Klostergebäude Kaiserstrasse

1020

Wien/Vienna, Austriche

Architect

Owner

User

Contact Details

Other Information

Parts of the building can be visited.

Rammerstorfer J. et al., Gründerzeit mit Zukunft - Demonstrationsprojekt Kaiserstraße - Dokumentation und Monitoring, e7 Energie Markt Analyse GmbH, März 2017

Climate Zone Cfb

Altitude 171

HDD 3460

CDD 76

Conservation Area:

No

Level of Protection:

Building is under monument protection

Year of last renovation:

2013

Year of previous renovation:

2013

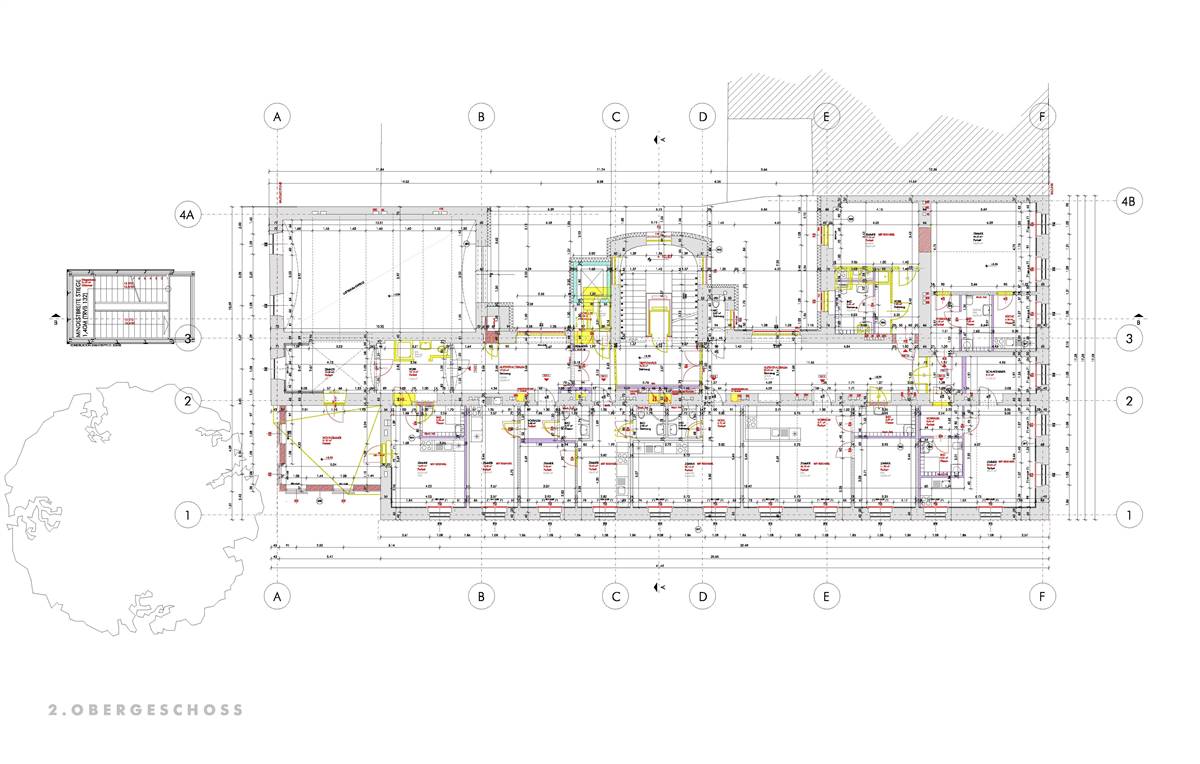

Secondary use:

Offices

Building occupancy:

Permanently occupied

Building typology:

