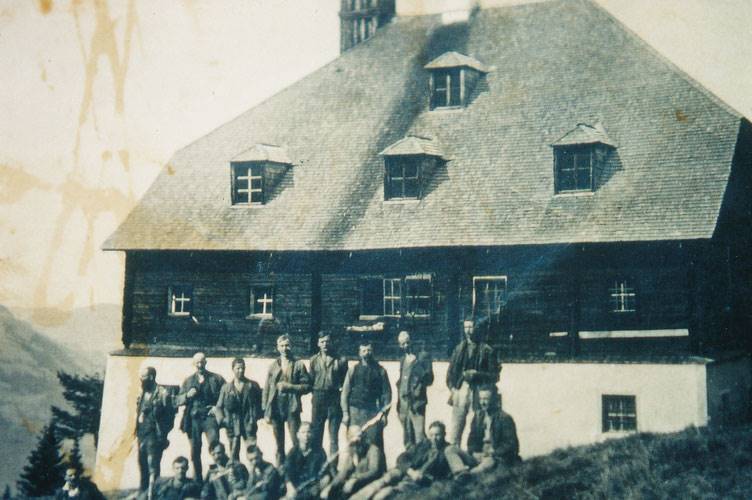

Kelchalm - Bochumer alpine hut

Kelchalmweg 1

6371

Aurach bei Kitzbühel, Austria

Architect

Owner

User

Contact Details

Other Information

https://bochumer-huette.jimdo.com/ The hut is a popular destination for hikers and also has overnight accommodation.

Model renovation of Bochumer Hütte

Climate Zone Dfb

Altitude 1432 m a.s.l.

HDD 2375

CDD 0

Conservation Area:

No

Level of Protection:

Year of last renovation:

2013

Year of previous renovation:

1831

Building occupancy:

Discontinuous occupancy (i.e. holiday home)

Number of occupants/users:

70

Building typology:

free-standing building

Number of floors:

4

Basement yes/no:

Yes

Number of heated floors:

4

Gross floor area [m²]:

812,0

Thermal envelope area [m²]:

1087,0

Volume [m³]:

2380,0

NFA calculation method:

NGF (de)

External finish:

Rendered

Internal finish:

Exposed woodwork

Roof type:

Pitched roof

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Capatect Baustoffindustrie GmbH

Bahnhofstraße 32; 4320 Perg

info@capatect.at

Tel.+43/7262/560-0

DI Christina Krimbacher

Mentlgasse 10/29 | A-6020 Innsbruck

info@christina-krimbacher.at

Tel.Tel. u. Fax 05 12 / 57 32 55

Isocell GmbH

Gewerbestraße 9, 5202 Neumarkt am Wallersee

office@isocell.at

Tel.+43 (0)6216 / 41 082 5

Ingenieurbüro Tassenbacher GmbH, umwelt : energie : mikrobiologie

Mühltal 13, 6363 Westendorf

office@tassenbacher.at

Tel.+43 664 34 201 38

RETROFIT SOLUTIONS

External Walls

External wall ground floor

External wall first floor

The natural stone masonry was insulated with 18 cm thick hemp insulation panels. The only "plastic insulation" Swisspor PSN (awarded the Austrian eco-label) was used in the ground area, as it was the only alternative. Perimeter below ground insulated with foam glass gravel.

