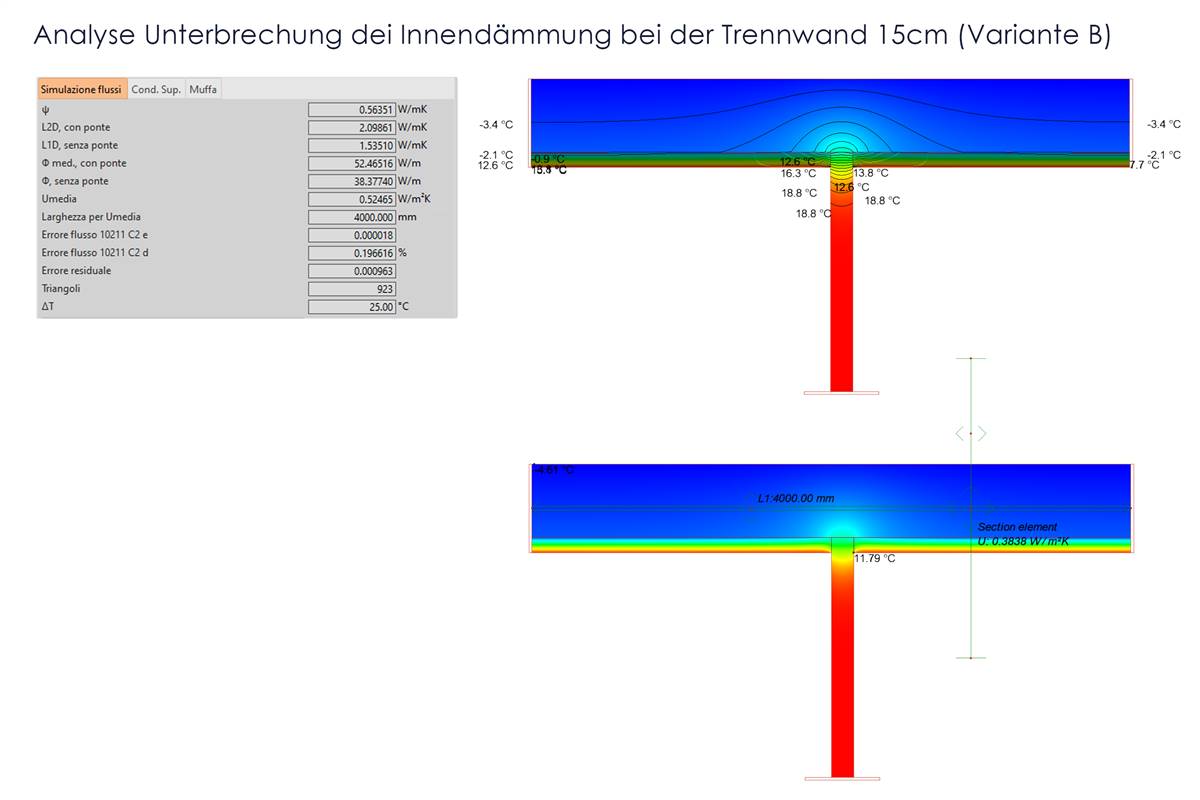

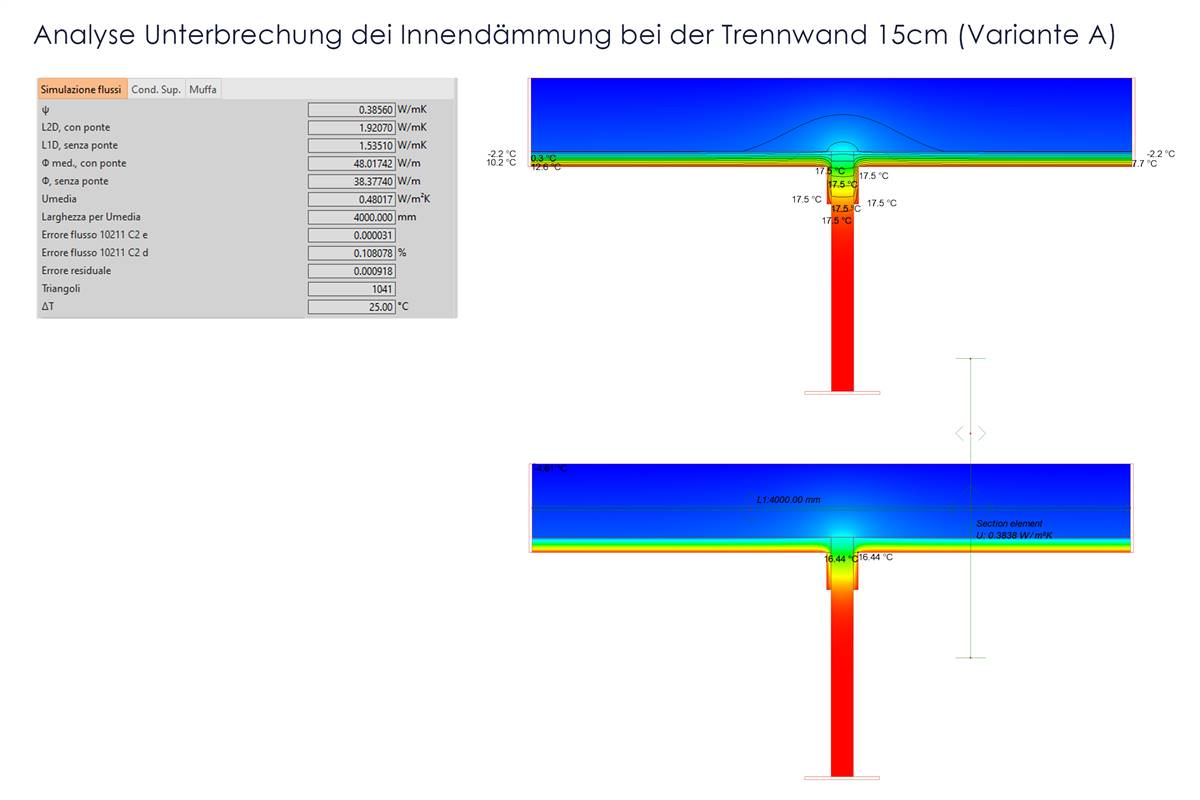

In order to leave the facade untouched, a 10-cm insulation was placed on the inside of all the external walls. A perlite insulation - TecTem from Knauf - was chosen because of its natural composition, which makes it suitable for indoor use. To install the insulation, the internal plaster was removed from the inner surface of the walls. Moreover, a few centimeters of flooring were removed along the wall joints, in order to place a layer of insulation underneath, to avoid thermal bridges. In this way, there won´t be cold spots that cause heat losses. The same principle is applied to the window connections. For this purpose, the interior insulation was laid up to the new window frame in order to prevent heat from being lost through the window splay. In addition, flank insulation was installed over the entire length of the walls in the stairwell area. Since the stairwell had to be kept in its original condition, the interior insulation prevented heat losses from the apartments to the hallway.