Semidetached house

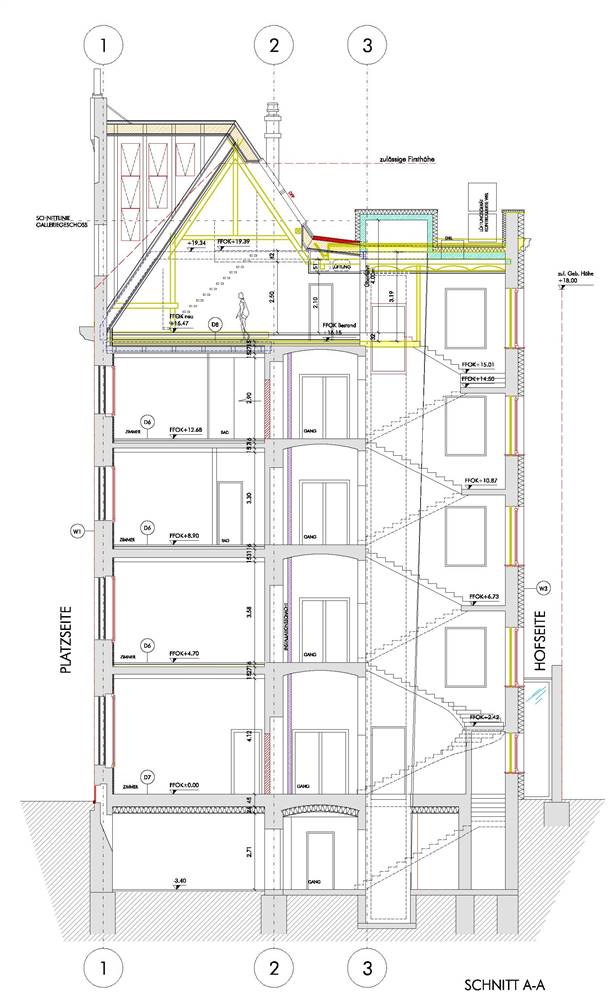

Number of floors:

4

Basement yes/no:

Oui

Number of heated floors:

4

Gross floor area [m²]:

3098,0

Thermal envelope area [m²]:

2559,51

Volume [m³]:

8732,37

NFA calculation method:

Gross floor area (BGF) according to Austrian "Energieausweis"

External finish:

Exposed brickwork

Internal finish:

Plastered (on hard)

Roof type:

Pitched roof

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Wohnfonds Wien

Lenaugasse 10, 1080 Wien

office@wohnfonds.wien.at

Tel.+43 1 4035919-0

Neighbour/abutter

NA

e7 energy innovation & engineering

Walcherstraße 11/43, 1020 Wien

office@e-sieben.at

Tel.+43 1 90782810

Trimmel Wall Architekten ZTGmbH

Johann-Hörbiger-Gasse 30, 1230 Wien - Mauer

info@architekten.or.at

Tel.+43 1 8893079

Bundesdenkmalamt (Federal Monuments Authority Austria)

Hofburg, Säulenstiege, 1010 Wien

service@bda.gv.at

Tel.+43 1 534150

kppk Ziviltechniker GmbH

Schottenfeldgasse 65/10, 1070 Wien

office@kppk.at

Tel.+43 1 5352123

kppk Ziviltechniker GmbH

Schottenfeldgasse 65/10, 1070 Wien

office@kppk.at

Tel.+43 1 5352123

Schöberl & Pöll GmbH

Lassallestraße 2/6-8, A-1020 Wien

office@schoeberlpoell.at

Tel.+43 1 7264566

Paul Wegerer, TU Wien, Institut für Hochbau und Technologie

Karlsplatz 13, 1040 Wien

Margarete Havel, Havel und Havel

Rekawinkler Hauptstraße 18, 3031 Pressbaum

Life Cycle Analysis (LCA) econ calc, version 2.0.1, by Energieinstitut Vorarlberg