15 mm

1000 mm

30 mm

10mm

180 mm

15 mm

1000 mm

30 mm

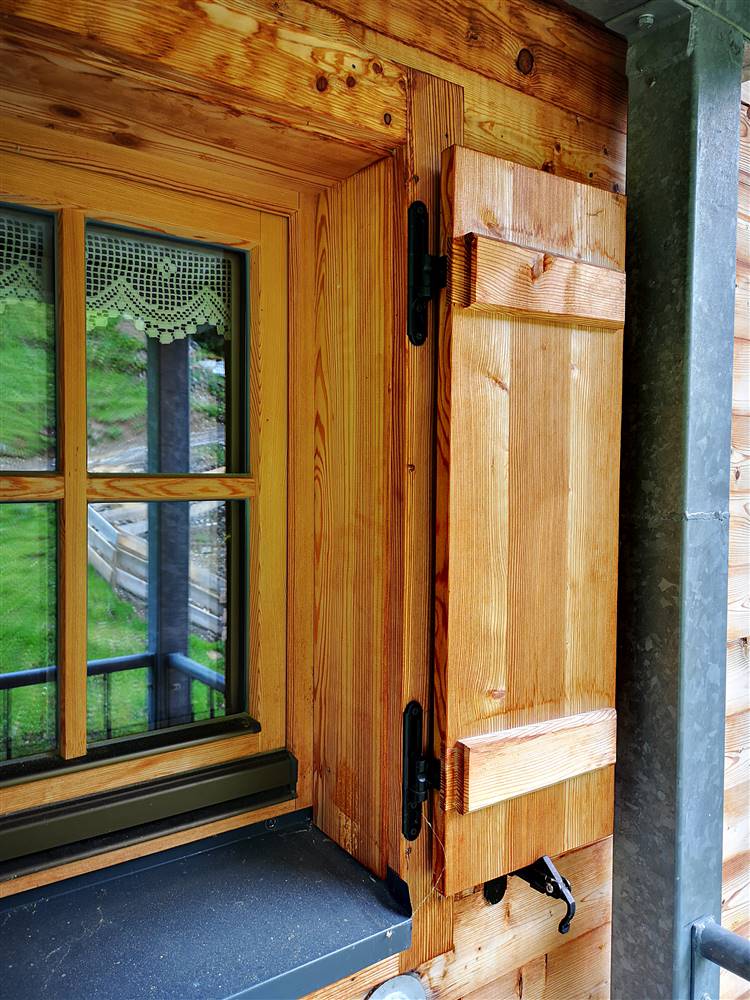

On the facade 16 mm wood fibre board filled and insulated with 18 cm cellulose was used. Then came battens and local untreated larch. From the inside, dormer cladding, window shades and some bathrooms were left in natural spruce.