15 mm

450 mm

15 mm

15mm

450 mm

15 mm

100 mm

15 mm

Windows

Single window with 3-pane insulating glazing

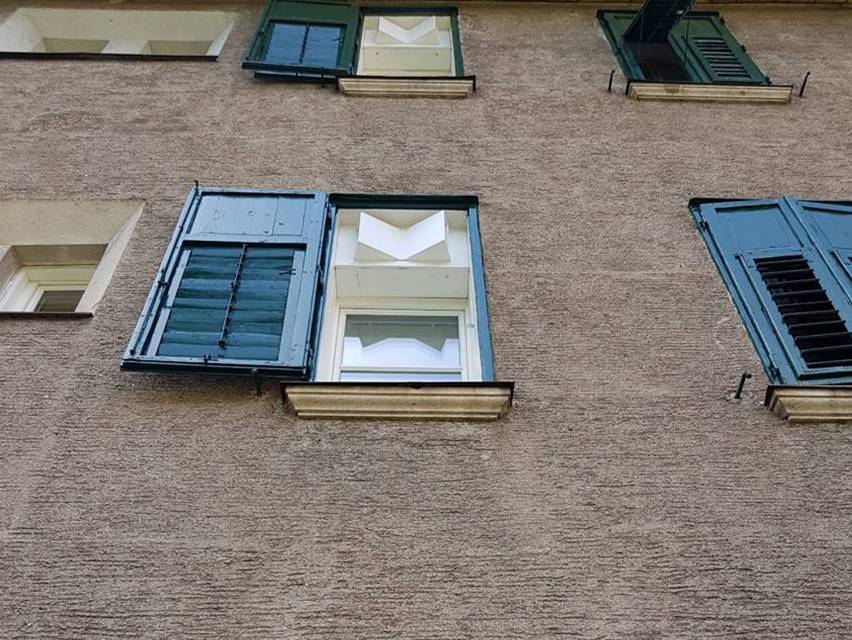

With a U-value of about 2.5 W/m²K, the original windows from 1926 would have been a weak element of the building envelope - both in terms of energy loss and of reduced comfort due to the low surface temperature. Since the building is not listed, the client and architect decided to replace the windows and they developed a solution that is fascinating for its simplicity and helped avoid waste material and to reduce costs:

