Hiša trentarskih vodnikov

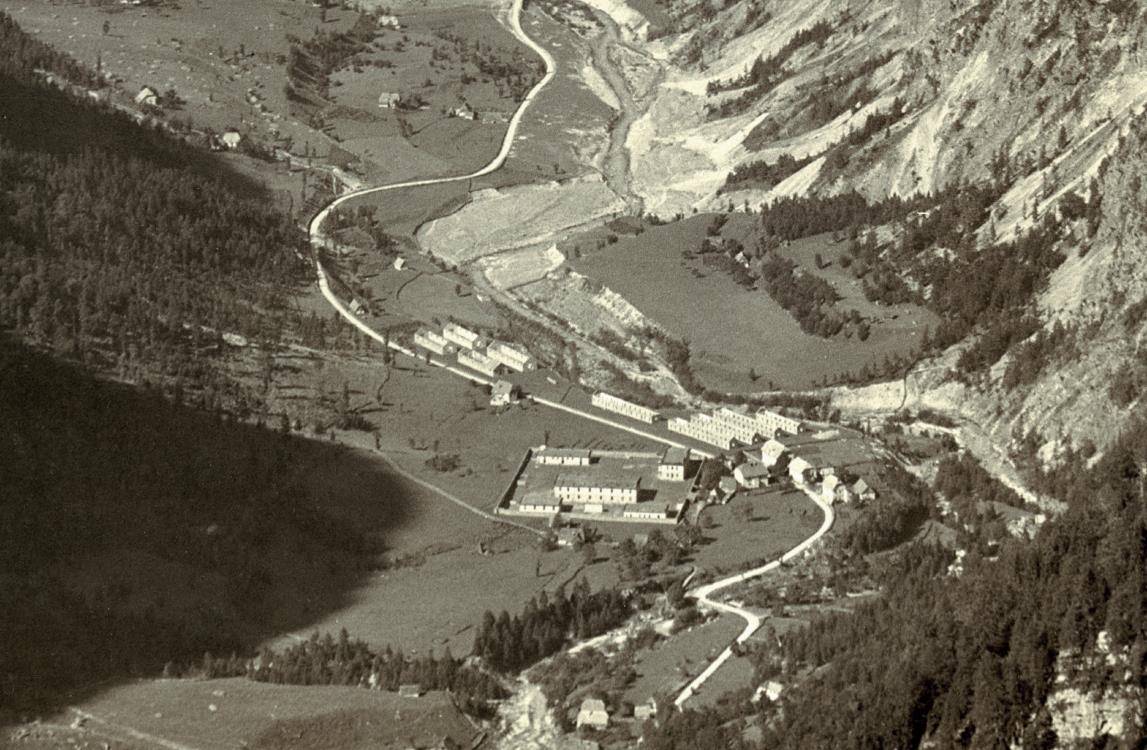

Na Logu v Trenti

5232

Trenta, Slowenien

Architekt

Besitzer

Bewohner

Ansprechpartner

Other Information

The building is used as congress centre and to support social life of the local community.

Klimazone DFc

Höhe über dem Meer 628 m ü.d.M.

Ensembleschutz:

Ja

Stufe der Unterschutzstellung:

national park

Letzte Sanierung:

2012

Vorhergehende Sanierungen:

1999

zusätzliche Nutzung:

fire brigade

Gebäudebelegung:

Unoccupied

Gebäudetyp:

Detached house

Anzahl der Stockwerke:

2

Keller ja/nein:

Nein

Anzahl der beheizten Stockwerke:

1

Bruttogeschossfläche [m²]:

618,0

Thermische Gebäudehülle [m²]:

917,0

Volumen [m³]:

2071,0

NGF Berechnungsmethode:

Außen:

Exposed woodwork

Innen:

Plastered (on substructure)

Dach:

Pitched roof

RENOVIERUNGS-PROZESS

Architektur

BESCHREIBUNG

Erhaltungszustand

DENKMALWERT

Ziel der Sanierung

Institute of the Republic of Slovenia for Nature Conservation

Tobačna 5. Ljubljana

Ing-arh, Polona Čeh s.p.