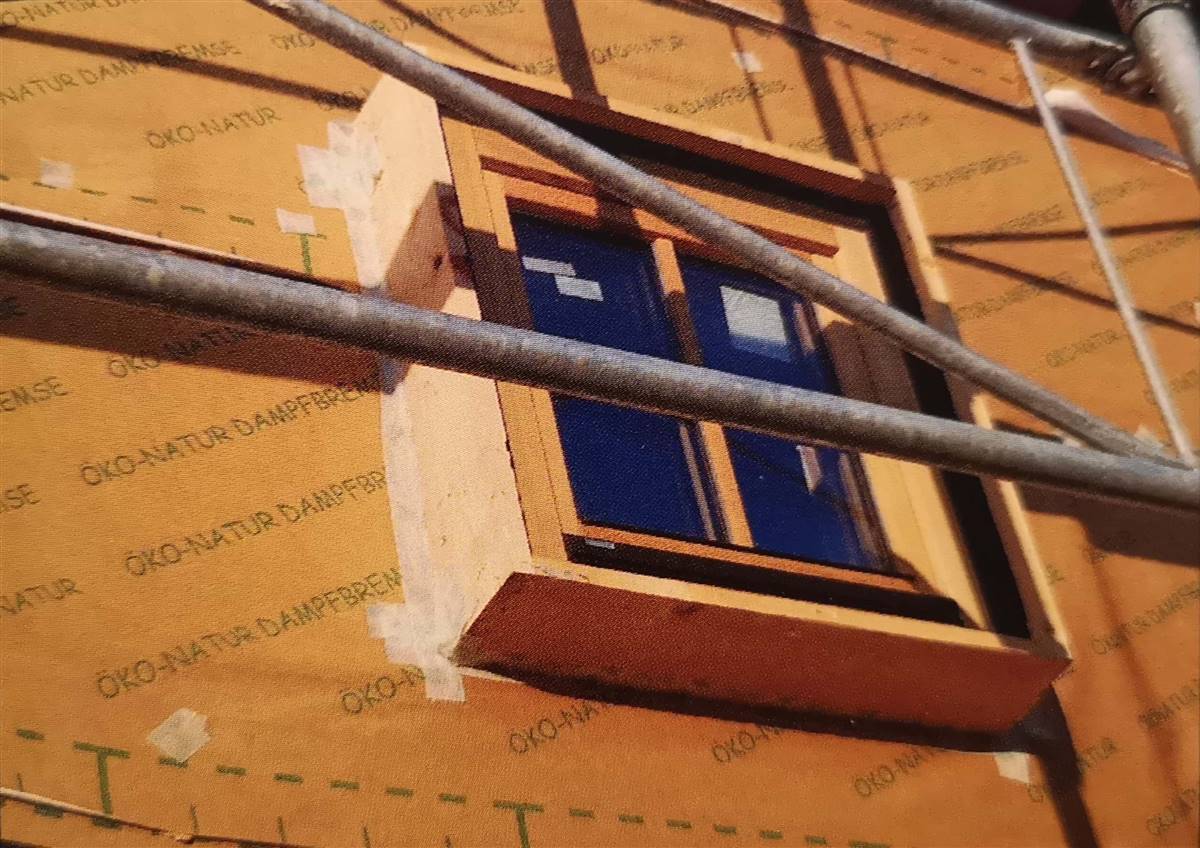

The wall was renovated from the outside, where the layers were removed up to the load-bearing wooden log construction. The combination of a closed air cavity and mineral wool insulation without a vapour barrier trapped the heat and moisture coming from inside the hut in the insulation, causing condensation in the mineral wool and local damage to the wood block structure, which had to be repaired. The new difuse oppened structure consists of Eco-natur vapour barrier on the wooden structure, which prevents heat and moisture from penetrating the insulation, so that no condensation is created in the insulation and the wooden structure is protected.

24 mm

2 mm

70 mm

40 mm

140 mm

25 mm

25mm

50 mm

16 mm

180 mm

1 mm

140 mm

24 mm

Windows

Window external wall, first floor

A paper vapour barrier is applied over the wooden block construction (upper floors), window blind sticks are set into the insulation level and glued to the vapour barrier. Larch windows oiled with glazing 0.60 W/m²K. Glued vapour-tight on the inside and diffusion-open on the outside. The window joints are manually stuffed with cellulose fibre strips by the ladies of the Bochum section!

The design and materials of the windows imitate the original windows. The proportions of the building and the installation depth of the windows have been maintained even after the increase in the wall depth by inserting the new windows into the insulation layer, which also reduces the thermal bridges of the window installation.

| Existing window type | Box-type window |

| Existing glazing type | Single |

| Existing shading type | NA |

| Approximate installation year | 1900 |

| New window type | Coupled window |

| New glazing type | Triple |

| New shading type | NA |

| New window solar factor g [-] | 0,4 |

Other interventions

ROOF

MEASURES TO INCREASE AIRTIGHTNESS

The roof was opened, the dormers were demolished and replaced. The vapour barrier was newly applied to the roof boarding and later glued with a wall vapour barrier. The new dormers (wooden beam construction with cellulose ged.) were built. The roof was then provided with 24 cm thick insulation of single-layer wood fibre boards with a U-value of 0.15 W/m²K.

The new roof was built for financial reasons and also because of a practical use of the folding roof as an appearance from the 1960s.

2 mm

25 mm

118 mm

25 mm

25 mm

120 mm

240 mm

1 mm

30 mm

120 mm

25 mm

Blower Door Test with comprehensive leakage detection. Facade and roof tested from the outside with overpressure. Unfortunately no result, because of too high pressure losses via the foundations (not sanitable).