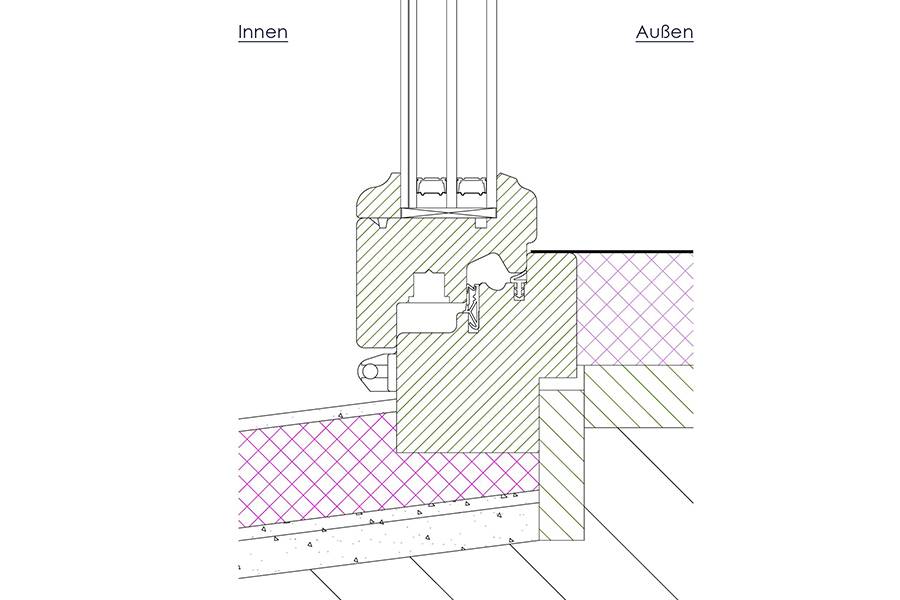

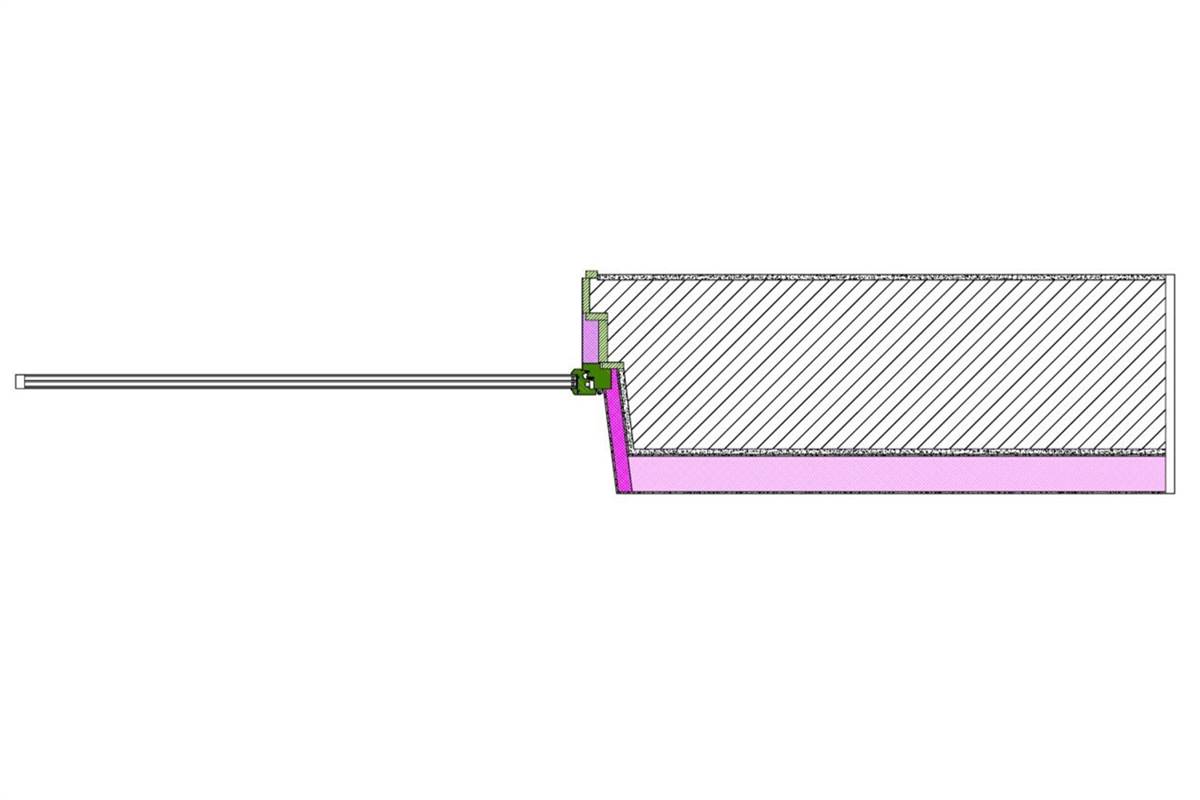

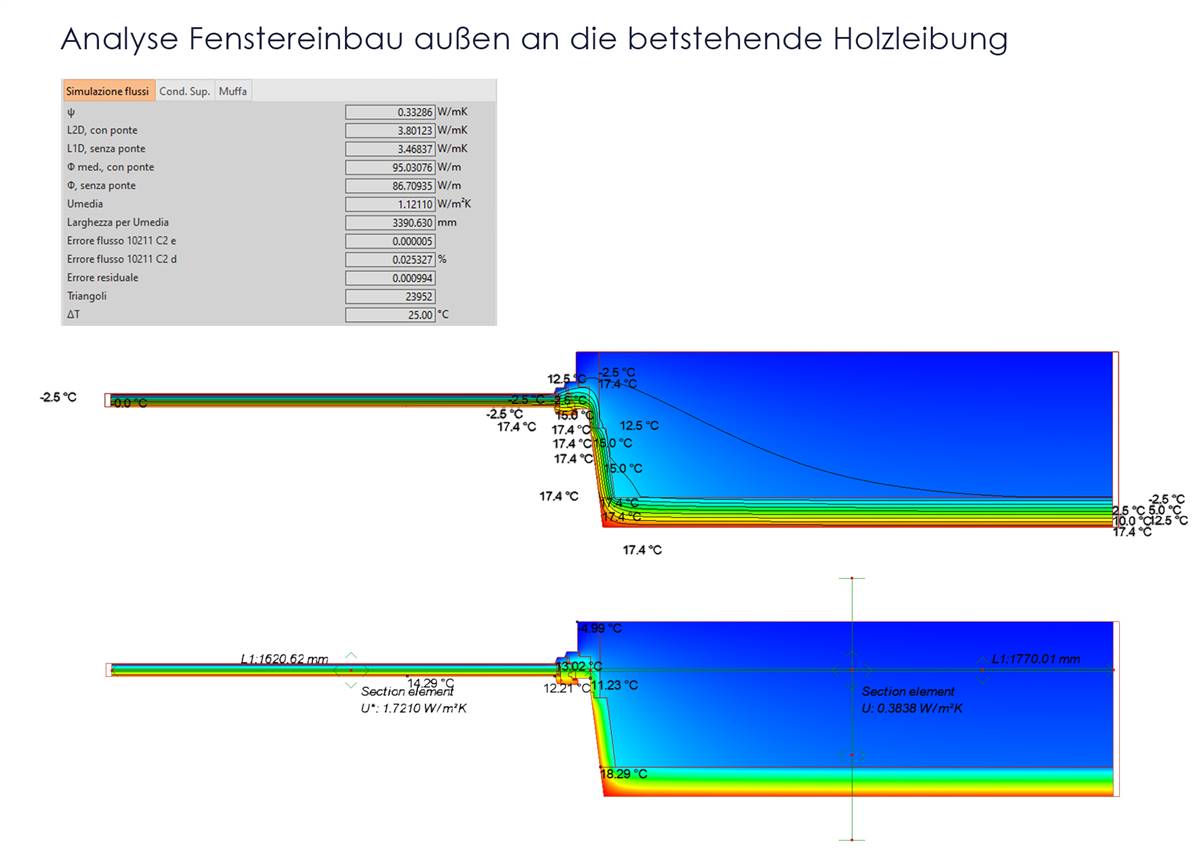

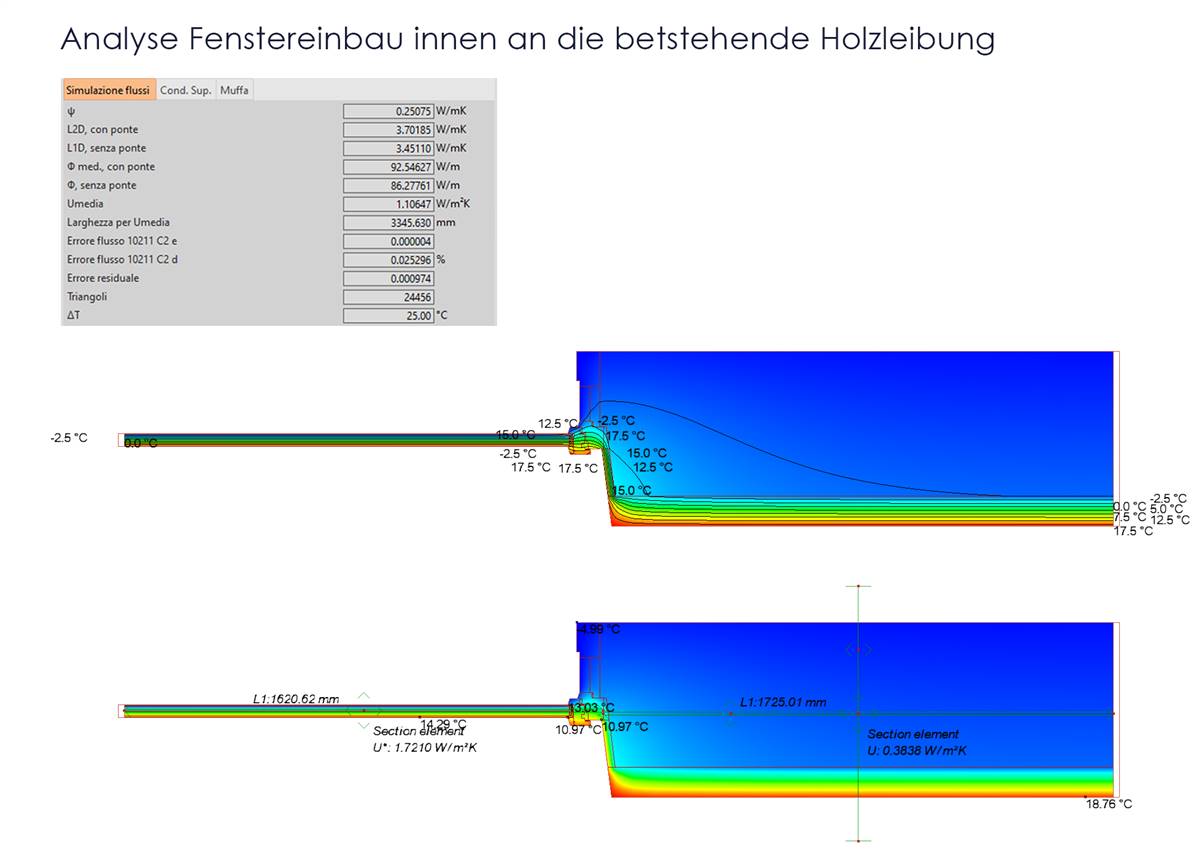

The new wooden window with triple glazing and energetically optimised frame has two sashes again, the division into 3 fields each takes up the look of the original two sashes under the transom and the bottom-hung sash above. It is positioned in the place of the inner plane of the old box window in the existing window frame, so that (i) the window area remains the same size even with the new frame and (ii) the frame perceived on the outside is very filigree, (iii) installation is very simple and (iv) the installation thermal bridge is very easily avoided - by insulating the indentation in the "old" box cavity and on the inside the adjoining reveal. A drawing of the detail, as well as the 2-D calculation of the thermal bridge, for the implemented variant as well as the investigated alternative of keeping the window in the outermost plane can be seen by browsing through the images on the right.

| Existing window type | Box-type window |

| Existing glazing type | Single |

| Existing shading type | Outer shutter |

| Approximate installation year | 1926 |

| New window type | Sash window |

| New glazing type | Triple |

| New shading type | Outer shutter |

| New window solar factor g [-] | 0,47 |

Other interventions

OTHER

To complete the insulation most effectively, external insulation was placed in the basement and in the attic, i.e. in the non-habitable area. Since the attic was not developed as a habitable space and this project was not in the near future, 20-cm thick polystyrene boards were laid on the floor in a double layer. The final layer is a USB wooden panel to keep the roof truss accessible.

The ecological aspect of this measure is that the material can be dismantled and reused at any time in case of an extension.

HVAC

HEATING

VENTILATION

AIR CONDITIONING

Since there was no heating system in the entire house before the renovation, the single gas-heater was replaced by a central heat pump heating system.

