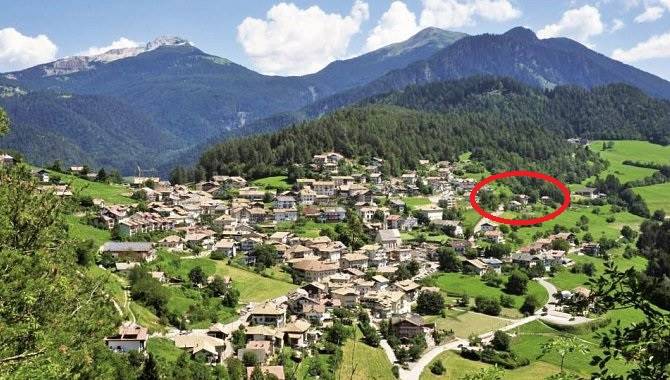

House Pernter

Main Road 20

39040

Truden in the natural preserve, Italia

Contact Details

Other Information

architektur südtirol 2017/2018

Climate Zone F

Altitude 1100 s.l.m.

HDD 268

CDD 0

Conservation Area:

No

Level of Protection:

NA

Year of last renovation:

2017

Year of previous renovation:

1965

Secondary use:

Agricultural & Fishery

Building occupancy:

Permanently occupied

Number of occupants/users:

5

Building typology:

Detached house

Number of floors:

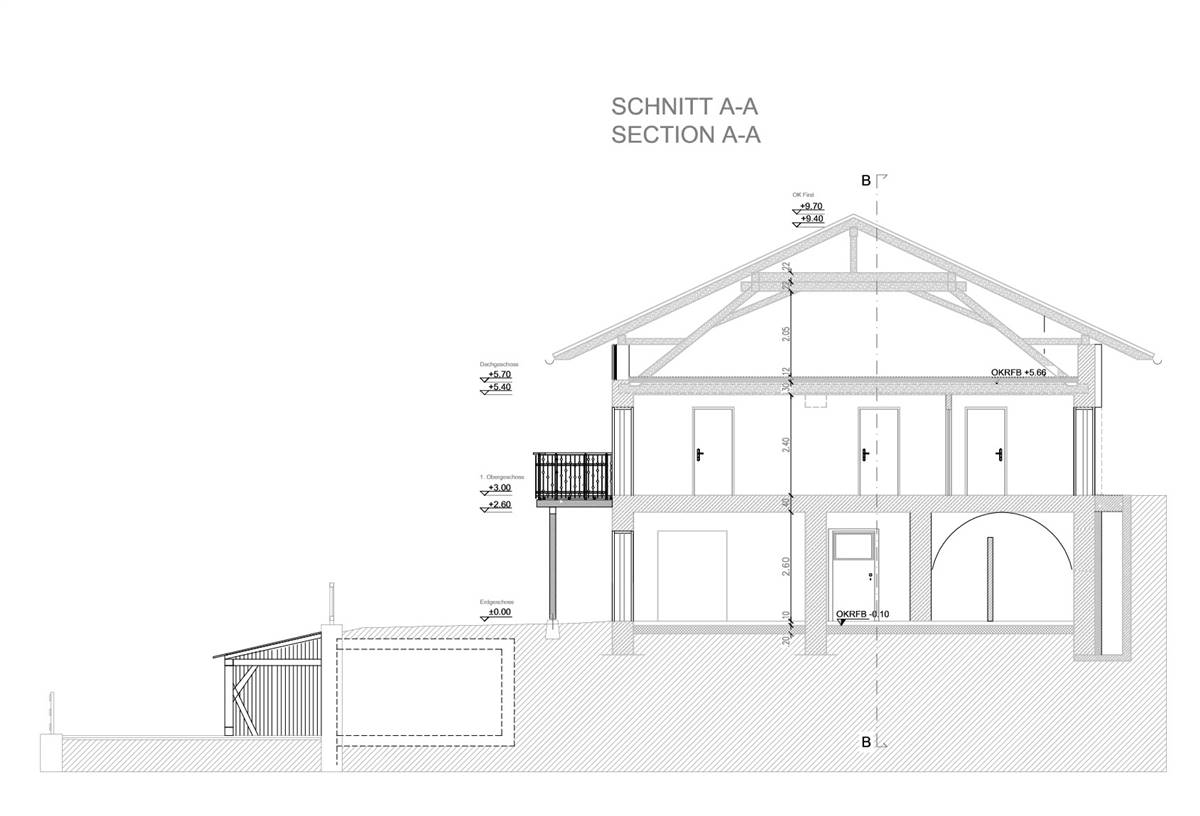

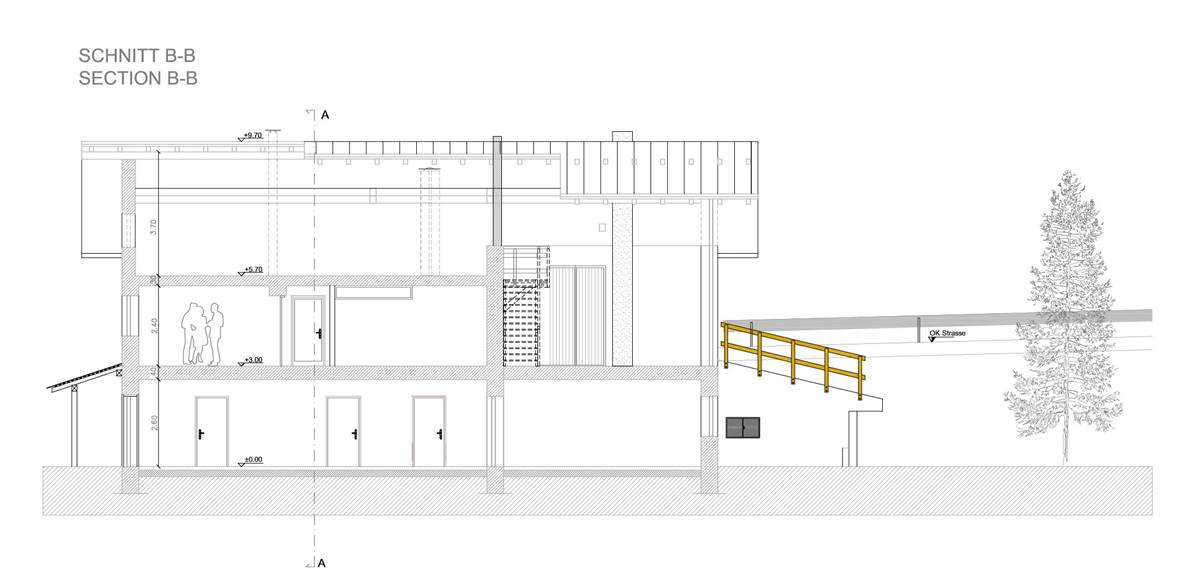

3

Basement yes/no:

No

Number of heated floors:

2

Gross floor area [m²]:

336,0

Thermal envelope area [m²]:

225,0

Volume [m³]:

642,0

NFA calculation method:

Useful area (it)

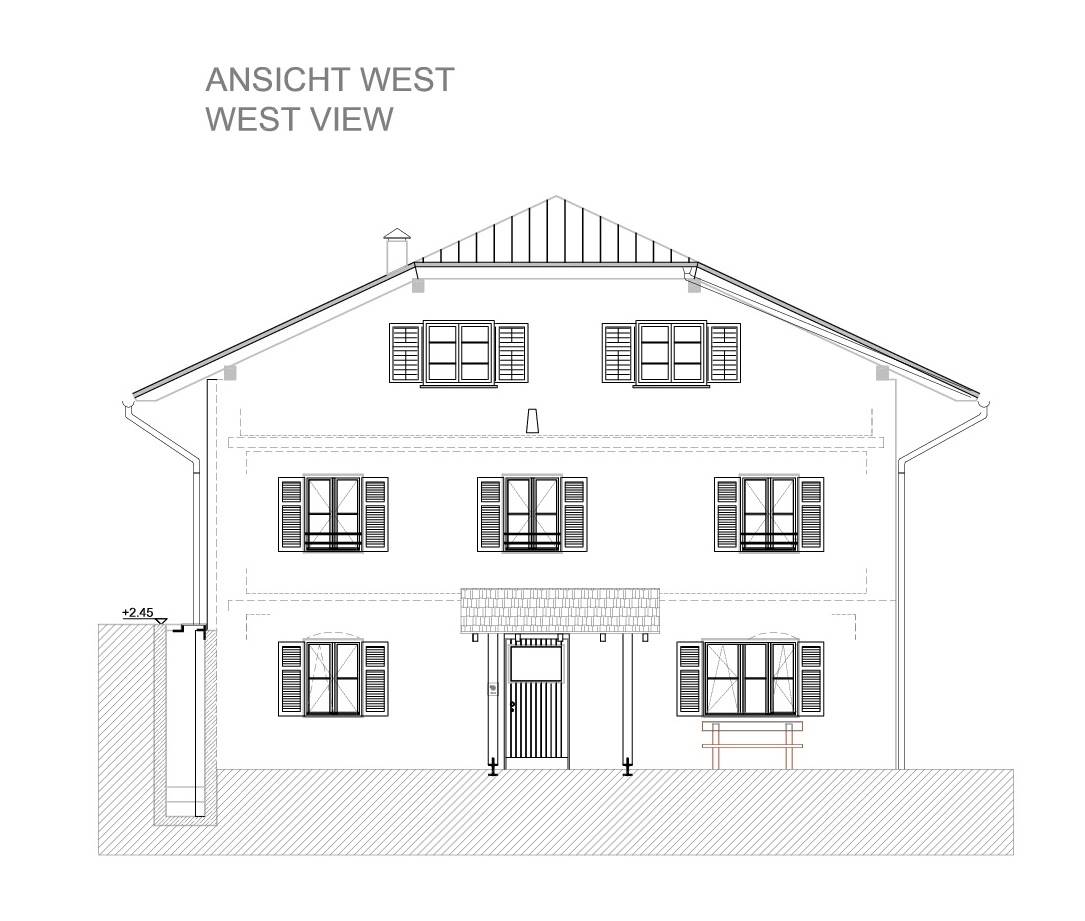

External finish:

Rendered

Internal finish:

Plastered (on hard)

Roof type:

Pitched roof

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Oscar Dibiasi

Hügelgasse 14, I-39040 Montan

info@oscar-dibiasi.com

Tel.333 1403644

Marcus Varesco

Fleimstalerstraße 1 , 39044 Neumarkt

marcus@bampi-varesco-steiner.it

Tel.339 6561576

Hygrothermal assessment NA

Life Cycle Analysis (LCA) NA

RETROFIT SOLUTIONS

External Walls

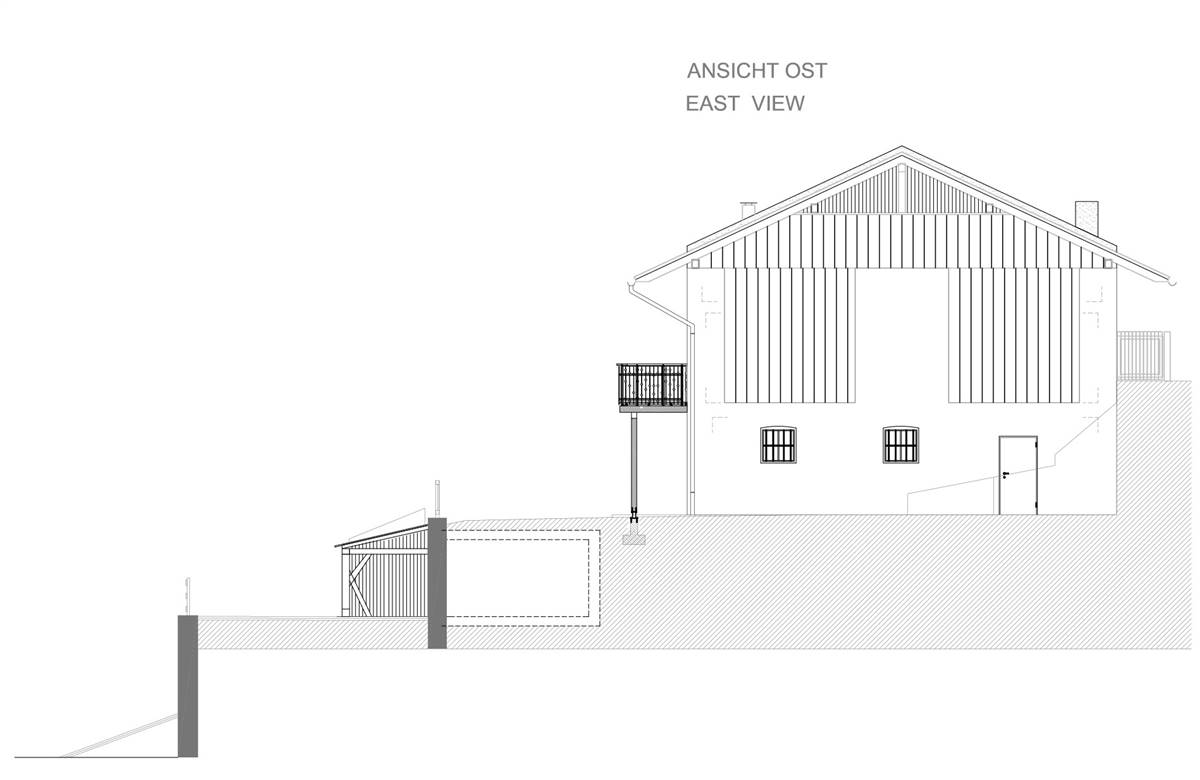

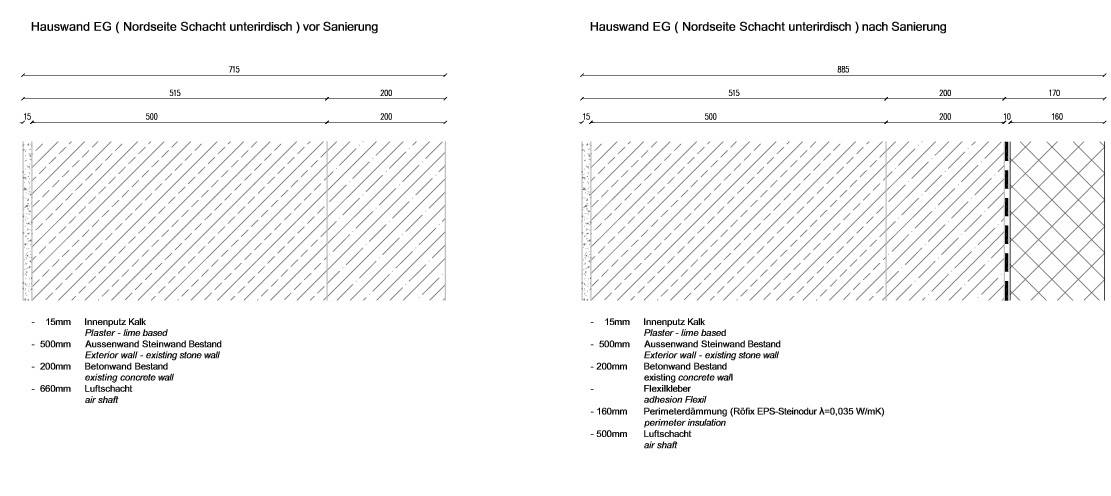

Exterior Wall nord side air shaft

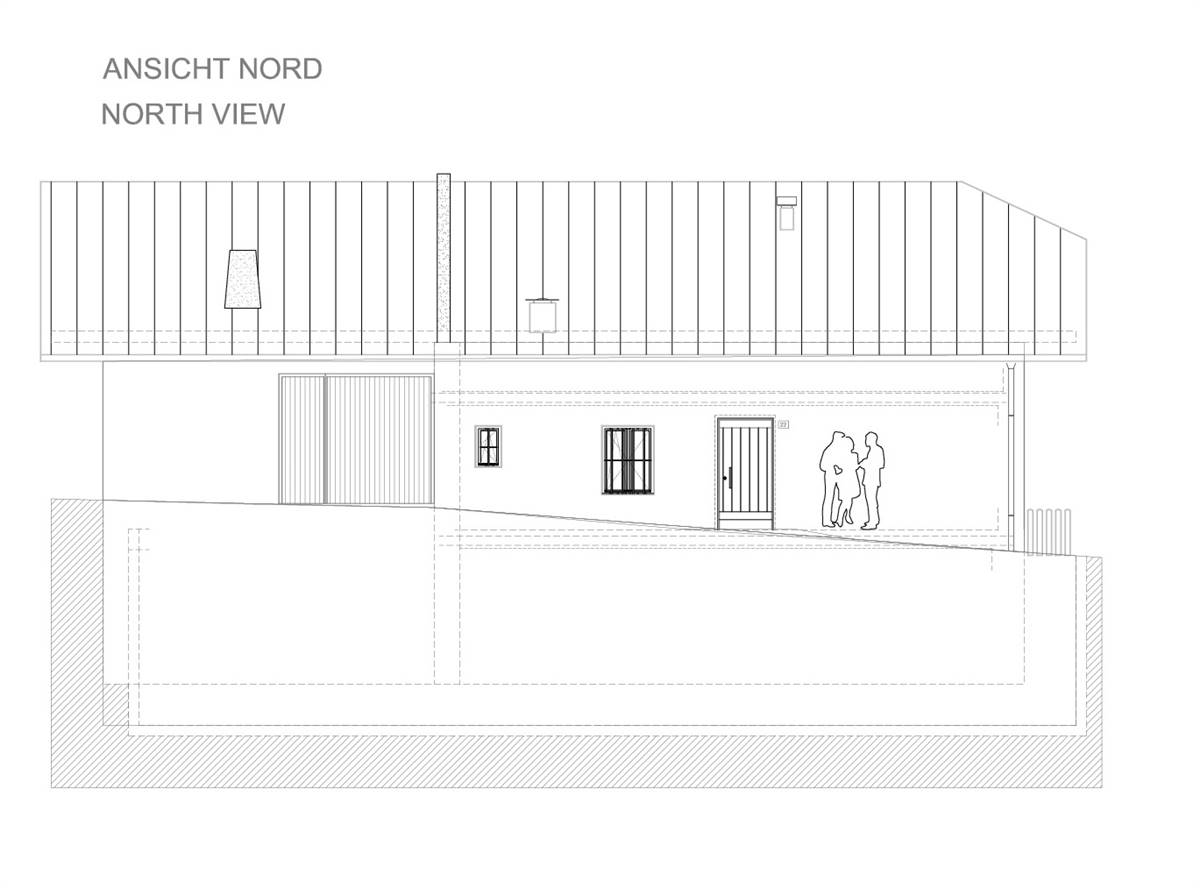

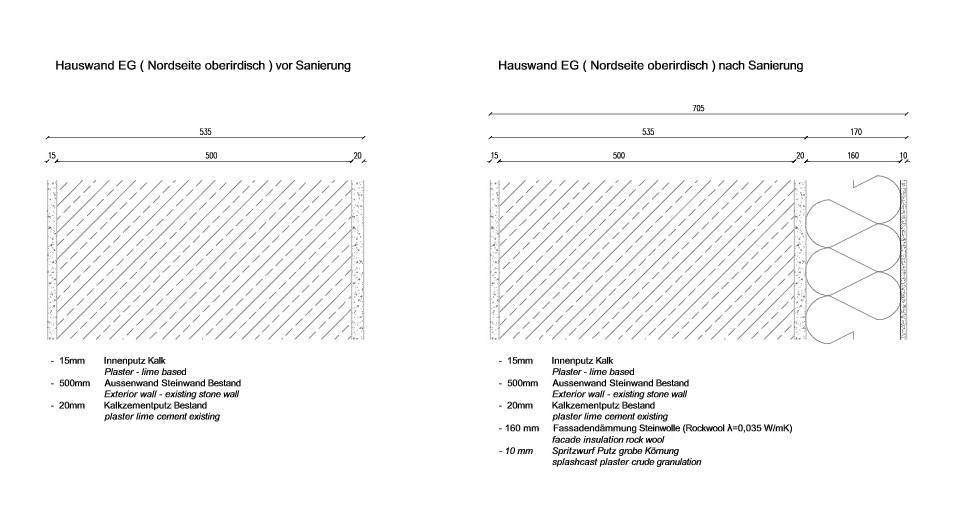

Exterior Wall nord side top floor

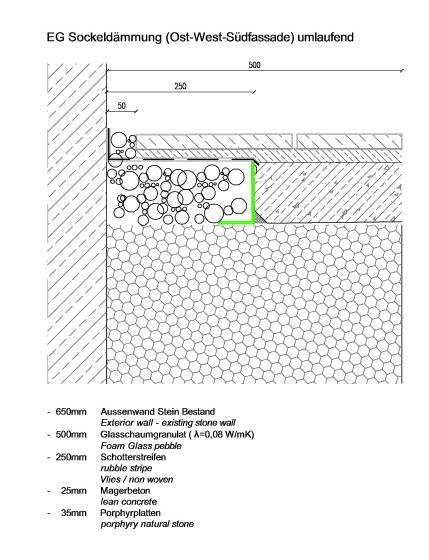