HVAC

HEATING

VENTILATION

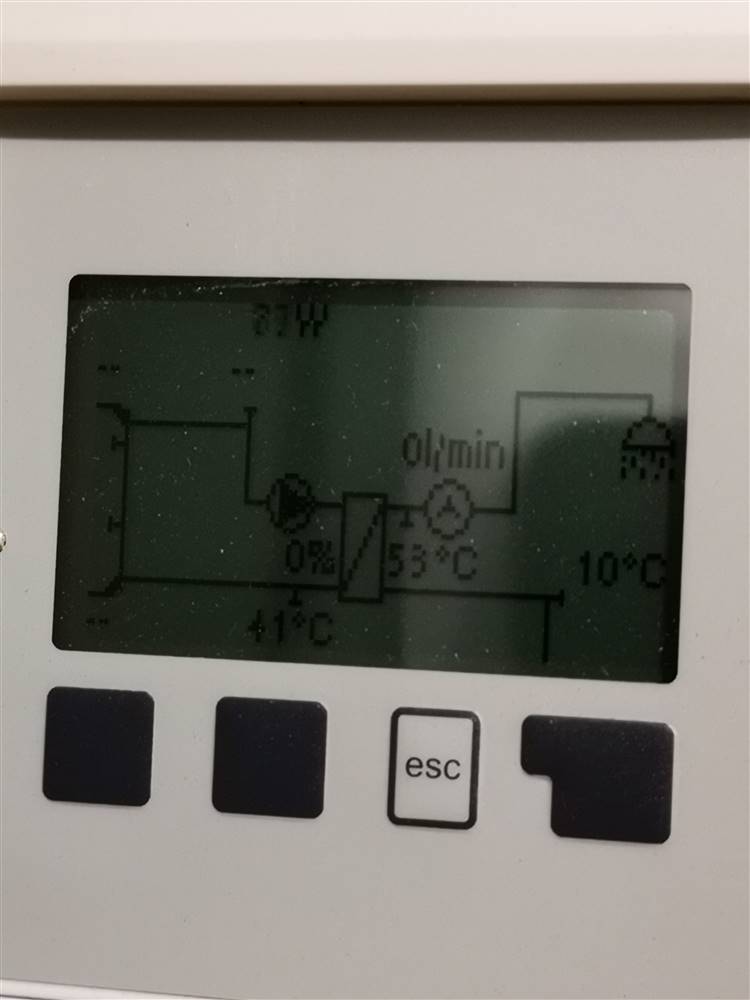

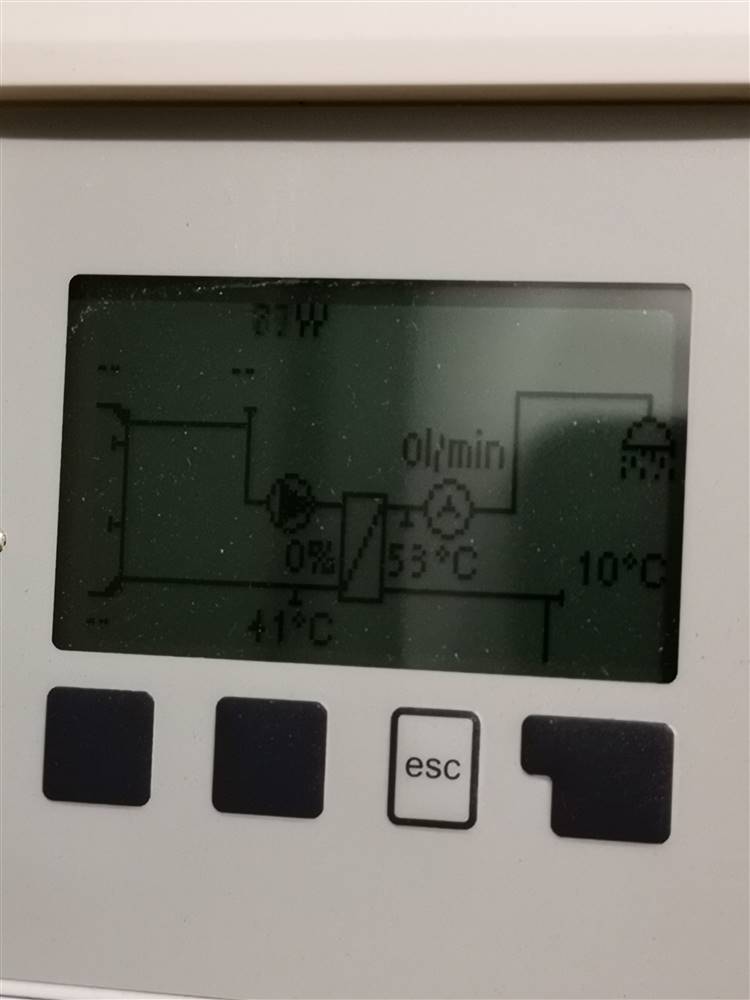

DOMESTIC HOT WATER

Until 2014, the primary heating system of the hut was a biodiesel cogeneration plant that produced both heat and electricity. Since the hut now has its own electricity connection, it was possible to retrofit the heating system. Currently, the main heating system consists of a pellet boiler that heats the two thousand liter tanks connected in series. In addition, the heat generation is supported by a solar system installed on the south-east facade of the hut. The secondary heating system is the wood tiled stove in the stube.

