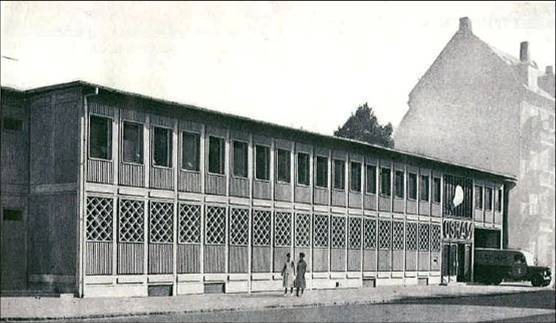

Osramhuset (The Osram Building)

Valhalsgade 4

2200

Copenhagen N, Danimarca

architetto

Owner

User

Contact Details

Other Information

Kultur N, Valhalsgade 4, 2200 Copenaghen, Danimarca

IEA-SHC Task47

Climate Zone Cfc

Altitude 18 s.l.m.

HDD 3720

CDD 22

Conservation Area:

No

Level of Protection:

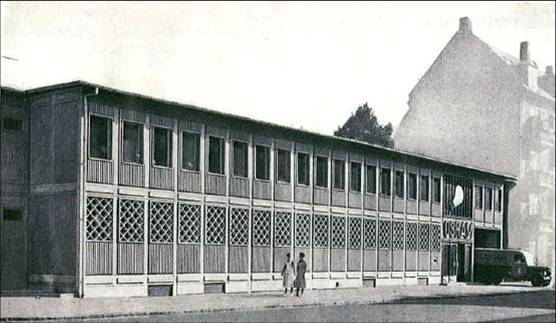

The facade is worthy of preservation/protected

Year of last renovation:

2009

Year of previous renovation:

0

Secondary use:

NA

Building occupancy:

Discontinuous occupancy (i.e. holiday home)

Building typology:

Detached house

Number of floors:

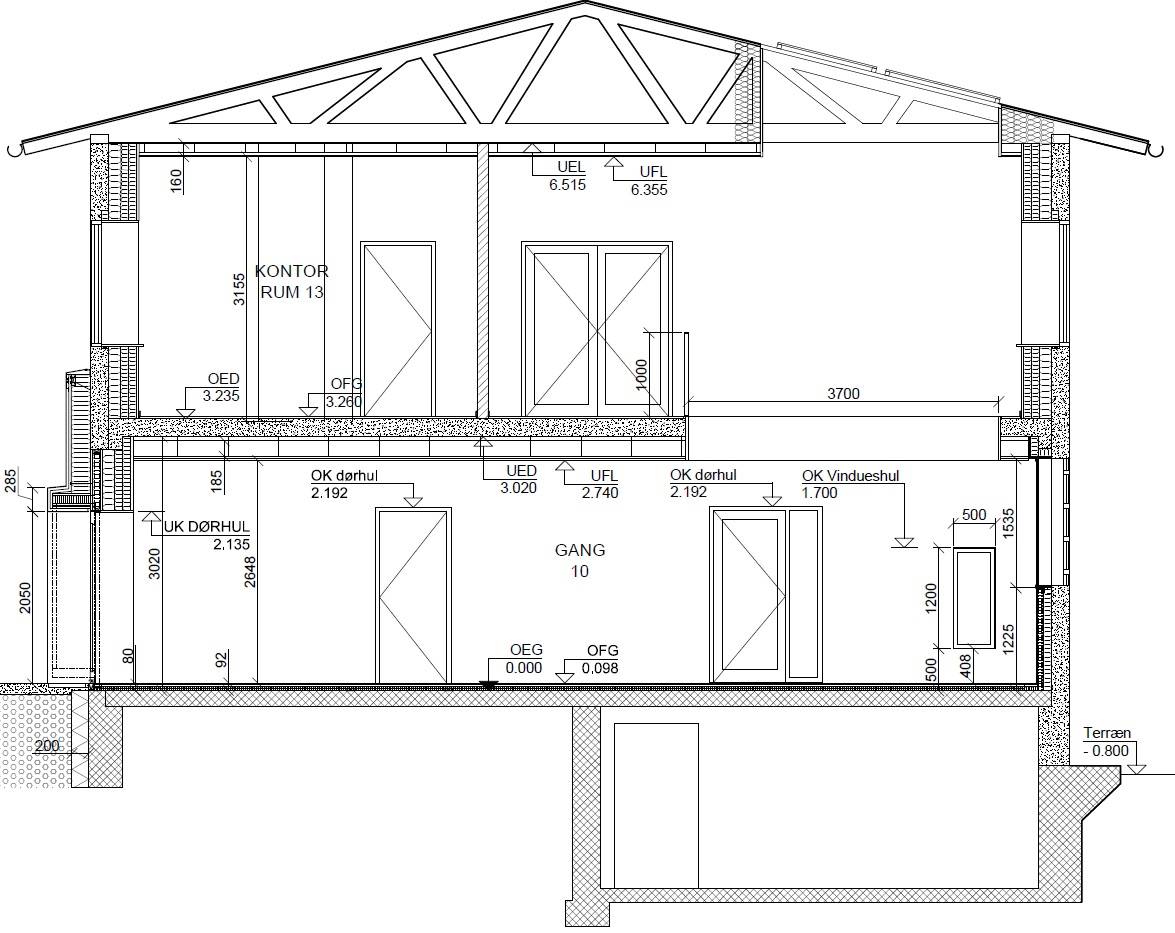

1

Basement yes/no:

Si

Number of heated floors:

2

Gross floor area [m²]:

872,0

Volume [m³]:

5768,0

NFA calculation method:

Danish Building Regulations

External finish:

Rendered

Internal finish:

Plastered (on substructure)

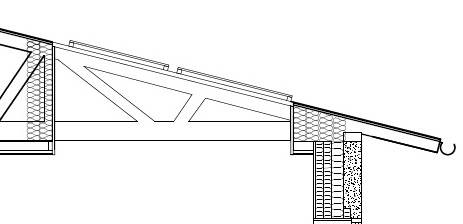

Roof type:

Pitched roof

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Municipality of Copenhagen (owner)

Rådhuspladsen 1, 1599 Copenhagen, Denmark

osram@kff.kk.dk

Tel.+45 3366 3366

Tegnestuen T-Plus ApS

Egelykkevej 13, 2720 Vanløse

Tel.+45 8853 5000

Wissenberg A/S

Hejrevej 26, 4. sal, 2400 København NV

info@wissenberg.dk

Tel.+45 3386 3486

Wissenberg A/S

Hejrevej 26, 4. sal, 2400 København NV

info@wissenberg.dk

Tel.+45 3386 3486

Wissenberg A/S

Hejrevej 26, 4. sal, 2400 København NV

info@wissenberg.dk

Tel.+45 3386 3486

PME Elrådgivning A/S

Energivej 3, 4180 Sorø

pme@pme.dk

Tel.+45 7021 1122

Building industry - active participation in project

Several - see comments

RETROFIT SOLUTIONS

External Walls

Wall type 1

Wall type 2

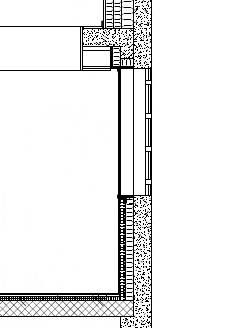

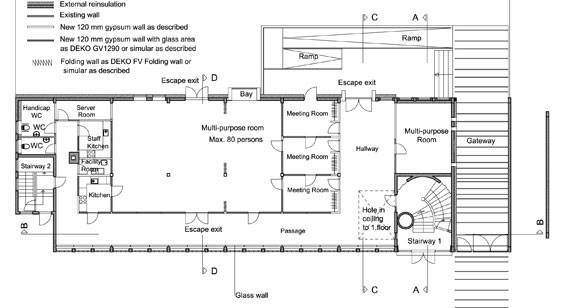

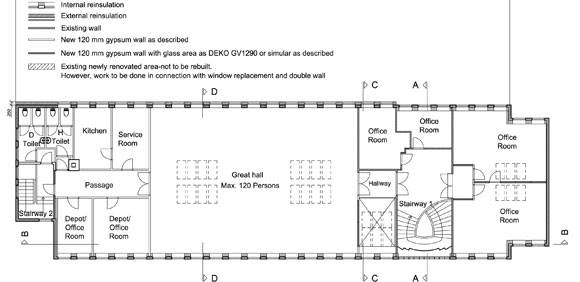

The facade of the building could not be touched and therefore this part of the building was insulated on the inside, i.e. by adding a layer of glass from floor to ceiling on the inside of the construction. Below the windows 50 mm insulation was added as well.

Reversibility was not considered. The important thing here is that the facade of the building has maintained its appearance from the outside and adding a layer of glass on the inside along with a layer of insulation below the windows has reduced heat loss significantly.

60 mm

60 mm

120 mm

60mm

60 mm

120 mm

85 mm

26 mm

The back of the building and the wall facing the gate had no restrictions and thus an external layer of insulation was added.

The cladding panels have been engraved with a pattern that evokes the original concrete windows.

240 mm

20 mm

10mm

380 mm

240 mm

20 mm

Windows

Window 1

Window 2

Window 3

Since the facade could not be altered, a layer of glass was added to the inside (floor to ceiling).

| Existing window type | Fixed window |

| Existing glazing type | Single |

| Existing shading type | Fixed shading |

| Approximate installation year | 1953 |

| New window type | Fixed window |

| New glazing type | Single |

| New shading type | Fixed shading |

| New window solar factor g [-] | 0,5 |

Windows not part of the facade towards the street were replaced

| Existing window type | Double window |

| Existing glazing type | Double |

| Existing shading type | NA |

| Approximate installation year | 1990 |

| New window type | Double window |

| New glazing type | typology |

| New shading type | NA |

| New window solar factor g [-] | 0,5 |

No roof windows were there before the intervention. 16 Velux GGU F08 660 x 1400 mm and 12 Velux GGU F06 660 x 1180 mm were added in order to improve the daylighting levels in the building.