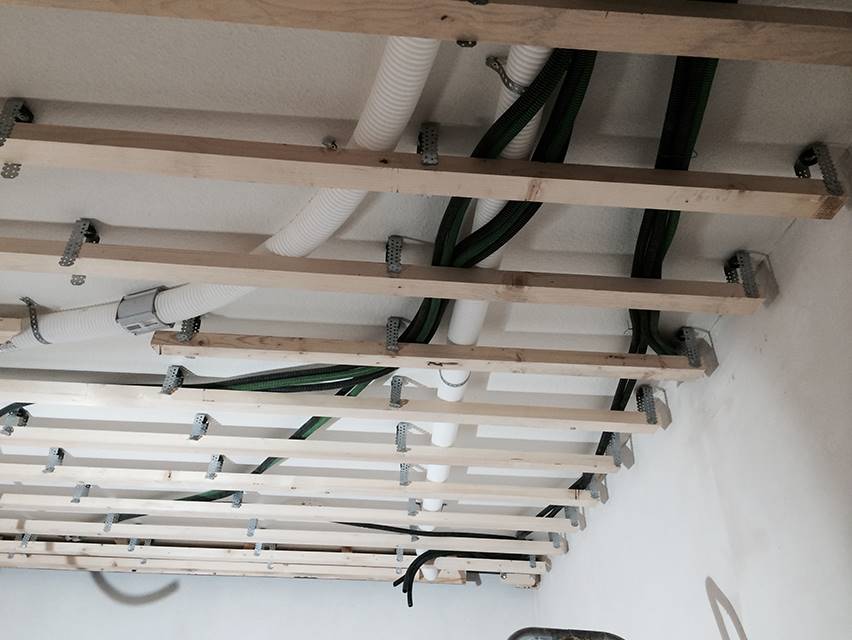

To make the installation as easy as possible, the heating system was installed in the ceiling. With a room height of 2.85m, it was possible to install the clay panels with embedded heating pipes in a suspended ceiling. In addition to the insulation made of natural material, a user-friendly design was also chosen for the heating system by using clay. In addition, clay has humidity-regulating properties, which allow the material to absorb the humidity and to gradually release it. The entire system was thus no longer directly visible to the occupant after shoring. After the renovation, all the apartments can be permanently heated.

| New primary heating system | |

|---|---|

| New system type | Heat pump |

| Fuel | Electricity |

| Distribuition system | Radiating ceiling |

| Nominal power | 11 kW |

In order to guarantee a constant good air quality and to avoid the heat waste related to ventilation, each flat was equipped with a dedicated ventilation system with heat recovery. The ventilation unit themselves were places in the bathroom and the air ducts were led through the suspended ceiling.

No holes had to be drilled in the façade to supply the fresh air and to remove the stale air: the supply and exhaust air is guided via a customized construction in the bathroom window, inconspicuously housed in the area of the former tilting window above the transom.

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Decentralized |

| Type flow regime | Overflow |

| Heat recovery | Si |

| Humitidy recovery | No |

| Nominal power | 0,27 kW |

| Electric power | 0,27 kW |

| Control system | Continue, 5 control points (30-150 m3/h) |

Thanks to the renovation, the cooling of the apartments during summer was also made possible: the heat pump can be switched from heating to cooling mode, and the radiating ceiling can provide space cooling.

This is not a "full air conditioning" (no moisture can be extracted from the air by the cooling surfaces, for example), but rather a supplementary measure to ensure summer comfort. Together with this system, the window shutters - with their flap elements typical of the region - allow to protect the building from overheating while letting a certain amount of light entering the house.

| New cooling system | |

|---|---|

| Type | Heat pump |

| Distribuition system | Radiating ceiling |

| Nominal power | 10,61 kW |

| Electric power | 2,72 kW |

Energy Efficiency

Voluntary certificates: No

Primary Energy 45 kWh/m2.y

Consumption_estimation_After: 21 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: Steady state simulation (e.g. EPC, PHPP)

Consumption_estimation_Including_DHW: Si

Consumption_estimation_Before: 365 kWh/m2.y

Consumption_estimation_After: 45 kWh/m2.y

Internal Climate

Since a heating and cooling system is installed in the entire building, the indoor temperature can be maintained at a constant and comfortable level. This has greatly improved the comfort in the living spaces, as the fluctuations of the outside temperature are no longer perceivable from the inside.

The new ventilation system ensures fresh and clean air in each apartment. Since a single ventilation unit was installed separately for each apartment, the operation of the system can be managed as needed. An automatic exchange of the entire air volume is assured every 2 hours, but the air flow can be increased or decreased by the users. Thanks to the system, the occupants noticed a clear reduction of dust in the air.

Costs

The Italian government supplies a financial subsidy to people who take energy-efficiency measures during the building renovation works. In the case of the presented refurbishment, the owners were able to deduct from the taxes the 2/3 of the costs during the years following the work. An additional financial benefit was the reduction of heating need, which led to direct money saving in relation to lower bill payments: the running cost for each apartment was therefore reduced from 5,000-6,000€ to 800€. Since a conventional refurbishment was expected to lead only to a 20% -reduction of the total costs, the additional measures were paid back after only a few years.

500.000€ (total)

2.400,00€ im Jahr (total)

Lifecycle cost

No