House Breuer, Tschagguns

Batloggstraße 36

6780

Schruns/Tschagguns, Austriche

Architect

Owner

User

Contact Details

Other Information

https://stand-montafon.at/raum-region/montafoner-baukultur/verleihung-montafoner-baukultur-2017/haus-breuer-tschagguns https://www.db-bauzeitung.de/db-metamorphose/stall-b-tschagguns-breuer/

Climate Zone Dfc

Altitude 690

HDD 2947

CDD 24

Conservation Area:

No

Level of Protection:

Year of last renovation:

2015

Year of previous renovation:

1914

Secondary use:

NA

Building occupancy:

Permanently occupied

Number of occupants/users:

4

Building typology:

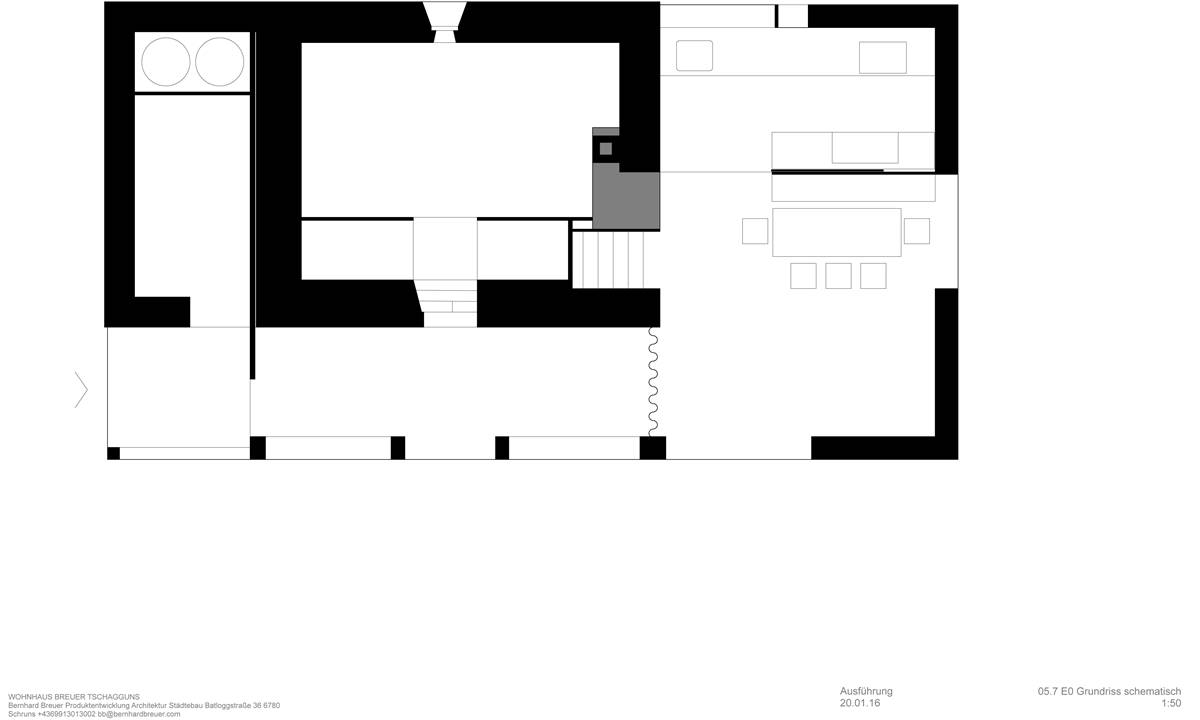

Detached house

Number of floors:

2

Basement yes/no:

No

Number of heated floors:

2

Gross floor area [m²]:

213,28

Thermal envelope area [m²]:

554,0

Volume [m³]:

692,39

NFA calculation method:

NGF (de)

External finish:

Exposed woodwork

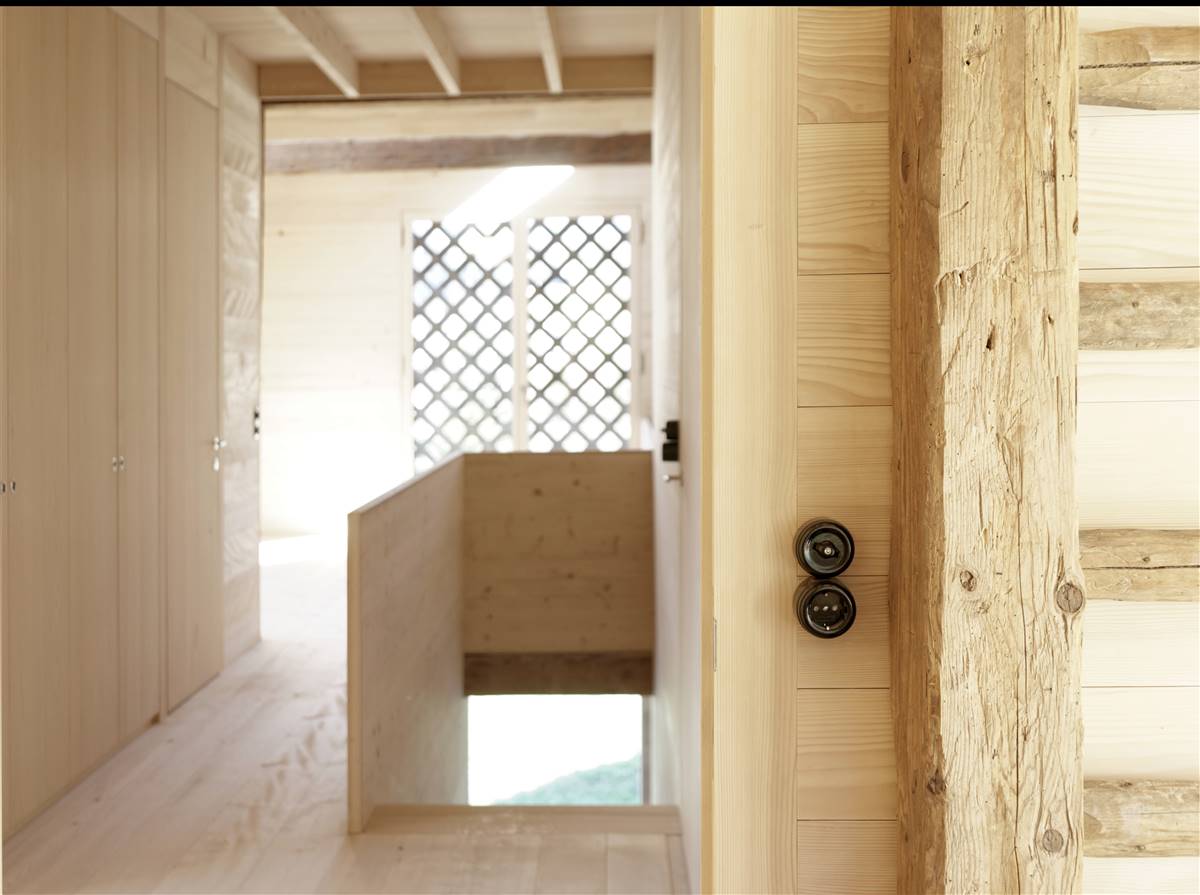

Internal finish:

Wood panelling

Roof type:

Pitched roof

RENOVATION PROCESS

Architecture

BUILDING DESCRIPTION

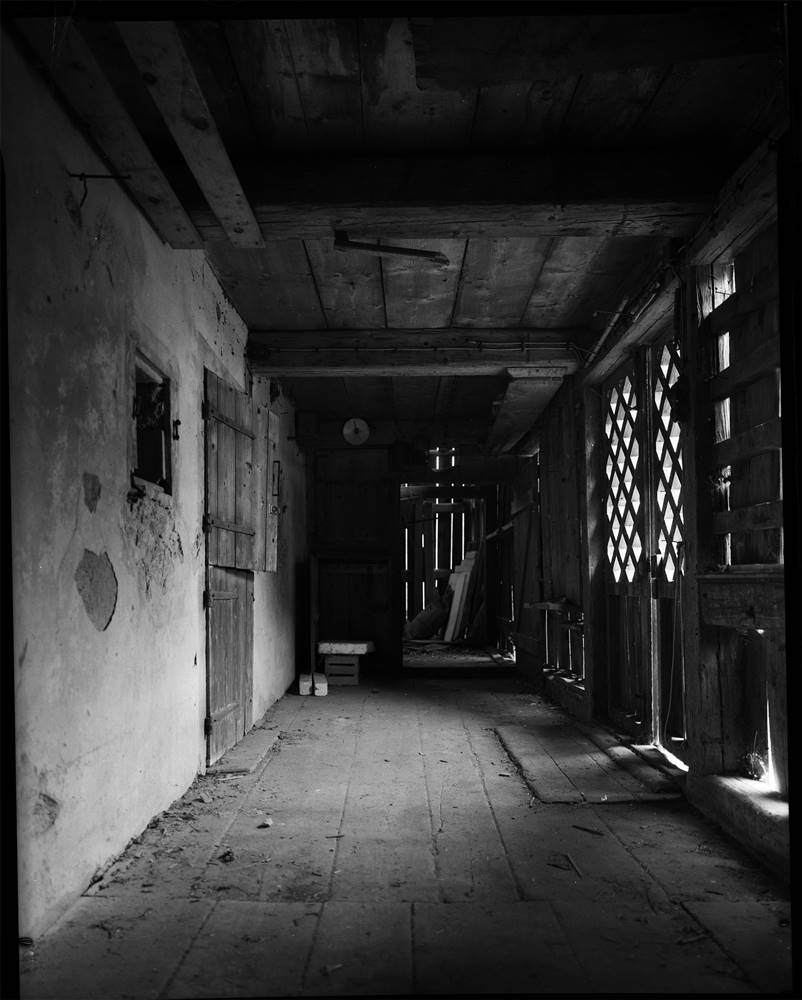

State of repair

HERITAGE SIGNIFICANCE

Aim of retrofit

Bernhard Breuer

Batloggstraße 36, 6780 Schruns, Österreich

RETROFIT SOLUTIONS

External Walls

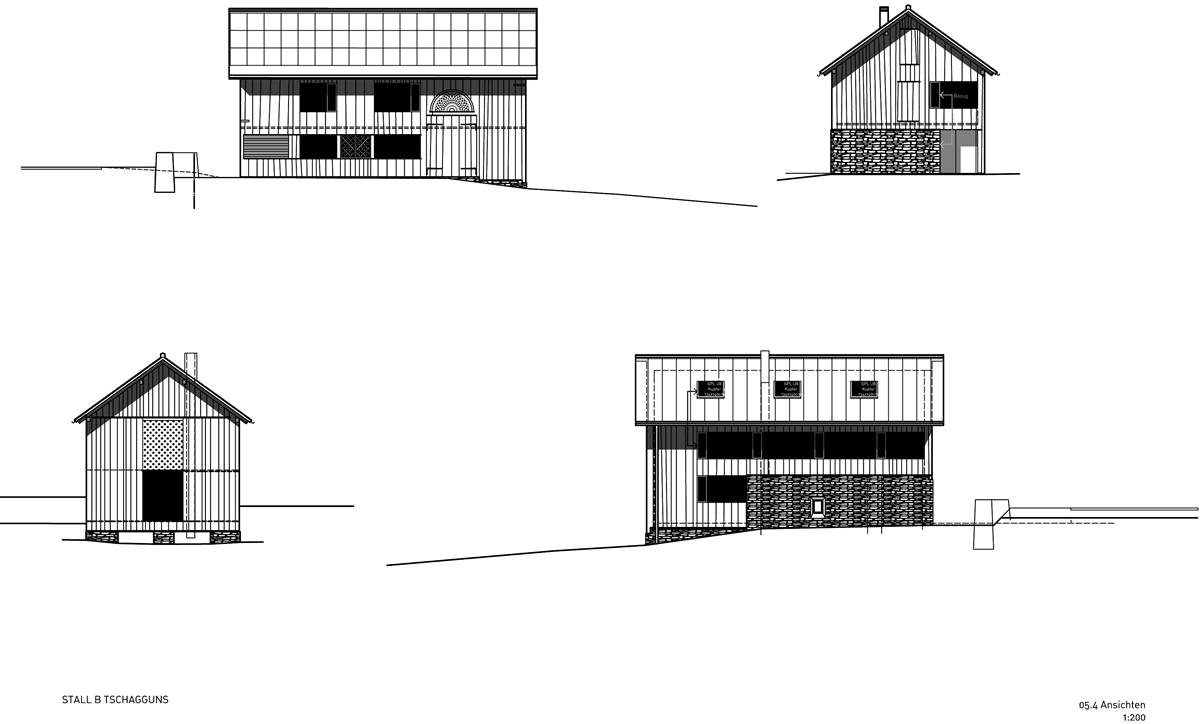

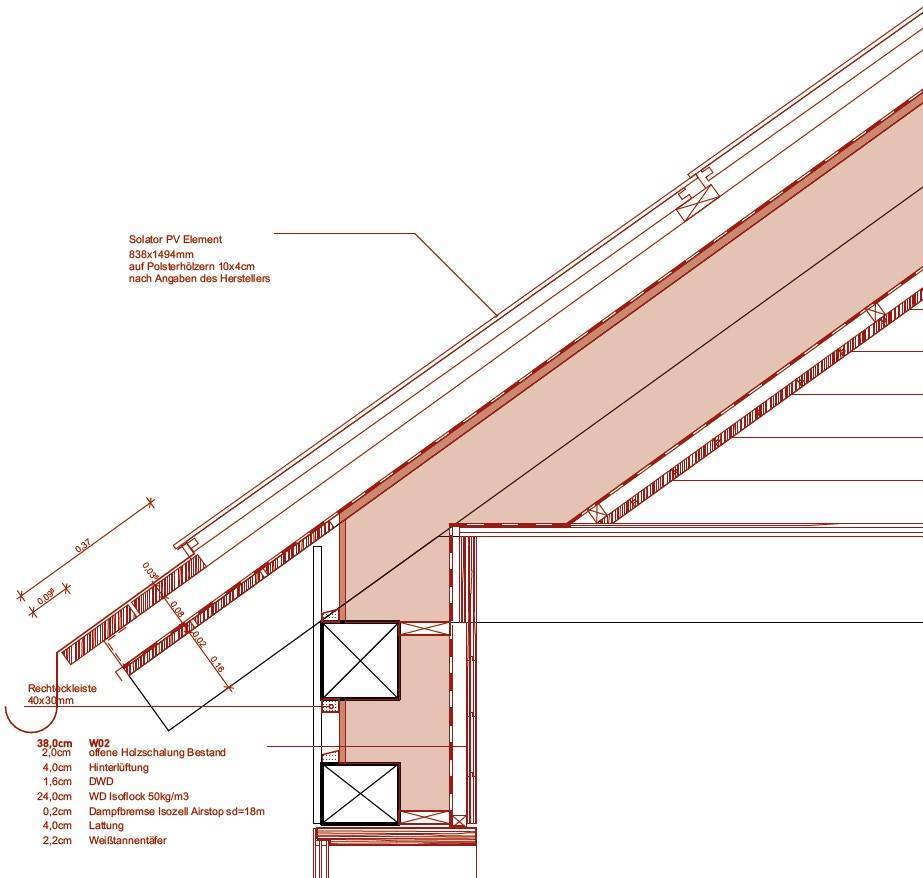

Outer wall as ventilated wooden construction

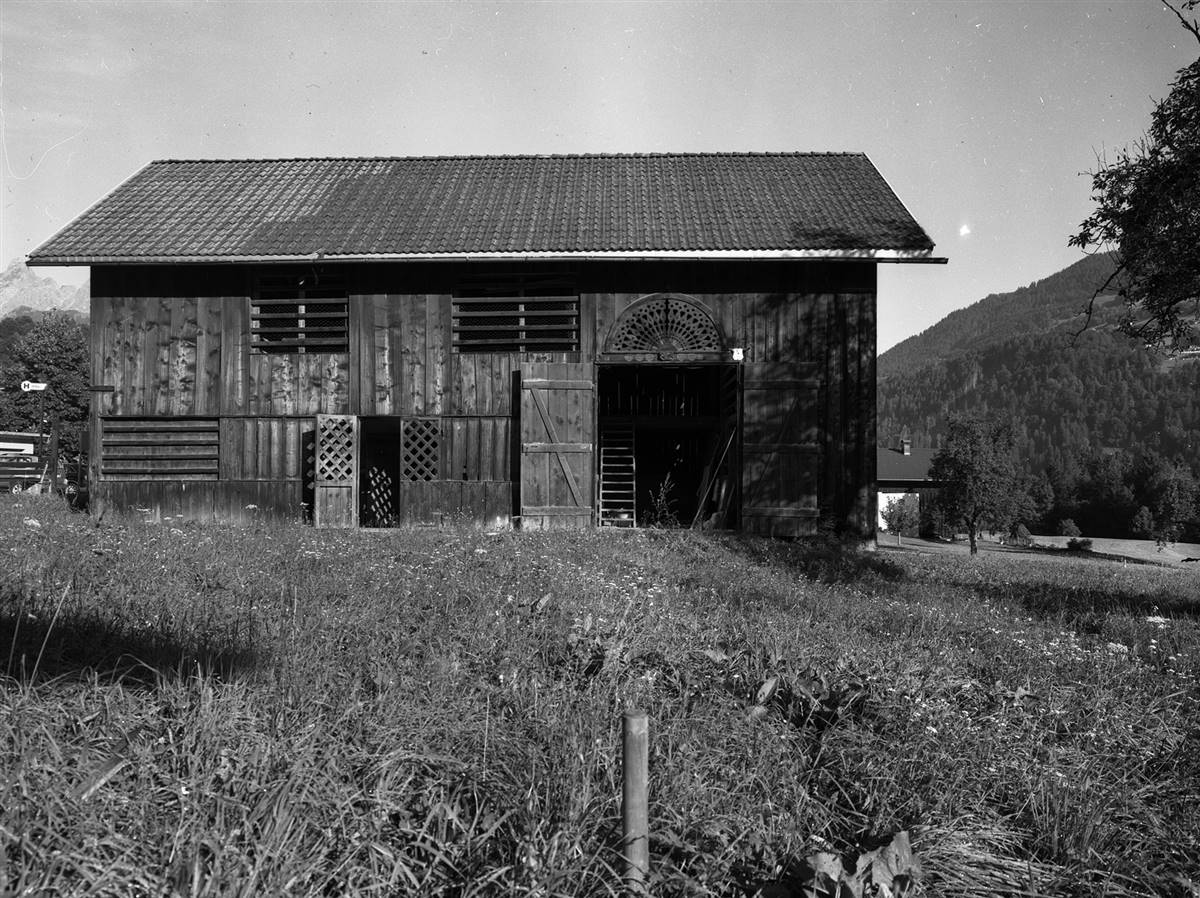

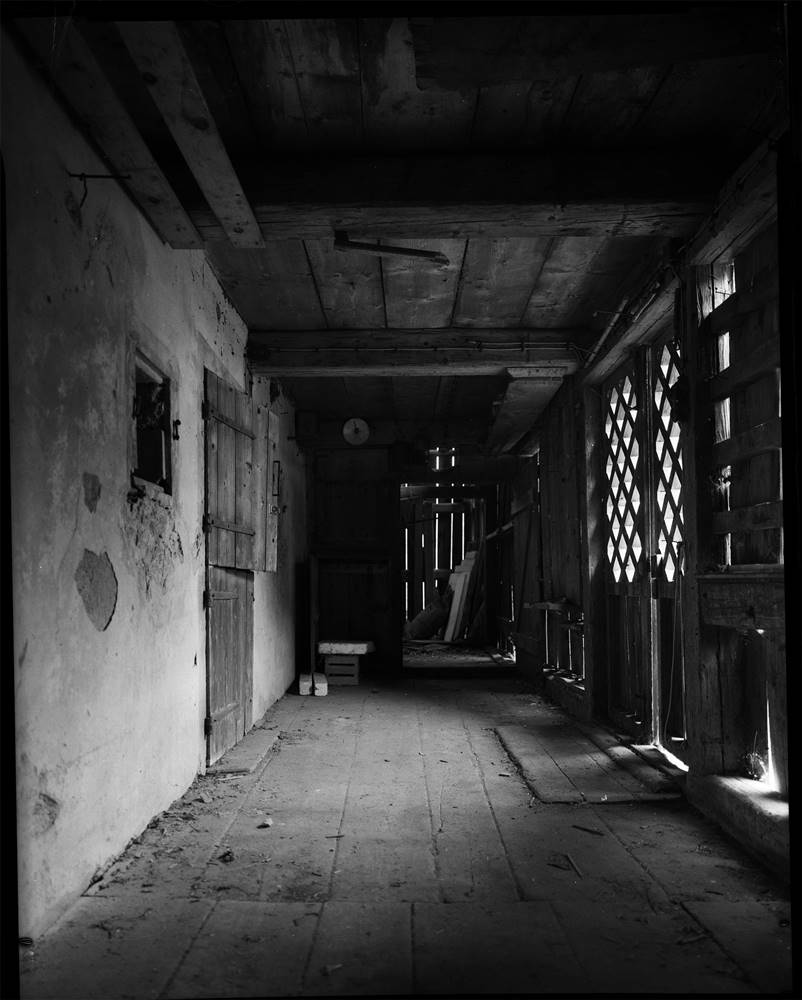

Before the renovation or reconstruction of the building, the building consisted only of a board formwork and partly in the base area of a natural stone wall. The plank formwork was retained and supplemented by a habitable wall construction. Driving rain protection is guaranteed by the existing wooden facade, which can also dry out on the inside thanks to the rear ventilation.

Although 80% of the outer appearance of the building has been preserved and only a few necessary openings in the building envelope have been added, a return to its original appearance seems illogical and therefore not relevant.