Other Software Ham4D_VIE for building physics rsp. inside insulation

RETROFIT SOLUTIONS

External Walls

Plastered facade with facing bricks

Exterior wall of extension

The existing facade was made of ceramic clinker tiles. Conservative measures such as substance-saving cleaning and repair of the facing brick surfaces, supplementing the historical clinker tiles and hydrophobing were made. The ceramic statue in the wall niche of the southern ornamental gable has been restored. The circular sandstone slabs, sandstone cross ornaments and sandstone coverings on the eastern and southern ornamental gables were cleaned, repaired and color-matched. Articulated facades and profiled plaster surfaces, such as cornices, window casings, window roofs and ornamented roof gable incl. figural representations were repaired and restorated as follows: - Manual removal of various later lime-cement coating - Surface cleaning, mechanical manual exposure of various decorative elements - Stabilisation of the sanding surface, closing of cracks - Plaster additions with cement-free natural hydraulic finished products

Paint systems were used in consultation with the Federal Monuments Authority Austria according to the following procedure: - Etching the facade - Pore-filling lime mud for closing cracks and small bumps - Double silicate glass topcoat

30 mm

600 mm

30 mm

30mm

600 mm

30 mm

50 mm

3 mm

The extension was designed with a contemporary ceramic facade.

The outer material was adapted to the historic ceramic facade.

