Ansitz Kofler

39100

Bozen, Italy

Architect

Contact Details

Other Information

Master Thesis Hannes Mahlknecht, several conference proceedings

Climate Zone dfa

Altitude 260 m a.s.l.

HDD 2570

CDD 0

Conservation Area:

Yes

Level of Protection:

Listed under BLR-LAB 4980 from 25.07.1977

Year of last renovation:

2008

Year of previous renovation:

1925

Secondary use:

NA

Building occupancy:

Permanently occupied

Number of occupants/users:

6

Building typology:

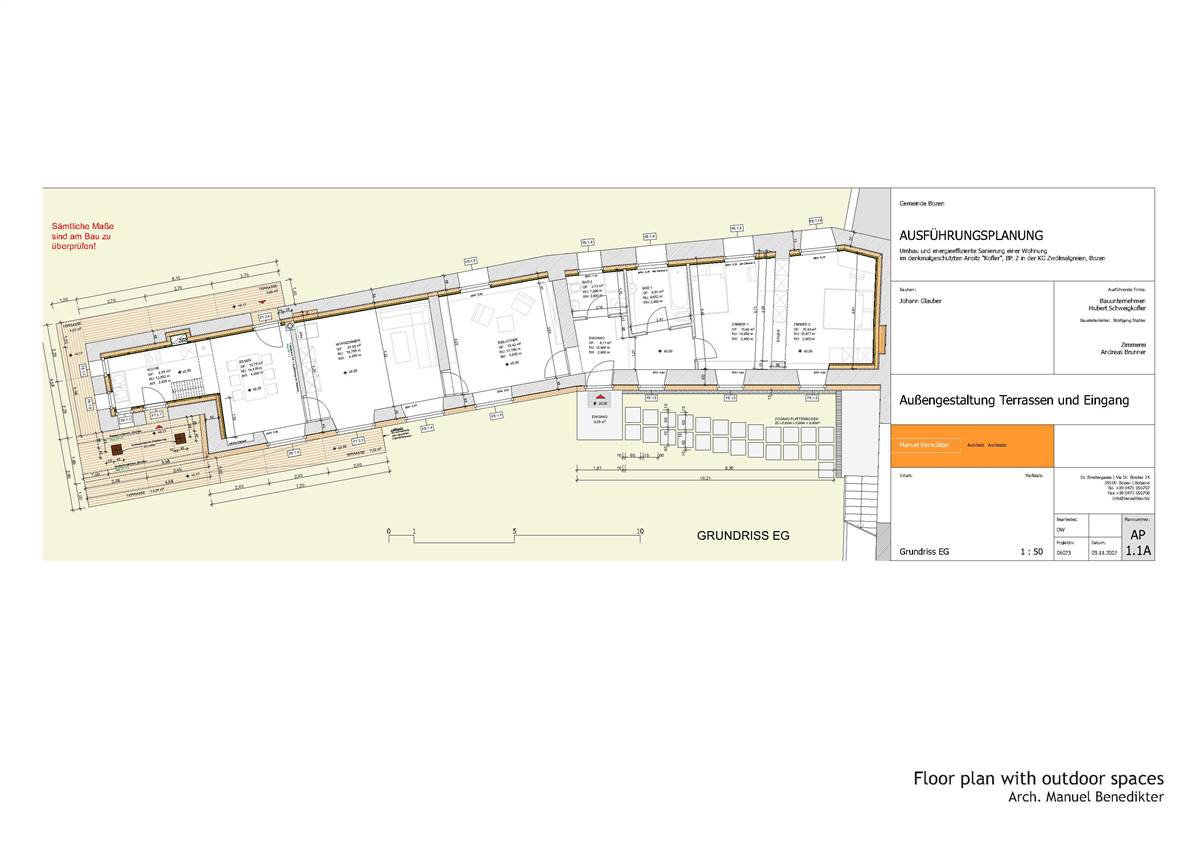

Refrubished was the wing of a detached house

Number of floors:

1

Basement yes/no:

No

Number of heated floors:

1

Gross floor area [m²]:

176,0

Thermal envelope area [m²]:

1206,0

Volume [m³]:

742,0

NFA calculation method:

Useful area (it)

External finish:

Rendered

Internal finish:

Plastered (on hard)

Roof type:

Terrasse above dwelling

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Hans Glauber

Building owner

Eurac Research

Drususallee 1, 39100 Bozen

renewable.energy@eurac.edu

Manuel Benedikter

Zwölfmalgreiner Straße 11, 39100 Bozen

info@benedikter.biz

Felderer Klammsteiner energytech

Negrellistraße 13, 39100 Bozen

info@energytech.it

Hygrothermal assessment with Wufi for the wall profile and Therm for 2D thermal bridge verification

