Lövstabruk, Stable building

Street 76

819 66

Tierp, Sweden

Owner

Contact Details

Other Information

To visit the project please contact: Cecilia Wretling, cecilia.wretling@sfv.se

Climate Zone Dfc

Altitude 26 m a.s.l.

HDD 2838

CDD 21

Conservation Area:

Yes

Level of Protection:

Enskilt byggnadsminne sedan 1996

Year of last renovation:

2010

Year of previous renovation:

1986

Secondary use:

NA

Building occupancy:

Discontinuous occupancy (i.e. holiday home)

Building typology:

Stable building

Number of floors:

1

Basement yes/no:

No

Number of heated floors:

0

Gross floor area [m²]:

1830,0

NFA calculation method:

Sweden

External finish:

Cladding

Internal finish:

Exposed woodwork

Roof type:

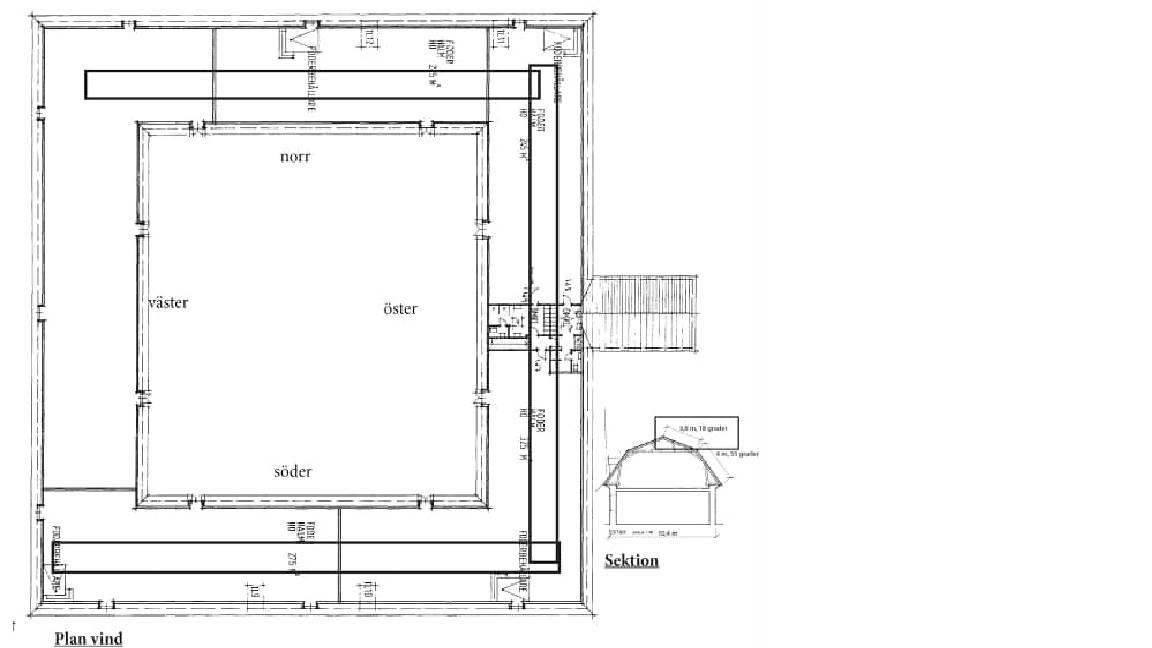

Mansard roof

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Statens fastighetsverk

Odinslund 2, 753 10 Uppsala

sfv@sfv.se

RETROFIT SOLUTIONS

Other interventions

ROOF

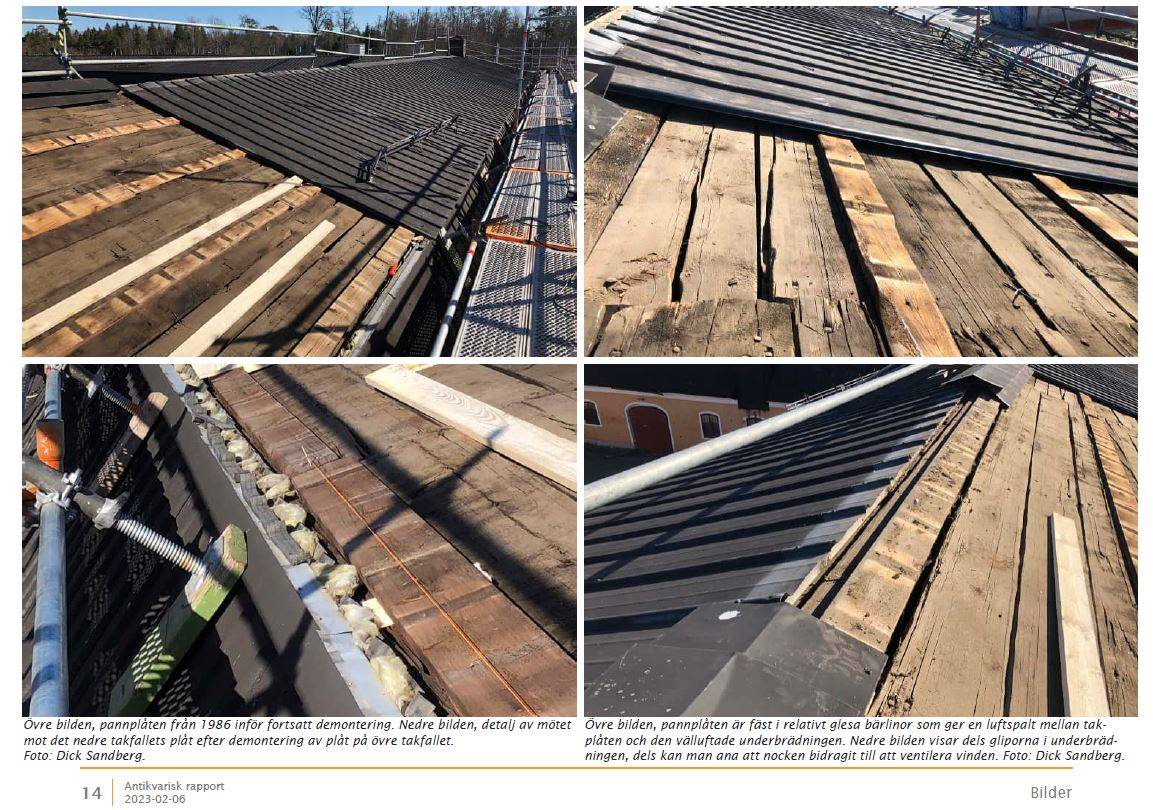

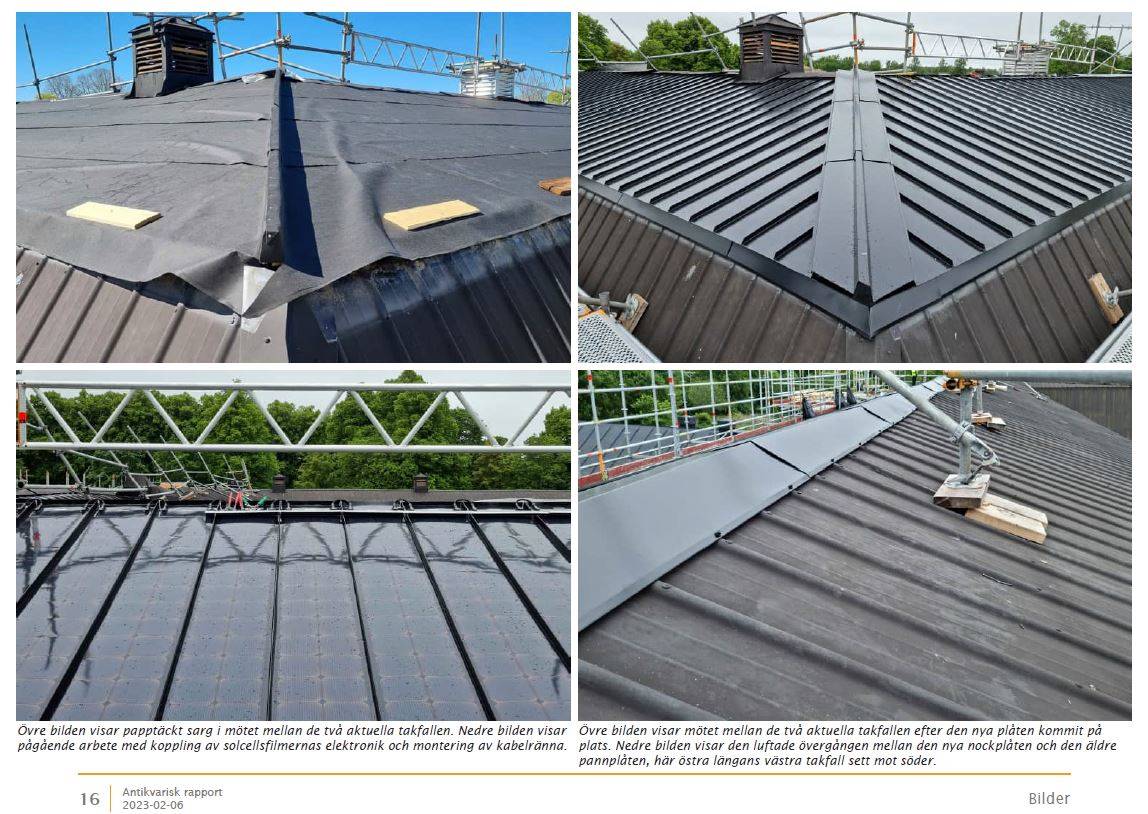

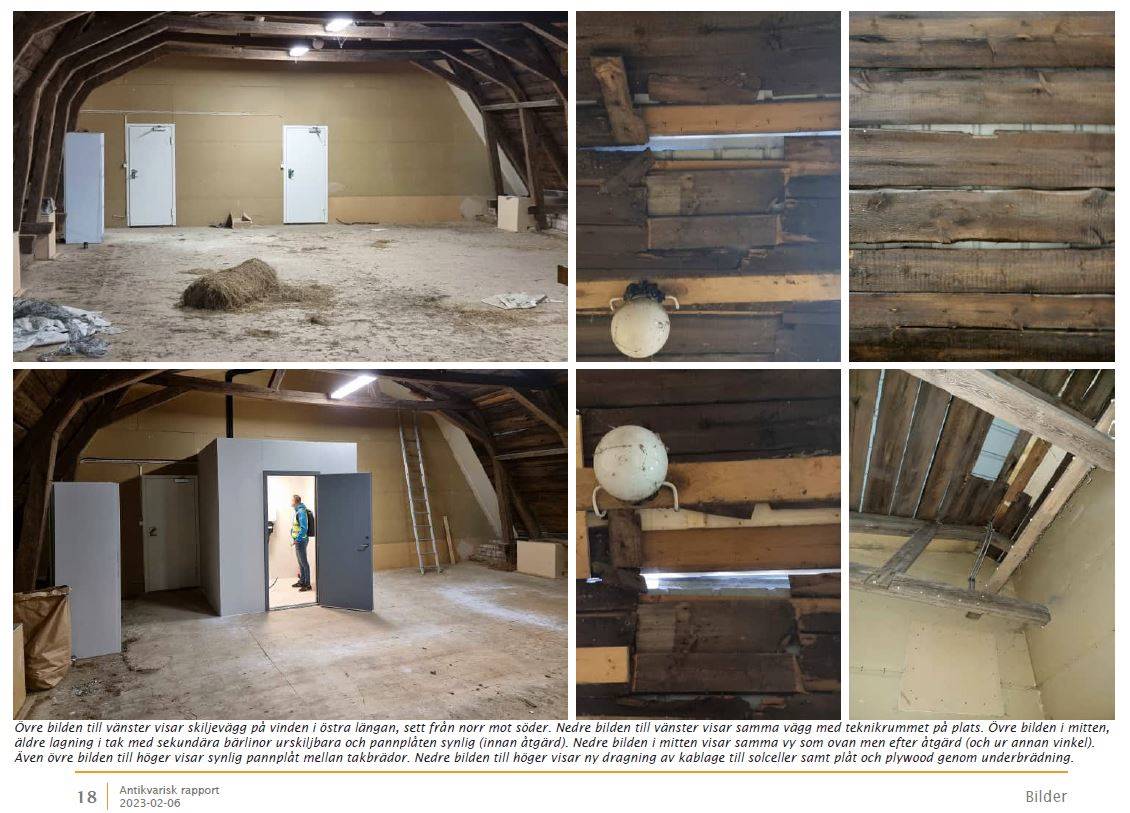