20 mm

150 mm

20mm

40 mm

16 mm

240 mm

2 mm

40 mm

22 mm

Windows

window room east

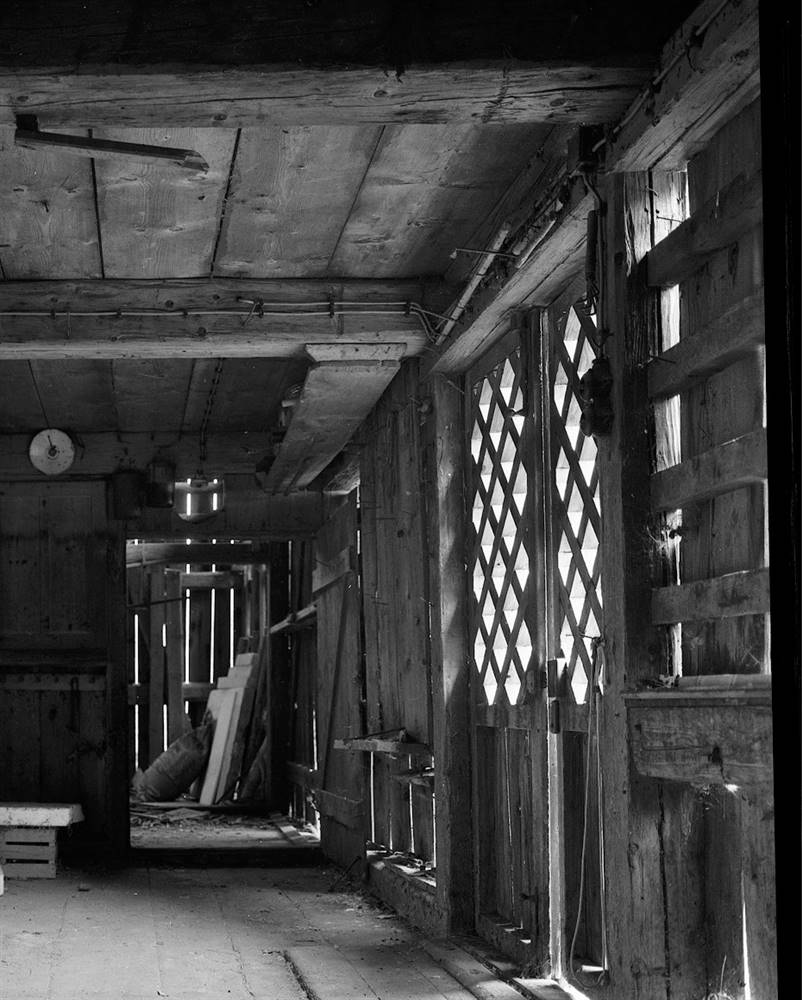

Before the renovation, there were virtually no glass windows at all, only openings without glass, with appropriate shading elements or enclosing elements to withstand the winter.

Existing openings were glazed and their shading elements were preserved. In some parts of the building, however, it was necessary to install additional openings to ensure the required light quality of the rooms. The architect worked with many fixed elements aligned with the external walls and only the most needed part of those elements that could be opened.