RETROFIT SOLUTIONS

External Walls

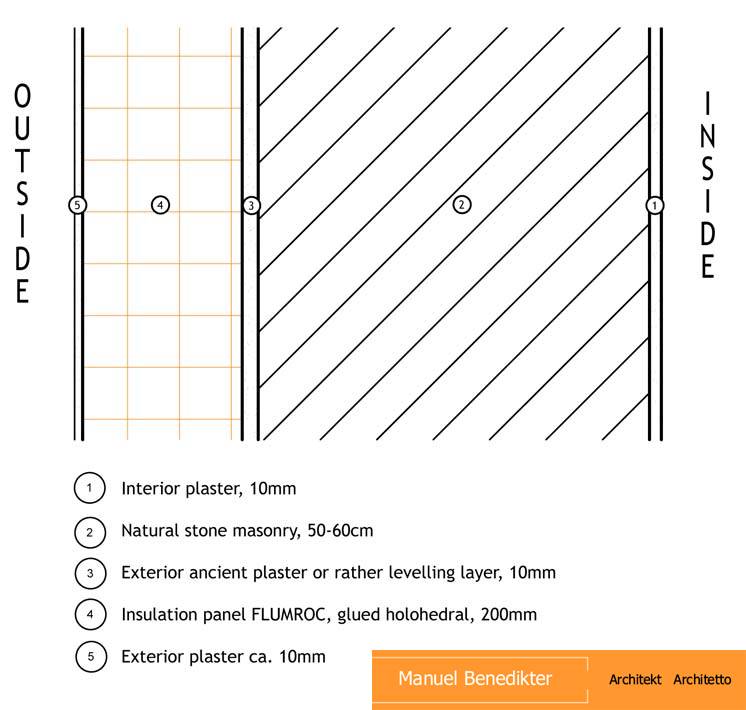

Walls with exterior insulation

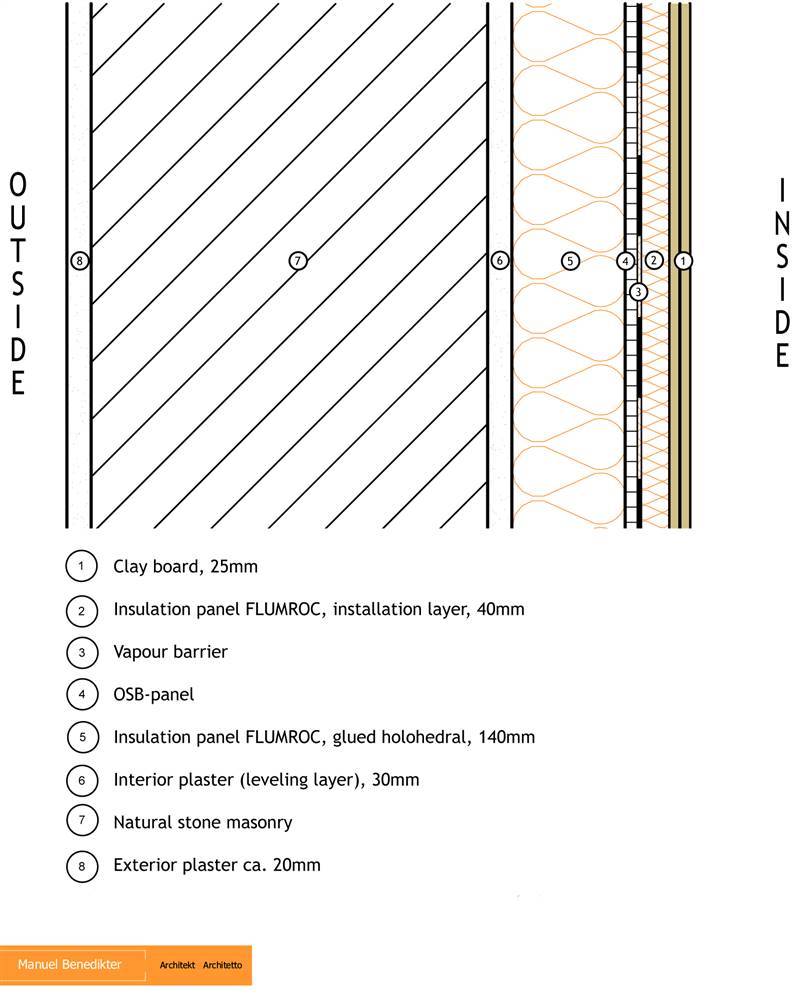

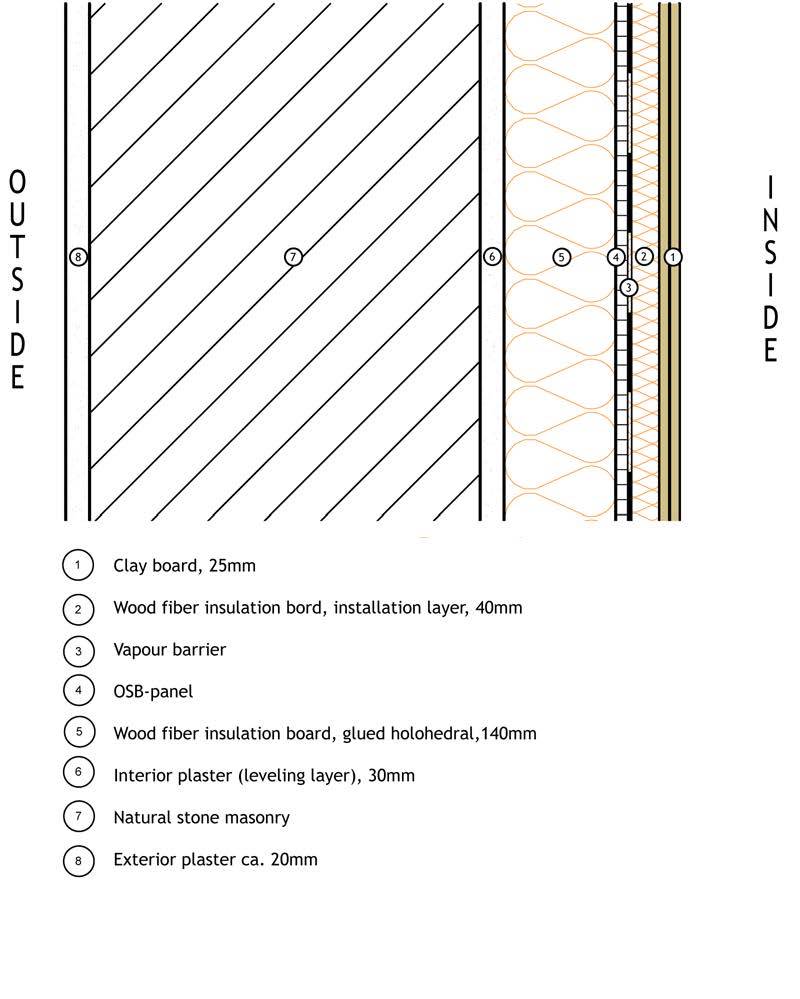

Walls with interior insulation

Thermal bridges

Monitored temperature and humidity profile

Since the western facade -on the one hand side- is visually disticted from the rest of the building, due to terasse and balcony and -on the other hand side- with rebuilding the historical window openings, the intervention on this facade was anyway considerable, in agreement with the heritage authority exterior insulation could be applied.

As a first step, the earth around the building was taken off until the foundation in a deepness of 60cm. Then non-hygroscopic insulation boards (XPS, 2x12cm) were placed parametrical around the building and glued to the exterior plaster and plastered. After this, 20cm of mineral wool insulation (FLUMROC Compact) were glued on the upper parts of the ancient stone masonry. These panels have a special compacted surface and coating on one side for better adhesion of the exterior plaster. Finally a waterproofing membrane as protection for the foundation was applied, and the trench filled with gravel.