Kranjska cesta 4, 4240 Radovljica

Institute for the Protection of Cultural Heritage of Slovenia

Poljanska cesta 40, 1000 Ljubljana

Šlibar inženiring d.o.o.

Motnica 17, 1236 Trzin

Karlovšek d.o.o.

Antona Skoka 7, 1230 Domžale

SANIERUNGS-LÖSUNGEN

Außenwände

Ground floor_Stone masonry

First floor - timber frame structure with wooden facade and roof

Construction design of the exterior ground walls (stone masonry, λ = 1,7 W/mK) has changed only by adding a layer of thermal insulation (XPS 6cm, λ = 0,035 W/mK) which slightly improved it's thermal performance but still not enough to meet the conditions of a low-energy house. Since the ground floor in unheated and intended for garages and storage, thermal performance was not in the first place.

500 mm

5 mm

500mm

60 mm

3 mm

Traditional wooden roof was built in 1999 without any thermal insulation. Renovation in 2012 has altered the roof and the gables in terms of thermal performance. Thermal insulation layers were added in the roof assembly, gables were completely renovated and finished with vertically installed larch wooden boards. (Larch is a local tree).

100 mm

160 mm

22mm

40 mm

16 mm

160 mm

16 mm

60 mm

15 mm

Fenster

Facade windows

Roof windows

The windows on the ground floor remained existing from 1999. New wooden windows on the gables and in the "porch" are divided by wooden beams into four glazed fields.

| Fenstertyp Bestand | Coupled window |

| Verglasungsart Bestand | Single |

| Verschattung Bestand | NA |

| Neuer Fenstertyp | casement window |

| Verglasungsart des neuen Fensters | Double |

| Verschattung des neuen Fensters | NA |

Roof windows were replaced with new energy efficient windows with double glazing.

| Ungefähres Einbaujahr | 2012 |

| Neuer Fenstertyp | Roof window - Centre pivot |

| Verglasungsart des neuen Fensters | Double |

Weitere Maßnahmen

DACH

SONSTIGES

MASSNAHMEN UM DIE LUFTDICHTIGKEIT ZU VERBESSERN

Before 2012 there was no thermal insulation in the roof assembly. Thermal insulation was applied internally to maintain the existing wood shingle roof. Timber structure was also preserved. To improve the supply of a daylight in the conference room in the attic, various roof windows were installed with approval of the heritage office.

Flat concrete roof was originally built in 1936. In 1999 traditional pitched roof was built on top of the former flat concrete roof. Energy renovation of the attic took place in 2012.

50 mm

140 mm

50 mm

100 mm

1 mm

14 mm

8 mm

14 mm

50 mm

The upper floor only.

HVAC

HEIZUNG

BRAUCHWARMWASSER

The old heating system on fossil fuels (propane-butane) was replaced by a biomass boiler (wood chips). In the renovated building, there is a new boiler room with a Fröling furnace with a power of 150 kW with two storage tanks for 6000 liters of hot water. The biggest gain is efficient heating with significantly lower costs and locally supplied wood chips. The new heating system will supply the renovated building as well as the main building of the TNP museum and info center.

| Heizungssystem nach Sanierung | |

|---|---|

| Art der Heizung | Boiler |

| Brennstoff | Biomass |

| Wärmeverteilung | |

| Nennleistung | 150 kW |

ERNEUERBARE ENERGIE

Biomasse

Biomass Heating System supplying two buildings.

| Biomass System | |

|---|---|

| Type | |

| Storage size | |

| Origin of biomass | |

| Overall yearly production | kWh |

Energieeffizienz

Freiwillige Zertifikate Nein

Primärenergie 24 kWh/m2.y

Energieverbrauch nach Sanierung 48 kWh/m2.y

Primärenergie

Energieverbrauch nach Sanierung 24 kWh/m2.y

Type_of_monitoring: Continuous

Kosten

1.100.000 eur

Nein

Umwelt

emissions_at_use_stage_after_intervention: 1.080 total