Groundfloor plinth insulation

The underground plinth in the North was treated with a cold bitumen coating and insulated with a 16 cm perimeter insulation that reaches from the foundations to the first floor.

As the wall is located in proximity to the shaft, the addition of the insulation layer is not visible from the outside.

15 mm

500 mm

200 mm

160mm

10 mm

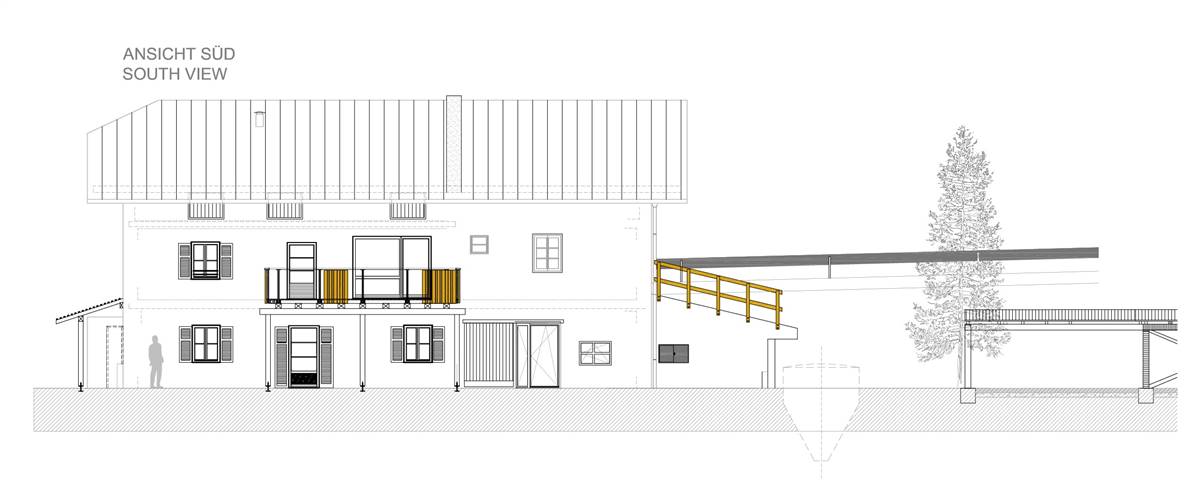

From there, an stone wool insulation with the same thickness was applied until the upper edge of the facade. This facade insulation is only applied on the North side, that during winter cools down the most.