10 mm

600 mm

10 mm

10mm

200 mm

10 mm

600 mm

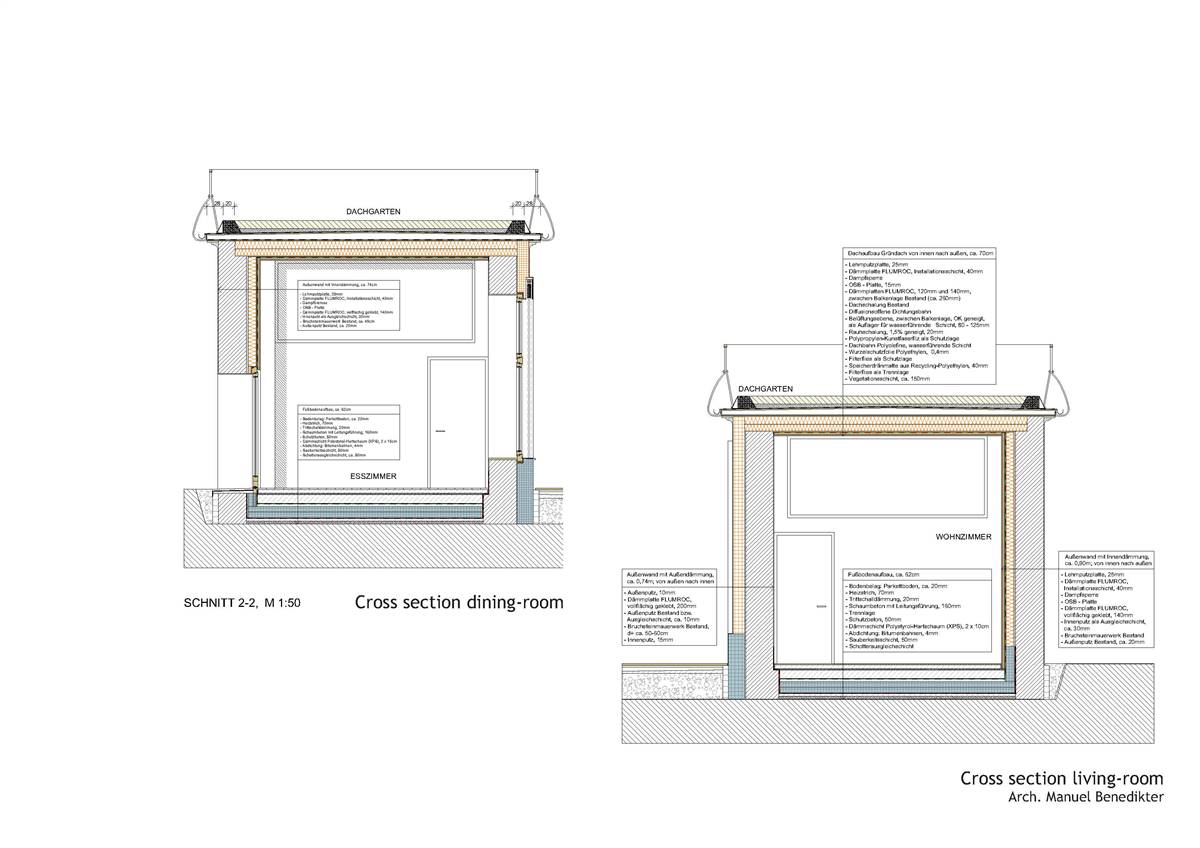

10 mm

All walls except the western facade were insulated from inside: Also here XPS was used in the lower part and placed all around the perimeter in direct contact with the floor insulation. From about half a meter upwards 14cm thick mineral wool panels (FLUMROC Compact) form the main insulation layer. The following OSB panel serves as support for the vapour barrier(sd>100), special attention was paid to seal all joints with tape. At the junction to the ceiling the vapour barrier of the wall and the vapour retarder of the ceiling (sd=2.0) overlap and are taped. All wet piping, electrical wiring and ductwork is placed in the 4cm thick installation layer - resulting in a total of 14+4=18cm of insulation and no installation breaking through the vapour barrier. As finish towards the inside follow finally 2.5 cm plasterboard.

In the bedroom, instead of mineral wool insulation, wood fibre boards were used.

20 mm

600 mm

30 mm

20mm

600 mm

30 mm

140 mm

20 mm

40 mm

25 mm

To prevent thermal bridges where partition walls abut outside walls, wherever possible, the internal wall was cut and insulation placed vertically against the wall. Where new partition walls were built up, interspaces to the external wall were left in order to place insulation, OSB-boarding and vapour barrier behind.

However, in some situations the wall was a bearing one and thus could not be cut. Therefore insulation on the border had to be applied. In one case in the corner an old chimney was found – and by insulating that internally the supplementary insulation along the partition wall could be avoided. Not in all points the elimination of thermal bridges was possible: In the bedroom an arch as separating and supporting element could neither be cut nor insulated alongside. Internal insulation and vapour barrier were brought there until the borders of the arch and finished with plaster. A sensor for temperature and humidity is monitoring this potentially critical point.

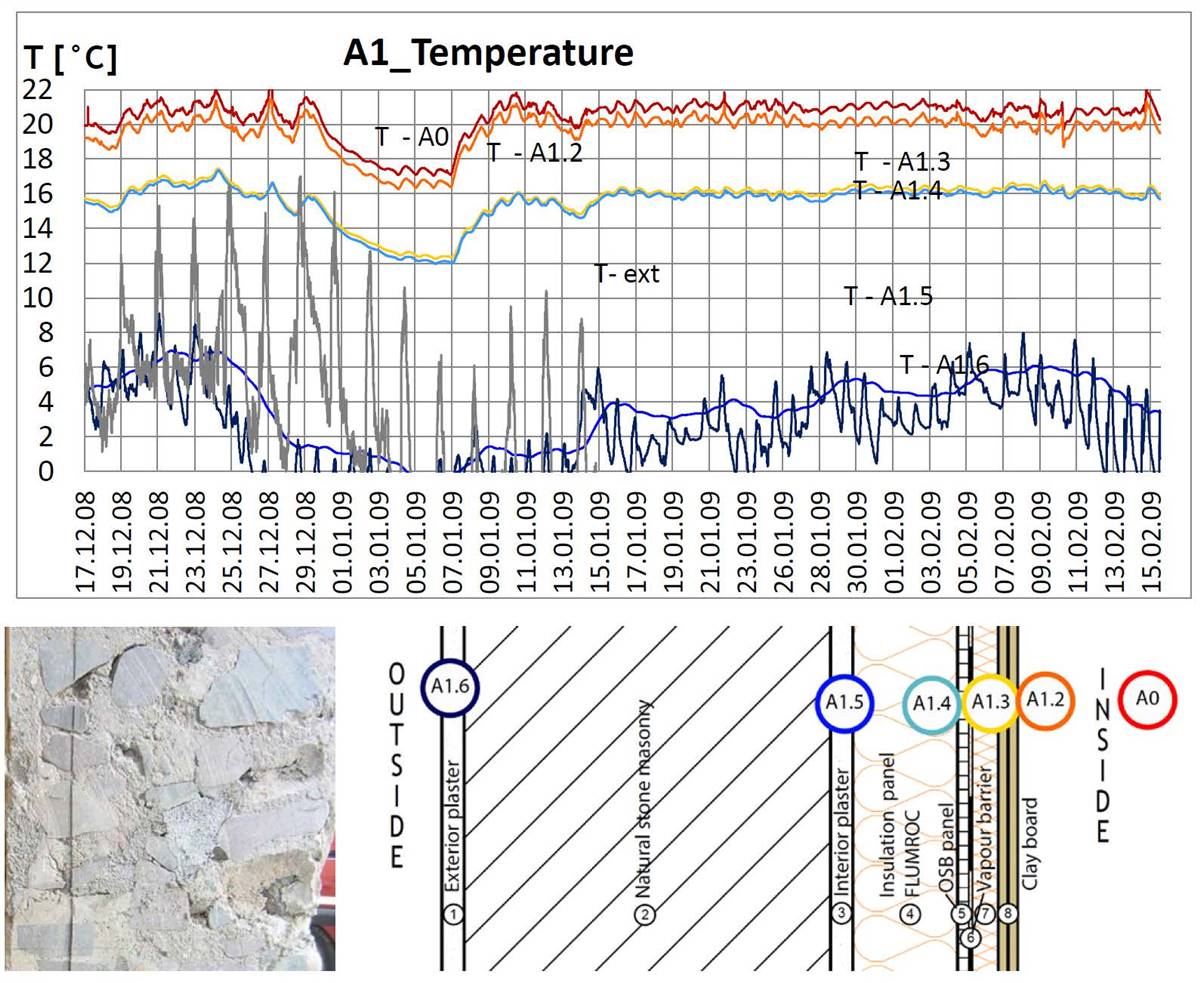

Since at Ansitz Kofler owner and architect aimed at an insulation thickness which was considerably higher than the ~8cm capillary active insulation - at that time in practice usually assumed as safe - they opted for a solution with vapour barrier (sd>100). Accordingly high effort was put in avoiding any potential failure: any penetration of the vapour barrier was avoided (4cm installation layer), sealing tapes were applied with care, a blower door test after preliminary installation was done to attest airtightness in a phase were they still could have intervened etc. The monitored data indicate safe conditions.