5mm

120 mm

250 mm

15 mm

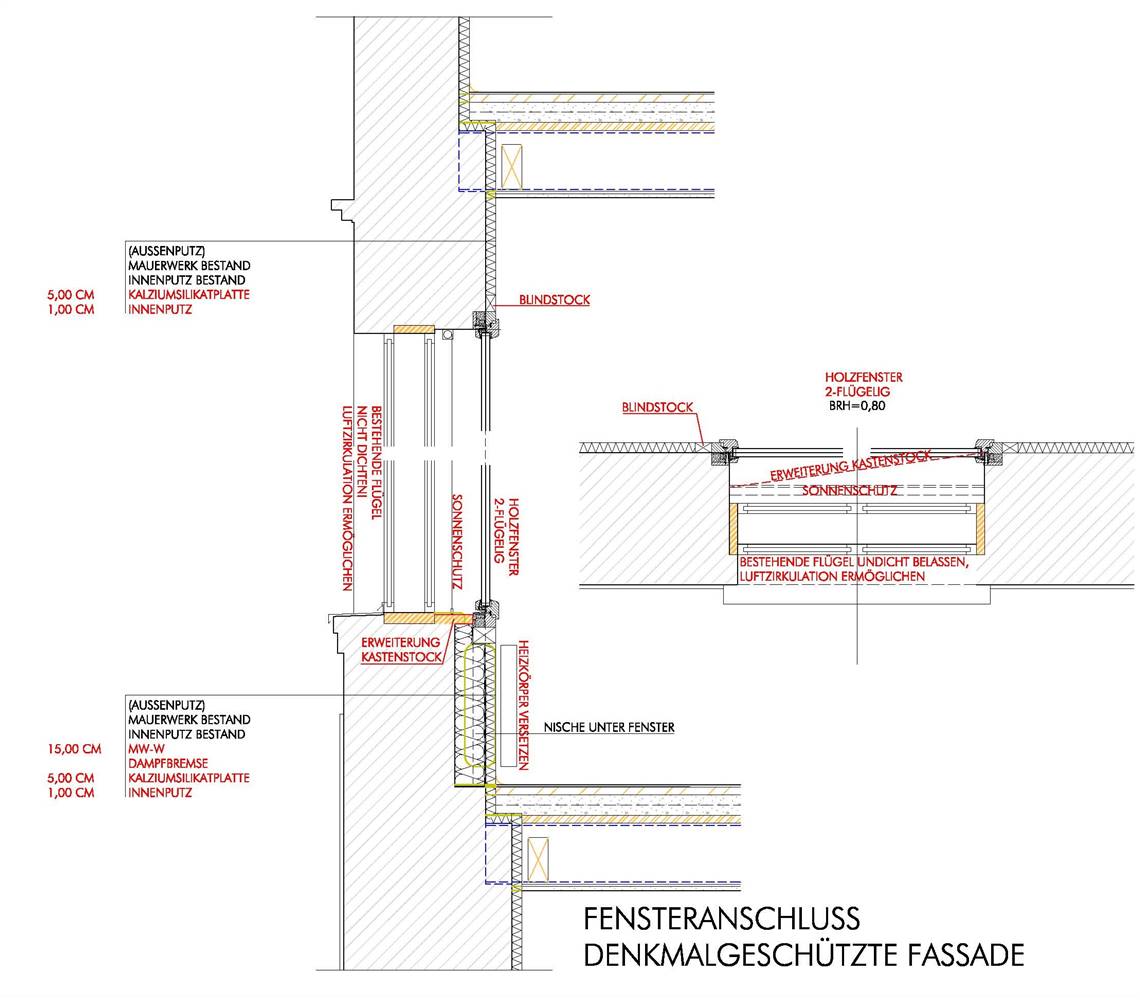

Windows

Viennese box window

Slanted glazing in monument protection

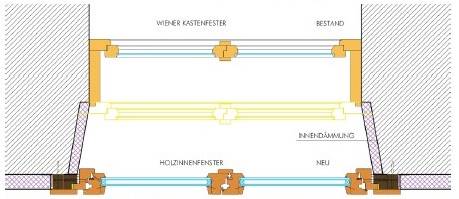

The outer wings of the box windows in listed facades were renovated and on the inside a new wooden window with special interior insulation was added. The solution sets the new inner wing completely flush with the inner wall and improves the thermal situation through internal insulation and reveal insulation. The sunshades are positioned between the wings in the lintel in existing roller blind niches. This layout represents a novel solution for old buildings.

Some parts of the window were maintained (e.g. frame)

| Existing window type | Box-type window |

| Existing glazing type | Single |

| Existing shading type | Roller blinds |

| New window type | Box-type window |

| New glazing type | Double |

| New shading type | Roller blinds |

| New window solar factor g [-] | 0,6 |

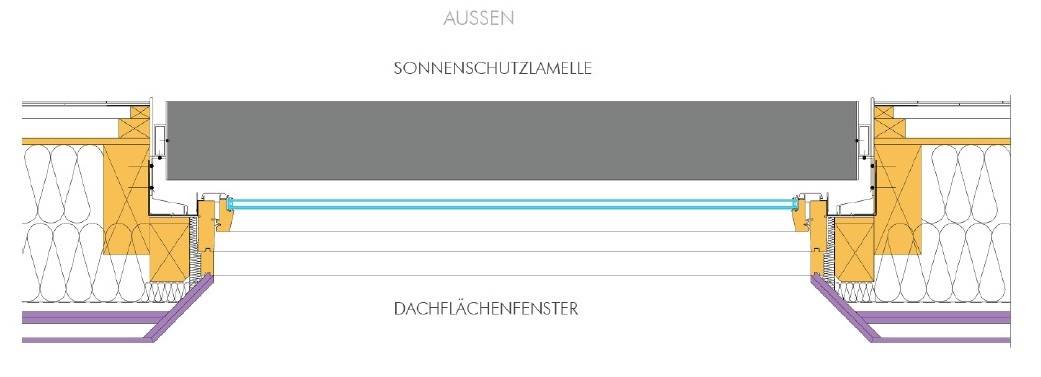

The sufficient exposure of the two-storey loft extension was a particular challenge because of the huge closed listed roof area to the south. In cooperation between the monuments office and the planner, an exemplary solution was developed and implemented with this project. Thus, large-scale two-storey vertical light bands are integrated into the roof landscape due to the special shape of the outer sunblinds. The sunblinds lie flush with the outside of the roof and are fixed so that the horizontal view and sufficient sun protection are in balance. The exterior cleaning of the glass surfaces takes place annually with a special cleaning device.