The original heating system with a wood-tiled stove was retained, as it is a very traditional aspect of the mountain huts, but also provides tangible warmth, which is part of the well-being of the Tyrolean mountain hut experience and is expected by visitors.

| New primary heating system | New secondary heating system | |

|---|---|---|

| New system type | Stove | NA |

| Fuel | Biomass | Hot water |

| Distribuition system | Radiators | |

| Nominal power | 22 kW | kW |

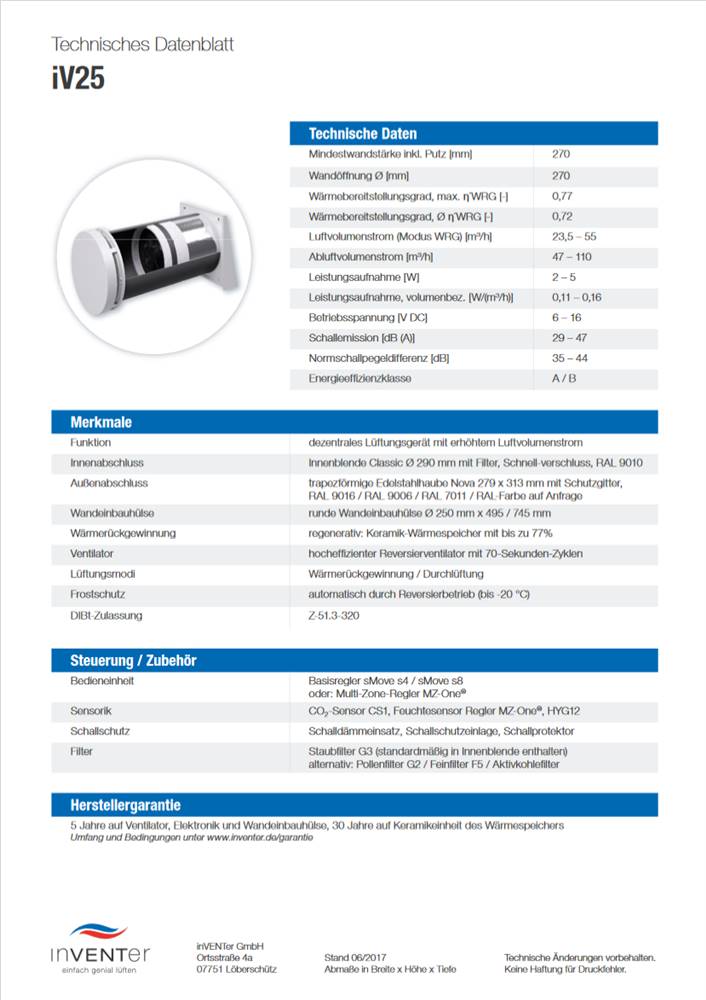

A group of two ventilation units (INVENTERIV25) mounted in the wall provides ventilation of the laundry rooms with heat recovery.