The first image on the T profile shows that indoor surface is slightly colder than indoor air, temperature before and after vapour barrier practically identical, major temperature difference along main insulation (Δ A1.4-A1.5), and nearly no temperature

Windows

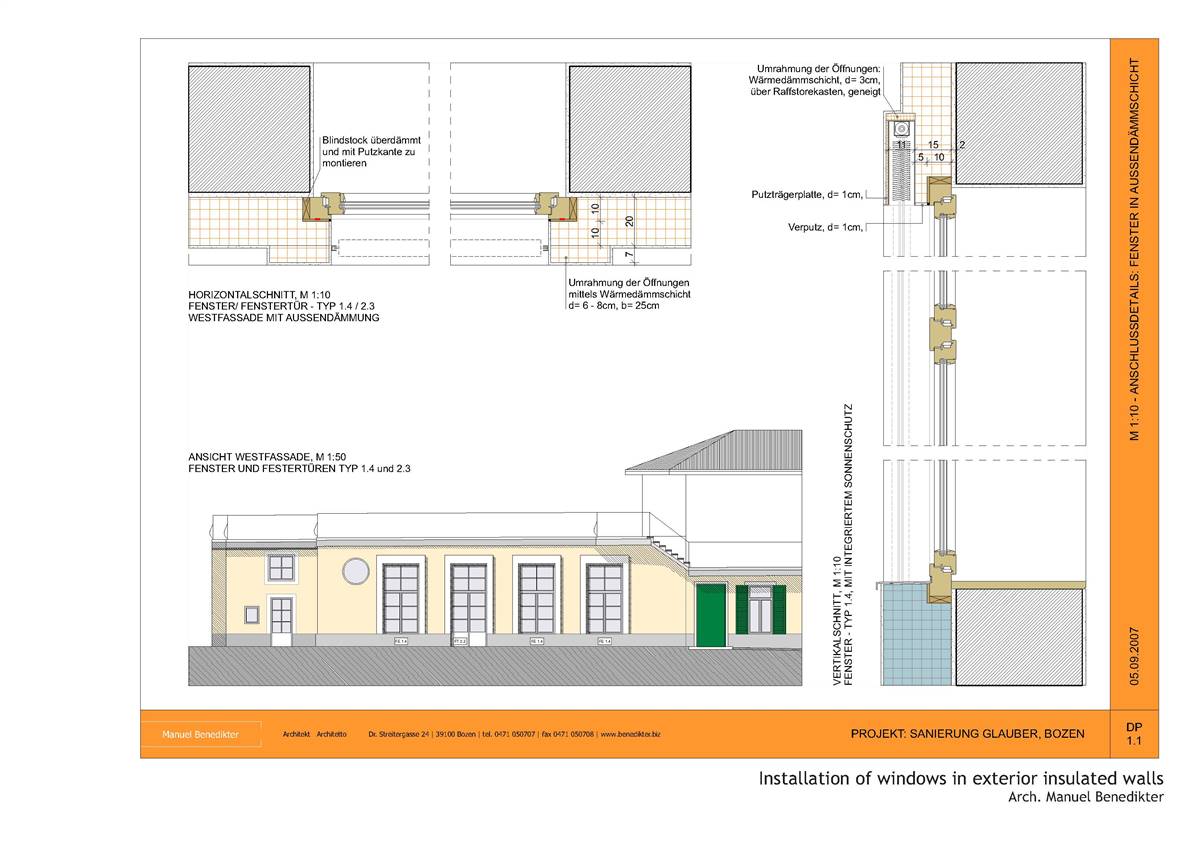

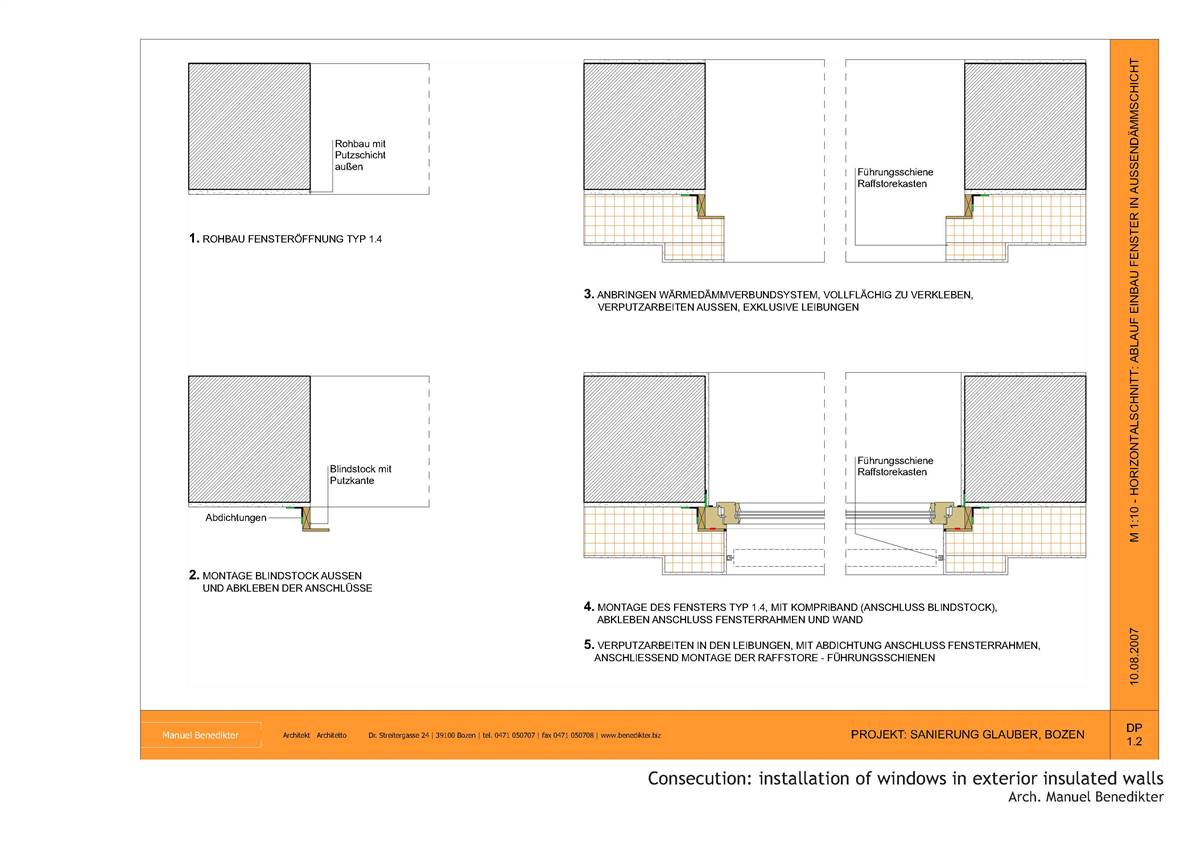

Window (with exterior insulation)