15 mm

500 mm

20 mm

160mm

10 mm

0 mm

The plinth of the East-, West- and South-facade is surrounded by a 50 cm wide stripe of foam glass pebble, reaching from the foundations to the ground level. It allows moisture, originating from precipitations or the soil, to evade.

application subterranean, invisible

650 mm

500mm

250 mm

Windows

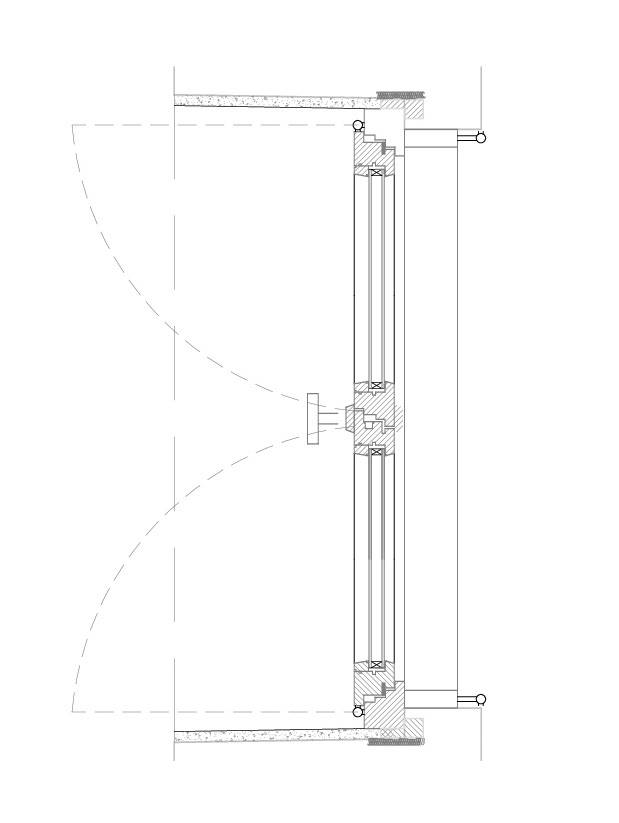

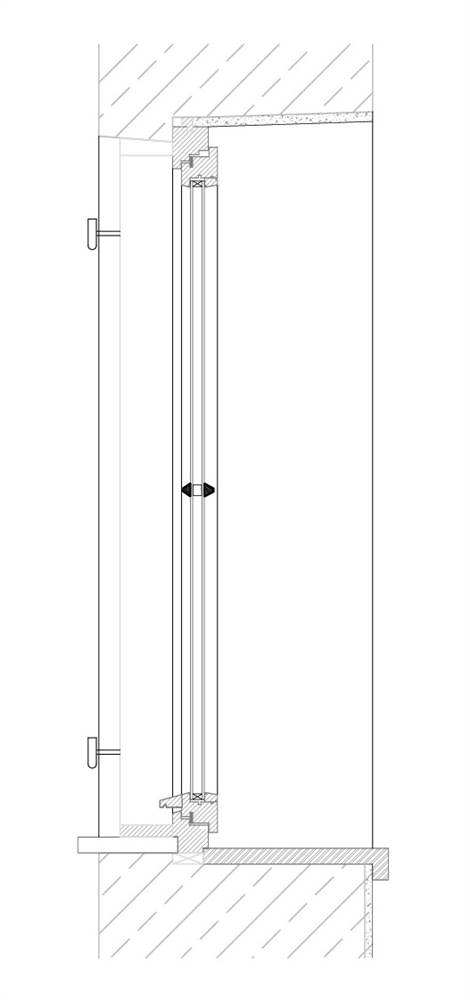

window living-room

All windows were replaced with new elements to fulfill current technical standards. The new lattice windows and balcony doors are close to the original, but have a double security glazing. Windows: Spruce wood, double laminated safety glazing U-value: 1,1 Shutters: Spruce wood, folding elements with fixed horizontal battens. Color: light green, as in many traditional farm houses