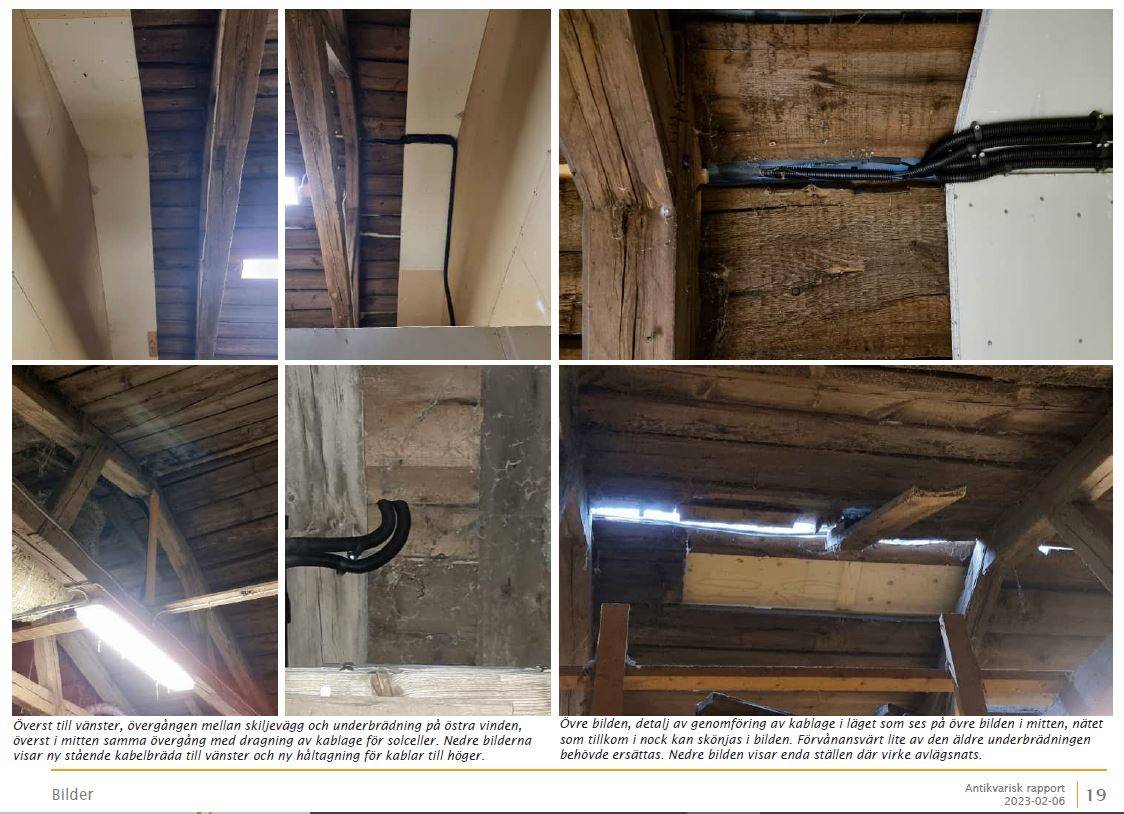

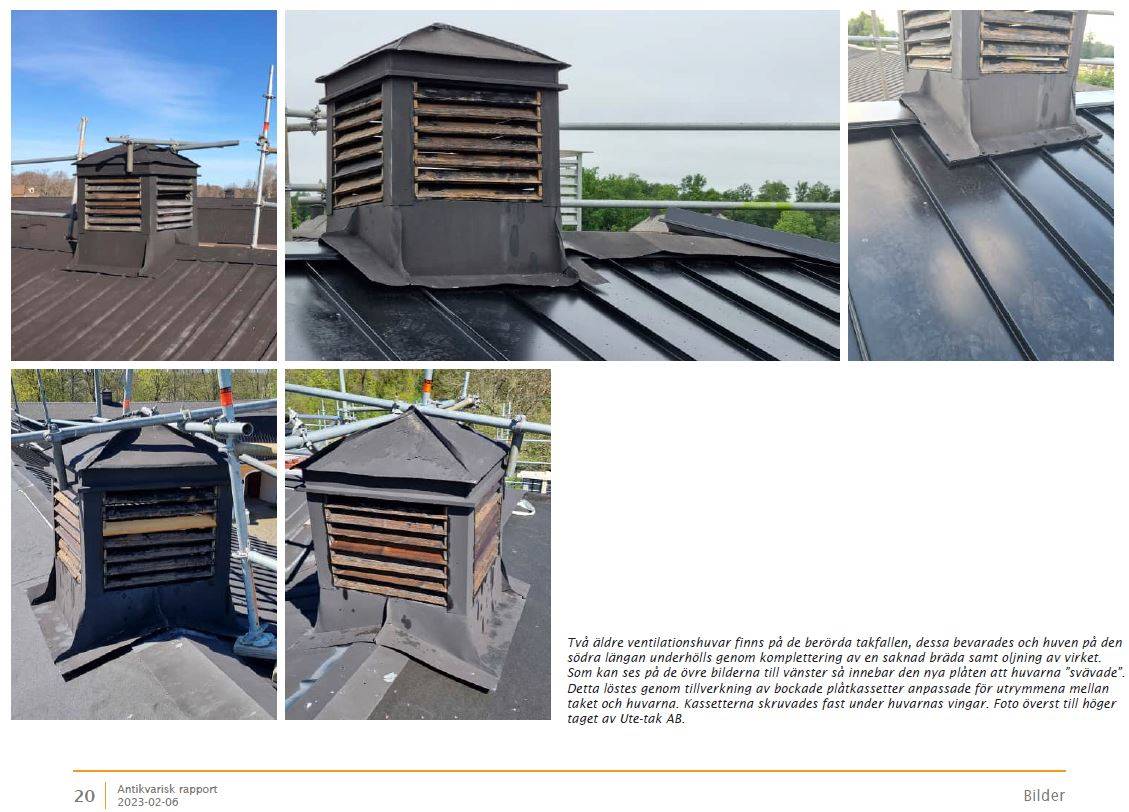

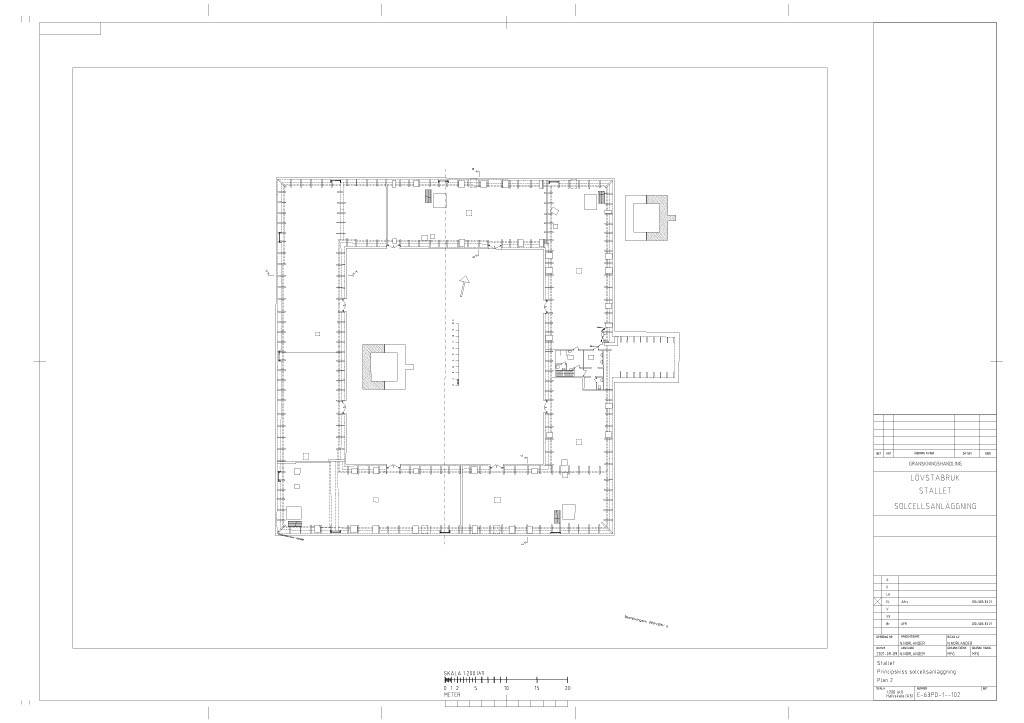

Reversible mounting of solar panels is carried out with integrated solar panels in new metal sheets of the brand Lindab SRP25N (SR=Solar roof), specially adapted for solar panels, SveaSolar was the contractor. The roof construction consisted of rough roof boards that were retained. In order to make the substrate smooth, plywood was laid over, then underlay cloth and folded sheet metal in a slightly narrower dimension than normal, approximately 400mm wide, which matches the thin film (brand Sunwind), which was glued on top (neither mono. nor polycrystalline panels).