| Existing window type | Awning/Hopper |

| Existing glazing type | non glazing |

| Existing shading type | Outer shutter |

| Approximate installation year | 1900 |

| New window type | Coupled window |

| New glazing type | Triple |

| New shading type | Outer shutter |

| New window solar factor g [-] | 0,47 |

Other interventions

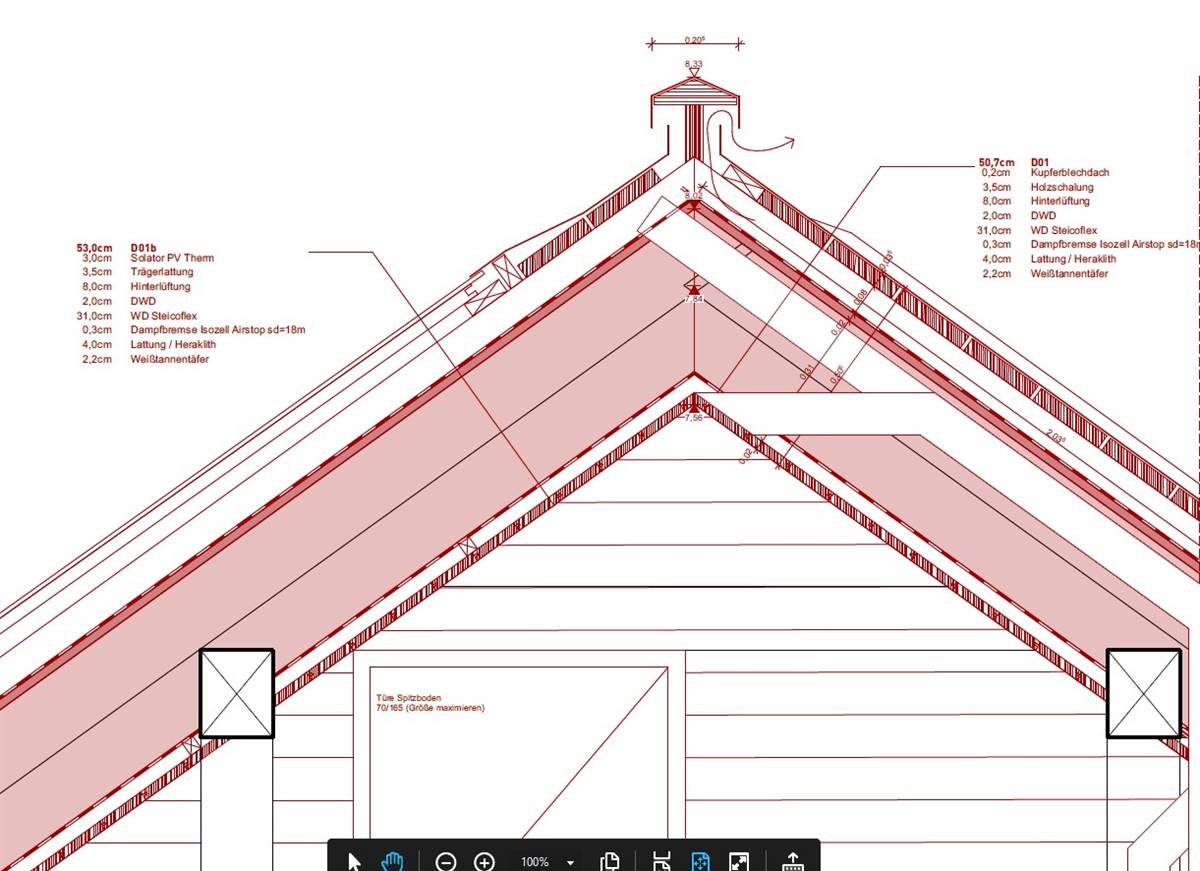

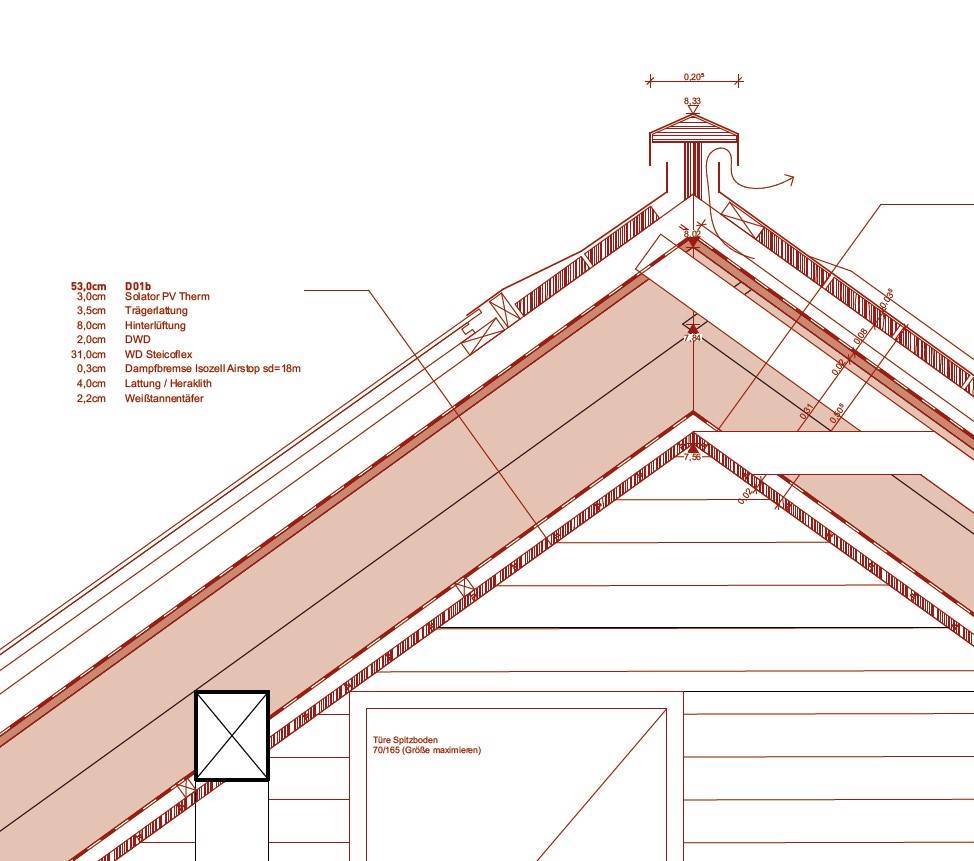

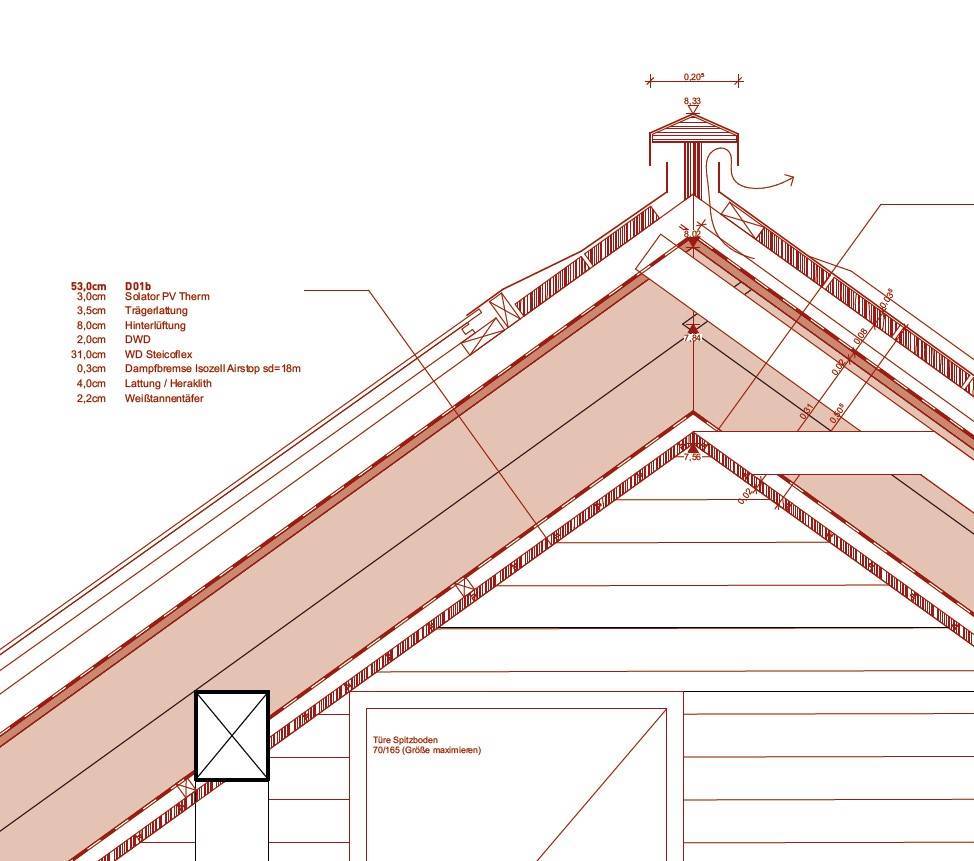

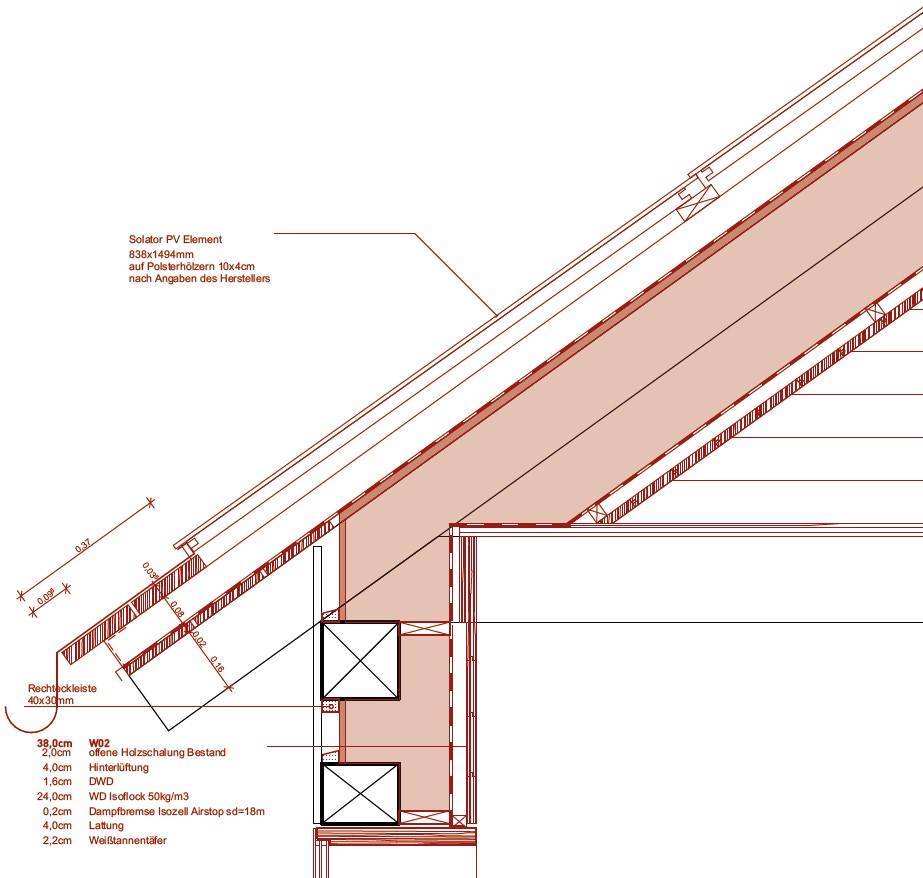

ROOF

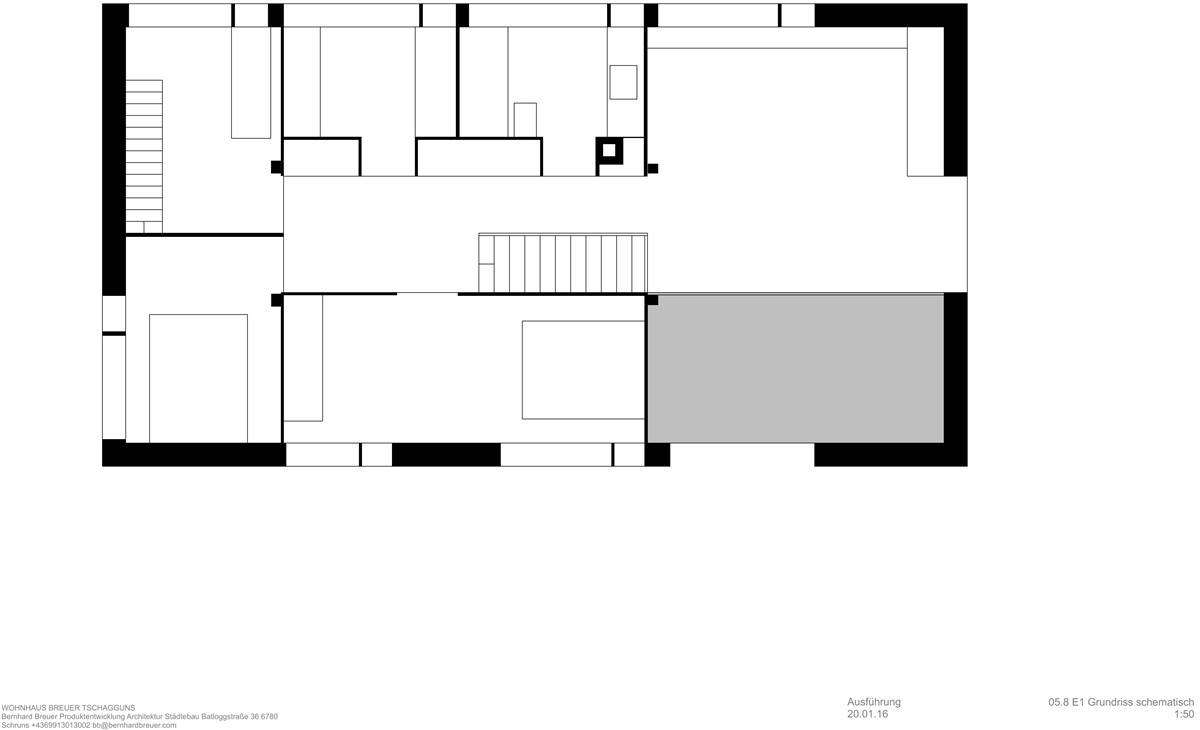

GROUND FLOOR

The complete roof was renewed. The southwest side of the roof was designed as a copper roof to enhance the colour spectrum of the weathering wood, which ranges from black to brown-orange and silver-grey to extend its green shimmer. The south-eastern side of the gable roof is fully equipped with integrated PV and solar thermal modules. The roof pitch of 35° and the orientation of the building make this half of the roof an ideal energy supplier.

The original roof had roof tiles.

20 mm

150 mm

2 mm

30 mm

80 mm

338 mm

0 mm

47 mm

15 mm

Before the reconstruction, the floor consisted only of thick wooden planks that separated the interior of the building from the ground. In the course of the conversion, this naturally had to be replaced by a full-fledged floor structure in order to make the building habitable. This consists of a concrete floor slab, thermal insulation, a heatable screed and a floor covering.

20 mm

3 mm

200 mm

150 mm

5 mm

200 mm

2 mm

80 mm

20 mm

HVAC

HEATING

VENTILATION

DOMESTIC HOT WATER

Before the reconstruction there were no building services connections. The building had to be completely equipped with building services. The main heating system is a tiled storage stove, which is supported by a thermal solar system. The building is heated on the one hand by the direct heat output of the stove as well as by foot and wall heating. The heat is stored in two 800 litre storage tanks. The wood consumption is about 6 solid cubic meters of beech firewood per year.