timber frame with indigenous larch with UV protection glaze

| Existing window type | Casement window |

| Existing glazing type | Single |

| Existing shading type | Outer shutter |

| Approximate installation year | 1923 |

| New window type | Casement window |

| New glazing type | Double |

| New shading type | Outer shutter in wood |

| New window solar factor g [-] | 0,0 |

Other interventions

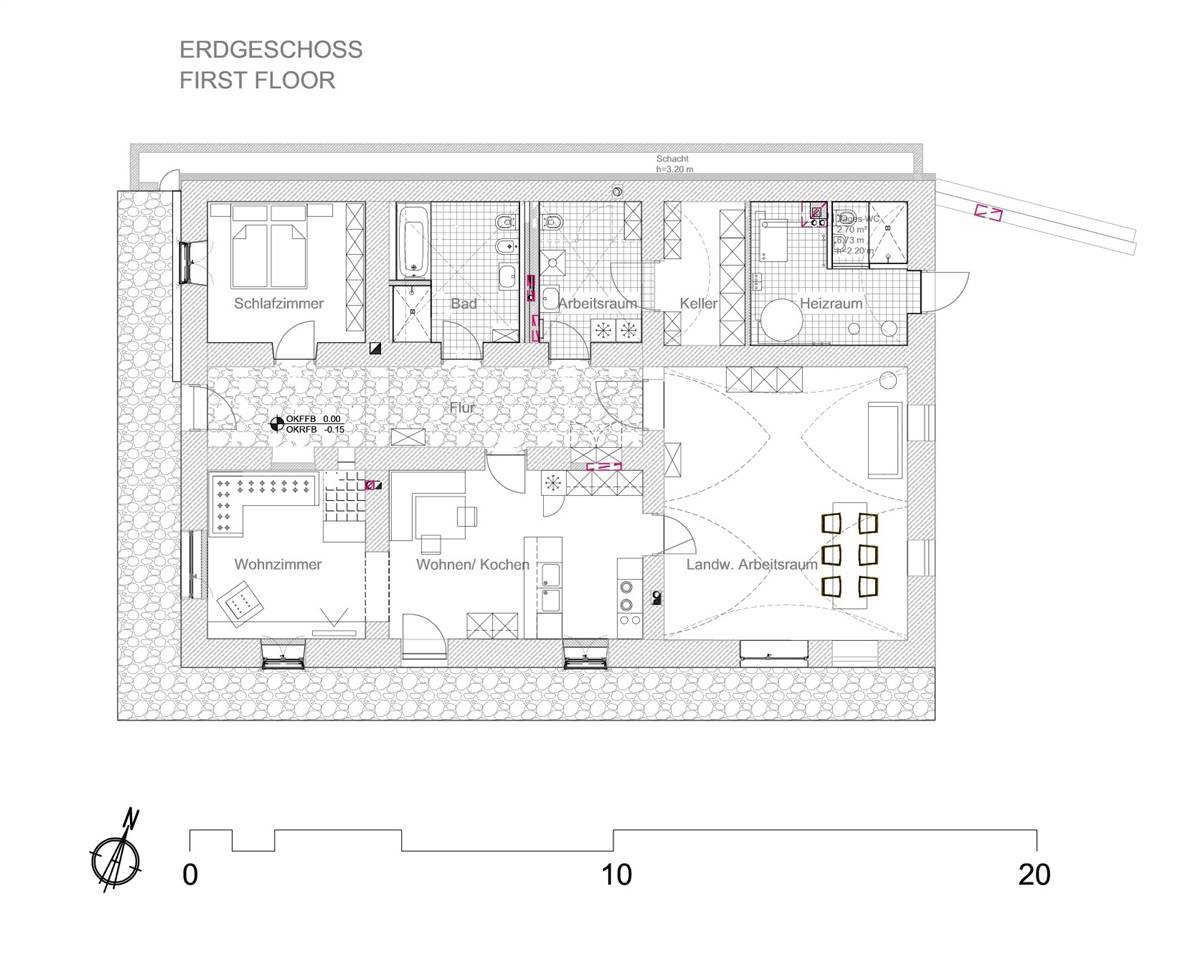

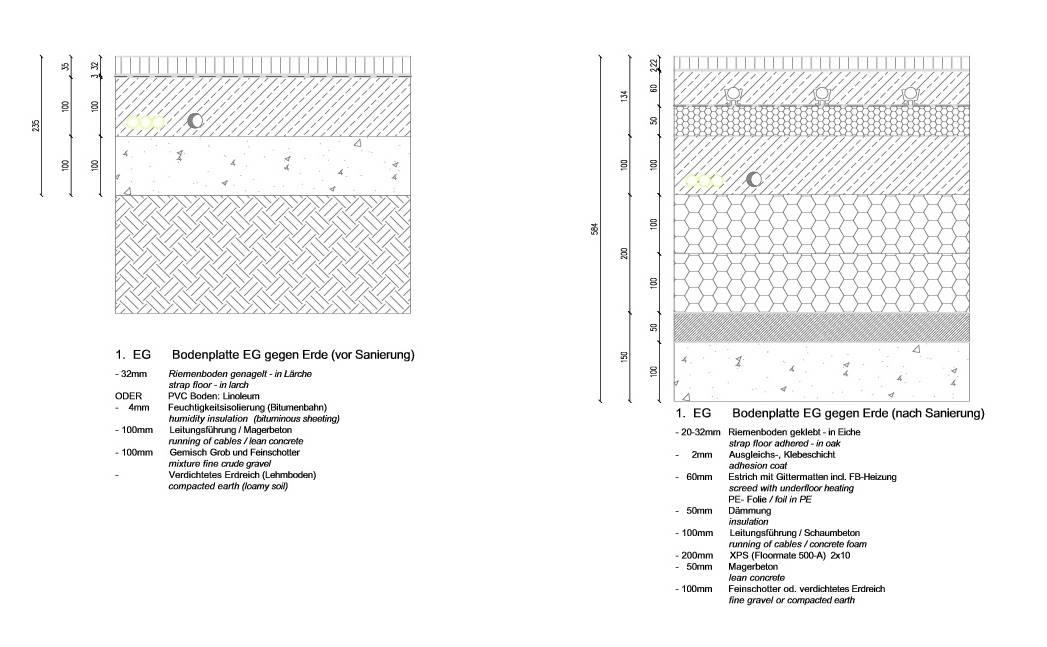

GROUND FLOOR

OTHER

Usually the Floor covering was built directly on the soil. This led to the renewal of the groundfloor flooring: in order to block the cold from the soil, a 20cm layer of XPS was laid. On top of this insulation the new floor structure with the underfloor heating was installed.

