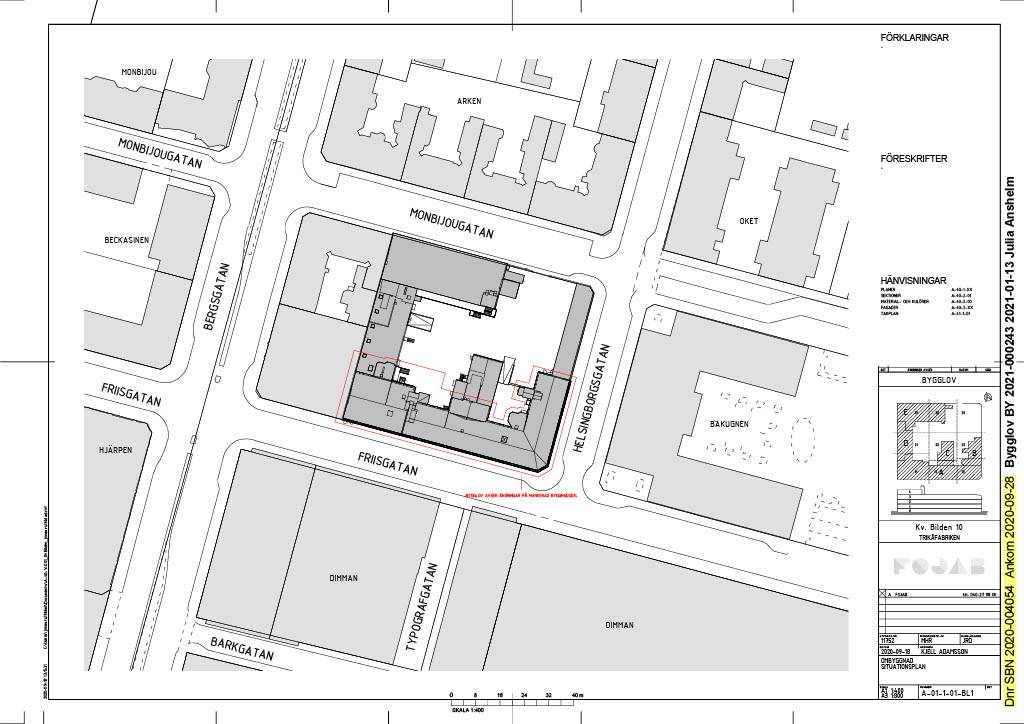

Trikåfabriken

Monbijougatan 17C, Kvarteret Bilden

211 53

Malmö, Sweden

Owner

Contact Details

Other Information

To visit the project, please contact Moa Persson, moa.persson@stena.com

Climate Zone Cfb

Altitude 12 m a.s.l.

HDD 2214

CDD 27

Conservation Area:

Yes

Level of Protection:

The building is located within the national interest for cultural heritage, Malmö (M114).

Year of last renovation:

2020

Year of previous renovation:

1970

Building occupancy:

Permanently occupied

Number of occupants/users:

522

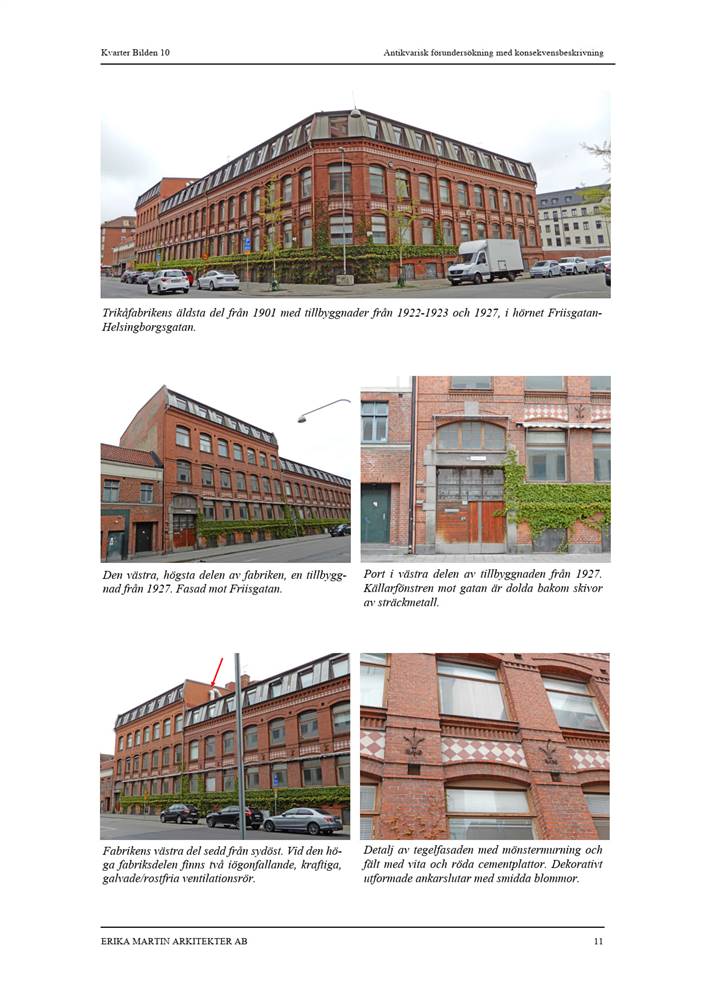

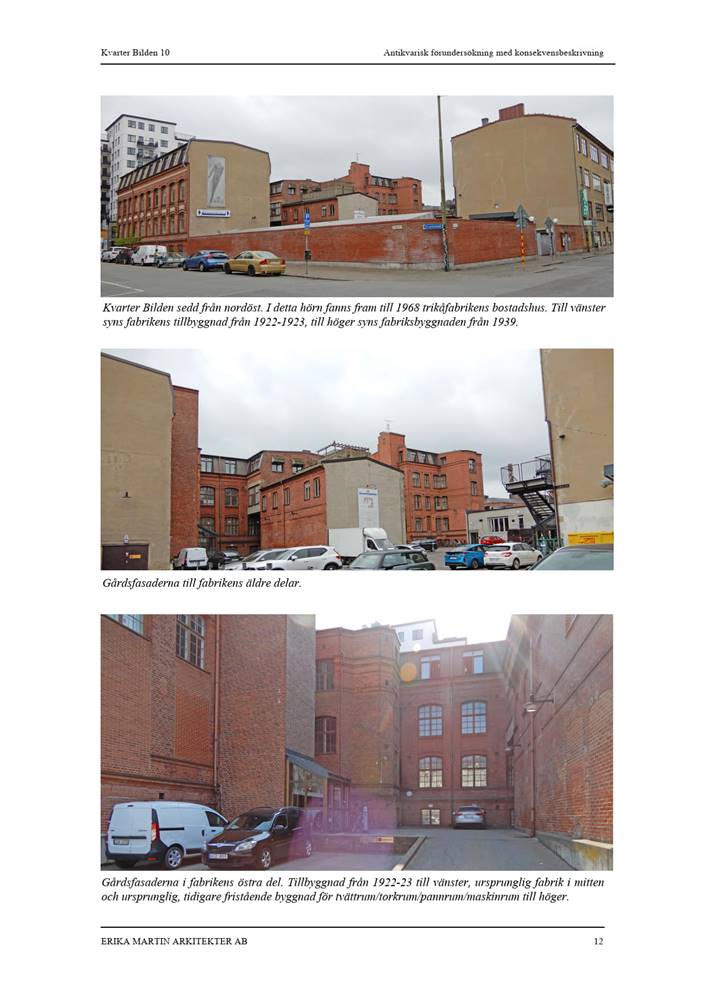

Building typology:

Old knitwear factory

Number of floors:

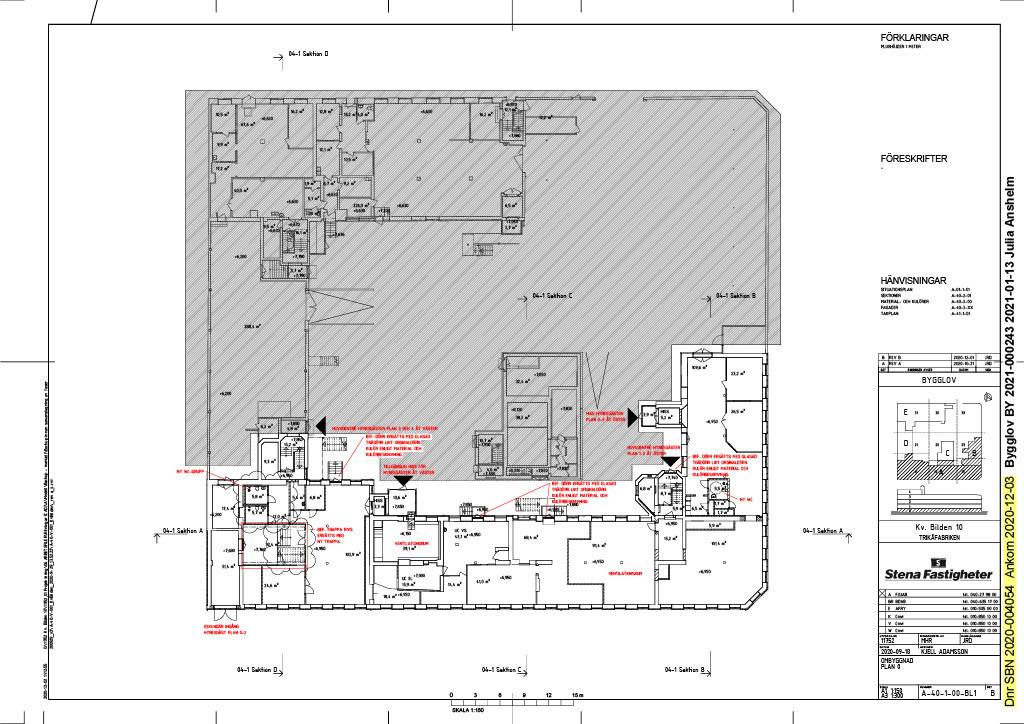

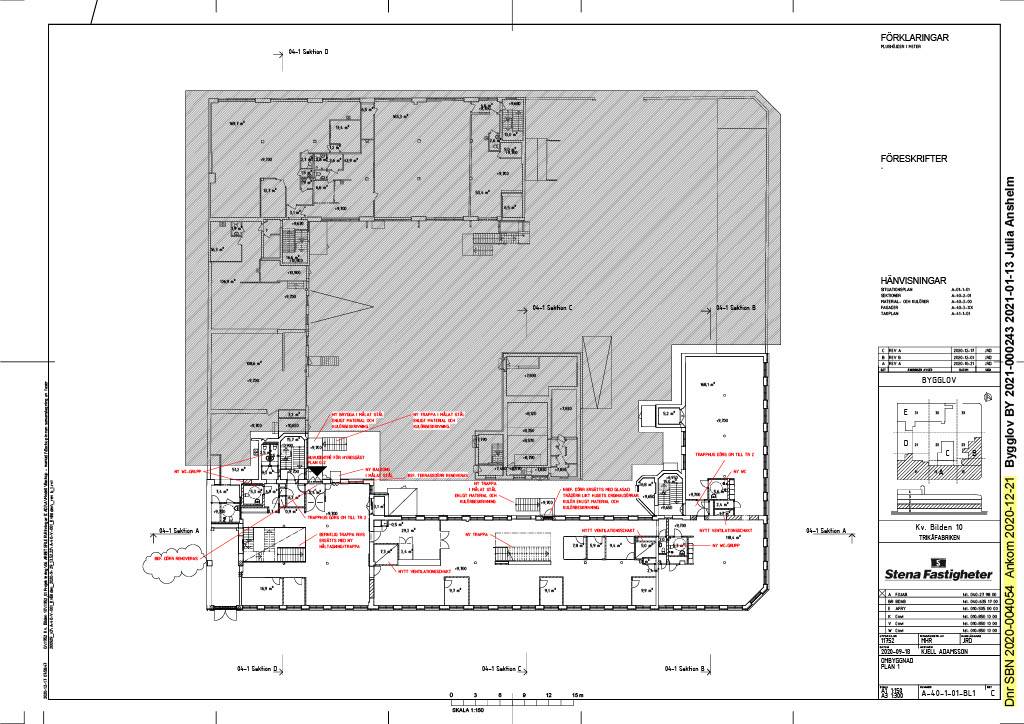

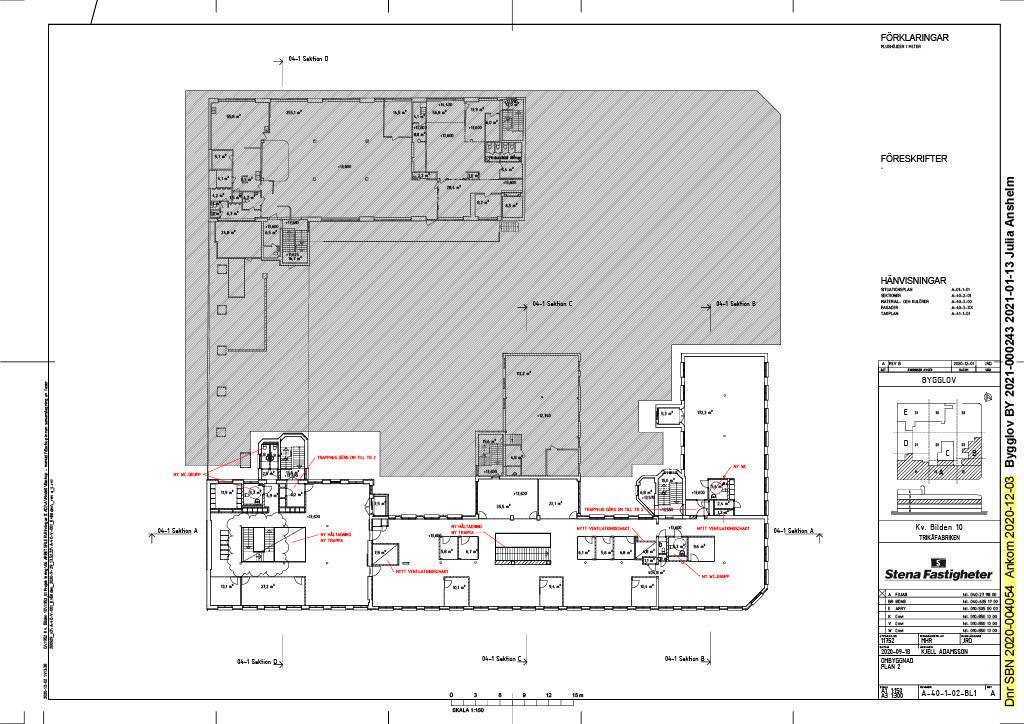

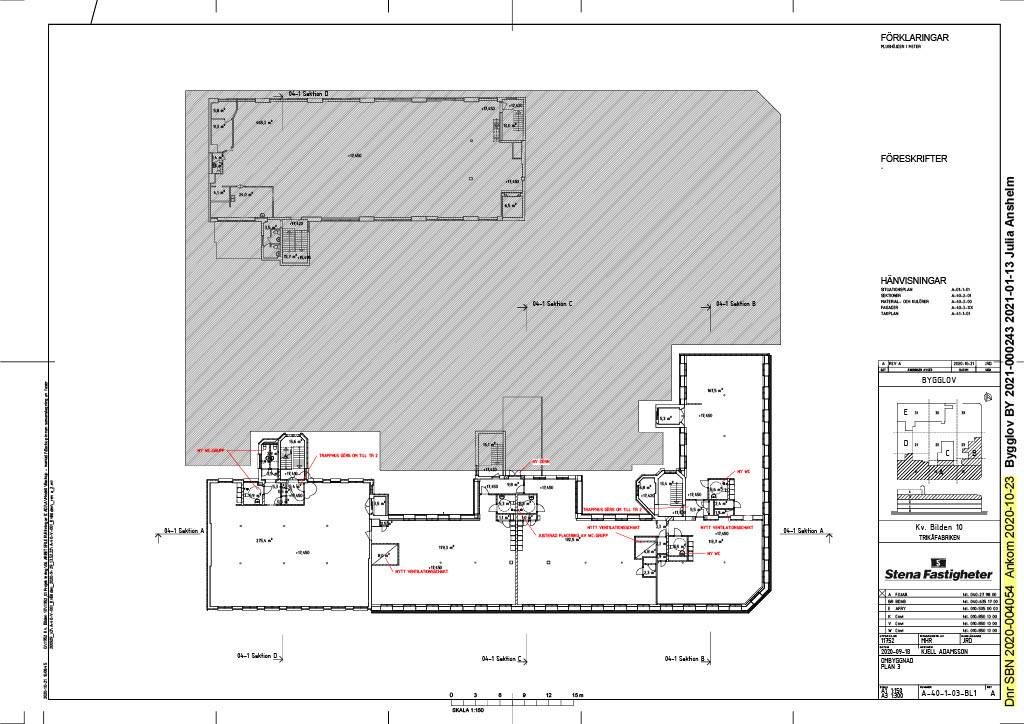