New roof windows were established. The only limitations were on the front facade.

| Existing window type | None |

| Existing glazing type | None |

| Existing shading type | NA |

| Approximate installation year | 2000 |

| New window type | Double window |

| New glazing type | Double |

| New shading type | NA |

| New window solar factor g [-] | 0,46 |

Other interventions

MEASURES TO INCREASE AIRTIGHTNESS

The airtightness was improved significantly due to the insulation of the facade (inside and outside), the new windows and the floor to ceiling glass on the inside of the exterior wall (ground floor of facade). No other measures were carried out to specifically improve airtightness.

HVAC

HEATING

VENTILATION

DOMESTIC HOT WATER

"The original heating system was based on district heating using steam supply. The heat distribution system was a single pipe system. The new heating system is based on district heating using hot water supply. The heat distribution system is a two pipe system and thermostat valves have been added to the radiators."

The changes in the heating system would not influence other parts of the building.

| New primary heating system | |

|---|---|

| New system type | Heat exchanger |

| Fuel | District heating (water) |

| Distribuition system | Radiators |

| Nominal power | NA kW |

The original ventilation system was a simple mechanical exhaust system where air was removed from toilets and kitchens. In the renovated building mechanical ventilation with heat recovery was installed and this was supplemented by natural ventilation via the roof windows. The natural ventilation is controlled by electric motors based on the indoor climate.

In this case the solution was easily compatible, since only the facade of the building was to be preserved, i.e. no ristrictions regarding the internal parts of the building. This meant that the new ventilation ducts could be placed where most appropriate.

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Combined - natural + mechanical w. heat recovery |

| Type flow regime | Combined |

| Heat recovery | Si |

| Humitidy recovery | No |

| Nominal power | NA kW |

| Electric power | 0,0 kW |

| Control system | NA |

Hot water is produced by district heating/heat exchanger and therefore changes as described above. In addition solar heating was added to the building to supplement the district heating using hot water supply.

The solar panels are placed on the roof. The solution is compatible since only the facade of the building was being preserved.

| New DHW system | |

|---|---|

| Type | with heating system |

| Hot_water_tank | Si |

| With heat recovery | No |

RENEWABLE ENERGY SYSTEMS

SolarThermal

Velux Solar collectors were installed on the roof. 2 panels of 1.34 m x 1.80 m resulting in a total area of 4.82 m2.

The solution is compatible since there were no restrictions on the roof construction.

The solar panels are mounted on the sloping roof facing south-east.

| SolarThermal System | |

|---|---|

| Type | Flat collector |

| Collector area | 4,82 m² |

| Elevation angle | 22,0 |

| Azimuth | 135,0 |

| Overall yearly production | 10,0 kWh |

| Heating_contribuition | 0,0 kWh |

| DHW contribuition | 10,0 kWh |

| Cooling contribuition | 0,0 kWh |

Energy Efficiency

Voluntary certificates: No

Consumption_estimation_Before: 158 kWh/m2.y

Consumption_estimation_After: 37 kWh/y

Primary Energy

Consumption_estimation_Calculation_method: NA

Internal Climate

The indoor climate of the building was improved significantly by the renovation process. The insulation of the building envelope along with the installation of new windows increased the thermal comfort in the building. Another important aspect of the building renovation is the improved lay-out of the building and the flexibility with which the building can now be used. The improved indoor climate has also helped to make the entire building area useable.

The increase in air tightness and the removal of cold surfaces (windows and walls) have helped to remove draught and general discomfort in the building. The indoor air quality has also improved significantly by the introduction of a combined mechanical and natural ventilation system. The mechanical system has heat recovery and will ventilate the building during winter. When indoor temperatures or CO2-levels in the building get too high, the automatic natural ventilation will be initiated (opening of roof windows).

Daylighting levels in the building were raised by introducing roof windows, that would both help raise daylight levels on the first floor and on the ground floor (see pictures). The lighting systems in the building have also been improved. The general lighting system has been fitted with automatic control, so that the electric lighting is dependent on daylight levels in the building (there is a manual override to this function). Also, decorative LED lighting has been added to the window sills in the original façade windows of the building, making it possible to set the scene for any arrangement in the building.

Costs

The total renovation costs (investment total), the part of the investment actually related to energy savings (investment energy), the energy savings per year (savings), the simple payback time (payback time) and the expected CO2-emission reductions (CO2-reduction) is given in the table. The total investment for the renovation project was approximately 564,000 € of which 212,000 € were directly aimed at energy reductions. The expected total savings per year was 13,000 €, i.e. resulting in a simple payback time for the entire project of approximately 18 years. This should result in CO2-reductions of approximately 29 tons per year.

563988 (total)

Amount includes: Everything

Cost of energy related interventions:

212000 (total)

Amount includes: Everything

13615 (total)

Annual electricity cost

9301 (total)

.jpg)

.jpg)