New wlight bands were integrated into the roof landscape

| Existing window type | |

| Existing glazing type | |

| Existing shading type | NA |

| New window type | Fixed window |

| New glazing type | Double |

| New shading type | Fixed shading |

| New window solar factor g [-] | 0,6 |

Other interventions

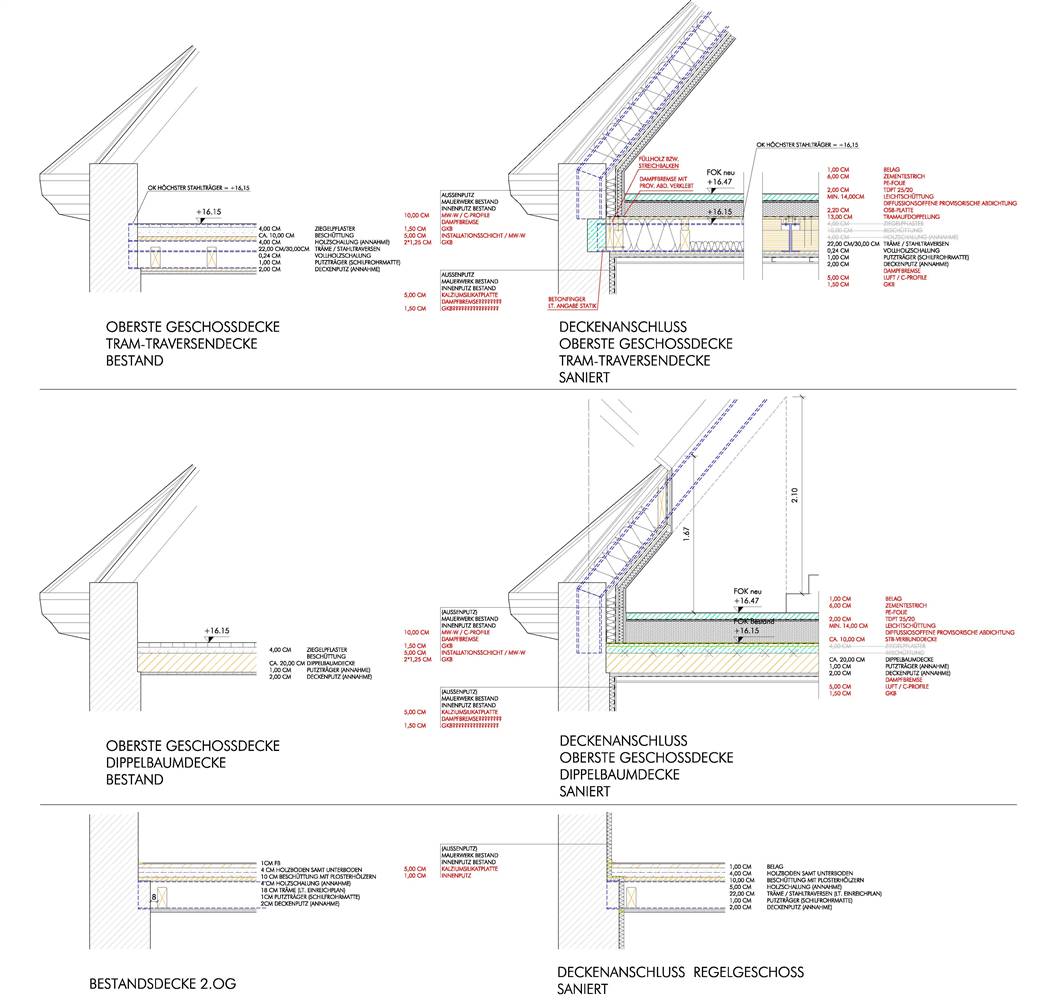

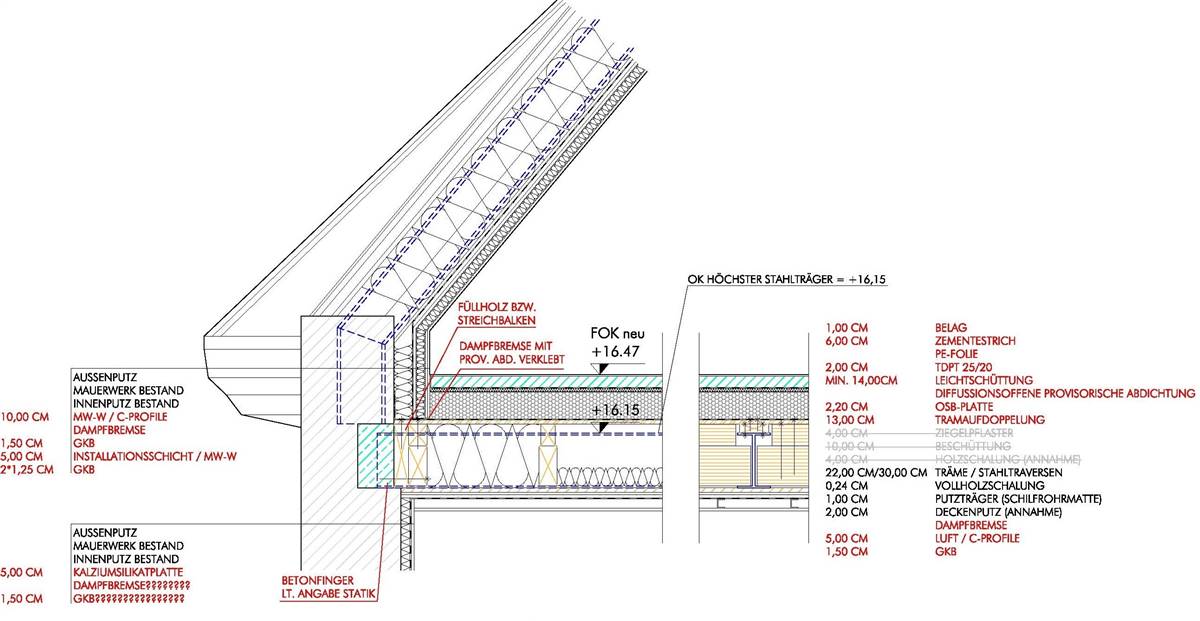

ROOF

The roofing to the street was made of the original slate, the one to the courtyard-side was done with Eternit lace stencils and the dormers in zink. The roof was equiped with a high quality intermediate rafter insulation and an inside, mineral rafter insulation. The roof gaiters were insulated with highly efficient insulating material. The gallery floor is illuminated on the court side via generous glass fronts of the dormers. In order to ensure an appropriate illumination of the attic apartments, 4 vertical light bands with 4 roof windows each were installed symmetrically to the south gable-end in the roof area. The fixed sunblinds avoid the summer overheating, but allow solar heat gains to be used in the winter. On the one hand, they guarantee a view into the open and on the other hand they create a homogeneous roof surface. In order to be able to mount the lamellas flush with the roof surface, an installation detail has been developed in which the level of the roof windows is located on the inside. The lowest window of each lightband is openable and manufactured with a ladder, so that the second escape and rescue route is given from each unit in the attic.

The roof surfaces were covered with historic slate cover and all zinc plating was redone.

13 mm

30 mm

80 mm

13 mm

110 mm

1 mm

340 mm

15 mm

1 mm

25 mm

HVAC

HEATING

VENTILATION

DOMESTIC HOT WATER

The existing converter station which connects the district heating system with the heating system of the building was renewed. The attic floor is heated by a floor heating. On the third floor a floor heating could be realized on a footfall sound insulation due to a completely new floor structure with screed. On the second floor, there is a mixed system: in the rooms with interior insulation, floor heating was carried out due to the limited possibility of fixing the radiator consoles to the walls. On the second floor the remaining rooms are supplied by radiators. The first floor and the ground floor are heated by radiators. On the first floor some of these radiators were partially renewed. On the ground floor, the existing heat supply was not renewed. The chapel was equipped with wall heating on three sides.