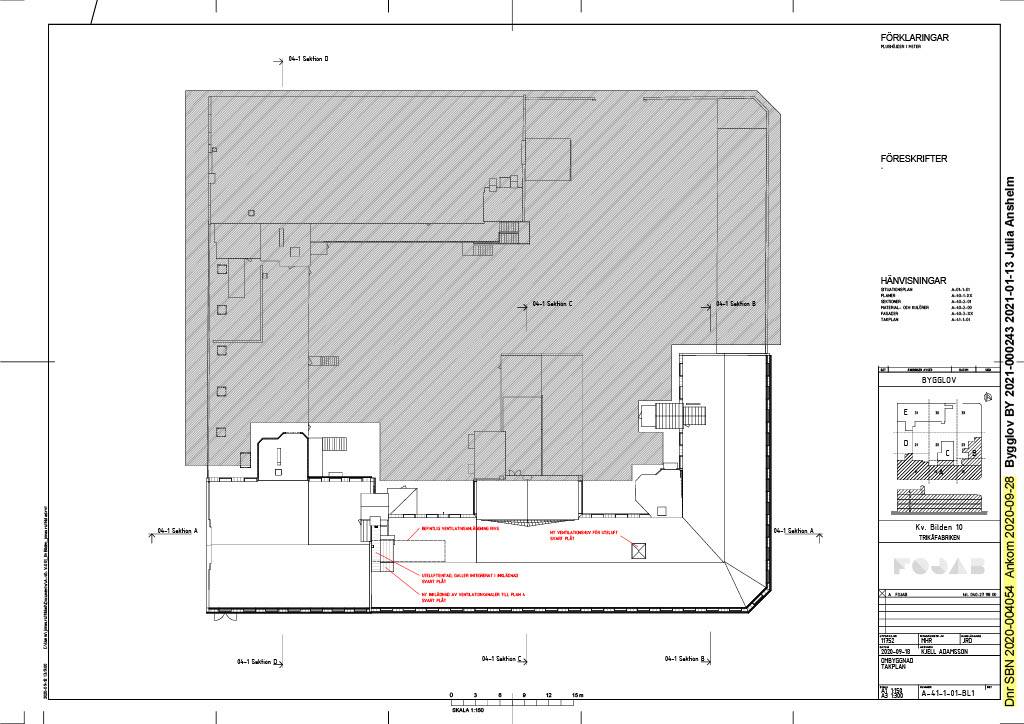

3

Basement yes/no:

Yes

Number of heated floors:

0

Gross floor area [m²]:

0,0

Thermal envelope area [m²]:

0,0

NFA calculation method:

Sweden

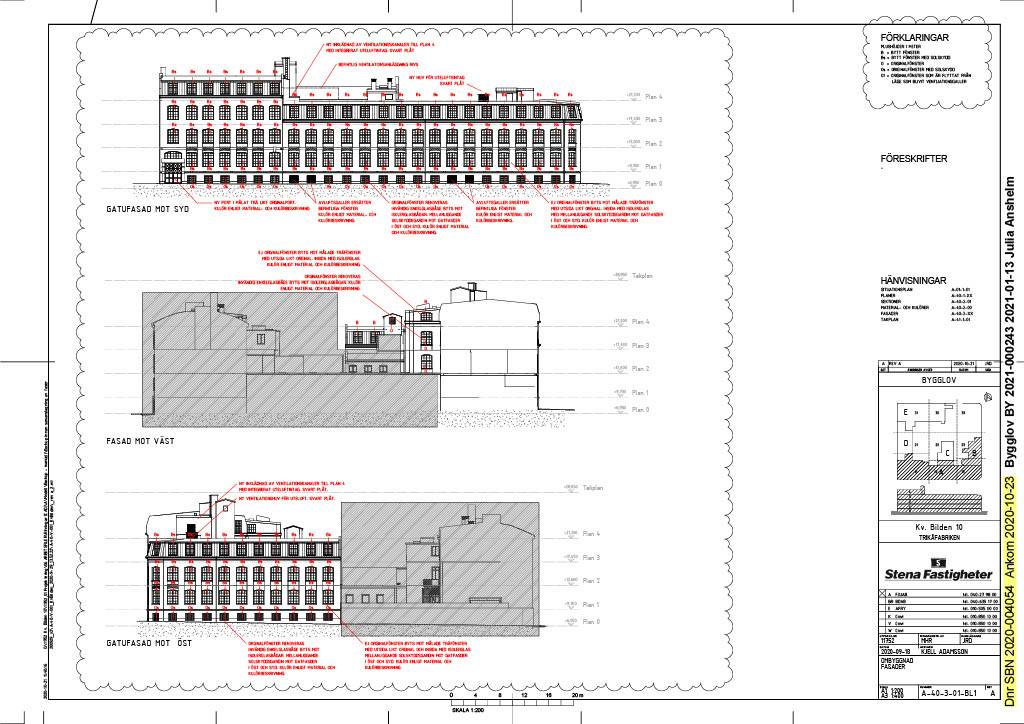

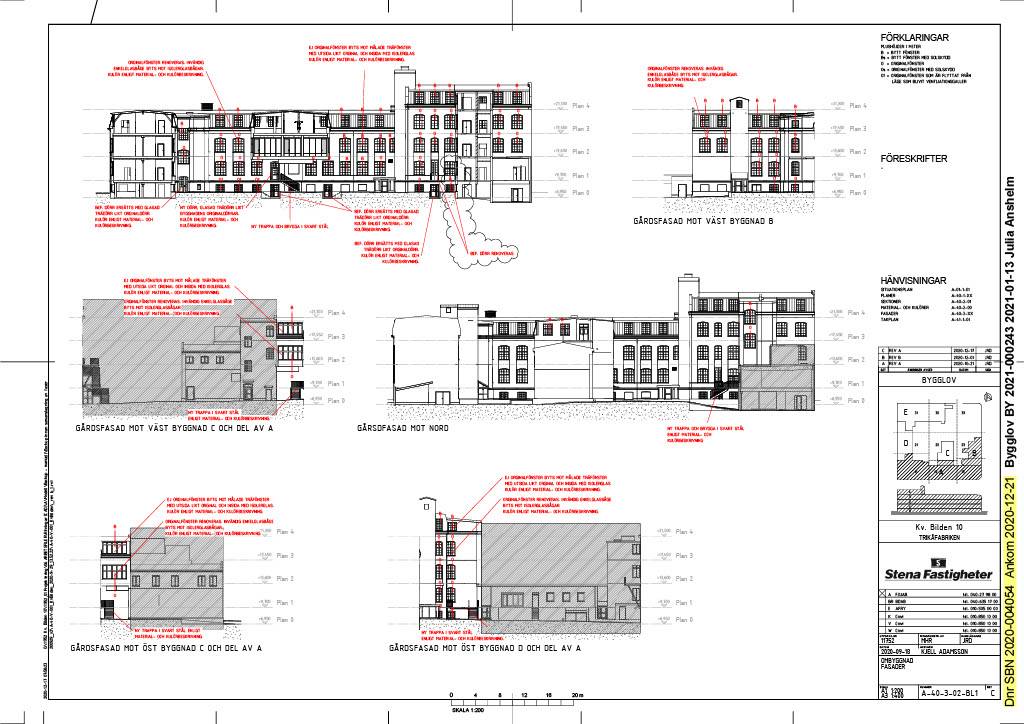

External finish:

Exposed brickwork

Internal finish:

Plastered (on substructure)

Roof type:

Pitched roof

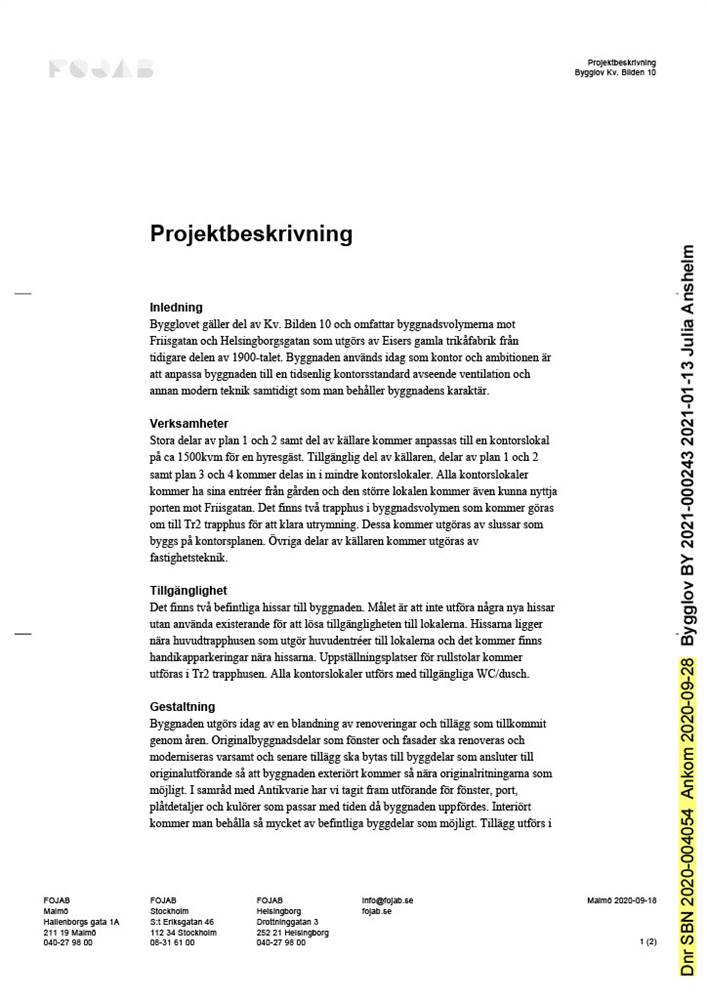

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

RETROFIT SOLUTIONS

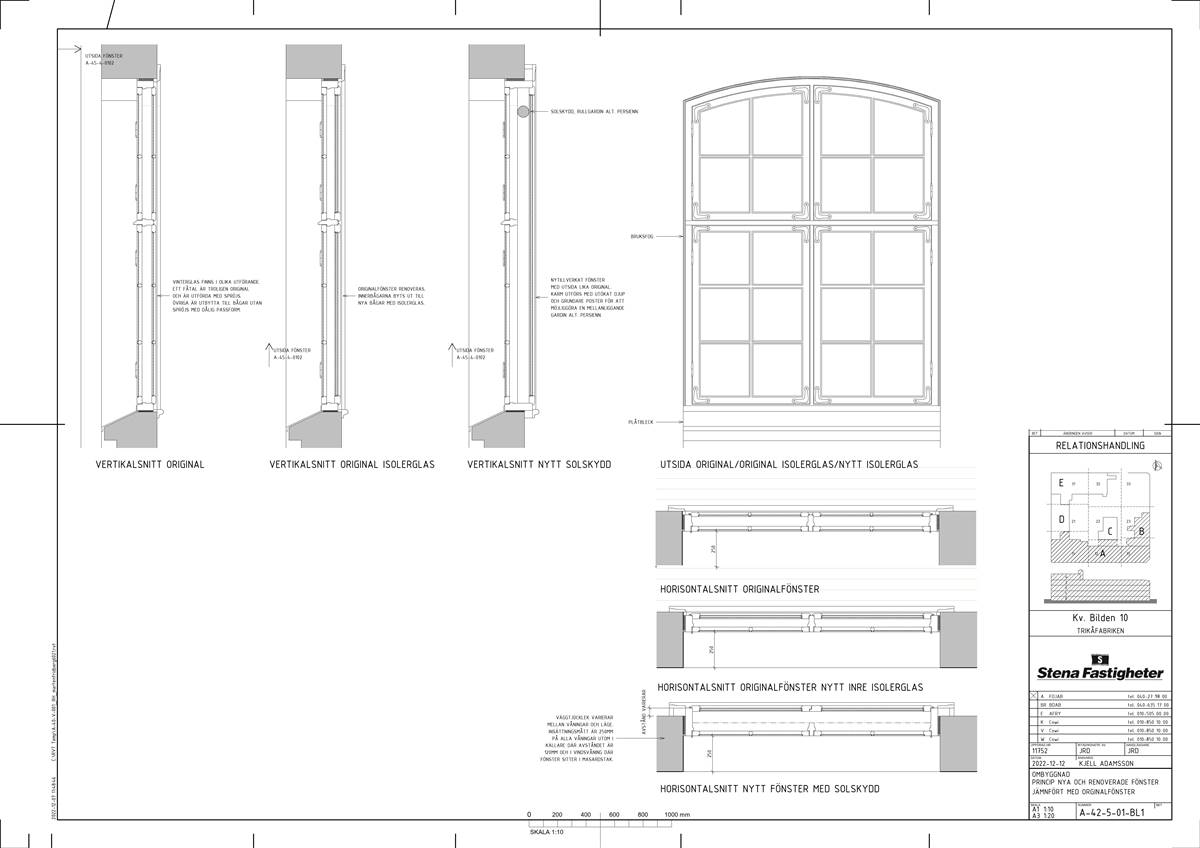

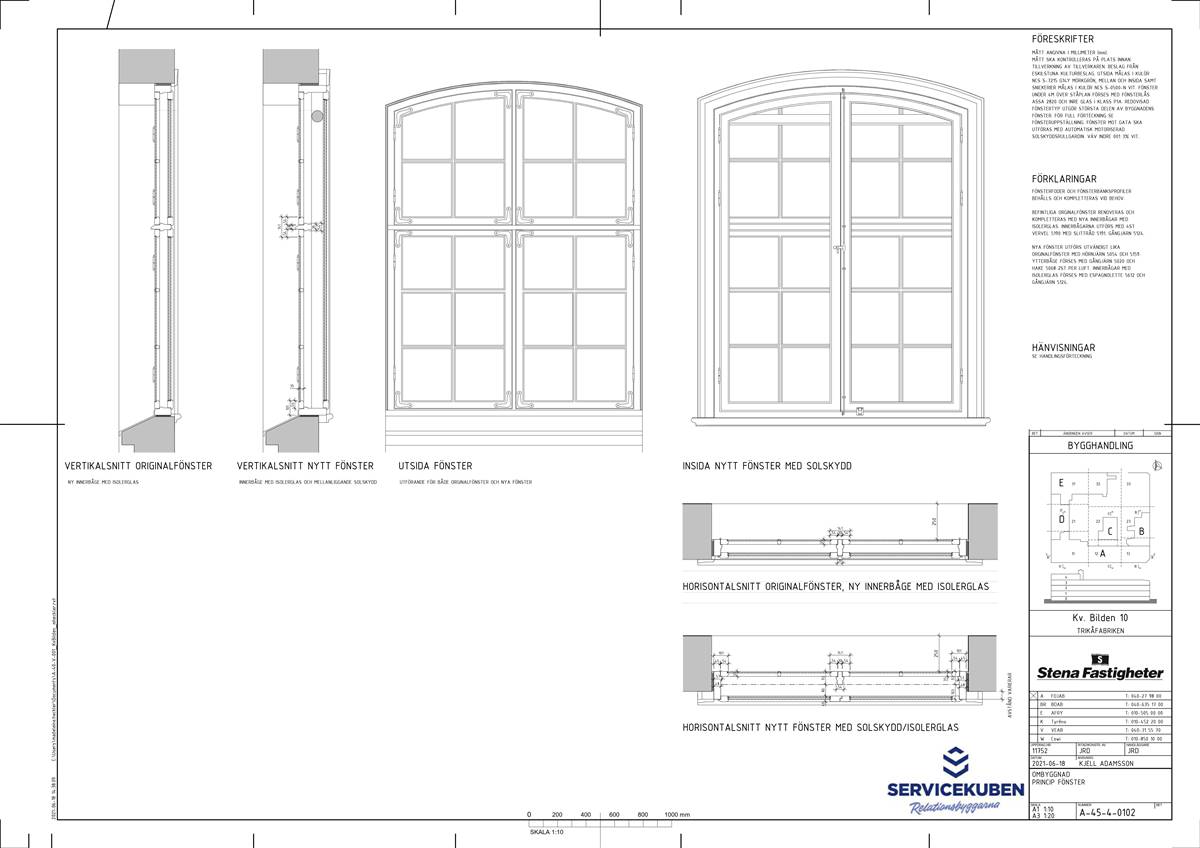

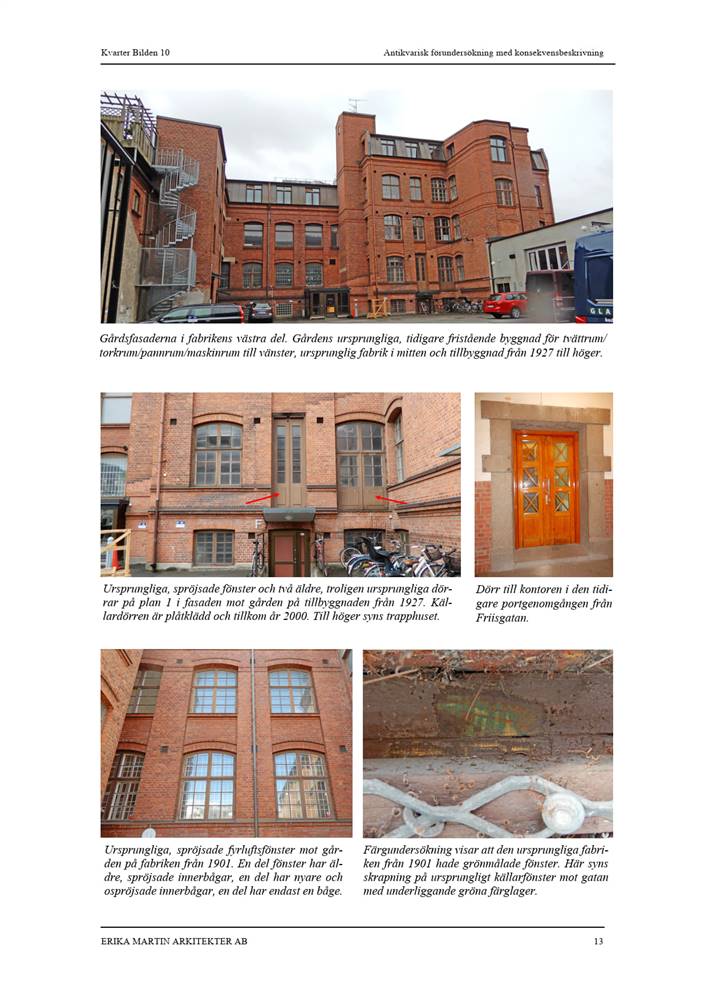

Windows

Existing windows renovated and upgraded

New windows with built-in sun protection

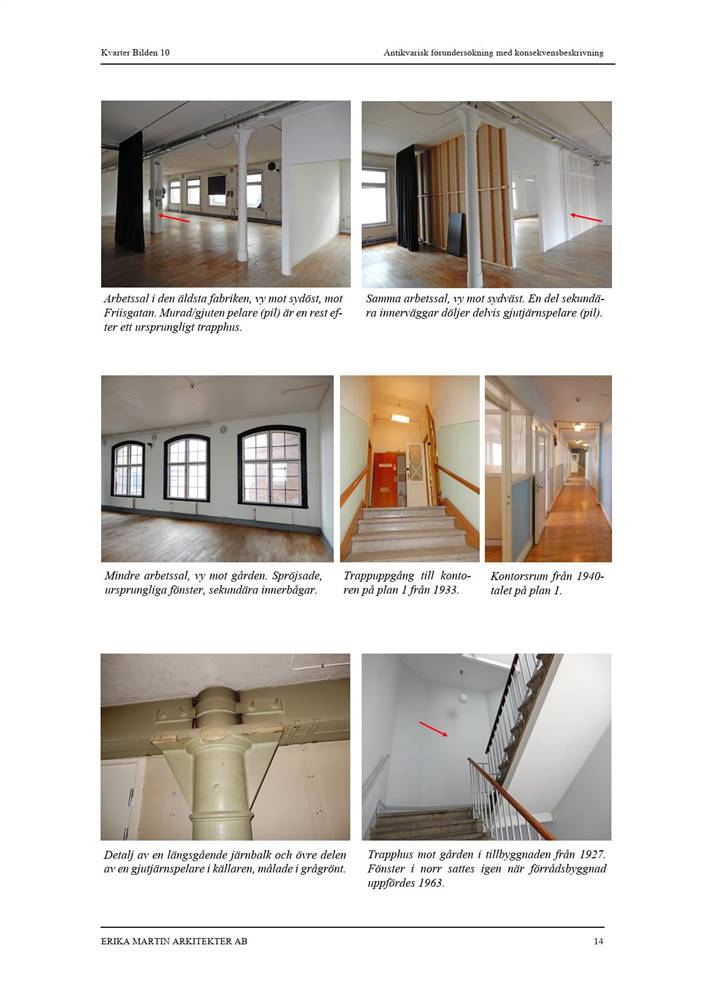

Most of the existing windows were 70's wooden windows with 2 glasses. The windows that weren't damaged have been renovated, insulated with new internal frames (insulating glass) and restored to their original appearance.

The outcome is very positive. Existing original windows differ to some extent, some have simple sashes, some have loose original inner sashes and some have relatively new inner sashes with poor fit that do not fulfil any major function. The interventions should be adapted to the conditions of each window.

| Existing window type | Casement window |

| Existing glazing type | Double |

| Existing shading type | NA |

| Approximate installation year | 1970 |

| New window type | Casement window |

| New glazing type | Double |

| New shading type | NA |

| New window solar factor g [-] | 0,0 |

New windows with insulating glass have been recreated in the old style. Windows in sunny locations have been fitted with an intermediate sunscreen that is controlled by sunlight and temperature. The building has been divided into different sections where each section is controlled by a sensor placed on the roof. It reacts to the sun and follows a sun curve. When the sun is shining, the curtains close automatically, and they open automatically when the sun is no longer there. However, with a certain delay (sun curve) to minimise the curtains going up and down as soon as the sun goes into clouds. The curtains can be temporarily controlled at each window, but after a couple of hours they automatically go into the position indicated by the sensor, in order to minimise the need for cooling on sunny days.

The intervention is very positive for the overall image of the building. New windows must be designed as copies of original windows in terms of material, shape (arched or rectangular top), timber dimensions, dividers, hanging, drip mouldings and other details. External sashes shall be fitted with single glazing and glass-breaking glazing bars.

| Existing window type | Casement window |

| Existing glazing type | Double |

| Existing shading type | Roller blinds |

| Approximate installation year | 1970 |

| New window type | Casement window |

| New glazing type | Double |

| New shading type | Inner shutter |

| New window solar factor g [-] | 0,0 |

HVAC

HEATING

VENTILATION

AIR CONDITIONING

DOMESTIC HOT WATER

During the renovation, a completely new district heat exchanger was installed where smart control (e.g. AI) is possible to optimise the heating system and reduce heating costs. All heating pipes, radiators and tap water pipes in the project are new.