application subterranean, invisible

0 mm

100 mm

32 mm

50 mm

200 mm

100 mm

50 mm

60 mm

32 mm

HVAC

HEATING

VENTILATION

DOMESTIC HOT WATER

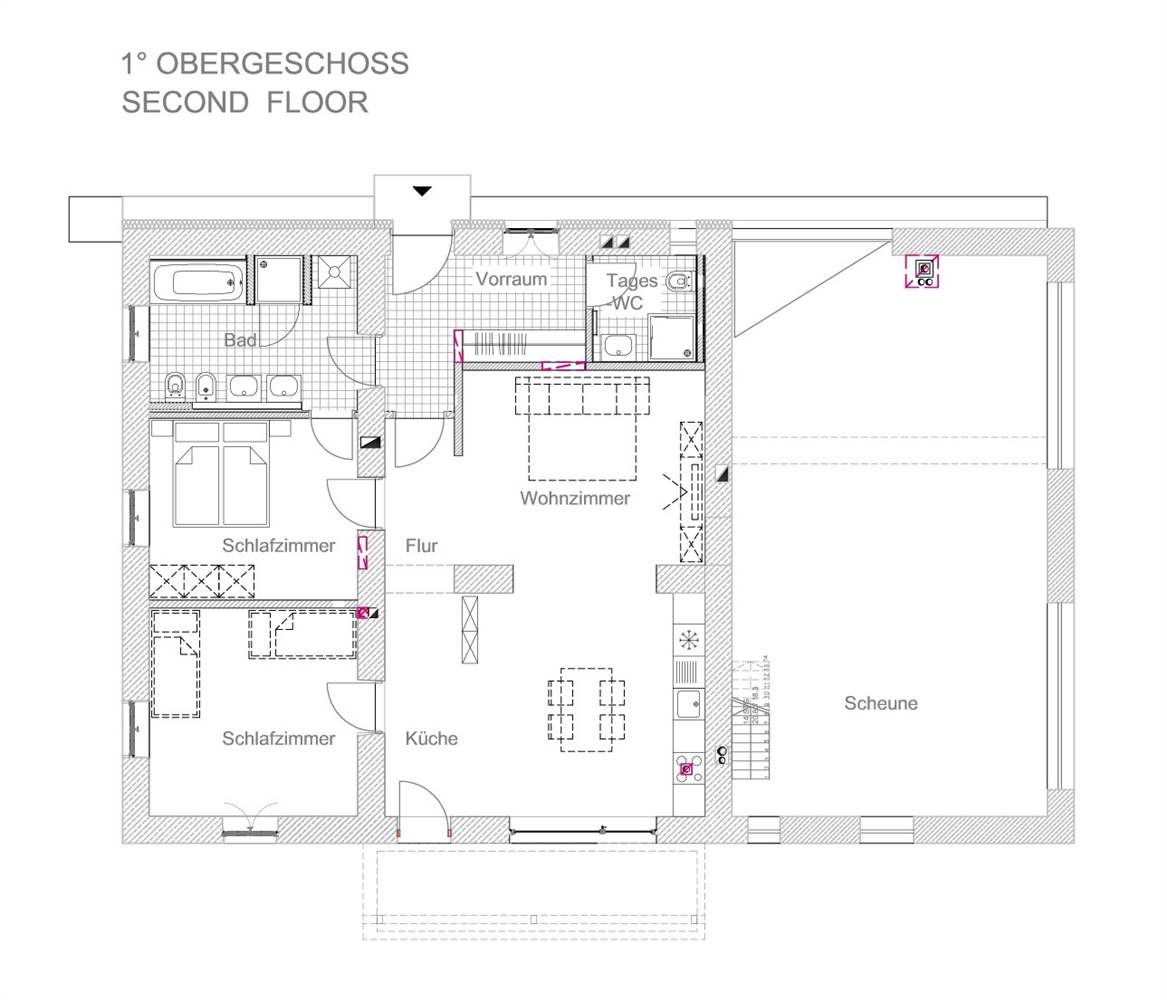

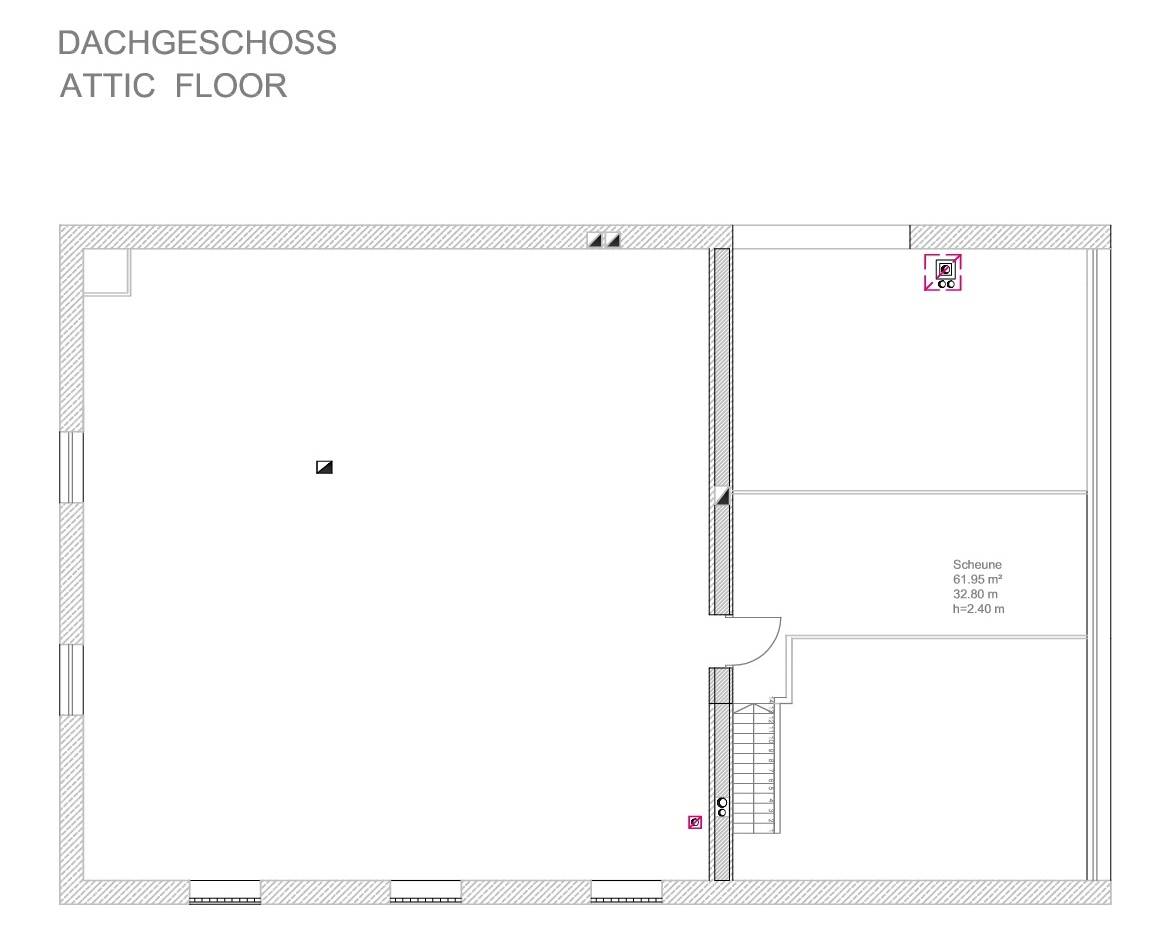

As a part of the renovation works, a central heating plant was installed. This led to the renewal of the groundfloor flooring: in order to block the cold from the soil, a 20cm layer of XPS was laid. On top of this insulation the new floor structure with the underfloor heating was installed. Similarly, underfloor heating was installed on the 1st floor. The ducts were laid between the structural wooden beams and insulated with light aggregate. On top of the beams, footfall sound insulation and finally the screed layer with underfloor heating were laid. The heating plant is fueled by wood pellets and located underground on the outside, allowing for the realization of additional spaces such as a deposit and a working space within the existing building. The existing chimneys were maintained and renovated were needed. Were no longer needed, the chimney shafts were used as installation shafts for HVAC ducts. The wood-fired stove on the groundfloor remains active and in the kitchen a new wood-fired hearth was installed to complement the electric hotplates.

Pellets are stored outside of the building in an underground steel tank.

| New primary heating system | New secondary heating system | |

|---|---|---|

| New system type | Boiler | Stove |

| Fuel | Biomass | Wood |

| Distribuition system | Radiating floor | Air |

| Nominal power | 14,9 kW kW | NA kW |

In the bathroom on the groundfloor facing North mechanical ventilation replaces the window in order to guarantee sufficient ventilation. The device also is equipped with a heat recovery function. For the dehumidification of the building there is a narrow shaft on the North of the building. The existing opening of the shaft was only maintained on the North-East edge of the building, while the remaining surface was covered. In order to guarantee a good cross ventilation, the entrance door to the shaft on the other side has a large ventilation grill.

NA

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Room-by-room |

| Type flow regime | NA (Natural) |

| Heat recovery | Si |

| Humitidy recovery | No |

| Nominal power | NA kW |

| Electric power | kW |

| Control system | NA |

RENEWABLE ENERGY SYSTEMS

SolarThermal

Biomass

The solar-thermal plant was installed as a large area collector on the roof of the adjacent building, taking advantage of its favorable inclination and position. In the summer months, a large part of the warm water demands can be covered. The plant is a custom built high-performance large area collector, made of a powder-coated aluminum hollow-cell frame profile with lateral thermal insulation and a highly selective copper absorber.