This wall heating in the chapel was installed with the aim to prevent contamination of the wall painting. Since the heat dissipation now mainly works through radiation, in contrast to former convection-induced air movements, the transport of impurities are largely reduced.

| New primary heating system | |

|---|---|

| New system type | Existing district heating / heat exchanger |

| Fuel | Waste (approx. 33 %) and CHP |

| Distribuition system | Floor heating, radiators or wall heating |

| Nominal power | 160 kW kW |

The existing basement rooms could be used for the location of the ventilation station. The external air intake takes place via the outer wall of the parish garden. Existing shafts were used for the exhaust air and the supply and exhaust air ducts . The semi-central system was chosen for comfort ventilation. The heat recovery rate of the heat exchanger (plate countercurrent exchanger) is at least 82.5%. The filtering of the outside air is done with a high quality F7 pocket filter. The individual regulation of the air volume flow for each residential unit is ensured by a V-Box.

In order to keep the renovation work in the building minimally invasive, the former coal lift shaft was used for the exhaust air duct and part of the existing toilet tower was used for the routing of the supply and exhaust air. The ventilation distribution in the floors is located in the suspended false ceilings in the easily revisable corridor and staircase area.

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Semi-centralized |

| Type flow regime | |

| Heat recovery | Oui |

| Humitidy recovery | No |

| Nominal power | 1,051 kW kW |

| Electric power | 0,8 kW |

| Control system | individual control in each dwelling |

The hot water supply for the attic floor, as well as for the second and third floor is made via decentralized home stations. The home station is a prefabricated unit for supplying heating surfaces (floor heating or radiators) and for heating water in a 2-wire system. The station is fed from the heating flow and from the cold water network from the central installation shaft. This requires a year-round operation of the network; Decentralized heating saves a separate hot water and a circulation line as well as the resulting storage and circulation losses. In the refurbished apartments, attention was paid to the use of water-saving fittings. The ground floor and the first floor are supplied centrally from the technical room. The distribution is made from a 1,000 l water heater in the basement. The storage tank is charged with district heating via its own heat exchanger.

No measures had to be taken on count of conservation.

| New DHW system | |

|---|---|

| Type | decentral boiler |

| Hot_water_tank | Oui |

| With heat recovery | No |

Energy Efficiency

Voluntary certificates: In the context of "Gründerzeit mit Zukunft" and in cooperation with the House of the Future plus project "Monitor +", a building certification with Total Quality Building (TQB) was carried out according to the quality criteria of ÖGNB (Austrian Sustainable Building Council). The aim of the certification was a holistic representation of the building according to defined sustainability criteria. In addition, the building was certified according to the criteria of klima:aktiv. In total, 708 out of 1,000 possible points were achieved for the project.

Primary Energy 125 kWh/m2.y

Consumption_estimation_After: 75,75 kWh/m2.y

Primary Energy

Consumption_estimation_After: 125 kWh/m2.y

Type_of_monitoring: Continuous

Description: Detailed moniroting of thermal comfort, comfort in terms of humidity and air purity (CO2 content)

Construction

Type_of_monitoring: Continuous

Internal Climate

The regulation of underfloor heating may not be optimally adjusted, because the thermostat is mounted in an apartment in the bedroom, but where cooler temperatures are desired, so that the living room is then too cool. The bathroom is described as too warm. With the warming and ventilation of the apartments in the cooler season, there is high satisfaction. There are no disturbances and noises. The overheating of the apartments in the summer is described as unpleasant. Despite the installation of a sun blinds, a tenant built an air conditioner.

Costs

5,160,000 € (total)

Amount includes: Structural work: approx. 1,100,000 €, Building services: approx. 900,000 €, Fillout: approx. 2,400,000 €, Fees and building site facilities: approx. 760,000 €

Cost of energy related interventions:

912,000 € (total)

Amount includes: Exterior insulation, interior insulation, renovation of the windows, roof renovation, heating installation and installation of the ventilation system including air distribution

11.48 € (per m2)

Annual heating cost

7.60 € (per m2)

(includes DHW) Oui

Annual electricity cost

0.78 € (electricity costs for building services), 3.10 € (electricity costs for use of building) (per m2)

silbersalz.jpg)

CarolineBegle - 1.jpg)