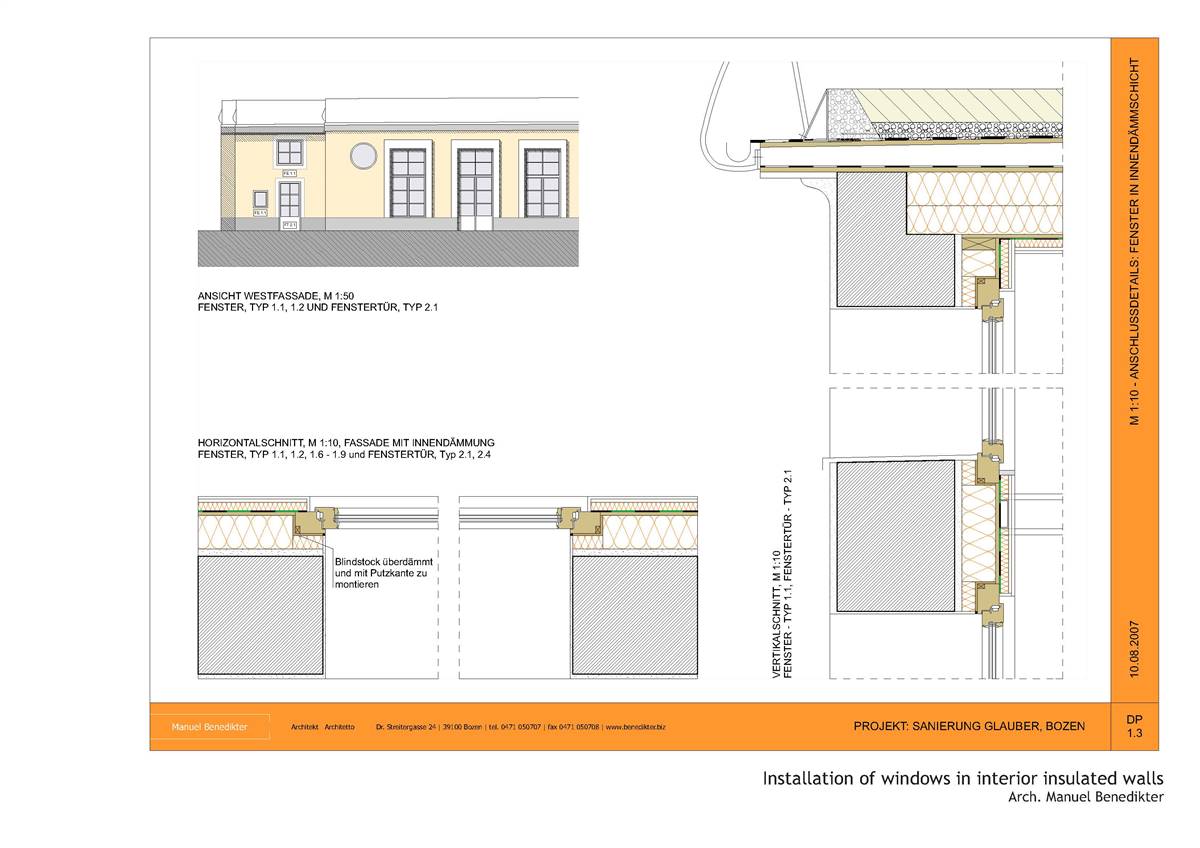

Window (with interior insulation)

In the west facade (which is the one with exterior insulation) the ancient openings were reconstructed. In order to allow for the most efficient position of the new window in a line with the insulation layer, the subframe (and on it later on the main frame) had to be placed just "outside" the original stone wall: this was achieved by posing it on a horizontal supporting joist and fixing it punctually with angle steel to the stone masonry. In order to avoid thermal, the roller-shutter casings are installed on the wall in the insulation layer. The subframe was completely covered by the mineral wool panels. After the plaster works were finished, the windows themselves were posed (this approach is quite typical for Italy, where windows are considered kind of "furniture" and come to the building site as late as possible). For guaranteeing airtight connection between subframe and main frame of the window, jointing tape was applied around the frame.

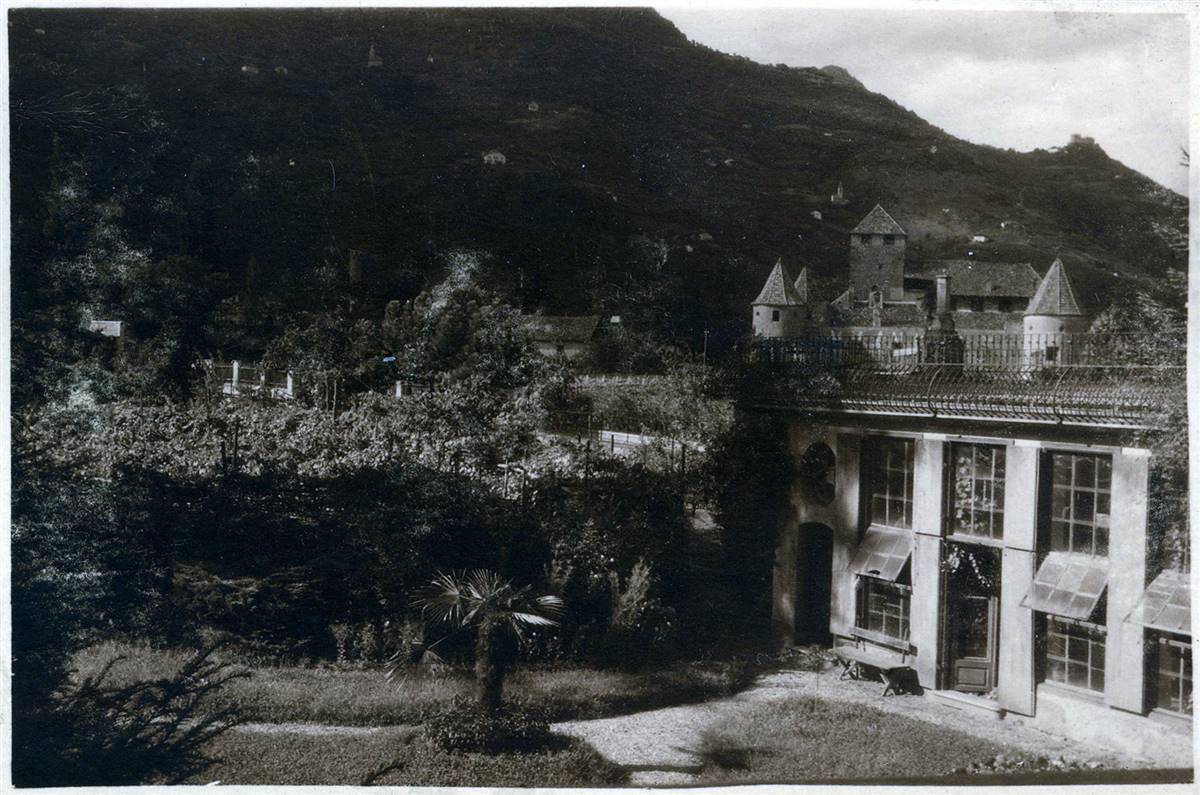

The preservation office of South Tyrol supported the wish of the owner, to go back towards the architectural appearance of the Orangery, since this approach would also connect the wing closer to the internal park, which is specifically part of the protection. Enlarging the again the window openings - which were reduced in 1925 refurbishment - was part of this concept. Also the regular detailing is inspired by to the Orangerie.

| Existing window type | Box-type window |

| Existing glazing type | Single |

| Existing shading type | Outer shutter |

| Approximate installation year | 1925 |

| New window type | Casement window |

| New glazing type | Triple |

| New shading type | Moveable shading |

| New window solar factor g [-] | 0,53 |

Also in combination with interior insulation, the windows were placed in the insulation layer. The subframes were thus again placed just inside the stone masonry, voids were filled with PUR-foam and a jointing tape applied all around.