The solution with "solar cell film" means that the sheet on the roof in question needed to be replaced, regardless of how much of the surface was covered by the solar cells. The measure thus involved an extensive intervention for the roof itself, but significantly less visual impact after the measure compared to conventional solar cell panels that are mounted on the outside of the existing roof.

25 mm

20 mm

300 mm

25 mm

20 mm

300 mm

RENEWABLE ENERGY SYSTEMS

Photovoltaic

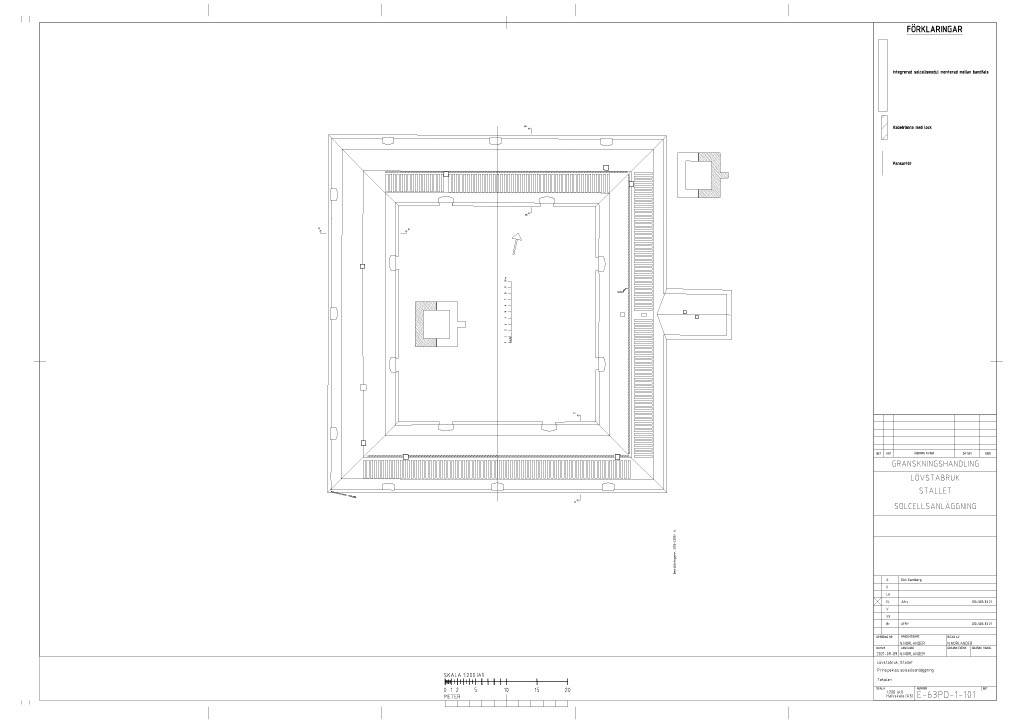

Solar cell film integrated in new folded sheet metal (Lindab Solar Roof). Solar cell modules with dimensions 3077x358 (LxW) were used. The power of the solar cells is 27.54 kW and according to calculations, the annual production should be 17,670 kWh/year. This means that the proportion of purchased energy will decrease sharply every year. Over a period of 5 years, 88,350 kWh of produced electricity is estimated to come from the facility. During 10 years, 176,700 kWh of electricity produced is estimated to come from the facility. SFV will be able to follow produced electricity monthly in SFV's system Vitec. The facility is to be used to supply the existing building with electricity. Any surplus will be able to be sold to the electricity company.