The measures were carried out with greater respect for the original structure and with minimal intervention. Before we started the renovation, we already had district heating in the property. However, we have a new technincal control centre and new heating pipes in the building. Nothing more than incoming district heating has been preserved.

| New primary heating system | |

|---|---|

| New system type | Fjärrvärme |

| Fuel | Biomass |

| Distribuition system | Radiators |

| Nominal power | 320 kW |

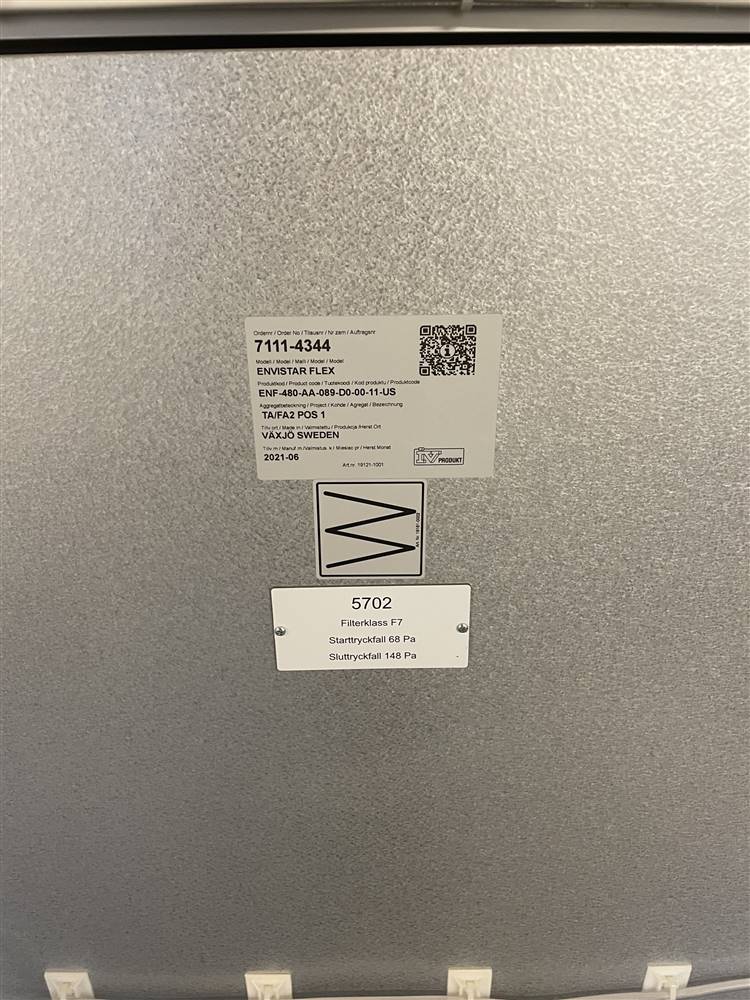

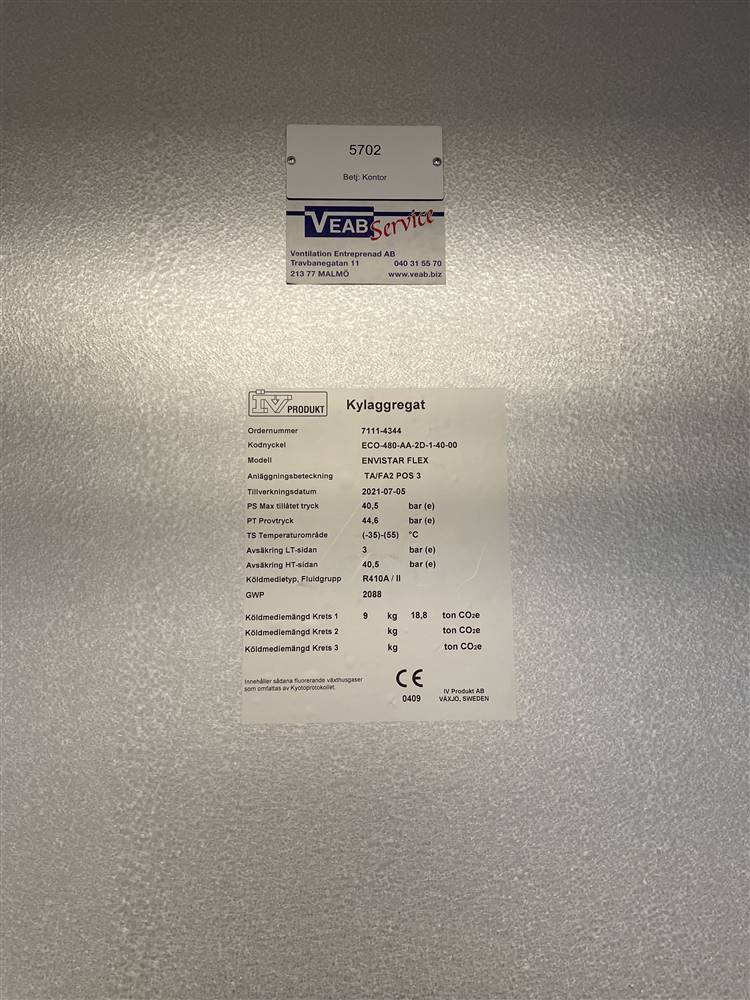

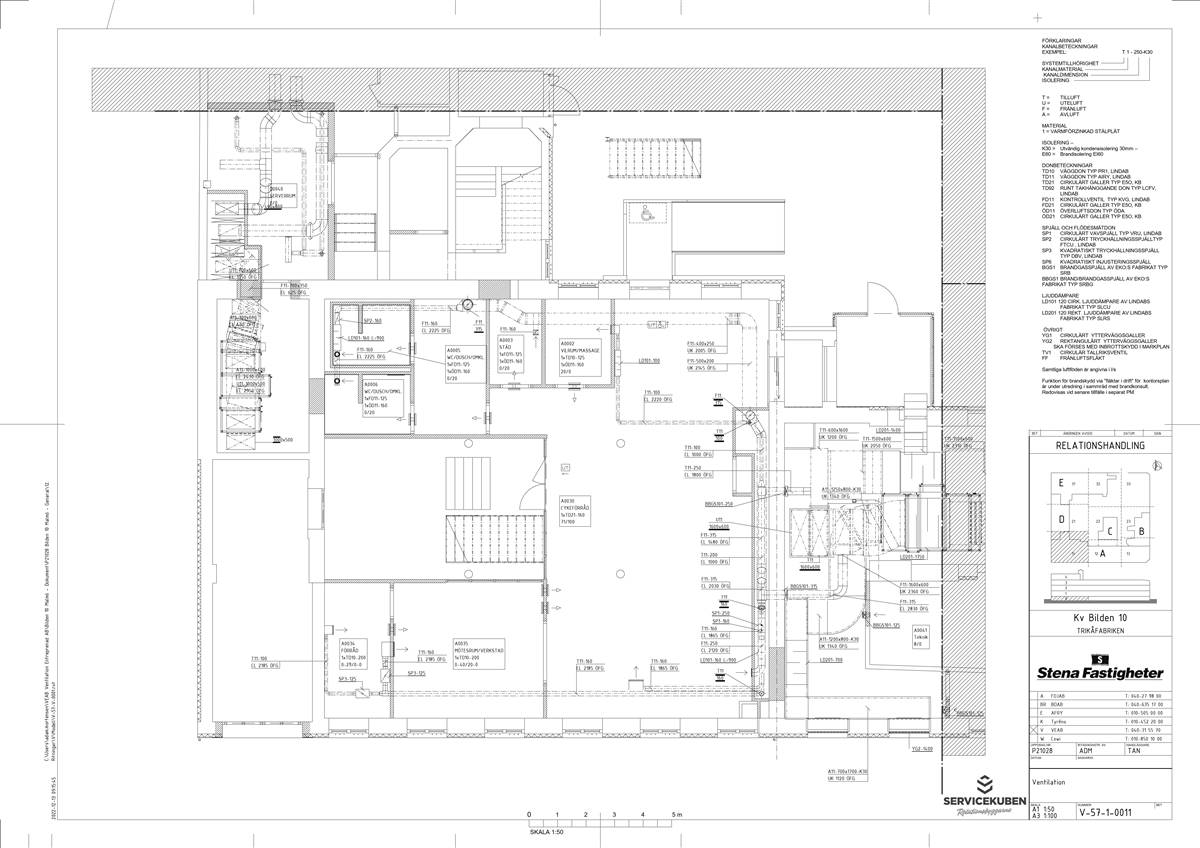

Ventilation and air-conditioning is provided by a VAV system with cooled supply air (Lindab). The four air handling units - with a capacity of between 1 m3/s and 4.5 m3/s - are located in an equal number of fan rooms. The airflow is regulated by presence and increases automatically if the temperature or carbon dioxide rises, Tenants cannot force the flow themselves. However, they can regulate the room temperature set point within a range determined by the property owner.

As much as possible, we have kept the original structure of the building. However, the structure of the building has had to be partly adapted with new holes in the floor for vertical shafts. It was important to retain the sense of space of the old factory premises. All electricity has been concealed and installations in the ceiling minimised. There are no large, winding ventilation systems here; ventilation has been kept down as far as possible. Both to give the rooms a cleaner look with high ceilings and to save energy. Flexibility has been a key concept for the building to have a long service life, but also to be able to easily adapt it for different activities today and in the future.

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Centralized |

| Type flow regime | Overflow |

| Heat recovery | Yes |

| Humitidy recovery | Yes |

| Nominal power | 2600 l/s kW |

| Electric power | 7,4 kW |

| Control system | Konstant |

The building is provided with comfort cooling integrated in the air handling units and distributed via ventilation air. Server rooms are supplemented with DX (Direct Expansion) cooling to cover peak power and redundancy.

The original structure was not greatly affected by the measures and all new installations were added with minimal intervention.

| New cooling system | |

|---|---|

| Type | NA |

| Distribuition system | NA |

| Nominal power | NA kW |

| Electric power | 0,0 kW |