Again, the window opening were partly enlarged in agreement with the conservation authority to go back to the Orangerie character, detailing is inspired by the original glazing.

| Existing window type | Box-type window |

| Existing glazing type | Single |

| Existing shading type | Outer shutter |

| Approximate installation year | 1925 |

| New window type | Casement window |

| New glazing type | Triple |

| New shading type | Roller blinds |

| New window solar factor g [-] | 0,53 |

Other interventions

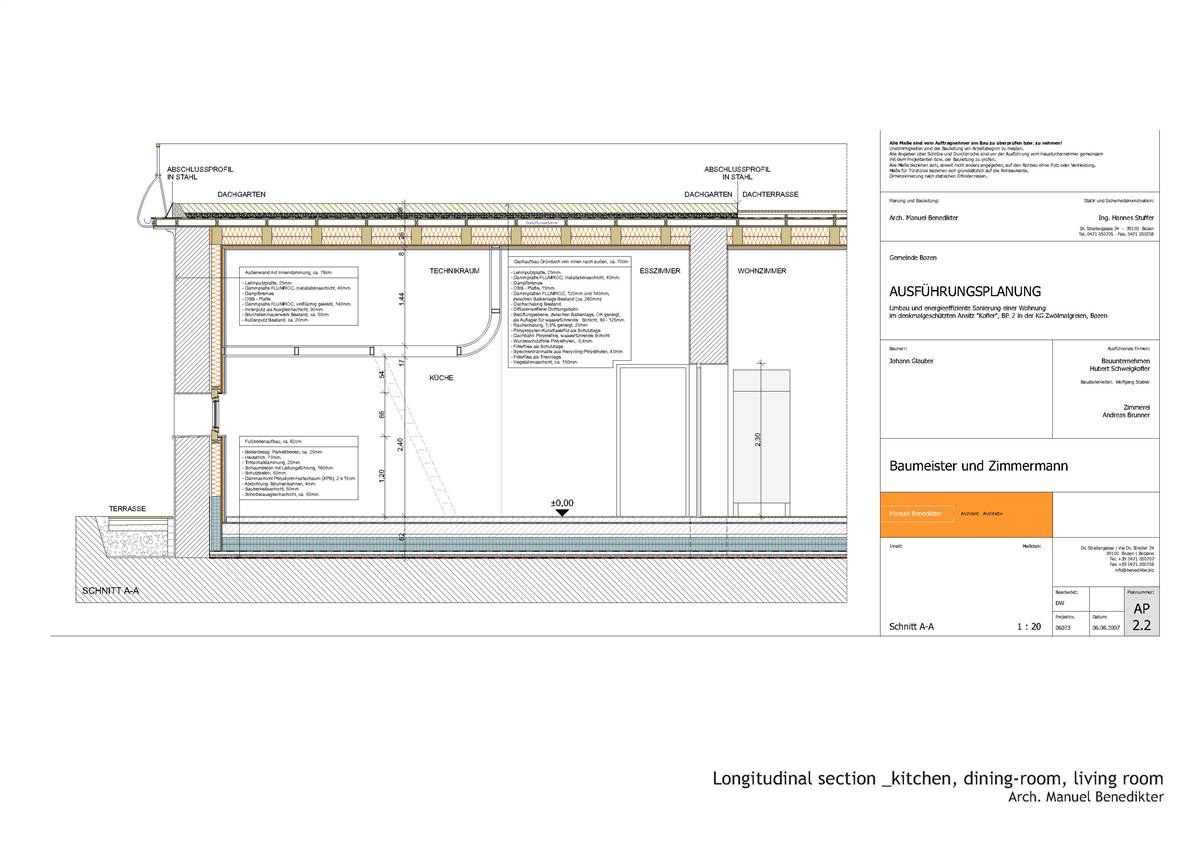

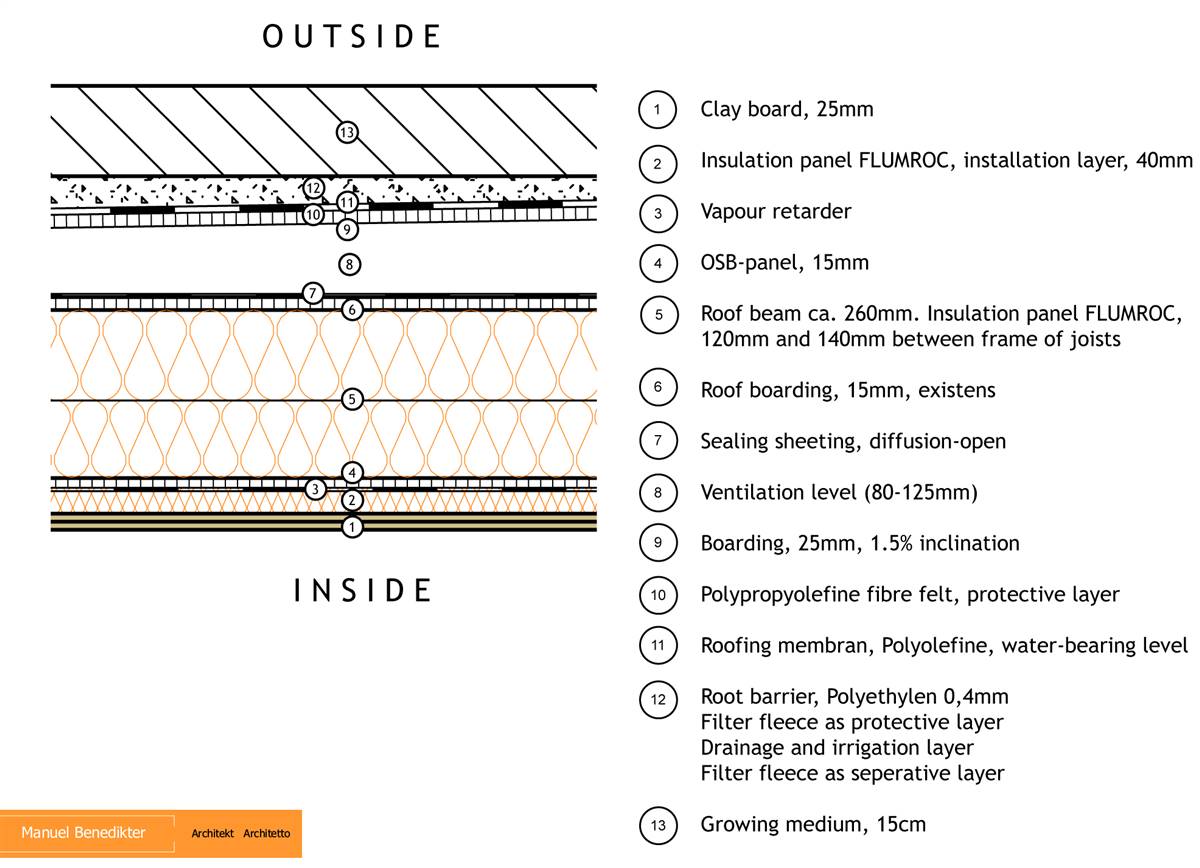

ROOF

GROUND FLOOR

MEASURES TO INCREASE AIRTIGHTNESS

The roof was refurbished from outside, in order to preserve the existing beam structure, inner wood boarding layer and interior plaster. The old water proofing layer was removed, FLUMROC mineral wool was placed in two layers (12 14cm) between the 26 cm high rafters on the existing wood boarding. On top of joists and insulation an OSB board and a diffusion open water tight sheet (Riwega USB CLASSIC) was posed. On this construction, transversal battens guarantee a 80-125mm high air space to ventilate off any moisture transferred by diffusion from the rooms, before the green roof with the a water draining layer (1.5% inclination) follows. When the roof was finished outside, from the inside a vapour retarder and 4cm installation layer filled with mineral wool where added. As finish clay boards were applied and painted.