| New primary heating system | New secondary heating system | |

|---|---|---|

| New system type | Stove | thermal solar system |

| Fuel | Biomass | thermal solar |

| Distribuition system | Es gibt verschiedene Wärmeabgabesysteme, wie eine Fußboden- und Wandheizung sowie über die Lüftung mit Wärmrückgewinnung. There are several distribution systems working together eg. a radiating floor and radiating wall and ventilation with heat recovery. | radiating wall and floor |

| Nominal power | kW | kW |

As part of the conversion, a ventilation with heat recovery was integrated into the building services system.

| Original roof build-up | New ventilation system |

|---|---|

| Type ventilation system | Centralized |

| Type flow regime | Overflow |

| Heat recovery | Oui |

| Humitidy recovery | No |

| Nominal power | kW |

| Electric power | kW |

| Control system |

Since there was previously only a single cold-water supply line for the stable building, a new system had to be integrated here. The heat is stored in two 800 litre storage tanks.

| New DHW system | |

|---|---|

| Type | with heating system |

| Hot_water_tank | Oui |

| With heat recovery | No |

RENEWABLE ENERGY SYSTEMS

SolarThermal

Photovoltaic

Biomass

The south-eastern area of the gable roof is fully equipped with integrated PV and solar thermal modules. The roof pitch of 35° and the orientation of the building make this half of the roof an ideal energy supplier. Thus, about 200% of the electricity demand and most of the hot water or heating requirements can be produced locally.

The thermal solar system is roof-integrated.

| SolarThermal System | |

|---|---|

| Type | Flat collector |

| Collector area | 20,0 m² |

| Elevation angle | 35,0 |

| Azimuth | -43,0 |