The solar-thermal plant was installed on the roof of an adjacent building and is invisible from the main building and the street.

The solar plant was integrated in the roof of an existing pavilion located below the house.

| SolarThermal System | |

|---|---|

| Type | Flat collector |

| Collector area | 8,0 m² |

| Elevation angle | 68,0 |

| Azimuth | 0,0 |

| Overall yearly production | 5,0 kWh |

| Heating_contribuition | 0,0 kWh |

| DHW contribuition | 3,0 kWh |

| Cooling contribuition | 0,0 kWh |

ETA PU Pellet boiler with modulating firing control

Pellets are stored outside of the building in an underground steel tank.

separate boiler room inside the building

| Biomass System | |

|---|---|

| Type | |

| Storage size | |

| Origin of biomass | |

| Overall yearly production | 14,0 kWh |

Energy Efficiency

Consumption_estimation_After: 26,50 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: NA

Internal Climate

medium 20° C in the wintertime in the heated rooms

good

very good

gut

Costs

The architect worked with a fixed budget determined by the client. In order to stay within the given budget, some of the commissioner's wishes such as the realization of bay-windows and thermal insulation on all facades could not be fulfilled. Also, the roof framework and covering could not be renovated. These cuts allowed for the realization of an underground pellet storage tank in steel and a solar-thermal plant. Both interventions are positioned out of sight and therefore do not take up space within the existing building or impact its appearance. The decision to insulate the Northern facade only is supported by the geographical exposition of the building: the other three sides are well exposed to the sun throughout the year. Besides the economic reasons – an insulation on all sides would have exceeded the budget – there was an architectonic argument, too: the re-making of all four facades would have drastically changed the tactile experience of the building's exterior. With a current-day plaster applied on an insulation layer it would have been impossible to preserve the character of the historical exterior.

1500 € (per m2)

Amount includes: The above mentioned costs contain all renovation work on the facade and the interior, the renewal of all building services (electricity and heating), the exterior pavings as well as the solar-thermal plant and the construction of a timber shed for bicycles and motorbikes.

2100 (total)

Annual electricity cost

1500 (total)

Lifecycle cost

No