Besides the attention which has always to be paid to the sealing well the green roof, in the specific case, preserving the pergola and railing around the terrace increased the needed level of attention further: the columns of the pergola were finally wleded with steel plates and posed on a protective rubber strip.

20 mm

260 mm

14 mm

25 mm

220 mm

80 mm

25 mm

260 mm

40 mm

40 mm

25 mm

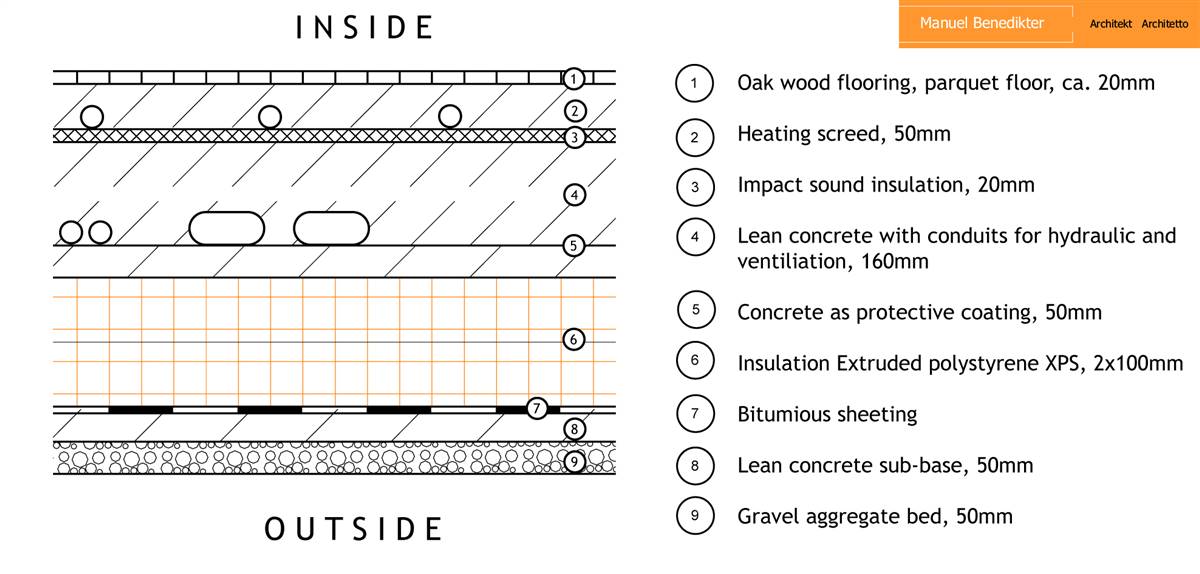

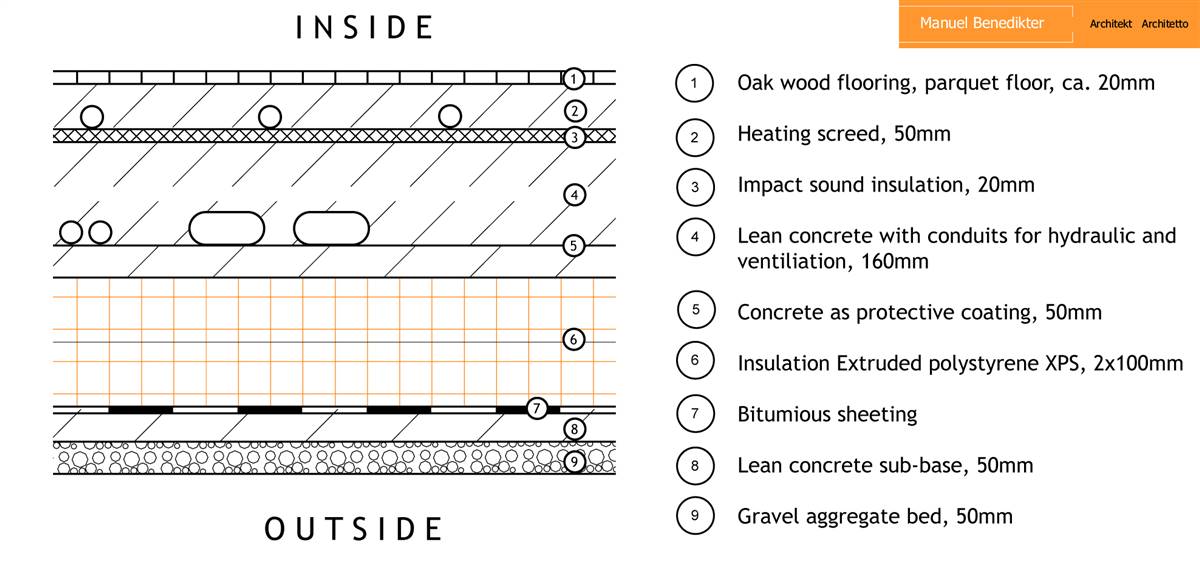

The floor was removed until the foundation and rebuild with a thermal insulation avoiding ascending moisture infiltration from the ground and from the walls. The multilayer floor was compounded on a gravel aggregate layer on whom a lean concrete sub-base (50 mm) was poured. This layer is used as blinding layer on which bituminous sheeting was applied. The sheeting was brought on the border of the walls and welded, in order to avoid lateral infiltration from the stone masonry. Next step was lay-out rigid insulation boards XPS (2 x 100 mm), which were covered with another protective concrete layer (50 mm). On this flat layer all conduits and electric cables were installed. Once all crafts had applied the conduits, a 16 cm thick layer of lean concrete was poured. A lightweight-screed in this case couldn’t be used as too much conducts crossed the layer. Conducts were lay and connected to the cable layer in the walls. The vapor barrier was turned around the border of the lean concrete.

The ancient floor (from 1925) was tiled. Under this layer a screed of some cm hight was found, which had been poured on the earth ground.