The south-eastern area of the gable roof is fully equipped with integrated PV and solar thermal modules. The roof pitch of 35° and the orientation of the building make this half of the roof an ideal energy supplier. Thus, about 200% of the electricity demand and most of the hot water or heating requirements can be produced locally.

The photovoltaic system on the remaining southern half of the roof was designed as an integrated PV system. Although the system is visible, it is not so different from the sheet metal roof of the second half of the roof.

| Photovoltaic System | |

|---|---|

| Type | NA |

| Collector area | 55,0 m² |

| Elevation angle | 35,0 |

| Azimuth | -43,0 |

A wood storage stove serves as the heating system, in the time while PV and thermal solar system have no output at all.

| Biomass System | |

|---|---|

| Type | Logs |

| Storage size | |

| Origin of biomass | local - Bartholomäberg, Vorarlberg, Austria |

| Overall yearly production | kWh |

Energy Efficiency

Consumption_estimation_Calculation_method: Steady state simulation (e.g. EPC, PHPP)

Consumption_estimation_After: 33 kWh/m2.y

Primary Energy

Consumption_estimation_Calculation_method: NA

Consumption_estimation_Including_DHW: No

Internal Climate

The residents of the house have shut down the ventilation system because it was too loud for them. There were also draughts. The desired air quality of the building will now be achieved by shock ventilation in the morning.

The building is in a rather remote location, which means there is little disturbing outside noise. Due to the low noise level, the internal building services are more important. This was also one of the reasons why the ventilation system was switched off.

Costs

The client has put great emphasis on local added value and has commissioned most of the services from local companies.

400000€ (total)

Amount includes: everything without ground and planning

1400€ (total)

Annual heating cost

400€ (total)

(includes DHW) Oui

Annual electricity cost

1000€ (total)

Lifecycle cost

No

silbersalz.jpg)

CarolineBegle - 1.jpg)