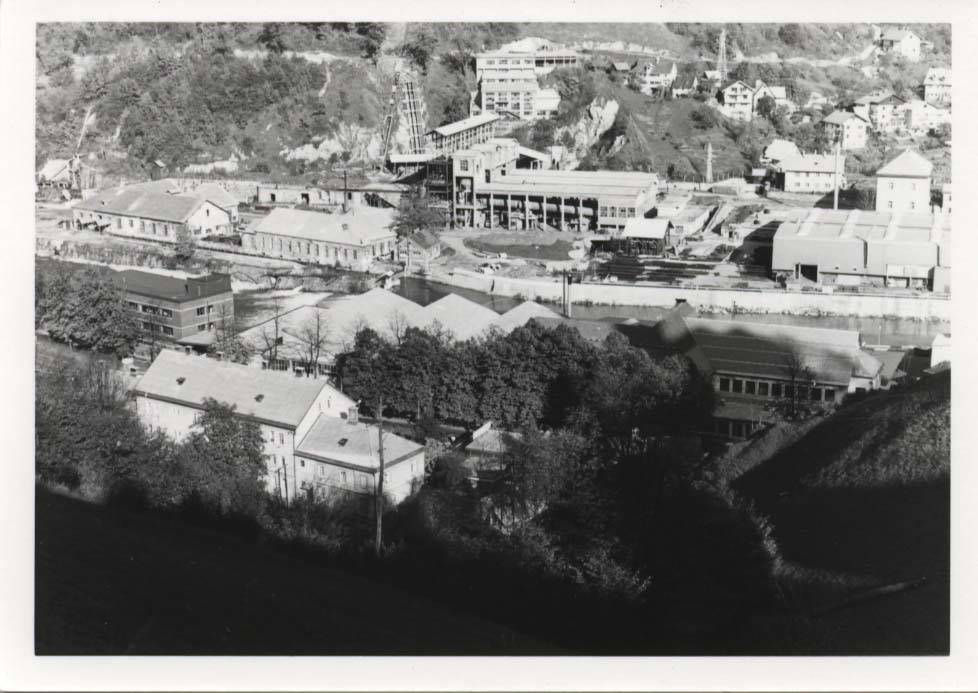

Idrija mercury smelting plant

Arkova ulica 50

5280

Idrija, Slovenia

architetto

Owner

User

Contact Details

Other Information

http://www.cudhg-idrija.si/en

https://idrija.si/files/other/news/54/599691.pdf

Climate Zone DFc

Altitude 300 s.l.m.

HDD 250

Conservation Area:

Si

Level of Protection:

UNESCO World Heritage List, cultural monument of national importance

Year of last renovation:

2017

Building occupancy:

Unoccupied

Building typology:

industrial plant

Number of floors:

7

Basement yes/no:

Si

Number of heated floors:

1

Gross floor area [m²]:

0,0

NFA calculation method:

External finish:

Rendered

Internal finish:

Plastered (on hard)

Roof type:

flat + single pitched roof

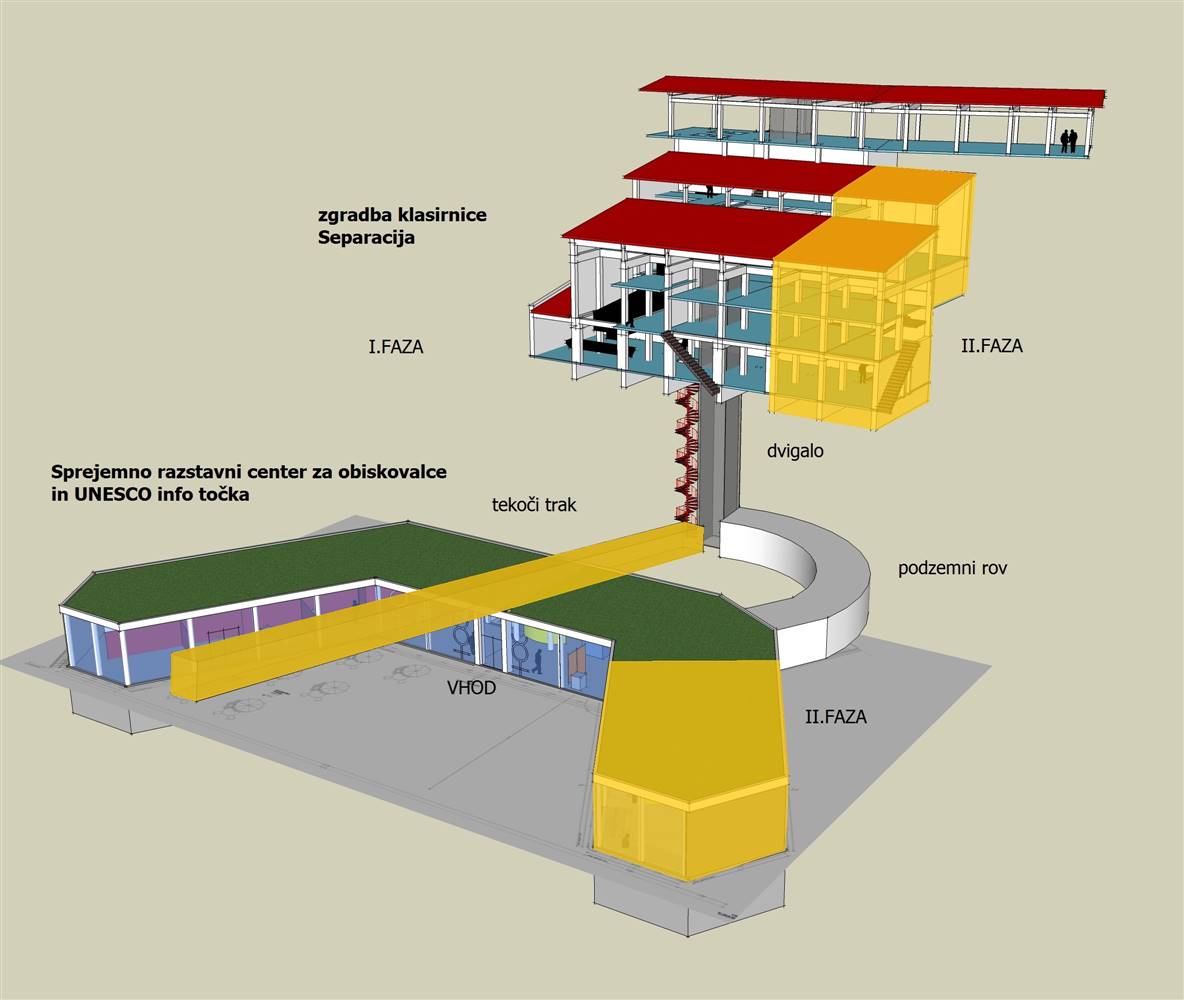

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Center za upravljanje z dediščino živega srebra Idrija

Bazoviška ulica 2, Idrija, 5280 Idrija

Aleš Hafner, univ.dipl.inž.arh. - Gea Consult

Mestni trg 5, 4220 Škofja Loka

Institute for the protection of cultural heritage of Slovenia

Delpinova 16, 5000 Nova Gorica

Ministry of Culture

Maistrova ulica 10, 1000 Ljubljana

RETROFIT SOLUTIONS

External Walls

Concrete frame structure filled with bricks and windows

Concrete frame structure with masonry walls in between. All walls, except in the basement, are additionally thermally insulated with EPS panels on the inside of the building, and a cement spray performed over them.

300 mm

300mm

80 mm

15 mm

Windows

Alu windows

The window openings remained the same, and the windows were replaced with ALU windows with double-layer thermopane glazing.

| New window type | industrial thermopan alu window |

| New glazing type | Double |

| New shading type | NA |

Other interventions

ROOF

OTHER

The roof is made of reinforced concrete beams, to which a wooden substructure is attached. The asbestos roofing has been replaced with a new suitable corrugated roofing. The roof is thermally insulated with soft mineral wool 25 cm thick, and the inside is lined with OSB panels, which are treated with cement spray over galvanized welded metal mesh.

0 mm

10 mm

250 mm

15 mm

15 mm

In some parts of the industrial plant there were additional modules (toilet, seminar room, elevator) established. They are heated and therefore also isolated as separate modules in the building.

In addition to the visitor centre all other parts of the building are kept very close to the initial state to serve the demonstration of the process. Areas where visitors stop (presentation elements, toilets) are separated from the other non heated areas.

HVAC

HEATING

AIR CONDITIONING

DOMESTIC HOT WATER

A boiler on pellets was constructed to heat the visitor centre. The radiating floor heating is in use in the visitor centre and radiators in other areas.

| New primary heating system | |

|---|---|

| New system type | Boiler |

| Fuel | Biomass |

| Distribuition system | Radiating floor |

| Nominal power | 150 kW |

| New cooling system | |

|---|---|

| Type | air conditioner |

| Distribuition system | Air |

| Nominal power | kW |

| Electric power | kW |

Combined with heating system.

| New DHW system | |

|---|---|

| Type | with heating system |

| Hot_water_tank | Si |

| With heat recovery | No |

RENEWABLE ENERGY SYSTEMS

Biomass

Boiler on pellets is used to generate heat for heating and hot domestic water.

| Biomass System | |

|---|---|

| Type | Pellet |

| Storage size | |

| Origin of biomass | |

| Overall yearly production | kWh |

Energy Efficiency

Voluntary certificates: No

Primary Energy

Consumption_estimation_Calculation_method: NA

Costs

2.300.000 eur

No