70 mm

15 mm

100 mm

5 mm

196 mm

210 mm

20 mm

49 mm

20 mm

To reach a continuous air-tight layer at Ansitz Kofler, the vapor barrier on the walls was (i) well connected to the vapor retarder on the roof, (ii) turned around the border of the lean concrete in the floor, and (iii) well connected with tape to the window sub-frame and other openings. All electric and hydraulic ducts and cables were installed on the inner side of the vapor barrier in order to prevent punctures. To check the tightness of the vapor barrier and to discover eventually leaks, a preliminary blower door-test was done before the application of wooden battens and plaster boarding. The final Blower Door test following European Standard UNI EN 13829, procedure B, resulted in a very good value of n50= 0,66/h (for comparison: 0.6 needed for PH certification, 1.0 for EnerPHIT)

HVAC

HEATING

VENTILATION

DOMESTIC HOT WATER

The ancient gas boiler was replaced by a pellet boiler, which supplies the all 5 apartments in the building complex with warm water fro heating and DHW. While the other four apartments use classical high temperature radiant systems, the retrofitted Orangery here presented has a floor heating system.

When a biomass boiler is projected, pellet storage must be dsignated for. Since there is no space available in the house or basement, the pellets are stored in a tunk buried in the garden - and brought to the reservoir in the heating room with a suction turbine. For the Tiled stove, which should be preserved as character defining element of the dwelling, a new insulated chimney pipe had to be built up to provide fresh air supply independent from ambient air. The stove was demounted and reconstructed with a hermetical lockable fresh air supply to ensure air tightness.

| New primary heating system | New secondary heating system | |

|---|---|---|

| New system type | Boiler | Stove |

| Fuel | Biomass | Biomass |

| Distribuition system | Radiating floor | direct |

| Nominal power | na (for the whole building) kW | na kW |

A central system for controlled ventilation with heat recovery ensures not only that the necessary exchange of air takes place automatically but also that the incoming air from outdoors is warmed by cooling the exhaust air. The installed ventilation system provides balanced air flow and achieves a maximum volume flow rate of 300m³/h – to reach the required air change volume of 0.4 m³/h and provide living areas up to 220 m² with fresh air, level 2 with 220 m³/h will be sufficient. The “Air-to-Air Heat Exchanger” recovers up to 85 percent of the heat from outgoing air. An automatic summer bypass unit has been integrated: guaranteeing that the outside air almost completely bypasses the heat exchanger prevents the supply air from being additionally warmed during warm summer months.

The ventilation unit is placed in a crawlspace above the kitchen, benefitting from the ample room height of 4m. The distribution ducts are integrated in the anyway refurbished floor, together with the hydraulic system in a concrete layer between thermal and sound insulation. Advantage from conservation point of view is the fact, that with ventilation system high indoor humidities which might induce condensation within the construction at any week point are avoided.

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Centralized |

| Type flow regime | Standard |

| Heat recovery | Yes |

| Humitidy recovery | No |

| Nominal power | 38W @ 150m³/h and 100Pa kW |

| Electric power | 0,0 kW |

| Control system | continous |

The domestic hot water is also provided by the pellet heating system. A stratified storage of 800 liter size serves as buffer. A circulation pump guarantees immediate hot water in the dwellings, results however also some heat losses.

At the time of retrofit no solar panels compatible with the listed building's demand were available. Nevertheless, the storage tank has a a two coil type heat exchanger - to allow for the integration of a solar circuit in future.

| New DHW system | |

|---|---|

| Type | with heating system |

| Hot_water_tank | Yes |

| With heat recovery | No |

RENEWABLE ENERGY SYSTEMS

SolarThermal

Biomass

Geothermal

Passive Solar: Thanks to going back to the Orangery character on the west facade, nearly one third of the transmission losses are balanced out by passive solar gains.

Active Solar: At this stage due to conservation restrictions no solar panels were installed. The storage for DHW was however chosen with two coil type heat exchanger - to allow for the integration of a solar circuit in future, when possibly aesthetics of solar panels have been furthere developed to fit in conservation areas.

| SolarThermal System | |

|---|---|

| Type |

With a pellet boiler providing the heat for space heating and DHW, the remaining heating demand is provided by a renewable and CO2 neutral source.

There is no visual impact on the ensemble, since the pellets tank could be buried, and there was also no material impact, as the pellets boiler itself was installed in the original heating room.

| Biomass System | |

|---|---|

| Type | |

| Storage size | |

| Origin of biomass | |

| Overall yearly production | kWh |

The air for the ventilation system is pre-heated in winter and pre-cooled in summer with a ground-to-air heat exchanger: The polypropylen pipes are laid in 1.5 to 2m depth in the earth around the buildings, with a gradient of 2% to guarantee condensation discharge and a antimicrobial layer consisting of silver particles.

The air inlet has a dust and pollen filter, a further benefit to allergy sufferers.

| Geothermal System |

|---|

Energy Efficiency

Voluntary certificates: Reaching KlimaHaus A level (<30 kWh/m²a) was volontary and going far beyond usual practice. In 2008 in Bozen reaching KlimaHaus C level (<70 kWh/m²a) would have been compulsory for new constructions. Also the "+" is volontary. The “+ “of the CasaClima A+ certification includes other criteria aside from energy consumption for heating. One of them is the prohibition to use fossil fuels for heating. Other criteria concern employed materials, which have to be sustainable for environment and health. Neither utilization of synthetic insulations (admitted for maximum of 20m² for exterior insulations on facades, as well as for terraces, flat roofs, perimetrical insulation and basement), floorings in PVC for floors, windows and doors, wood treated with chemical varnish, colors containing dissolvers, nor the utilization of tropical wood were allowed for this certification.

Consumption_estimation_After: 30 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: NA

Consumption_estimation_Including_DHW: No

Type_of_monitoring: Continuous

Description: In both living room and bedroom temperature (T) and relative humidity (RH) are monitored.

External Climate

Type_of_monitoring: Continuous

Description: On the terrace temperature (T), relative humidity (RH), wind speed and solar radiation are monitored. Since solar radiation is measured precisely at Bolzano airport, but mountains might shadow the building in the old town differently, a simple solar radiation sensor was chosen, to mainly complement available data.

Construction

Type_of_monitoring: Continuous

Description: Overall 4 wall profiles are monitored, each including (i) exterior surface T, (ii) T and RH between stone wall and insulation, (iii) T& RH before the vapour barrier, (iv) T&RH after the vapour barrier, (v) heat flux at the interior surface and (vi) interior surface T. Furthermore the T at the connection from partition to outer wall is monitored - to quantify the thermal bridge effect. Finally, T and RH are measured in two wooden beams.

Internal Climate

Monitoring results showed comfortable temperatures both in winter and summer. Monitored winter conditions ranged between 19°C and 21°C, with the lower temperatures corresponding to periods where the user was absent. In summer, the operative temperatures ranged between 24°C and 27°C with outdoor daily averages going up to 29°C.

With increasing the window size, the daylight availability was considerably increased. The inclinable shutters allow for personalised control of light and glare. The result was however not quantified with monitored data.

Costs

For the selection of the interior insulation an economic comparison between VIP (vacuum panel) insulation and mineral wool was made. For Bolzano real estate prices it would have been worthwhile to invest in VIP and gain respective living area. Since the building owner would also have lived himself in the appartment - and considered it to be "big enough" also with 20 cm less space - he opted nevertheless for the mineral wool option.

No

Environment

Next to the pellets tank there is also a water cistern for the rainwater, which is drained from the roof, stocked in the tank and used for domestic use.

Ansitz Kofler is situated in the old town of Bolzano, with direct access to the extensive bycicle network of the town. Weather protected bike parking is provided, both for inhabitants and guest.

Hans Glauber, the owner, is also one of the initiators of the car sharing system in Bozen.