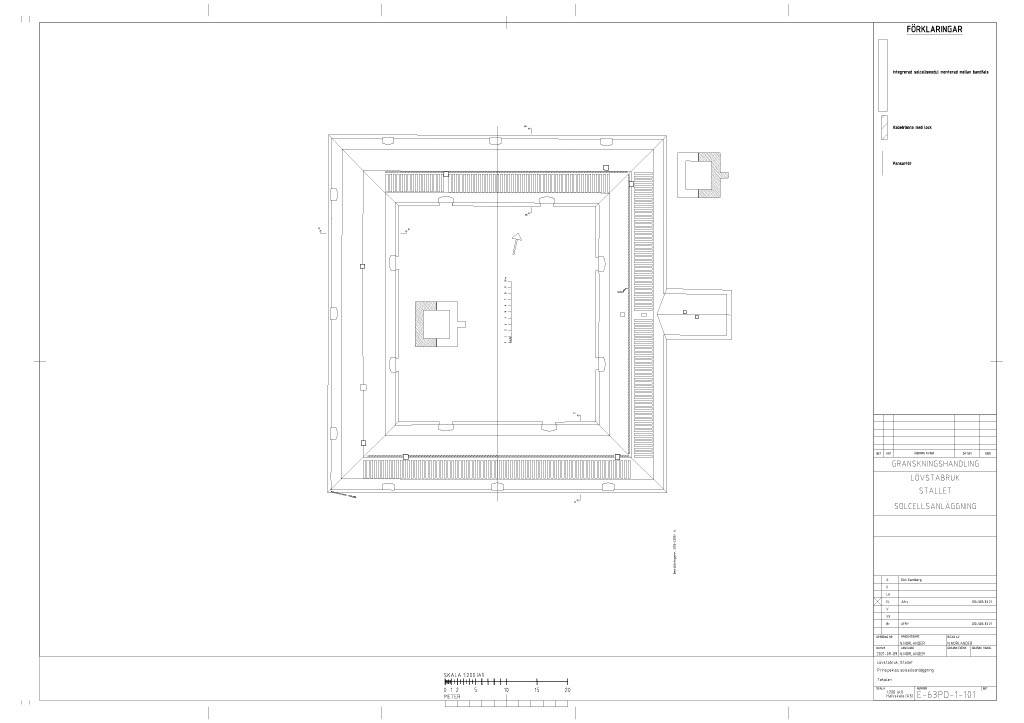

Initially, solar cells were planned on three of the roof slopes, to the north, east and South. Prior to the measure, the extent of the surface for solar cells was discussed it was established that the effect, of at least 18 kWp, as stated in the request documents, could be achieved on two roof pitches instead of three through more efficient use of the surface. With the new planning and the use of a larger area on two roofs, the effect is estimated at approx. 25-27 kWp. The measure was thus changed from three to two roof cases for mainly cultural and historical reasons. The solar cells were placed to the east and south, on the two upper parts of the roofs.

The work was carried out in stages so as not to expose too large areas and risk exposing the roof frame to rain in particular. Initially, it was intended that masonite would be used as a base for the roof sheet, this was changed to 12 millimeter thick construction plywood. Tarred roofing felt was laid as a substrate for sheet metal cladding and new sheet metal is made by Lindab SRP25N, specially adapted for solar cell film (SR=Solar roof). Solar cells in the form of series-connected thin-film modules were glued to the plate. The system has an integrated cable channel under the ridge plate.

| Photovoltaic System | |

|---|---|

| Type | Thin film |

| Collector area | 356,0 m² |

| Total nominal power | 27,54 kW |

| Elevation angle | 18,0 |

| Overall yearly production | 17670,0 kWh |

Energy Efficiency

Voluntary certificates: No

Consumption_estimation_Calculation_method: NA

Primary Energy

Consumption_estimation_Calculation_method: NA

Consumption_estimation_Including_DHW: No

Costs

The project's total cost amounts to SEK 2,862,000 (ca 255.545 Euros) and the decided cost framework amounted to SEK 2,613,000 (ca 233.312 Euros). The overrun is due to the fact that there was more under-work for the contractors on the roof and that it took more hours than estimated to mount the solar cells themselves.

2 862 000 kr (ungefär 243 682 Euros) (total)

Amount includes: The project's implementation costs include investigations, program documents, system documents, request documents, production and budget reserve. The project has been financed in its entirety via SFV's targeted grants for solar cells and the cost has therefore been taken as ongoing maintenance on SFV's annual income statement for Lövstabruk.

No