In the premises, hot water is heated either by local water heaters or flow-through heaters. There is no VVC (Hot Water Circulation).

The original walls were not affected by the new installations.

| New DHW system | |

|---|---|

| Type | with heating system |

| Hot_water_tank | Yes |

| With heat recovery | No |

RENEWABLE ENERGY SYSTEMS

Photovoltaic

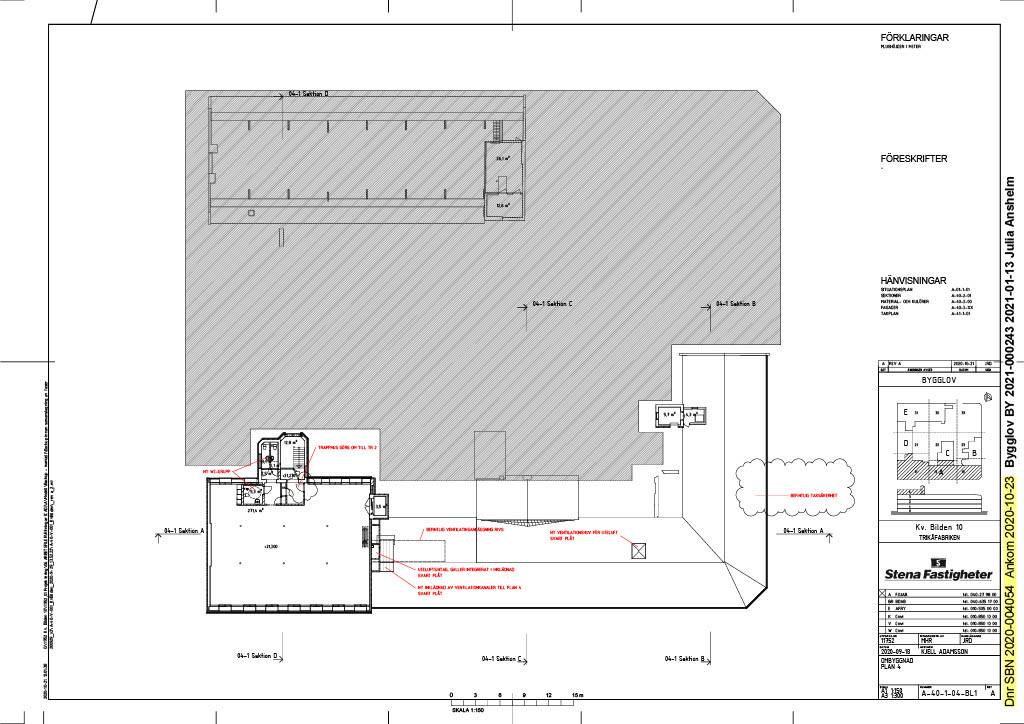

Solar cells with string optimisers are installed on the roof for maximum electricity production. Solar cells have been installed by Eon and they own the plant on our property. The optimiser makes each panel less dependent on other panels in the same string. The electricity from the solar cells will be used for cooling supply air, charging electric cars, and as property and business electricity. The Energy Hub inverter combines solar energy, storage and charging.

As the roof is low-slope, the solar cells are not visible from the ground, so this has not affected the appearance.

The roof was originally covered by a black tarred roofing felt. In the project we added a new waterproofing layer (new tarred roofing felt) before installing the solar panels. The structure has not had to be reinforced for the photovoltaic installation.

| Photovoltaic System | |

|---|---|

| Type | NA |

| Collector area | m² |

| Total nominal power | 60,0 kW |

| Overall yearly production | 58000,0 kWh |

Energy Efficiency

Voluntary certificates: No

Consumption_estimation_Calculation_method: IDA Indoor Climate and Energy 4.8

Consumption_estimation_After: 98 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: IDA Indoor Climate and Energy 4.8

Consumption_estimation_Including_DHW: Yes

Consumption_estimation_After: 119 kWh/m2.y

Costs

We have not had any funding other than to cover parts of the actual climate calculation (which was done in collaboration with IVL - Swedish Environmental Research Institute). We can already see that our operating costs have been reduced by having modern and optimised systems that talk to each other. With active material choices that last for a long time, we hope to keep maintenance costs down. In our project planning, we have worked hard to find solutions that are both sustainable but also contribute to keeping operating costs as low as possible.

113 500 000 SEK exkl. moms., ungefär 9 639 385 euros exkl. moms (total)

Amount includes: Everything is included in the project budget. Design (from feasibility study to construction documents), regulatory costs, certifications, project managers, climate calculations, production, inspection, etc. All project costs are included in this investment.

No