The openings for the supply air and exhaust air are hidden behind the solar thermal collectors on the façade so that they are not visible.

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Decentralized |

| Type flow regime | Single room ventilation |

| Heat recovery | Yes |

| Humitidy recovery | No |

| Nominal power | 0,010 kW |

| Electric power | 0,01 kW |

| Control system | CO2 sensor CS1, humidity sensor Controller / CO2-Sensor CS1, Feuchtesensor Regler |

The hot water is produced by flowing through a heat exchanger in a 1000-litre storage tank with heat supplied primarily by the solar thermal system and additionally by the pellet heating system.

This solution is a sustainable way to produce hot water. Having hot water for cooking and showering is a relatively new requirement of the visitors of the mountain hut, so there are not many historical aspects to follow.

| New DHW system | |

|---|---|

| Type | with heating system |

| Hot_water_tank | Yes |

| With heat recovery | No |

RENEWABLE ENERGY SYSTEMS

SolarThermal

Biomass

The solar thermal system consists of 7 flat collectors of 2.3m2 each, which are mounted in the south-east facade of the hut. The heat is stored in a 1000-litre tank, which is primarily used to heat water and also supports the heating system.

The solar thermal system is mounted on the south-east facade of the hut, which is basically hardly visible to tourists and visitors due to the orientation of the hut towards the hiking routes. Therefore the system is gentle on the historical appearance and does not look conspicuous.

| SolarThermal System | |

|---|---|

| Type | Flat collector |

| Collector area | 16,1 m² |

| Elevation angle | 59,0 |

| Azimuth | 165,0 |

| Cooling contribuition | 0,0 kWh |

Until 2014, the primary heating system of the hut was a biodiesel cogeneration plant that produced both heat and electricity. Since the hut now has its own electricity connection, it was possible to retrofit the heating system. Currently, the main heating system consists of a pellet boiler that heats the two thousand liter tanks connected in series. In addition, the heat generation is supported by a solar system installed on the south-east facade of the hut. The secondary heating system is the wood tiled stove in the stube.

The original heating system with a wood-tiled stove was retained, as it is a very traditional aspect of the mountain huts, but also provides tangible warmth, which is part of the well-being of the Tyrolean mountain hut experience and is expected by visitors.

| Biomass System | |

|---|---|

| Type | Pellet |

| Storage size | 8 m3 |

| Origin of biomass | |

| Overall yearly production | 66750,0 kWh |

Energy Efficiency

Voluntary certificates: The building fulfilled all mandatory criteria and achieved more than 750 points, so that it was awarded the "climate-active silver" level. All klimaaktiv criteria catalogues are based on a 1,000-point system, which is used by a neutral party to assess and evaluate the quality of planning and execution, energy and supply, the quality of building materials and construction, as well as central aspects of comfort and indoor air quality.

Primary Energy 157156 kWh/y

Consumption_estimation_Before: 145 kWh/m2.y

Consumption_estimation_After: 38 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: Steady state simulation (e.g. EPC, PHPP)

Consumption_estimation_Including_DHW: Yes

Consumption_estimation_After: 157156 kWh/y

Internal Climate

Chemical analysis of dust performed! No alarming values, no asbestos, but all the building flaws of the last decades are found. - Residues from PVC floors - Wood polish - Flame retardants from EPS - upholstered furniture - Cleaning agents

Costs

The price is not known.

No

silbersalz.jpg)

CarolineBegle - 1.jpg)